How to repair broken connector for backup camera – So, your backup camera’s acting up? Flickering images, no signal at all? Sounds like a classic case of a broken connector! Don’t worry, we’ve all been there – staring at that rearview mirror, wondering if that giant truck is actually closer than it looks.

This guide will help you fix that broken connector and get your backup camera back in action, so you can avoid those close calls and finally see what’s behind you.

Think of it like a detective story: we’ll identify the culprit (the broken connector), gather our tools (soldering iron, multimeter, etc.), and then get to work on the repair. By the end, you’ll be a backup camera repair pro, ready to tackle any future issues.

But hey, if you’re not feeling up to the challenge, you can always call a professional! Just remember, they’ll probably charge you more than a bag of chips and a soldering iron.

Identifying the Problem

A broken backup camera connector can be a frustrating issue, leaving you blind to what’s behind your vehicle. Understanding the problem is the first step towards a successful repair.

Types of Connectors

Backup camera connectors come in various forms, each with its own unique design and functionality. Some common types include:

- RCA Connector:This is a common type, featuring a circular plug with a single pin for video signal transmission.

- HDMI Connector:This offers high-definition video and audio transmission, providing a clearer and more detailed image.

- USB Connector:Used for digital video and audio transmission, USB connectors are versatile and compatible with various devices.

Signs of a Broken Connector

Recognizing the signs of a broken connector can help you diagnose the problem accurately. Here are some common symptoms:

- Flickering Images:A broken connector can cause intermittent video signals, resulting in flickering images on your screen.

- No Signal:If the connector is completely broken, you might experience a complete loss of signal, leaving your screen blank.

- Loose Connection:A loose connection can cause intermittent signal loss, leading to inconsistent image quality or a complete blackout.

Causes of a Broken Connector

Several factors can contribute to a broken backup camera connector. Some common causes include:

- Wear and Tear:Constant use and exposure to harsh weather conditions can wear down the connector’s pins and casing, leading to damage.

- Moisture Damage:Water ingress can corrode the connector’s electrical contacts, causing signal interference or a complete break.

- Improper Installation:Incorrect installation of the connector can lead to loose connections, strain on the wiring, and eventual damage.

Tools and Materials

To repair a broken backup camera connector, you’ll need the right tools and materials. These tools and materials will allow you to carefully disassemble the connector, repair any damaged wires, and reassemble the connector securely.

Essential Tools

The tools needed for repairing a broken connector are essential for ensuring a successful repair. These tools enable you to safely and effectively work on the connector, preventing further damage.

- Multimeter:A multimeter is used to test the continuity of the wires in the connector, ensuring that there are no breaks in the circuit. It can also be used to check the voltage of the camera, ensuring that it is receiving power.

- Soldering Iron:A soldering iron is used to melt solder, which is then used to connect wires together. A soldering iron is essential for repairing broken wires and ensuring a strong electrical connection.

- Wire Strippers:Wire strippers are used to remove the insulation from the ends of wires, exposing the bare copper wire for soldering. This allows for a clean and secure connection.

- Heat Gun:A heat gun is used to shrink heat shrink tubing, which is used to insulate the repaired wires and protect them from moisture and damage. This ensures a durable and reliable repair.

Necessary Materials

The materials required for repairing a broken connector are crucial for ensuring a durable and functional repair. These materials provide the necessary components for reconnecting the wires and protecting the repair from damage.

- Replacement Connectors:A replacement connector is needed if the existing connector is damaged beyond repair. This ensures that the camera can be properly connected to the vehicle’s electrical system.

- Solder:Solder is a metal alloy that is used to connect wires together. It melts at a low temperature, allowing for a strong and reliable connection.

- Heat Shrink Tubing:Heat shrink tubing is a type of plastic tubing that shrinks when heated. It is used to insulate the repaired wires and protect them from moisture and damage.

- Electrical Tape:Electrical tape is used to secure the repaired wires and provide additional insulation. It helps to prevent shorts and ensure a safe connection.

