Which primer over wood epoxy repair? This is a question that arises frequently for those seeking to restore damaged wood with a durable and aesthetically pleasing finish. The answer, however, is not a simple one, as the choice of primer hinges on several factors, including the type of epoxy used, the intended paint, and the specific characteristics of the wood itself.

Understanding these complexities is crucial for achieving successful results and ensuring that the repair lasts.

This guide delves into the intricacies of primer selection for wood epoxy repairs, offering insights into the compatibility between different primers and epoxy types, as well as the importance of proper application techniques. It also addresses common issues that may arise during the process, providing practical troubleshooting tips and solutions.

By navigating these considerations, you can confidently choose the right primer and achieve a long-lasting, aesthetically pleasing finish.

Understanding Wood Epoxy Repair

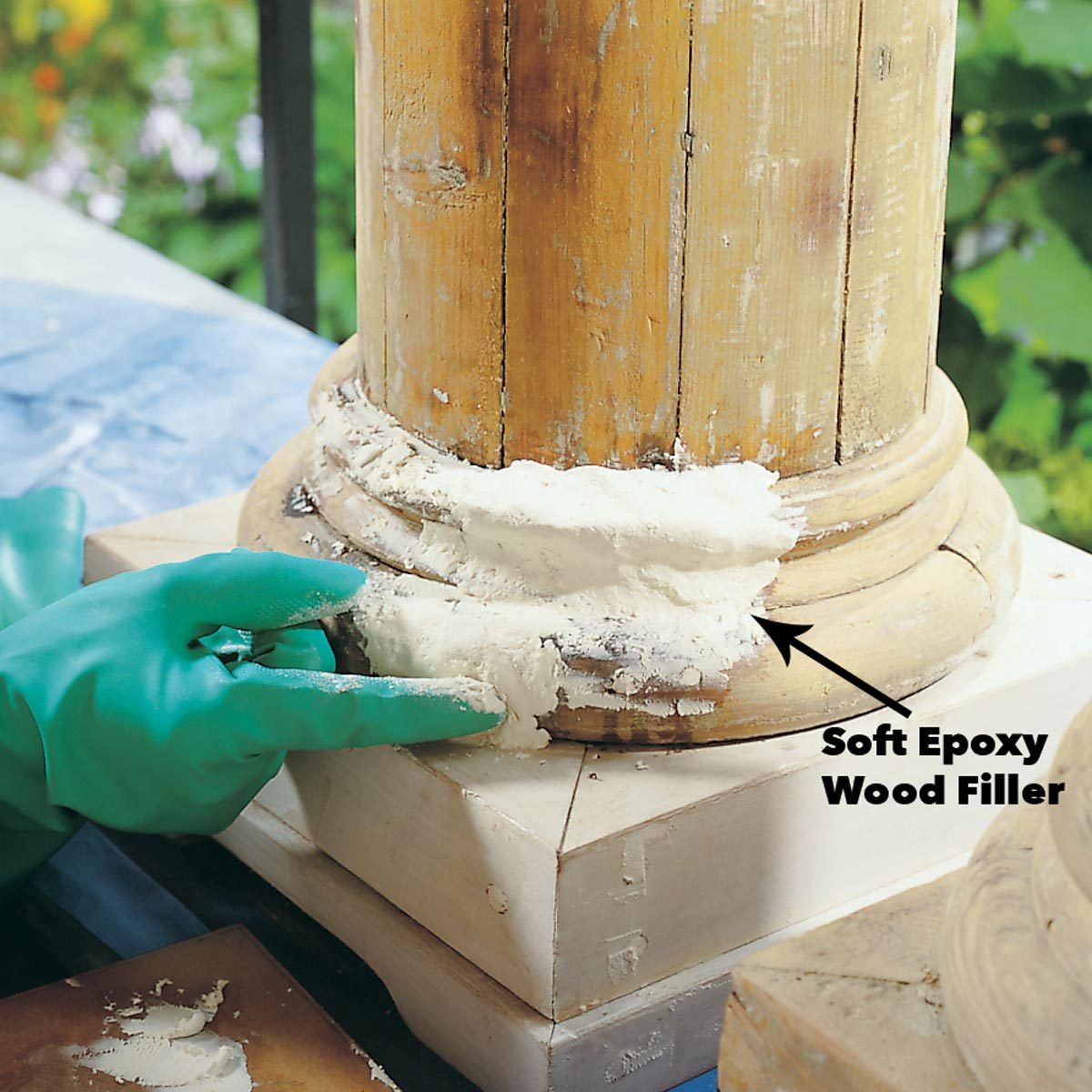

Wood epoxy is a powerful tool for restoring damaged wood. It’s a two-part adhesive that forms a strong, durable bond when mixed and cured. This makes it ideal for repairing cracks, holes, and other imperfections in wood.

Types of Wood Damage Epoxy Can Repair

Epoxy can effectively address a wide range of wood damage. Here are some common scenarios where epoxy is used:

- Cracks:Epoxy can fill cracks in wood, restoring its structural integrity. It’s especially useful for repairing cracks caused by drying, moisture, or impact.

- Holes:Epoxy can be used to fill holes in wood, whether they are caused by nails, screws, or other damage. This helps to restore the wood’s appearance and strength.

- Rot:While epoxy can’t completely eliminate rot, it can be used to stabilize and reinforce the affected area. It’s often used in conjunction with other wood repair methods to address rot damage.

- Splits:Epoxy can be used to glue together splits in wood, restoring the wood’s structural integrity. It’s especially useful for repairing splits caused by stress or impact.

Common Wood Repair Scenarios

Epoxy is a versatile material with many applications in wood repair. Here are some common examples:

- Furniture Repair:Epoxy can be used to repair cracks, holes, and other damage in furniture. It’s also used to reinforce joints and strengthen weak areas.

