How do you repair a cracked engine block? It’s a question that can send shivers down any car owner’s spine. A cracked engine block is a serious problem, but don’t panic just yet. There are a few ways to fix it, depending on the severity of the crack and your budget.

We’ll break down the repair options, from welding to epoxy, and even replacing the whole thing. We’ll also cover some preventative measures to keep your engine in tip-top shape and avoid a cracked block in the first place. So, buckle up, because we’re diving into the world of engine block repair.

Imagine your car as a living, breathing machine. The engine block is its heart, and a crack in that heart can be a major problem. The crack might be tiny, but it can lead to a whole lot of trouble like leaking coolant, losing compression, and even causing your engine to overheat.

So, what can you do? First, you need to assess the damage. Is the crack small and superficial, or is it a big, gaping wound? The severity of the crack will determine your repair options.

Assessing the Crack: How Do You Repair A Cracked Engine Block

Before attempting any repairs, you need to thoroughly assess the crack in your engine block. This involves identifying its location, severity, and potential causes. Understanding these factors is crucial for determining the best course of action and ensuring a successful repair.

Location and Severity of the Crack

The location and severity of the crack are key factors in determining the repair strategy. Cracks can occur in various parts of the engine block, each with its own implications.

- Cylinder Walls:Cracks in the cylinder walls can lead to coolant leaks, loss of compression, and engine failure. The severity of these cracks can vary from hairline fissures to large, open breaks.

- Water Jackets:Cracks in the water jackets, which surround the cylinders, can cause coolant leaks and overheating.

These cracks can be difficult to detect and can lead to significant damage if left untreated.

- Head Gasket Surface:Cracks on the head gasket surface can lead to coolant leaks and head gasket failure. This can result in a loss of compression and engine damage.

Potential Causes of the Crack

Several factors can contribute to the development of cracks in an engine block. Understanding the root cause can help prevent future issues and ensure a more durable repair.

- Overheating:Excessive engine temperatures can cause the metal of the engine block to expand and contract rapidly, leading to stress and potential cracking. This is a common cause of cracks, especially in older engines or those with cooling system problems.

- Improper Maintenance:Neglecting routine maintenance, such as coolant flushes and oil changes, can contribute to engine overheating and stress, increasing the risk of cracks.

- External Damage:Impacts from accidents, debris, or other external forces can cause significant damage to the engine block, including cracks.

Risks of Ignoring a Cracked Engine Block

Ignoring a cracked engine block can have serious consequences, potentially leading to catastrophic engine failure.

- Coolant Leaks:Cracks in the engine block can allow coolant to leak into the combustion chamber, leading to overheating and engine damage.

- Loss of Compression:Cracks in the cylinder walls can cause a loss of compression, resulting in reduced power and engine performance.

- Engine Failure:In severe cases, a cracked engine block can lead to complete engine failure, requiring a costly replacement.

Repair Options

Repairing a cracked engine block is a challenging task, but it’s often possible, depending on the severity and location of the crack. The choice of repair method will depend on factors like the type of engine, the material of the block, and the availability of specialized equipment.

