How to knead benoyl peroxide for brick repair – How to knead benzoyl peroxide for brick repair might sound like a strange question, but it’s actually a legitimate technique used in construction. Benzoyl peroxide, a powerful oxidizing agent, is often used in combination with other materials to create a strong, durable repair for damaged bricks.

This process involves carefully mixing benzoyl peroxide with the right ingredients, kneading the mixture to achieve the desired consistency, and then applying it to the damaged area. This guide will walk you through the steps involved, ensuring you understand the safety precautions and best practices for successful brick repair.

Benzoyl peroxide acts as a catalyst in this process, accelerating the hardening and bonding of the repair material. Understanding the properties of benzoyl peroxide and its role in brick repair is crucial to achieving a strong and long-lasting repair.

The correct mixing ratios, kneading techniques, and application methods are all essential factors that contribute to the effectiveness of the repair.

Understanding Benzoyl Peroxide and its Applications: How To Knead Benoyl Peroxide For Brick Repair

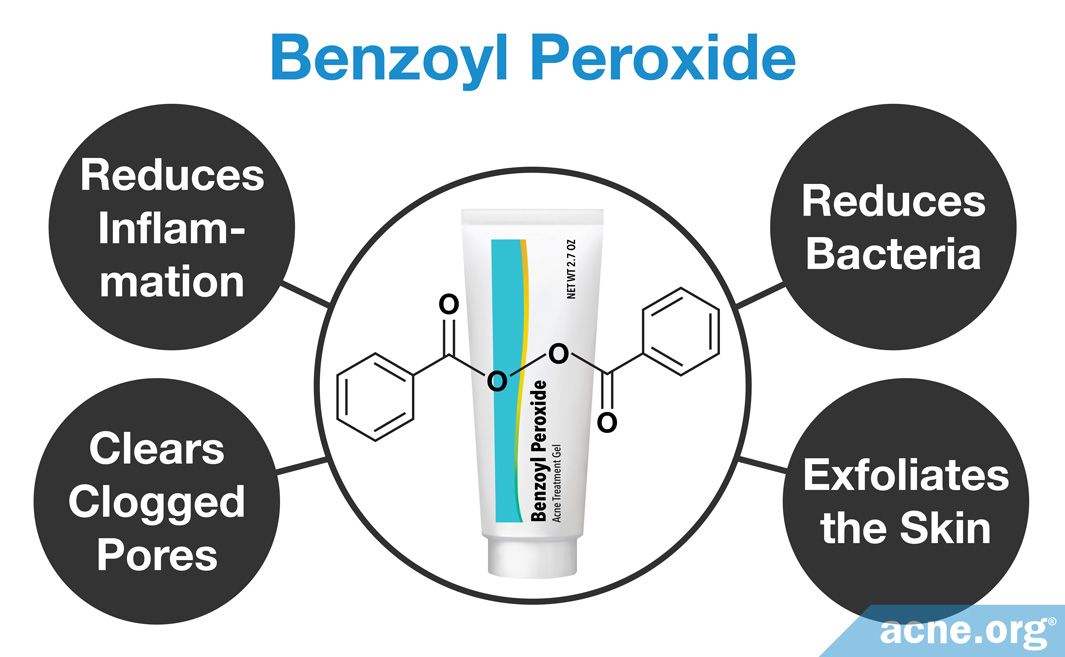

Benzoyl peroxide is a versatile chemical compound with a wide range of applications across various industries. Its unique properties make it a valuable ingredient in numerous products, including those used in construction. This section delves into the chemical composition, properties, and uses of benzoyl peroxide, highlighting its significance in brick repair.

Chemical Composition and Properties

Benzoyl peroxide is an organic compound with the chemical formula C 14H 10O 4. It is a white, crystalline solid that is practically insoluble in water but soluble in organic solvents like ether, chloroform, and benzene. The molecule consists of two benzoyl groups (C 6H 5CO-) linked by a peroxide group (-O-O-).Benzoyl peroxide is a powerful oxidizing agent, meaning it readily accepts electrons from other molecules.

