A/C repair line kits are indispensable tools for anyone tackling air conditioning repairs. These kits contain specialized components designed to streamline the repair process, offering convenience and efficiency for both professional technicians and DIY enthusiasts. From refrigerant lines and fittings to gauges and tools, a/c repair line kits provide everything you need to diagnose and fix common AC issues, making the repair process less daunting and more manageable.

Understanding the different types of kits available, their applications, and proper installation techniques is crucial for successful AC repairs. This guide explores the world of a/c repair line kits, providing insights into their features, benefits, and essential considerations for making informed choices.

What is an A/C Repair Line Kit?

An A/C repair line kit is a set of tools and components that are used to repair or replace the refrigerant lines in an air conditioning system. These lines are responsible for carrying the refrigerant between the condenser, evaporator, and compressor, and are essential for the proper functioning of the A/C system.

Components of an A/C Repair Line Kit

A/C repair line kits typically include the following components:

- Refrigerant lines:These are the lines that carry the refrigerant between the different components of the A/C system. They are usually made of copper or aluminum.

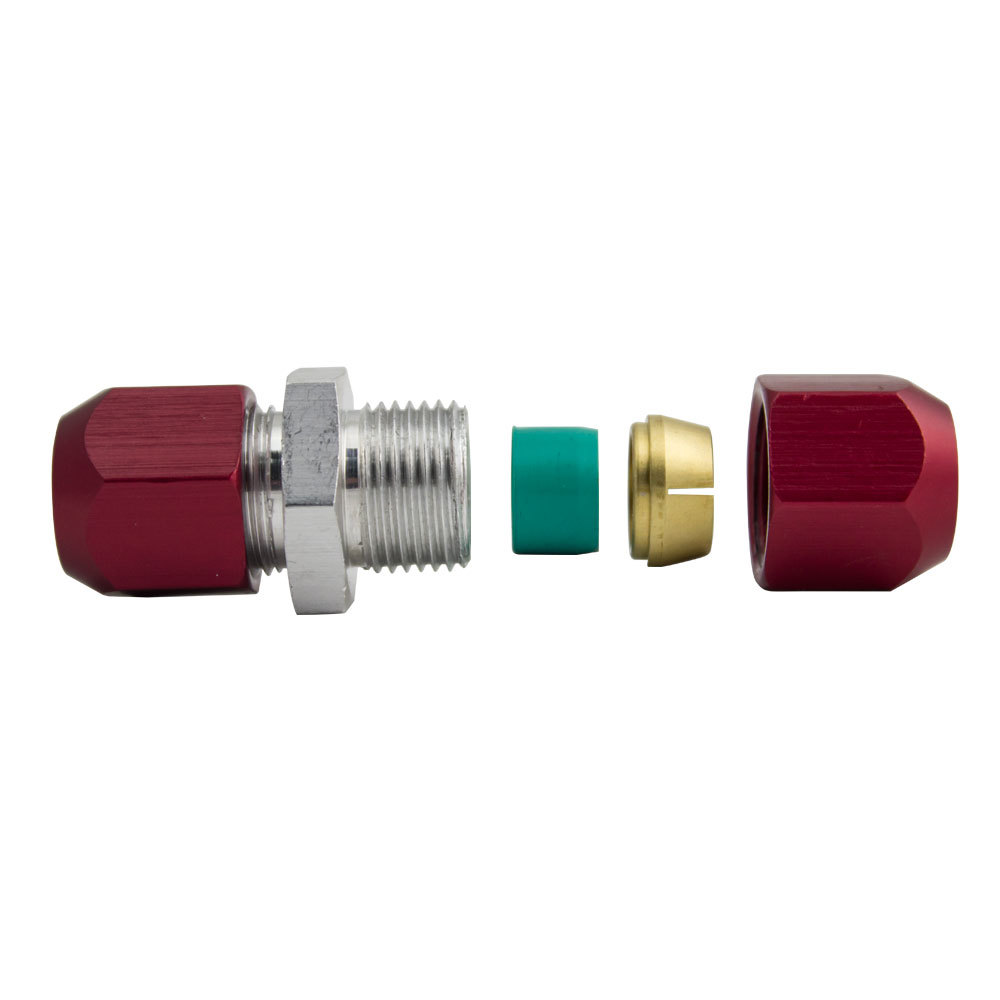

- Fittings:These are used to connect the refrigerant lines to the different components of the A/C system. They come in a variety of sizes and shapes.