Engine Block Repair Methods

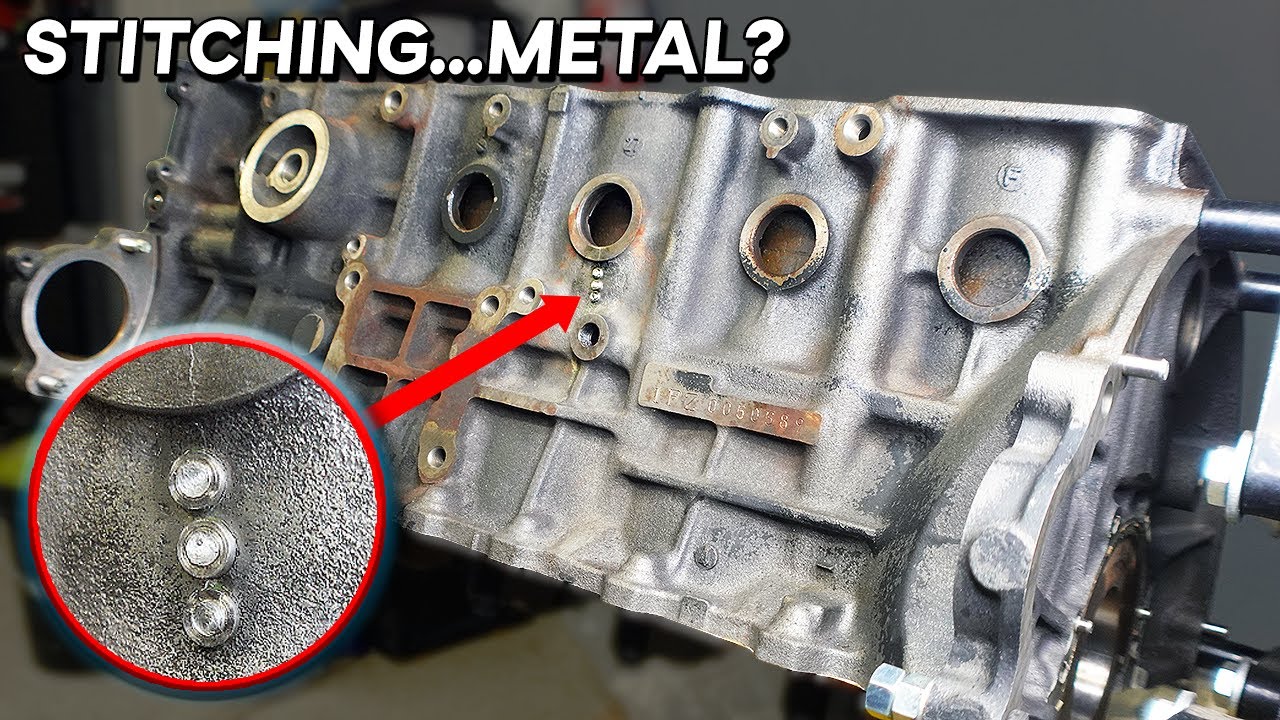

The following are some of the most common methods used to repair cracked engine blocks:

- Welding

- Brazing

- Epoxy Repair

Welding

Welding is a common repair method for cracked engine blocks, particularly for cracks in cast iron blocks. The process involves using a welding torch to melt metal filler material, which is then fused to the cracked area. Welding can be effective for repairing cracks in high-stress areas, such as the cylinder walls or the block’s main bearing surfaces.

- Advantages:Welding is a relatively strong and durable repair method, and it can be used to repair cracks in various locations. It is also a relatively cost-effective option, especially when compared to replacing the engine block.

- Disadvantages:Welding can be a complex process that requires specialized skills and equipment. Improper welding can weaken the engine block, potentially leading to further cracking. Also, the heat from welding can distort the engine block, requiring additional machining to restore the block’s original dimensions.

Brazing

Brazing is similar to welding, but it uses a lower-melting-point filler metal, which is applied to the cracked area using a torch. Brazing is often used for repairing cracks in aluminum engine blocks, as the heat from brazing is less likely to warp the aluminum.

- Advantages:Brazing is less likely to distort the engine block than welding, and it is also a relatively strong repair method. Brazing can be used to repair cracks in various locations, including those in the cylinder head or the block’s water jacket.

- Disadvantages:Brazing is not as strong as welding, and it may not be suitable for repairing cracks in high-stress areas. The process also requires specialized skills and equipment, and it can be more expensive than welding.

Epoxy Repair

Epoxy repair is a less invasive method for repairing cracks in engine blocks. Epoxy is a strong adhesive that can be used to bond the cracked surfaces together. Epoxy repair is often used for repairing hairline cracks or cracks in low-stress areas.

- Advantages:Epoxy repair is a relatively simple and inexpensive repair method. It is also less likely to distort the engine block than welding or brazing. Epoxy repair can be done on-site, which can save time and money.

- Disadvantages:Epoxy repair is not as strong as welding or brazing, and it is not suitable for repairing cracks in high-stress areas. Epoxy repairs are also not as durable as welding or brazing, and they may need to be re-applied over time.

Welding and Brazing

Welding and brazing are common methods for repairing cracks in engine blocks. These techniques involve fusing metal together to create a strong and durable bond, but they differ in their processes and applications.

Welding Process

Welding involves melting the base metal and filler metal together using a high-heat source, typically an arc or laser. The heat melts the metals, creating a molten pool that solidifies as it cools, forming a strong weld.

- Equipment:Welding engine blocks requires specialized equipment, including a welding machine (either arc or laser), welding rods or wire, safety gear (including welding mask, gloves, and protective clothing), and a suitable welding table or platform.

