A/C lines repair kit, a lifesaver for those battling refrigerant leaks in their air conditioning systems. Imagine the frustration of a sweltering summer day, only to discover your AC isn’t working. A faulty A/C line, often the culprit, can lead to a cascade of discomfort and costly repairs.

But fear not! An A/C lines repair kit can be your knight in shining armor, offering a quick and affordable solution to patch those pesky leaks and get your AC back in fighting shape. These kits, equipped with everything you need, from sealant to hoses, empower you to tackle the repair yourself, saving you time and money.

Whether you’re a seasoned DIYer or a novice tackling your first AC repair, this guide will equip you with the knowledge and confidence to navigate the world of A/C lines repair kits. We’ll delve into the different types of kits available, explore the steps for successful repair, and even discuss environmental considerations.

Get ready to become your own AC hero!

What is an A/C Lines Repair Kit?

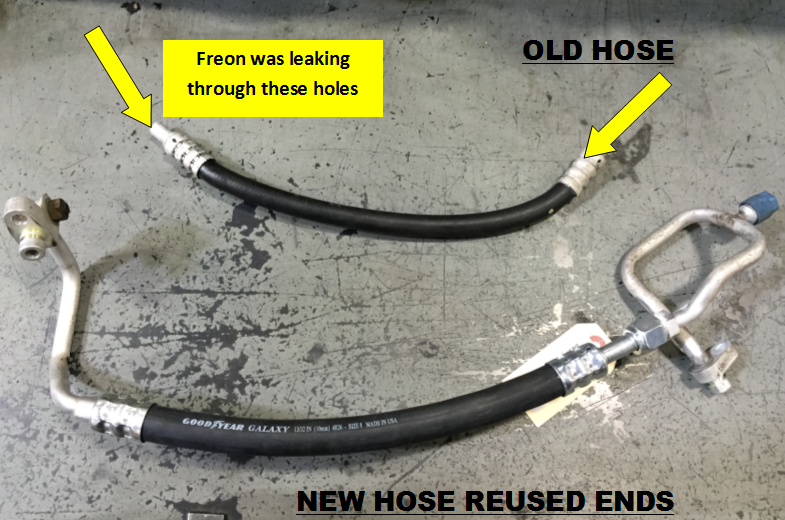

An A/C lines repair kit is a handy tool that allows you to fix leaks in your car’s air conditioning system without needing to replace the entire line. These kits are particularly useful for small leaks that occur in the refrigerant lines, which are responsible for carrying the cold refrigerant throughout your car’s A/C system.

Components of an A/C Lines Repair Kit

A typical A/C lines repair kit includes a variety of components designed to help you seal the leak effectively.

- Leak sealant:This is the main component of the kit. It’s a specially formulated liquid that’s designed to seal small leaks in the A/C lines. It typically comes in a small bottle or can, and you’ll need to inject it into the system using a specialized adapter.

- Adapter:This is a device that allows you to connect the leak sealant bottle to your car’s A/C system. The adapter is typically designed to fit the low-pressure port on your A/C system, which is where the refrigerant enters the system.

- Gauge:Some kits include a gauge that allows you to monitor the pressure in your A/C system. This can be helpful in determining if the leak has been successfully sealed.

- Instructions:Every kit comes with detailed instructions on how to use it. These instructions are essential for ensuring that you use the kit correctly and safely.

Benefits of Using an A/C Lines Repair Kit

Using an A/C lines repair kit offers several advantages over traditional repair methods, such as replacing the entire A/C line.

- Cost-effective:Repair kits are significantly less expensive than replacing the entire A/C line. This is because they only require you to replace the damaged section of the line, not the entire line.

- Convenience:Repair kits are designed to be easy to use.

They come with all the necessary components and instructions, so you can fix the leak yourself without needing to take your car to a mechanic.

- Time-saving:Using a repair kit can save you a significant amount of time compared to taking your car to a mechanic.

You can typically fix the leak in under an hour.

Types of A/C Lines Repair Kits

A/C lines repair kits come in various types, each designed for specific applications and repair needs. Choosing the right type depends on the type of damage, the location of the leak, and the specific A/C system being repaired.

Types of A/C Lines Repair Kits

A/C lines repair kits are broadly categorized into two main types:

- Sealant Kits:These kits contain a sealant that is injected into the A/C system to plug leaks. Sealant kits are typically used for small leaks in the A/C lines, such as pinholes or cracks. They are easy to use and relatively inexpensive, but they may not be effective for larger leaks or leaks in areas that are difficult to access.