- Flooring Repair:Epoxy can be used to repair cracks, holes, and other damage in wood floors. It’s also used to fill gaps between boards and create a smooth, even surface.

- Boat Repair:Epoxy is commonly used to repair cracks, holes, and other damage in boat hulls. It’s also used to seal leaks and strengthen the hull.

- Outdoor Structures:Epoxy can be used to repair damage in outdoor structures such as decks, fences, and sheds. It’s also used to reinforce joints and protect the wood from the elements.

Primer Basics

Primers are essential for creating a strong bond between the surface and the paint. They act as an intermediary, improving adhesion, enhancing the paint’s durability, and ensuring a smooth, even finish.

Primer Types and Their Suitability

Primers are categorized based on their chemical composition and intended use. Understanding these variations is crucial for selecting the right primer for wood epoxy repairs.

- Adhesion Promoters:These primers are designed to improve the adhesion of paint to surfaces that are difficult to bond with, such as plastics, metals, and previously painted surfaces. They create a microscopic bond between the surface and the paint, ensuring a strong and durable finish.

- Sealing Primers:Sealing primers are formulated to fill in pores and imperfections in the surface, creating a smooth and even base for the paint. They are particularly useful for surfaces with knots, grain, or other irregularities.

- Stain-Blocking Primers:Stain-blocking primers are designed to prevent stains from bleeding through the paint. They are effective at concealing watermarks, tannin stains, and other blemishes that can compromise the final paint finish.

Choosing the Right Primer for Wood Epoxy Repairs

Selecting the right primer for wood epoxy repairs is crucial for achieving a long-lasting and aesthetically pleasing finish.

- Epoxy Primer:Epoxy primers are specifically formulated to adhere to epoxy surfaces. They provide a strong bond and create a smooth, even surface for the paint to adhere to. They are ideal for wood epoxy repairs where the epoxy is exposed.

- Universal Primer:Universal primers are designed to adhere to a wide range of surfaces, including wood, metal, and plastic. They are a good option for repairs where the epoxy is covered by a layer of wood or other materials.