This property is responsible for its effectiveness in various applications, including its use as a bleaching agent, polymerization initiator, and antimicrobial agent.

Applications of Benzoyl Peroxide

Benzoyl peroxide finds applications in various industries, including:

Construction

Brick Repair

Benzoyl peroxide is used as a curing agent in epoxy resins for brick repair. It accelerates the hardening process of the epoxy, enabling a faster and more durable repair.

Mortar and Concrete

Benzoyl peroxide acts as a catalyst in mortar and concrete mixes, improving their strength and workability.

Other Industries

- Pharmaceuticals:Benzoyl peroxide is a common ingredient in acne medications, where it acts as an antimicrobial agent to kill bacteria that contribute to acne formation.

- Cosmetics:It is used as a bleaching agent in hair dyes and tooth whiteners.

- Food Industry:Benzoyl peroxide is used as a flour bleaching agent to improve its baking properties.

- Polymer Industry:It acts as a polymerization initiator in the production of plastics and resins.

Benefits of Using Benzoyl Peroxide for Brick Repair, How to knead benoyl peroxide for brick repair

Benzoyl peroxide offers several benefits when used in brick repair:

- Faster Curing Time:It accelerates the hardening process of epoxy resins, allowing for a quicker repair.

- Increased Strength:Benzoyl peroxide enhances the strength of the repaired area, making it more resistant to damage.

- Improved Durability:The repaired area becomes more durable and resistant to weathering and other environmental factors.

- Cost-Effective:Benzoyl peroxide is a cost-effective solution for brick repair, as it allows for faster and more efficient repairs.

Applying the Kneaded Mixture to Brick Repairs

Applying the benzoyl peroxide mixture to damaged bricks requires careful and precise application. It is crucial to achieve a smooth and even layer to ensure proper bonding and a seamless repair.

Applying the Kneaded Mixture

Applying the benzoyl peroxide mixture to damaged bricks requires careful and precise application. It is crucial to achieve a smooth and even layer to ensure proper bonding and a seamless repair.

- Prepare the surface:Before applying the mixture, clean the damaged brick surface thoroughly. Remove any loose debris, dirt, or dust. Use a wire brush or a scraper to remove any loose mortar or paint.

- Apply the mixture:Use a putty knife or a trowel to apply the kneaded benzoyl peroxide mixture to the damaged area. Apply a thin, even layer, ensuring that the mixture fills all the gaps and cracks.

- Smooth the surface:Use a damp sponge or a smooth trowel to smooth out the applied mixture. Ensure that the surface is level and flush with the surrounding brickwork.

- Clean up:Clean any excess mixture from the surrounding brickwork with a damp cloth.

Curing and Drying the Repaired Brickwork

Curing and drying the repaired brickwork is an important step to ensure proper bonding and a durable repair. The process involves controlling the environment to allow the benzoyl peroxide to react and harden.

- Protect from moisture:Keep the repaired area dry during the curing process. Avoid exposing it to rain or excessive humidity. A tarp or plastic sheeting can be used to protect the area.

- Control temperature:Maintain a consistent temperature during the curing process. Avoid extreme temperature fluctuations, as this can affect the curing process.

- Allow for drying:The drying time will depend on the thickness of the applied mixture, the ambient temperature, and humidity levels. Allow sufficient time for the mixture to fully cure and harden.

Safety Precautions and Considerations

When working with benzoyl peroxide, it’s crucial to prioritize safety to avoid potential hazards and ensure a safe working environment. Benzoyl peroxide is a powerful oxidizing agent and can pose risks if not handled correctly. Therefore, it’s essential to follow strict safety protocols and wear appropriate personal protective equipment (PPE).

Understanding the Hazards and Risks

Benzoyl peroxide is a highly reactive chemical that can cause various health hazards if not handled properly. It’s essential to understand the potential risks associated with benzoyl peroxide use and take appropriate precautions to minimize exposure.