- Repair Kits with Patches:These kits include patches that are applied to the damaged area of the A/C line. Patches are typically used for larger leaks or leaks in areas that are difficult to seal with sealant. They are more durable than sealant kits and can provide a more permanent repair.

However, they may be more difficult to apply and may require specialized tools.

Features of Different Types of Kits

- Sealant Kits:

- Advantages:Easy to use, relatively inexpensive, suitable for small leaks.

- Disadvantages:May not be effective for larger leaks, may not be suitable for all types of A/C systems, may not provide a permanent repair.

- Repair Kits with Patches:

- Advantages:More durable than sealant kits, can provide a more permanent repair, suitable for larger leaks.

- Disadvantages:May be more difficult to apply, may require specialized tools, may not be suitable for all types of A/C systems.

Applications of Different Types of Kits

- Sealant Kits:

- Suitable for small leaks in A/C lines, such as pinholes or cracks.

- Can be used on various A/C systems, including automotive, residential, and commercial systems.

- Repair Kits with Patches:

- Suitable for larger leaks, leaks in areas that are difficult to seal with sealant, and leaks in specific types of A/C lines, such as aluminum lines.

- May be more suitable for specific types of A/C systems, such as automotive systems.

Using an A/C Lines Repair Kit

Repairing a damaged A/C line can be a daunting task, but with the right tools and knowledge, it’s a manageable DIY project. An A/C lines repair kit provides the necessary components to fix leaks and restore your car’s cooling system.

Repairing a Damaged A/C Line

Before you start, it’s crucial to identify the leak. This can be done by visually inspecting the A/C lines for signs of damage or by using an A/C leak detector. Once you’ve located the leak, follow these steps:

- Prepare the area.Park your car on a level surface and engage the parking brake. Ensure the area around the A/C line is clean and free of debris.

- Gather your materials.You’ll need an A/C lines repair kit, a pair of pliers, a wrench, a clean rag, and a pair of safety glasses.

- Clean the damaged area.Use a clean rag to wipe away any dirt or debris from the damaged section of the A/C line.

- Apply the sealant.Depending on the type of repair kit, you may need to use a special tool to apply the sealant. Follow the instructions provided with your kit carefully.

- Allow the sealant to dry.After applying the sealant, allow it to dry completely according to the manufacturer’s instructions. This may take several hours.

- Test the repair.Once the sealant is dry, start your car and turn on the A/C. Check for any leaks or signs of refrigerant loss.

Safety Precautions

Working with refrigerant can be dangerous. Here are some essential safety precautions to follow:

- Always wear safety glassesto protect your eyes from any potential splashes or debris.

- Work in a well-ventilated areato avoid inhaling refrigerant fumes.

- Never use an open flamenear the A/C system.

- Avoid contact with the refrigerantas it can cause skin irritation and frostbite.

- Dispose of refrigerant properlyaccording to local regulations.

Troubleshooting Common Issues

Here are some common issues you might encounter during the repair process:

- The sealant doesn’t hold.This could be due to a large hole in the A/C line, a poorly cleaned surface, or the wrong type of sealant. If the sealant doesn’t hold, you may need to replace the damaged A/C line.

- The A/C system doesn’t cool.This could be due to a refrigerant leak, a faulty compressor, or a blocked condenser. If the A/C system doesn’t cool, you may need to have it professionally inspected and repaired.

Common A/C Lines Problems

Your A/C lines are a vital part of your car’s cooling system, carrying refrigerant to and from the evaporator and condenser. Over time, these lines can develop problems, leading to a decrease in cooling performance or even a complete failure of your air conditioning system.It’s important to be aware of common problems that can occur with A/C lines and their associated symptoms to address them promptly and prevent further damage.

Leaks

A/C line leaks are a common problem that can occur due to various factors, such as corrosion, damage from road debris, or wear and tear. Leaks can result in a gradual loss of refrigerant, leading to reduced cooling performance and ultimately, a complete failure of your A/C system.

Symptoms of Leaks

- Reduced cooling performance

- Warm air blowing from the vents

- A hissing sound coming from the A/C system

- Visible refrigerant leaks

Causes of Leaks

- Corrosion: Over time, A/C lines can corrode, especially in areas exposed to moisture and salt.

- Damage from road debris: Road debris can puncture or damage A/C lines, causing leaks.

- Wear and tear: A/C lines can wear out over time, leading to leaks.

Clogged Lines, A/c lines repair kit

Clogged A/C lines can restrict the flow of refrigerant, leading to reduced cooling performance. This issue often arises due to debris or contaminants accumulating within the lines.