Primer Selection for Wood Epoxy Repairs

Choosing the right primer for wood epoxy repairs is crucial for ensuring a durable and aesthetically pleasing finish. The primer acts as a bridge between the epoxy-treated surface and the subsequent paint or coating, promoting adhesion and preventing the underlying epoxy from affecting the final appearance.

Factors to Consider When Selecting a Primer

The selection of a primer for wood epoxy repairs involves considering several factors that directly impact the performance and longevity of the repair. These factors include:

- Compatibility with Epoxy: The primer must be compatible with the specific type of epoxy used for the repair. Some primers are formulated to adhere well to epoxy surfaces, while others may react negatively, leading to adhesion problems or discoloration.

- Surface Adhesion: The primer should have excellent adhesion to both the epoxy and the surrounding wood. This ensures a strong bond and prevents the primer from peeling or flaking off over time.

- Moisture Resistance: Wood is susceptible to moisture damage, and epoxy repairs are often used in areas prone to moisture exposure. Therefore, the primer should be moisture-resistant to prevent water from penetrating the repair and causing delamination or deterioration.

- Chemical Resistance: The primer should be resistant to chemicals that might come into contact with the repaired surface. This is especially important for repairs in areas exposed to cleaning agents, solvents, or other chemicals.

- Finish Compatibility: The primer should be compatible with the type of paint or coating that will be applied over it. Some primers are designed for specific types of paints, such as oil-based or water-based paints.

Primer Options for Epoxy-Treated Surfaces

Several primer options are available for use on epoxy-treated surfaces, each with unique properties and suitability for different applications.

Epoxy Primers

Epoxy primers are formulated specifically to adhere to epoxy surfaces and provide excellent adhesion, moisture resistance, and chemical resistance. They are often used for repairs in high-stress areas or where the repaired surface will be exposed to harsh conditions.

Acrylic Primers

Acrylic primers are water-based and offer good adhesion, moisture resistance, and compatibility with various paints. They are generally less expensive than epoxy primers and are suitable for repairs in areas with moderate exposure to moisture and chemicals.

Polyurethane Primers

Polyurethane primers provide excellent durability, moisture resistance, and chemical resistance. They are often used for repairs in areas exposed to heavy wear and tear, such as floors or outdoor furniture.

Oil-Based Primers

Oil-based primers are known for their durability and ability to seal porous surfaces. However, they are not always compatible with epoxy surfaces and can be more difficult to clean up than water-based primers.

Benefits and Drawbacks of Primer Types

The choice of primer depends on the specific requirements of the repair and the desired outcome.

Epoxy Primers

- Benefits: Excellent adhesion to epoxy surfaces, high moisture and chemical resistance, durable.

- Drawbacks: Can be more expensive than other primer types, may require specialized application techniques, limited compatibility with some paints.

Acrylic Primers

- Benefits: Water-based, easy to apply, good adhesion, relatively inexpensive, compatible with various paints.

- Drawbacks: May not offer the same level of moisture and chemical resistance as epoxy primers, may not be suitable for high-stress areas.

Polyurethane Primers

- Benefits: Durable, excellent moisture and chemical resistance, suitable for high-wear areas.

- Drawbacks: Can be more expensive than acrylic primers, may require specialized application techniques, may not be compatible with all paints.

Oil-Based Primers

- Benefits: Durable, good sealing properties, compatible with various paints.

- Drawbacks: May not be compatible with epoxy surfaces, can be difficult to clean up, may release harmful fumes.

Application Techniques

Applying primer over wood epoxy repairs is crucial for achieving a smooth, durable, and aesthetically pleasing finish. Proper surface preparation and application techniques are essential to ensure the primer adheres well and provides a suitable base for subsequent coatings.

Surface Preparation

Prior to applying primer, thorough surface preparation is paramount for optimal adhesion and durability. This involves:

- Cleaning the surface:Removing dust, dirt, debris, and any loose epoxy residue using a tack cloth or a damp cloth is crucial. This ensures the primer adheres to a clean, uncontaminated surface.