- Safety Precautions:Welding poses significant safety risks, including burns, eye damage, and inhalation of harmful fumes. Always wear appropriate safety gear and follow safety guidelines provided by the welding machine manufacturer. Proper ventilation is crucial to minimize exposure to fumes.

- Types of Welding:Common welding techniques for engine blocks include gas tungsten arc welding (GTAW), gas metal arc welding (GMAW), and laser welding. The choice of welding technique depends on the size and complexity of the crack, the type of metal, and the desired weld quality.

Welding vs. Brazing

Welding and brazing differ in the melting point of the filler metal and the resulting bond.

- Welding:The filler metal melts at a higher temperature than the base metal, creating a strong, continuous bond that is essentially a fusion of the base and filler metals. This is ideal for repairing large cracks or those requiring high strength.

- Brazing:The filler metal melts at a lower temperature than the base metal. The filler metal flows into the crack, creating a strong bond that is essentially a “glue” between the base metals. Brazing is suitable for smaller cracks and those where high strength is not a primary concern.

Brazing also minimizes the risk of warping or distortion in the engine block.

Importance of Qualified Professionals

Welding and brazing engine blocks are highly specialized tasks requiring extensive knowledge and experience. Improper welding or brazing can weaken the engine block, leading to further damage and potential engine failure. Therefore, it is crucial to engage qualified professionals with experience in welding or brazing engine blocks.

Epoxy Repair

Epoxy repair is a common method for fixing cracked engine blocks, offering a relatively simple and cost-effective solution. While it might not be as durable as welding or brazing, epoxy can be a viable option for smaller cracks or when the engine block is considered unrepairable by other methods.

Types of Epoxy

Choosing the right epoxy is crucial for a successful repair. Different types of epoxy are available, each with unique properties and limitations.

- High-strength epoxy:These epoxies are designed for high-stress applications and offer excellent adhesion and durability. They are often used for repairing cracks in engine blocks that are subject to significant vibration and heat.

- Two-part epoxy:This type of epoxy consists of a resin and a hardener that are mixed together to form a strong, durable bond. They are commonly used for engine block repairs due to their ease of application and versatility.

- Metallic epoxy:This type of epoxy contains metallic particles that enhance its strength and heat resistance. They are particularly suitable for repairing cracks in engine blocks that are exposed to high temperatures.

Epoxy Application

The application of epoxy requires meticulous preparation and precise application techniques to ensure a successful repair.

- Surface Preparation:Thoroughly clean the cracked area of the engine block. Remove any dirt, grease, oil, or rust using a wire brush, sandpaper, or a suitable cleaning agent.

- Crack Preparation:Depending on the size and depth of the crack, you may need to widen it slightly to allow for better epoxy penetration. This can be achieved using a small drill bit or a suitable tool.

- Mixing Epoxy:Carefully follow the manufacturer’s instructions for mixing the epoxy. Typically, you will need to mix the resin and hardener in specific proportions for a proper cure.

- Applying Epoxy:Apply the mixed epoxy to the prepared crack, ensuring complete coverage. Use a spatula or a suitable tool to spread the epoxy evenly and fill the crack completely.

- Curing Time:Allow the epoxy to cure completely according to the manufacturer’s instructions. This typically takes several hours or even days, depending on the type of epoxy and environmental conditions.

Best Practices, How do you repair a cracked engine block

To maximize the chances of a successful epoxy repair, it is essential to follow best practices:

- Proper Curing Environment:Cure the epoxy in a controlled environment, away from direct sunlight, heat, or moisture.

- Avoid Overheating:Avoid exposing the repaired area to excessive heat during the curing process, as this can affect the epoxy’s strength and durability.

- Pressure Relief:Apply a light pressure to the repaired area during the curing process to ensure a strong bond. This can be achieved using clamps or other suitable methods.

Engine Block Replacement

Replacing a cracked engine block is a significant repair that involves removing the old block and installing a new one. This process requires specialized tools and knowledge, and it’s often best left to professional mechanics.

Factors to Consider When Choosing a Replacement Engine Block

When choosing a replacement engine block, several factors are crucial to ensure compatibility and long-term performance.

- Compatibility:The replacement engine block must be compatible with the vehicle’s year, make, and model. It should also match the original engine’s specifications, such as displacement, cylinder configuration, and bore size.

- Condition:The replacement engine block should be in good condition, free from any defects or damage. Look for a block with low mileage and a clean history. Consider purchasing a remanufactured block, which is typically rebuilt to factory specifications, ensuring quality and reliability.