Symptoms of Clogged Lines

- Reduced cooling performance

- Warm air blowing from the vents

- A rattling sound coming from the A/C system

Causes of Clogged Lines

- Debris: Debris, such as dirt, leaves, or metal shavings, can accumulate within the A/C lines.

- Contaminants: Refrigerant oil can break down over time, creating contaminants that can clog the lines.

Damaged Lines

A/C lines can become damaged due to accidents, road debris, or even improper installation. Damage can result in leaks, restricted refrigerant flow, and ultimately, a complete failure of your A/C system.

Symptoms of Damaged Lines

- Reduced cooling performance

- Warm air blowing from the vents

- Visible damage to the A/C lines

- A hissing sound coming from the A/C system

Causes of Damaged Lines

- Accidents: A/C lines can be damaged in accidents, especially if they are located in the front of the vehicle.

- Road debris: Road debris can puncture or damage A/C lines, causing leaks.

- Improper installation: Improper installation of A/C lines can lead to damage and leaks.

Importance of Professional Inspection and Repair

It’s crucial to seek professional inspection and repair for complex A/C line problems. A qualified technician can accurately diagnose the issue, identify the root cause, and recommend the appropriate repair solution.

Attempting to repair A/C lines yourself can be dangerous due to the high pressure involved. Improper repair can lead to further damage and leaks, increasing the risk of injury.

Maintenance and Care: A/c Lines Repair Kit

Just like any other part of your car’s air conditioning system, your A/C lines need regular maintenance and care to ensure optimal performance and longevity. Neglecting these crucial components can lead to costly repairs down the line.

Regular Inspections

Regular inspections are essential for identifying potential problems early on, preventing them from escalating into major issues. A visual inspection of the A/C lines should be conducted during each routine car maintenance check. Look for signs of wear and tear, such as cracks, leaks, corrosion, or damage.

If any of these signs are present, it’s important to have the lines inspected and repaired by a qualified technician.

Preventative Measures

Taking preventative measures can significantly extend the lifespan of your A/C lines.

- Avoid driving through rough terrain or areas where the A/C lines are susceptible to damage.

- Park your car in shaded areas to prevent the A/C lines from overheating.

- Have your A/C system serviced regularly, including a thorough inspection of the lines.

- Use a high-quality A/C refrigerant and ensure the system is properly charged.

- Avoid using harsh chemicals or cleaners on the A/C lines, as these can damage the material.

Extending the Lifespan of A/C Lines

Following these tips can help extend the lifespan of your A/C lines:

- Regularly inspect the A/C lines for any signs of damage or leaks.

- Avoid driving through rough terrain or areas where the A/C lines are susceptible to damage.

- Park your car in shaded areas to prevent the A/C lines from overheating.

- Have your A/C system serviced regularly, including a thorough inspection of the lines.

- Use a high-quality A/C refrigerant and ensure the system is properly charged.

- Avoid using harsh chemicals or cleaners on the A/C lines, as these can damage the material.

Choosing the Right Repair Kit

Selecting the appropriate A/C lines repair kit is crucial for a successful repair and to ensure the longevity of your system. Choosing the wrong kit can lead to compatibility issues, improper repairs, and even damage to your A/C system.

This section will guide you through the factors to consider when choosing the right kit for your needs.

Factors to Consider

Choosing the right A/C lines repair kit involves considering several factors, such as the type of A/C system, refrigerant compatibility, and kit features. Here is a table summarizing the key considerations:

| Factor | Description |

|---|---|

| Type of A/C System | Different A/C systems use different types of lines and fittings. Ensure the kit is compatible with your system. |

| Refrigerant Compatibility | The kit should be compatible with the refrigerant used in your A/C system. Check the kit’s specifications and your system’s manual for compatibility. |

| Kit Features | Consider features like the number of fittings, tools included, and ease of use. Choose a kit that provides the necessary components and tools for your repair. |

Decision-Making Process

A flowchart can help you visualize the decision-making process for selecting the right A/C lines repair kit:[Insert flowchart here. The flowchart should illustrate a series of steps starting with identifying the type of A/C system, followed by determining the refrigerant used, and then selecting a kit compatible with both.

The flowchart should also include branches for specific scenarios, such as if the kit doesn’t include all necessary tools or if the kit isn’t compatible with the system. ]

Alternatives to Repair Kits

Sometimes, a repair kit might not be the best solution for your A/C lines. In such cases, you might want to explore other options like professional replacement or welding. Let’s delve into these alternatives, understanding their advantages and disadvantages.