- O-rings:These are used to seal the connections between the refrigerant lines and the fittings. They are usually made of rubber.

- Tools:These are used to cut, bend, and flare the refrigerant lines. They may include a tubing cutter, a flaring tool, and a bending tool.

- Vacuum pump:This is used to evacuate the air and moisture from the A/C system before charging it with refrigerant.

- Manifold gauge set:This is used to measure the pressure of the refrigerant in the A/C system. It can also be used to monitor the flow of refrigerant during the charging process.

Types of A/C Repair Line Kits

There are different types of A/C repair line kits available, depending on the specific needs of the repair. Some common types include:

- Basic kits:These kits include the essential tools and components needed for most basic repairs. They are typically suitable for DIY repairs.

- Professional kits:These kits include a wider range of tools and components, and are designed for professional use. They may include tools for more complex repairs, such as brazing and welding.

- Specialty kits:These kits are designed for specific types of A/C systems, such as automotive or commercial systems. They may include components that are specific to the particular type of system.

Applications of A/C Repair Line Kits

A/C repair line kits are essential tools for technicians working on a variety of air conditioning systems. They are used to connect the refrigerant lines and other components of the system, allowing for proper charging and troubleshooting. These kits are particularly useful in situations where the existing lines are damaged, leaking, or need to be replaced.

Types of Air Conditioning Systems

A/C repair line kits are used in a wide range of air conditioning systems, including:

- Residential air conditioners

- Commercial air conditioners

- Automotive air conditioners

- Refrigeration systems

Repair Scenarios Where Line Kits are Essential

Line kits are essential in several repair scenarios, such as:

- Replacing damaged lines:When refrigerant lines are damaged due to corrosion, punctures, or other issues, a new line kit is needed to restore the system’s functionality.

- Adding new components:When adding components to the system, such as an additional evaporator or condenser coil, a line kit is required to connect the new components to the existing system.

- Troubleshooting leaks:Line kits can be used to isolate leaks in the system, allowing technicians to identify the specific location of the leak and make necessary repairs.

Simplifying the Repair Process

A/C repair line kits streamline the repair process by providing technicians with the necessary tools and components in a convenient package. This includes:

- Pre-charged lines:The lines in the kit are pre-charged with refrigerant, eliminating the need for technicians to charge the system separately. This saves time and reduces the risk of contamination.

- Pre-assembled components:Line kits typically include pre-assembled components, such as fittings, valves, and hoses, which further simplify the installation process.

- Easy to use:Line kits are designed to be user-friendly, making it easier for technicians to connect the components and complete the repair.

Choosing the Right A/C Repair Line Kit

Choosing the right A/C repair line kit is a bit like picking the right tools for the jobyou want something that’s gonna get the job done properly and not leave you feeling like you’ve wasted your time and money. There are a few things to consider when choosing a kit, so let’s dive in!

Factors to Consider When Choosing an A/C Repair Line Kit

When choosing an A/C repair line kit, you need to consider a few things to make sure you’re getting the right kit for your needs. These factors will help you pick the right kit and avoid any unnecessary headaches.

- Type of A/C System:You need to know what type of A/C system you’re working on. Different systems use different types of refrigerants and fittings, so you need to make sure your kit is compatible with your system. Check the manufacturer’s specs or look for a kit specifically designed for your type of A/C system.

- Refrigerant Type:Different A/C systems use different types of refrigerants. Make sure the kit you choose is compatible with the type of refrigerant used in your system. You don’t want to end up with a kit that can’t handle the refrigerant you need.

- Kit Components:Look at the components included in the kit. Do you need a manifold gauge set, a vacuum pump, a recovery tank, or other accessories? Make sure the kit has everything you need to do the job properly. Some kits are more comprehensive than others, so make sure you’re getting what you need.

- Kit Quality:You get what you pay for. Choose a kit from a reputable manufacturer that uses high-quality materials and construction. A cheap kit might not last as long or perform as well, so it’s worth investing in a quality kit.