Tool and Material Descriptions, How to repair broken connector for backup camera

This table provides a comprehensive overview of the tools and materials needed for repairing a broken backup camera connector, along with their purposes and where to find them.

| Tool/Material | Description | Purpose | Where to Find |

|---|---|---|---|

| Multimeter | A device used to measure electrical properties, such as voltage, current, and resistance. | To test the continuity of the wires in the connector and ensure that there are no breaks in the circuit. | Electronic stores, hardware stores, online retailers |

| Soldering Iron | A tool used to melt solder, which is then used to connect wires together. | To repair broken wires and ensure a strong electrical connection. | Electronic stores, hardware stores, online retailers |

| Wire Strippers | A tool used to remove the insulation from the ends of wires, exposing the bare copper wire for soldering. | To allow for a clean and secure connection when soldering wires. | Electronic stores, hardware stores, online retailers |

| Heat Gun | A tool that produces hot air, used to shrink heat shrink tubing. | To shrink heat shrink tubing, which insulates the repaired wires and protects them from moisture and damage. | Hardware stores, online retailers |

| Replacement Connectors | A new connector that replaces a damaged connector. | To ensure that the camera can be properly connected to the vehicle’s electrical system. | Electronic stores, automotive parts stores, online retailers |

| Solder | A metal alloy that is used to connect wires together. | To create a strong and reliable connection between wires. | Electronic stores, hardware stores, online retailers |

| Heat Shrink Tubing | A type of plastic tubing that shrinks when heated. | To insulate the repaired wires and protect them from moisture and damage. | Electronic stores, hardware stores, online retailers |

| Electrical Tape | A type of tape used to secure the repaired wires and provide additional insulation. | To prevent shorts and ensure a safe connection. | Hardware stores, online retailers |

Repairing the Connector

Repairing a broken backup camera connector requires careful attention and a methodical approach. The goal is to restore the connection and ensure a clear signal transmission between the camera and the display unit.