Professional Replacement

Professional replacement involves having a certified technician completely replace the damaged A/C line. This method offers several benefits, but it also comes with some drawbacks.

- Advantages:

- Durability:A new A/C line ensures long-lasting performance and reliability, eliminating the risk of future leaks.

- Peace of Mind:Professional installation guarantees proper sealing and minimizes the chances of future issues.

- Warranty:Many replacement parts come with a manufacturer’s warranty, providing additional protection.

- Disadvantages:

- Cost:Professional replacement is typically the most expensive option, as it involves labor costs and the price of the new A/C line.

- Time:Replacing an A/C line can be time-consuming, requiring scheduling with a technician and potentially taking several hours or even days to complete.

Welding

Welding is another alternative for repairing A/C lines. It involves using specialized equipment to fuse the damaged section, creating a permanent seal.

- Advantages:

- Cost-Effective:Welding is often less expensive than a full replacement, especially for minor repairs.

- Quick Turnaround:Welding repairs can be completed relatively quickly, reducing downtime.

- Disadvantages:

- Expertise Required:Welding A/C lines requires specialized skills and equipment, making it unsuitable for DIY projects.

- Potential for Damage:If not performed correctly, welding can weaken the A/C line, leading to future leaks.

- Limited Applicability:Welding is not always a viable option for all types of damage, such as severe corrosion or extensive leaks.

Cost-Effectiveness of Repair Options

The cost-effectiveness of each repair option depends on the severity of the damage and the specific A/C system.

- Repair Kits:These are generally the most affordable option, especially for minor leaks. However, they may not provide a permanent solution, and their effectiveness can vary.

- Welding:This is a cost-effective alternative for moderate damage, but it requires specialized expertise and can be risky if not performed correctly.

- Professional Replacement:This is the most expensive option but offers the best long-term solution, ensuring reliability and durability. It’s often the most cost-effective solution in the long run, especially for severe damage.

Note:Always consult with a certified A/C technician to determine the most appropriate repair method for your specific situation.

Environmental Considerations

While A/C line repair kits can be a convenient and cost-effective solution for fixing leaks, it’s crucial to consider their environmental impact and dispose of them responsibly.

Refrigerant Disposal

Refrigerant is a crucial component of your A/C system, but it’s also a potent greenhouse gas. Improper disposal can contribute to climate change.

- Never release refrigerant into the atmosphere.This can significantly harm the environment.

- Find a certified technician or recycling facilityto properly dispose of the refrigerant.

- Check for local regulationson refrigerant disposal and follow them strictly.

Kit Components

A/C line repair kits often contain components that can be harmful to the environment if not disposed of correctly.

- Avoid throwing kit components into regular trash.This can contaminate landfills and pollute the environment.

- Check with your local recycling centerfor proper disposal options.

- Consider using reusable or recyclable componentswhenever possible.

Eco-Friendly Practices

While not all repair kits are created equal, there are some eco-friendly options available.

- Choose kits made with recycled materialsor those that have minimal environmental impact.

- Look for kits with a focus on sustainabilityand responsible manufacturing practices.

- Opt for kits with biodegradable or recyclable componentswhenever possible.

Summary

Armed with the right A/C lines repair kit, you can conquer those pesky leaks and restore your AC to its former glory. Remember, safety is paramount, so always follow instructions carefully and consider seeking professional help for complex issues.

By understanding the basics of A/C line repair, you can keep your home cool and comfortable, saving money and enjoying the peace of mind that comes with a job well done. So, grab your toolkit, let’s get to work!

Expert Answers

What are the most common symptoms of an A/C line leak?

Common symptoms include a decrease in cooling power, a hissing sound coming from the AC system, and a noticeable drop in refrigerant levels.

How long does it take to repair an A/C line leak using a repair kit?

The time required for repair varies depending on the severity of the leak and the type of repair kit used. Simple leaks can be repaired in as little as 30 minutes, while more complex issues may require several hours.

Can I use an A/C lines repair kit on any type of AC system?

Not all repair kits are compatible with all AC systems. It’s crucial to check the kit’s specifications and ensure it’s compatible with your specific AC unit.

How often should I inspect my AC lines for leaks?

Regular inspections are recommended, ideally every 12 months, to catch any potential leaks early.

What should I do with the old refrigerant and repair kit components?

Proper disposal of used refrigerant and kit components is crucial. Check with your local waste management authority for guidelines on responsible disposal.