- Sanding:Lightly sanding the repaired area with fine-grit sandpaper (180-220 grit) helps create a slightly roughened surface that enhances primer adhesion. This step is especially important for epoxy repairs that may have a glossy finish.

- Removing sanding dust:After sanding, it’s vital to remove all sanding dust particles using a tack cloth or a vacuum cleaner. Any remaining dust can interfere with primer adhesion and result in imperfections in the final finish.

Primer Application

Once the surface is properly prepared, applying the primer becomes a straightforward process:

- Choosing the right primer:Select a primer specifically designed for wood and compatible with the subsequent topcoat. For instance, if you plan to use oil-based paint, an oil-based primer is recommended.

- Applying the primer:Apply the primer evenly and thinly using a brush, roller, or spray gun. The chosen method depends on the size and shape of the repaired area and personal preference.

- Drying time:Allow the primer to dry completely according to the manufacturer’s instructions. This typically takes several hours but can vary depending on the primer type, temperature, and humidity levels.

- Sanding (optional):After the primer dries, lightly sand the surface with fine-grit sandpaper to smooth out any imperfections and create a uniform surface for the topcoat. This step is optional but can contribute to a smoother and more professional finish.

Recommended Application Methods

The best application method for primer depends on the size and shape of the repaired area and personal preference:

- Brush:For small repairs or intricate areas, a brush provides precise control and allows for thorough coverage. It’s particularly useful for reaching tight corners and edges.

- Roller:For larger repairs, a roller offers a faster and more efficient application. It’s ideal for covering flat surfaces and achieving a consistent finish.

- Spray gun:For extensive repairs or multiple surfaces, a spray gun offers the fastest and most uniform application. It requires some skill and practice but can achieve a professional-looking finish.

Important Note:Always follow the manufacturer’s instructions for the specific primer you choose, as they may contain additional recommendations or precautions for application and drying time.

Primer and Epoxy Compatibility

The success of your wood epoxy repair depends not only on the quality of the epoxy but also on the primer you choose. The compatibility between these two materials is crucial for a long-lasting and durable repair. This section will delve into the compatibility factors between primers and epoxy types, discuss potential issues arising from incompatible combinations, and provide recommendations for choosing compatible products.

Factors Affecting Compatibility

Understanding the compatibility factors between primers and epoxy types is essential for achieving a successful wood epoxy repair. Compatibility issues can arise from differences in chemical composition, adhesion properties, and drying times.

- Chemical Composition:Primers and epoxies are formulated with different chemical compounds. Some primers may contain solvents or additives that can react negatively with certain epoxy types, leading to poor adhesion or even a weakening of the epoxy’s structural integrity.

- Adhesion Properties:The ability of a primer to adhere to both the wood substrate and the epoxy is critical. If the primer doesn’t adhere well to the wood, the epoxy layer will not be properly anchored, leading to delamination or peeling. Similarly, if the primer doesn’t bond well to the epoxy, the repair will be compromised.

- Drying Times:The drying time of the primer and the epoxy must be compatible to avoid issues like trapping solvents or causing premature curing. If the primer dries too quickly, the epoxy may not have enough time to adhere properly. Conversely, if the epoxy cures before the primer is fully dry, the primer may not be able to fully bond with the epoxy.

Potential Issues from Incompatible Combinations, Which primer over wood epoxy repair

Using incompatible primer and epoxy combinations can lead to several issues, compromising the integrity and longevity of the repair.

- Poor Adhesion:This is a common issue that can occur when the primer and epoxy do not bond well together. The repair may peel or delaminate, leading to a weakened structure and a need for re-repair.

- Chemical Reactions:In some cases, the chemical components of the primer and epoxy may react negatively, causing the epoxy to become brittle, weak, or even discolored.

- Solvent Trapping:If the primer dries too slowly, solvents from the primer may be trapped by the epoxy, preventing it from fully curing. This can result in a soft and weak repair.