- Kit Size and Portability:Think about how you’ll be using the kit. Do you need a compact kit that’s easy to transport? Or do you need a larger kit with more components? Choose a kit that fits your needs and your workspace.

- Price:Kits can range in price from a few hundred quid to a few thousand. Set a budget and stick to it. Don’t overspend on a kit that’s more than you need, but don’t skimp on quality either.

Comparing Brands and Models

There are a few different brands and models of A/C repair line kits on the market, so it’s important to compare them before you make a decision. Some popular brands include:

- Robinair:Robinair is a well-known brand that makes high-quality A/C repair line kits. Their kits are generally more expensive, but they’re also built to last and perform well.

- Yellow Jacket:Yellow Jacket is another popular brand that makes a wide range of A/C repair line kits. Their kits are known for their durability and reliability. They offer a variety of kits to suit different needs and budgets.

- Mastercool:Mastercool is a good option for those looking for a more affordable A/C repair line kit. Their kits are still well-made and reliable, but they’re not as expensive as some of the other brands.

Compatibility with Specific A/C Systems

Before you buy an A/C repair line kit, make sure it’s compatible with your specific A/C system. Different A/C systems use different types of refrigerants and fittings, so it’s crucial to get a kit that’s compatible with your system.

Check the manufacturer’s specifications for your A/C system or consult with a qualified HVAC technician to ensure you’re getting the right kit.

Remember: Always consult with a qualified HVAC technician before attempting any A/C repair work. They can help you choose the right kit and ensure that you’re doing the work safely and correctly.

Installation and Usage of A/C Repair Line Kits

Installing and using an A/C repair line kit is a bit of a faff, but it’s pretty straightforward once you know what you’re doing. You’ll need to make sure you’re using the right kit for your job, and that you’ve got all the right tools and equipment.

Safety Precautions

Safety is paramount when working with A/C systems. Always wear safety glasses and gloves to protect yourself from potential hazards. Make sure you have proper ventilation and avoid working in confined spaces without adequate airflow.

Installation of A/C Repair Line Kits

Before you start, you’ll need to gather all the necessary tools and materials. These usually include:

- A/C repair line kit

- Wrench set

- Screwdrivers

- Vacuum pump

- Manifold gauge set

- Leak detector

- Refrigerant charging hose

- Safety glasses

- Gloves

The installation process typically involves these steps:

- Identify the A/C system components:Locate the compressor, condenser, evaporator, and expansion valve. This is crucial for understanding how the A/C system operates and for connecting the repair line kit to the correct components.

- Prepare the A/C system:Before installing the repair line kit, ensure the A/C system is properly evacuated and purged.

This step removes any air and moisture that can cause problems.

- Connect the repair line kit:Connect the repair line kit to the A/C system using the appropriate fittings. The kit will usually include hoses and fittings for connecting to the high-pressure and low-pressure sides of the system.

- Test the system:Once the repair line kit is installed, test the A/C system to ensure it is working properly. Use the manifold gauge set to check the pressure and temperature readings, and use a leak detector to check for any leaks.

Using A/C Repair Line Kits

A/C repair line kits are typically used for various tasks, such as:

- Refrigerant charging:Repair line kits can be used to add refrigerant to the A/C system. This is essential when the system is low on refrigerant or if the system has been repaired.

- Refrigerant recovery:These kits are used to remove refrigerant from the A/C system, which is essential when the system is being serviced or disposed of.

- Vacuuming:The vacuum pump included in the kit is used to remove air and moisture from the A/C system before adding refrigerant. This is a crucial step in ensuring the system operates efficiently.

- Leak detection:The leak detector included in the kit can be used to identify leaks in the A/C system.

This is important for preventing refrigerant loss and ensuring the system operates efficiently.

Important Tips for Using A/C Repair Line Kits

- Always follow the manufacturer’s instructions:Each A/C repair line kit comes with a set of instructions that must be followed carefully. This ensures the kit is used safely and effectively.

- Use the correct tools and equipment:Make sure you have the right tools and equipment for the job. Using the wrong tools can damage the A/C system or the repair line kit.