- Skin Contact:Benzoyl peroxide can irritate and burn the skin, leading to redness, itching, and blistering. Direct contact with concentrated solutions can cause severe skin damage.

- Eye Contact:Contact with benzoyl peroxide can cause severe eye irritation, redness, and even corneal damage.

- Inhalation:Inhaling benzoyl peroxide dust or fumes can irritate the respiratory system, causing coughing, shortness of breath, and even lung damage.

- Ingestion:Ingesting benzoyl peroxide can cause severe gastrointestinal irritation, vomiting, and even internal bleeding.

- Fire Hazard:Benzoyl peroxide is a powerful oxidizer and can ignite readily in the presence of combustible materials. It’s crucial to store it away from heat, sparks, and open flames.

Personal Protective Equipment (PPE)

Wearing appropriate PPE is essential to protect yourself from the hazards of benzoyl peroxide. This includes:

- Gloves:Wear chemical-resistant gloves made of nitrile or neoprene to protect your hands from contact with benzoyl peroxide.

- Eye Protection:Wear safety goggles or a face shield to protect your eyes from splashes or dust.

- Respiratory Protection:Use a respirator with appropriate cartridges to protect your lungs from inhaling benzoyl peroxide dust or fumes.

- Protective Clothing:Wear a lab coat or other protective clothing to prevent skin contact with benzoyl peroxide.

Safe Handling Practices

Here are some essential safety practices to follow when handling benzoyl peroxide:

- Work in a Well-Ventilated Area:Ensure adequate ventilation to minimize exposure to benzoyl peroxide fumes.

- Avoid Contact with Combustible Materials:Keep benzoyl peroxide away from flammable materials like paper, wood, and solvents.

- Store Properly:Store benzoyl peroxide in a cool, dry, and well-ventilated area, away from direct sunlight and heat sources.

- Handle with Care:Avoid spilling or dropping benzoyl peroxide. If a spill occurs, clean it up immediately with appropriate materials and dispose of the waste properly.

- First Aid:If you come into contact with benzoyl peroxide, immediately remove contaminated clothing and flush the affected area with plenty of water for at least 15 minutes. If you experience any adverse effects, seek medical attention immediately.

Additional Safety Considerations

- Avoid Mixing with Other Chemicals:Benzoyl peroxide can react violently with certain chemicals, such as strong acids and bases. Avoid mixing it with other chemicals unless you are sure it is safe.

- Proper Disposal:Dispose of benzoyl peroxide according to local regulations. Never pour it down the drain or dispose of it in the trash.

- Training and Awareness:Ensure all personnel handling benzoyl peroxide receive proper training on its hazards and safe handling practices.

Concluding Remarks

By following the steps Artikeld in this guide, you can confidently use benzoyl peroxide to repair damaged bricks. Remember to prioritize safety by wearing appropriate PPE and working in a well-ventilated area. The key to success lies in understanding the properties of benzoyl peroxide, meticulously following the kneading techniques, and applying the mixture correctly to the damaged brickwork.

With careful preparation and execution, you can achieve a durable and seamless repair that blends seamlessly with the existing brickwork.

Top FAQs

What are some common applications of benzoyl peroxide in construction besides brick repair?

Benzoyl peroxide is also used in concrete repair, patching cracks in stucco, and strengthening mortar joints.

Is it safe to use benzoyl peroxide indoors?

While benzoyl peroxide is generally safe for outdoor use, it’s important to ensure adequate ventilation when working indoors. Always consult the product’s safety data sheet for specific recommendations.

What happens if I mix the benzoyl peroxide incorrectly?

An incorrect mix ratio can affect the strength and durability of the repair. It may also lead to a less desirable consistency, making it difficult to apply.

How long does it take for the benzoyl peroxide mixture to cure?

The curing time can vary depending on factors like temperature, humidity, and the specific mix ratio. It’s usually recommended to allow the repaired area to dry completely before applying any further coatings or finishes.