- Premature Curing:If the epoxy cures before the primer is fully dry, the primer may not be able to bond properly with the epoxy. This can lead to a weak and brittle repair.

Choosing Compatible Products

To ensure a successful wood epoxy repair, it is crucial to choose compatible primer and epoxy products. Here are some recommendations for selecting compatible products:

- Consult Product Data Sheets:Always refer to the product data sheets of both the primer and epoxy. They will provide information on compatibility, application instructions, and potential issues.

- Choose Products from the Same Manufacturer:Using primer and epoxy products from the same manufacturer increases the likelihood of compatibility. Manufacturers often formulate their products to work together.

- Test Compatibility:Before applying the primer and epoxy to the entire repair area, perform a small-scale test on a hidden section of the wood. This will allow you to assess compatibility and ensure the products work together properly.

Primer and Paint Compatibility: Which Primer Over Wood Epoxy Repair

The compatibility between primer and paint is crucial for achieving a durable and aesthetically pleasing finish. Choosing a paint compatible with the primer is essential for proper adhesion, preventing peeling, cracking, and other issues that can compromise the overall appearance and longevity of the repair.

Primer and Paint Compatibility

A compatible primer and paint combination ensures a strong bond between the layers, allowing the paint to adhere properly to the primed surface. When the primer and paint are compatible, the paint will not react negatively with the primer, resulting in a smooth and even finish.

- Adhesion:Compatible primer and paint create a strong bond, preventing the paint from peeling or flaking off.

- Durability:Proper compatibility enhances the paint’s durability, protecting the repaired area from wear and tear.

- Aesthetics:A compatible combination results in a smooth, even, and consistent finish, enhancing the overall appearance of the repair.

Choosing Compatible Primer and Paint

The choice of primer and paint depends on the specific type of wood and the desired finish. For example, if you’re repairing a piece of furniture made from softwood, a primer designed for softwoods is recommended. Similarly, if you want a high-gloss finish, a primer compatible with gloss paints is necessary.

- Primer Type:Primers are available in various formulations, including oil-based, latex, and epoxy.

- Paint Type:Paints also come in various formulations, including oil-based, latex, and acrylic.

- Manufacturer Recommendations:Always consult the manufacturer’s recommendations for compatibility.

Examples of Compatible Primer and Paint Combinations

- Oil-Based Primer and Oil-Based Paint:This combination is often used for high-gloss finishes and provides excellent adhesion and durability.

- Latex Primer and Latex Paint:This combination is a popular choice for interior projects, offering good adhesion and ease of application.

- Epoxy Primer and Epoxy Paint:This combination is ideal for high-performance applications, offering superior adhesion and resistance to chemicals and moisture.

Final Thoughts

The journey of restoring damaged wood with epoxy and primer is a testament to the power of preparation and informed decision-making. By carefully considering the compatibility of materials, mastering proper application techniques, and addressing potential issues, you can transform flawed surfaces into durable and visually appealing works of art.

Remember, the key to success lies in understanding the intricacies of each step, ensuring that every choice contributes to a final result that stands the test of time.

FAQ Resource

Can I use any primer over wood epoxy?

No, not all primers are compatible with wood epoxy. Some primers can react negatively with epoxy, causing adhesion problems or even damaging the epoxy layer. It is essential to choose a primer specifically designed for use with epoxy.

What are the benefits of using a primer over wood epoxy?

Primers provide several benefits, including improved adhesion of the paint to the epoxy surface, enhanced durability of the finish, and a smoother, more uniform surface for painting.

How do I know if my primer is compatible with my epoxy?

Check the product labels and technical data sheets of both the primer and the epoxy for compatibility information. Look for statements indicating that the products are compatible or suitable for use together.

What if I accidentally use an incompatible primer?

If you suspect that you have used an incompatible primer, it is best to remove it before applying paint. Consult the product instructions for removal methods.