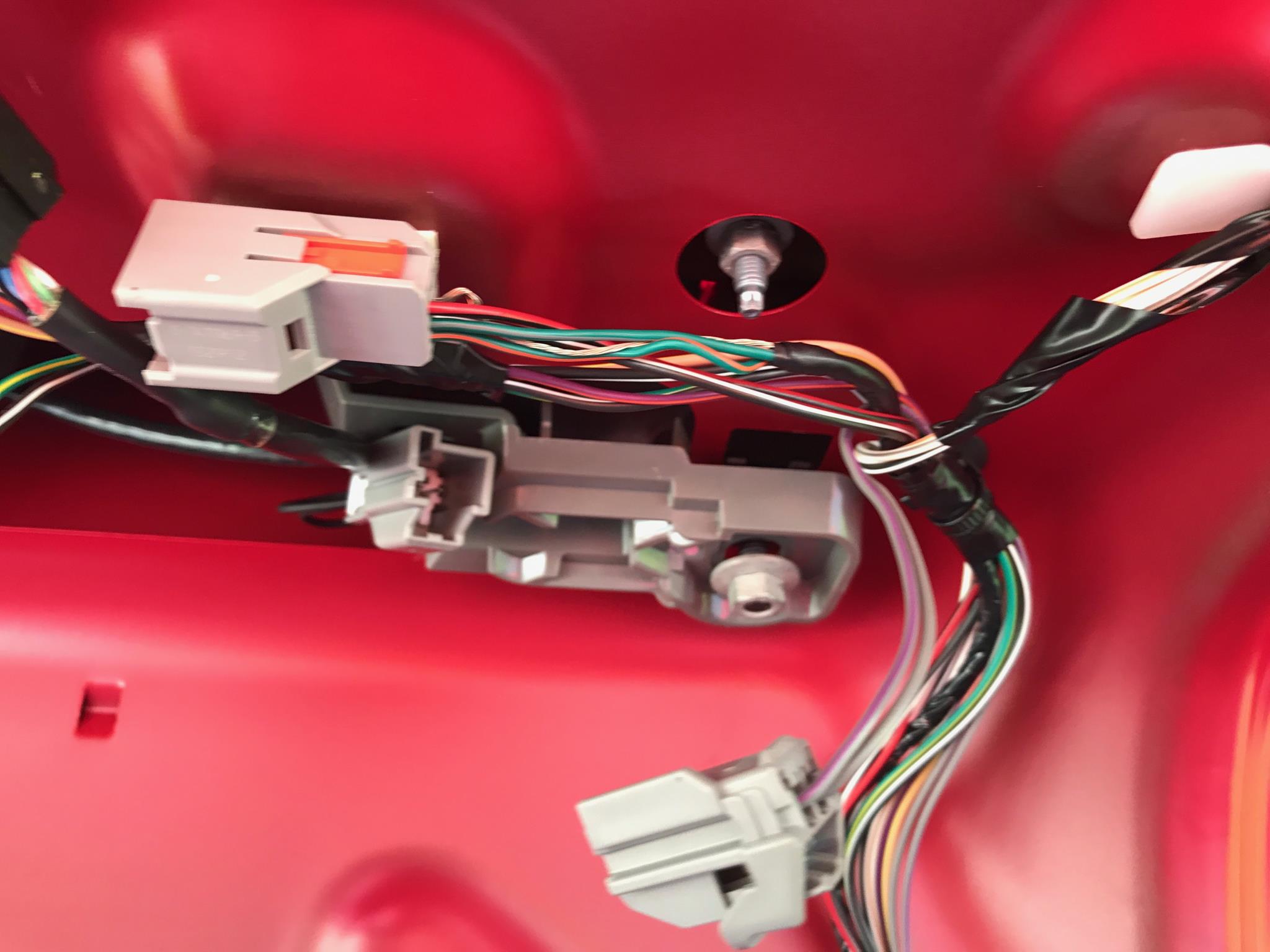

Disconnecting the Connector

Before starting the repair process, it’s crucial to disconnect the connector from the camera and display unit. This step prevents any accidental damage to the electrical components during the repair.

- Locate the connector on the camera and the display unit.

- Gently pull the connector apart, ensuring that you are not applying excessive force.

- If the connector is stuck, you can use a small tool like a flathead screwdriver to help separate the connectors.

Inspecting for Damage

Once the connector is disconnected, it’s time to carefully inspect it for damage. Identifying the specific type of damage will help determine the best repair approach.

- Check for any broken or bent pins on the connector.

- Look for any signs of corrosion or oxidation on the connector pins or the connector housing.

- Examine the wires leading to the connector for any breaks or fraying.

Replacing or Repairing Damaged Parts

Depending on the severity of the damage, you may need to replace the entire connector or just repair the damaged parts.

- If the connector is severely damaged, it’s recommended to replace it with a new one.

- If the damage is limited to a few pins or wires, you can attempt to repair them.

- For repairing broken pins, you can use a soldering iron to reattach the broken pin to the connector.

- For repairing frayed wires, you can use electrical tape or heat shrink tubing to insulate the damaged area.

Safety Precautions

When working with electrical components, it’s essential to prioritize safety.

- Always wear safety glasses to protect your eyes from any potential debris or sparks.

- Work in a well-ventilated area to prevent the buildup of harmful fumes.

- Be careful not to touch any live electrical wires.

- Use appropriate tools and equipment for the repair task.

Soldering the Connector Wires

Soldering is a crucial step in repairing a broken connector. It ensures a secure and reliable electrical connection between the wires and the connector.

- Clean the connector pins and the wire ends with a soldering iron tip cleaner or a piece of fine-grit sandpaper to remove any oxidation or debris.

- Apply a small amount of solder to the connector pin and the wire end.

- Heat the connector pin and the wire end with a soldering iron until the solder melts.

- Gently touch the wire end to the connector pin and hold it in place until the solder cools and solidifies.

- Repeat the process for each wire connected to the connector.

Testing and Troubleshooting

After successfully repairing the connector, it’s crucial to test its functionality and ensure the backup camera is working as expected. This step involves verifying the camera’s connection and assessing the image quality. However, if issues persist, troubleshooting steps are necessary to identify and address the problem.

Testing the Repaired Connector

To test the repaired connector, connect the backup camera to the vehicle’s system and turn on the reverse gear. The camera should activate, displaying a clear image on the monitor. If the camera doesn’t work, check the wiring connections for any loose or damaged wires.

Ensure the camera is powered on and receiving a signal from the vehicle’s system. If the image is distorted or blurry, the camera itself may be faulty.