- Be aware of potential hazards:A/C systems use refrigerants that can be flammable and harmful if inhaled. Always work in a well-ventilated area and avoid contact with the refrigerant.

- Don’t overfill the system:Adding too much refrigerant can damage the A/C system. Use the manifold gauge set to monitor the refrigerant levels and ensure the system is not overfilled.

- Dispose of refrigerant properly:Refrigerant is a hazardous material and must be disposed of properly. Check with your local regulations for proper disposal methods.

Maintenance and Troubleshooting of A/C Repair Line Kits

You’ve got your A/C repair line kit, and you’re ready to tackle those refrigerant leaks. But, like any tool, you need to keep it in tip-top shape to ensure it’s working properly and lasts a good while. This section covers how to maintain your kit and what to do if things go wrong.

Maintaining the Kit

Keeping your A/C repair line kit in good condition is essential for accurate and safe refrigerant handling.

- Clean it regularly: After each use, wipe down the hoses, gauges, and fittings with a clean cloth. This removes any dirt, oil, or refrigerant residue that could affect performance or cause corrosion.

- Inspect for damage: Before each use, check the hoses, gauges, and fittings for any signs of wear, cracks, or leaks. If you find any damage, replace the affected parts immediately.

- Store it properly: When not in use, store the kit in a cool, dry place, preferably in its original case. This protects it from dust, moisture, and extreme temperatures.

- Lubricate moving parts: Some kits have valves or fittings that require lubrication. Refer to the manufacturer’s instructions for recommended lubricants and application methods.

- Calibrate gauges regularly: Gauges are crucial for accurate refrigerant readings. If you notice any inconsistencies or suspect they are off, get them professionally calibrated.

Troubleshooting Common Issues

Even with proper maintenance, you might encounter some issues with your A/C repair line kit. Here are some common problems and solutions:

- Leaking hoses: Check the hoses for cracks, punctures, or loose fittings. Replace any damaged hoses.

- Gauge malfunction: If a gauge is not working properly, try replacing the batteries (if applicable) or check for any loose connections. If the issue persists, the gauge may need to be replaced.

- Clogged fittings: If a fitting is clogged, try cleaning it with a small wire brush or compressed air. If the blockage persists, the fitting may need to be replaced.

- Incorrect refrigerant readings: If the gauges are not reading accurately, make sure they are properly calibrated. Also, ensure that the hoses are connected securely and that there are no leaks in the system.

Importance of Proper Storage and Handling

Storing and handling your A/C repair line kit correctly is crucial for its longevity and safety.

- Keep it in a dry and cool place: Extreme temperatures and humidity can damage the hoses, gauges, and fittings. Store it in its original case or a similar container.

- Handle it with care: Avoid dropping or mishandling the kit. This can damage the hoses, gauges, or fittings.

- Protect it from direct sunlight: Prolonged exposure to direct sunlight can damage the hoses and gauges.

- Keep it away from flammable materials: Refrigerant is flammable, so keep the kit away from open flames or sparks.

Last Point: A/c Repair Line Kit

Equipped with the right a/c repair line kit, you can confidently approach AC repairs with increased efficiency and precision. By understanding the kit’s components, applications, and proper usage, you can tackle common AC issues with greater ease and ensure the optimal performance of your cooling system.

Whether you’re a seasoned technician or a DIY enthusiast, mastering the use of an a/c repair line kit empowers you to take control of your AC maintenance and repair needs.

Commonly Asked Questions

What are the most common types of A/C repair line kits?

A/C repair line kits come in various types, each designed for specific applications. Some common types include basic kits for simple repairs, professional kits for complex tasks, and specialty kits for specific AC systems.

How do I choose the right A/C repair line kit?

Consider the type of AC system you have, the complexity of the repair, and your experience level. Research different brands and models to find a kit that meets your needs and budget.

What safety precautions should I take when using an A/C repair line kit?

Always prioritize safety when working with refrigerants and AC systems. Wear appropriate safety gear, such as gloves and eye protection, and follow the manufacturer’s instructions carefully.

How do I maintain my A/C repair line kit?

Clean the kit regularly, store it in a dry and cool place, and inspect it for any damage before each use.