- Cost:The cost of a replacement engine block varies depending on the make, model, and condition of the block. It’s important to compare prices from different suppliers to find the best value.

Proper Installation and Alignment

Proper installation and alignment of the new engine block are essential for optimal performance and longevity.

- Alignment:The engine block must be precisely aligned with the transmission and other components. Misalignment can lead to vibration, premature wear, and even damage to other parts of the engine.

- Torque Specifications:All bolts and fasteners must be tightened to the manufacturer’s specified torque values. Overtightening can damage the engine block or other components, while undertightening can lead to leaks or looseness.

- Cooling System:The cooling system must be thoroughly flushed and inspected for leaks. A properly functioning cooling system is crucial for preventing overheating and engine damage.

Prevention and Maintenance

The best way to avoid a cracked engine block is to prevent it from happening in the first place. Regular maintenance and proper care can significantly reduce the risk of cracks and extend the life of your engine.

Proper Cooling System Function

A properly functioning cooling system is crucial for preventing engine overheating, a major cause of engine block cracks. The cooling system’s primary function is to regulate the engine’s temperature, preventing it from reaching dangerous levels. A malfunctioning cooling system can lead to overheating, which can cause the engine block to warp and crack.

- Regularly check the coolant level:Low coolant levels can lead to overheating, so it’s essential to ensure the coolant level is always within the recommended range.

- Inspect the radiator for leaks:A leaking radiator can cause coolant loss and overheating.

- Check the thermostat:A faulty thermostat can prevent the coolant from circulating properly, leading to overheating.

- Ensure proper fan operation:The cooling fan helps to dissipate heat from the engine. A malfunctioning fan can cause overheating.

Regular Engine Maintenance

Regular maintenance practices can help identify potential problems early on, allowing for timely repairs and preventing major damage, including cracks.

- Oil changes:Regular oil changes are crucial for engine health. Dirty oil can clog the oil passages, leading to overheating and damage to engine components.

- Air filter replacement:A dirty air filter restricts airflow to the engine, causing it to run inefficiently and overheat.

- Spark plug inspection and replacement:Faulty spark plugs can cause misfires, which can lead to overheating.

- Fuel system cleaning:A dirty fuel system can lead to inefficient combustion, resulting in overheating and damage to engine components.

Avoiding Overheating

Overheating is a major contributor to engine block cracks.

- Avoid prolonged idling:Idling for extended periods can cause the engine to overheat, especially in hot weather.

- Monitor engine temperature gauge:Pay attention to the engine temperature gauge and address any unusual readings promptly.

- Use appropriate engine oil:Using the correct type and viscosity of engine oil is essential for proper lubrication and heat dissipation.

- Avoid overloading the engine:Overloading the engine can cause it to work harder and overheat.

Identifying Potential Engine Problems Early On

Early detection of engine problems can help prevent major damage and costly repairs.

- Unusual noises:Listen for unusual noises coming from the engine, such as knocking, rattling, or grinding. These could indicate a problem with engine components.

- Check engine light:The check engine light is a warning signal that something is wrong with the engine.

- Excessive smoke:Excessive smoke from the exhaust can indicate a problem with the engine, such as oil burning or a leaking head gasket.

- Loss of power:A loss of power can be a sign of a variety of engine problems, including overheating.

Closing Summary

Dealing with a cracked engine block can be a real pain, but it doesn’t have to be the end of the road for your car. With the right approach, you can get your ride back in shape and hitting the streets again.

Remember, prevention is key. Regular maintenance and proper care can help prevent cracks in the first place. So, keep an eye on your engine’s health and don’t let those cracks get the best of you!

Question Bank

What are the signs of a cracked engine block?

Common signs include coolant leaks, loss of engine power, overheating, and a knocking sound coming from the engine.

How much does it cost to repair a cracked engine block?

The cost depends on the repair method used, the severity of the crack, and the make and model of your vehicle. A simple epoxy repair might cost a few hundred bucks, while replacing the entire engine block could run you thousands.

Can I drive my car with a cracked engine block?

It’s not recommended. Driving with a cracked engine block can cause further damage and even lead to a complete engine failure.

How long does it take to repair a cracked engine block?

The repair time depends on the method used and the complexity of the job. A simple epoxy repair might take a few hours, while replacing the engine block could take several days.