Troubleshooting Steps

If the camera still doesn’t work after repair, it’s essential to systematically troubleshoot the problem. The following steps can help pinpoint the issue:

- Check the wiring connections:Ensure all wires are securely connected to the connector and the camera. Inspect for any signs of damage, such as frayed or broken wires. If necessary, replace any damaged wires.

- Verify power supply:Check the camera’s power source. Ensure the fuse is not blown and the power supply is working correctly. If necessary, test the power supply with a multimeter.

- Inspect the camera:Examine the camera for any signs of damage, such as cracks or water intrusion. If the camera appears damaged, it may need to be replaced.

- Test the camera with a different connector:If the camera is working with a different connector, the problem likely lies with the repaired connector. Recheck the repair process and ensure all connections are secure.

- Check the vehicle’s system:If the camera is working with a different vehicle, the problem may lie with the vehicle’s system. Consult a mechanic or automotive specialist to diagnose the issue.

Troubleshooting Flowchart

The following flowchart illustrates a systematic approach to troubleshooting a non-functional backup camera:[Image Description: A flowchart depicting the troubleshooting process for a backup camera. The flowchart starts with a question: “Does the camera work?”. If the answer is “Yes”, the problem is solved.

If the answer is “No”, the flowchart branches out to a series of steps: 1. Check the wiring connections, 2. Verify power supply, 3. Inspect the camera, 4. Test the camera with a different connector, and 5.

Check the vehicle’s system. Each step has a corresponding question, leading to a solution or a further step in the troubleshooting process.]

Preventive Measures: How To Repair Broken Connector For Backup Camera

Taking proactive steps to prevent future connector damage is crucial for ensuring the longevity and reliability of your backup camera system. By implementing simple practices and using high-quality components, you can significantly minimize the risk of encountering similar issues in the future.

Proper Handling and Maintenance

Proper handling and maintenance of the backup camera connector are paramount in preventing damage. Here are some tips:

- Avoid excessive force when connecting or disconnecting the connector. Gently insert and remove the connector to prevent bending or breaking the pins.

- Always disconnect the connector before cleaning or performing any maintenance on the camera or wiring. This prevents accidental damage to the connector while working on the system.

- Inspect the connector regularly for signs of wear or damage, such as bent pins, cracks, or corrosion. If you notice any issues, address them promptly to prevent further damage.

Using High-Quality Connectors

The quality of the connector plays a significant role in its durability and lifespan. Using high-quality connectors offers numerous advantages:

- High-quality connectors are made from durable materials that can withstand wear and tear, reducing the risk of damage from repeated use.

- They often feature robust construction and precise pin alignment, ensuring reliable electrical connections and minimizing the risk of signal interference or loss.

- Investing in high-quality connectors can save you money in the long run by reducing the need for frequent replacements.

Environmental Protection

Exposure to harsh environmental conditions can accelerate connector deterioration. Protecting the connector from moisture and extreme temperatures is crucial:

- Avoid exposing the connector to direct sunlight or extreme heat, as this can damage the plastic housing and potentially melt the connector pins.

- Protect the connector from moisture by using a waterproof cover or sealant, especially in areas prone to rain or humidity.

- Consider using a connector with a weatherproof design, which often features a sealed housing and protective coverings for the pins.

Conclusion

There you have it! With a little patience and a dash of technical know-how, you’ve successfully tackled the mystery of the broken backup camera connector. Now you can confidently reverse into tight spots, knowing your camera has your back (literally).

So, next time you see that blinking red light on your dashboard, don’t panic! You’ve got this! Remember, even the most seasoned mechanics started somewhere, and you’re well on your way to becoming a DIY car repair wizard.

Quick FAQs

Can I use regular electrical tape to fix the connector?

While electrical tape can be a temporary fix, it’s not a long-term solution. It’s best to use heat shrink tubing or a replacement connector for a more durable and reliable repair.

What if the connector is damaged beyond repair?

If the connector is severely damaged, it’s best to replace it with a new one. You can find replacement connectors online or at an automotive parts store.

Is it safe to solder the connector myself?

Soldering can be dangerous if you’re not careful. Always wear safety glasses and work in a well-ventilated area. If you’re not comfortable soldering, it’s best to leave it to a professional.