How to put tire pressure sensors on work wheels d9r – Want to upgrade your ride with Work Wheels D9R and ensure optimal tire performance? Tire pressure sensors are crucial for maintaining proper inflation and ensuring a smooth, safe driving experience. This guide dives into the world of tire pressure sensors, exploring their purpose, installation, and maintenance to help you achieve a seamless setup on your Work Wheels D9R.

We’ll guide you through the process of choosing the right sensors, understanding their compatibility, and installing them correctly. From calibration and programming to troubleshooting potential issues, this comprehensive guide has everything you need to confidently install and maintain your tire pressure sensors.

Understanding Tire Pressure Sensors

Tire pressure sensors are essential components for maintaining optimal tire pressure in vehicles, especially in work wheels like the Work Wheels D9R. They play a crucial role in ensuring safe and efficient driving by constantly monitoring tire pressure and alerting the driver of any deviations from the recommended levels.

Tire Pressure Sensor Function

Tire pressure sensors are small electronic devices installed within the valve stem of each tire. They contain a pressure sensor, a transmitter, and a battery. The pressure sensor continuously monitors the tire pressure and transmits this data to the vehicle’s onboard computer via radio frequency (RF) signals. The onboard computer then displays the tire pressure readings on the dashboard, allowing the driver to stay informed about the condition of their tires.

Importance of Maintaining Proper Tire Pressure

Maintaining proper tire pressure is essential for several reasons:

- Enhanced Fuel Efficiency: Underinflated tires increase rolling resistance, leading to higher fuel consumption. Properly inflated tires reduce friction and improve fuel economy.

- Improved Handling and Stability: Properly inflated tires provide optimal grip and stability, enhancing vehicle control and reducing the risk of skidding or accidents.

- Increased Tire Lifespan: Underinflated tires wear out faster due to increased friction and heat. Maintaining proper tire pressure extends tire life and reduces premature wear.

- Enhanced Safety: Maintaining proper tire pressure is crucial for safety. Underinflated tires can lead to blowouts, while overinflated tires can increase the risk of tire failure and uneven wear.

Types of Tire Pressure Sensors, How to put tire pressure sensors on work wheels d9r

There are two primary types of tire pressure sensors:

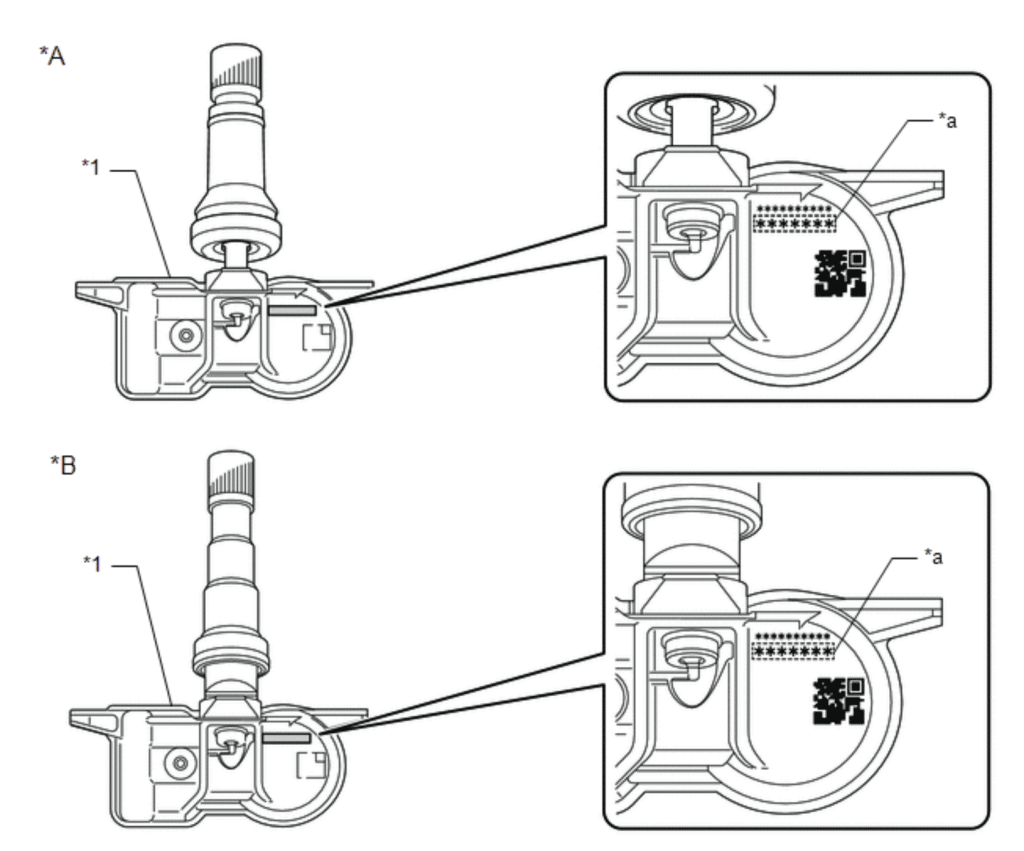

- Direct Tire Pressure Sensors (DTPS): These sensors are directly mounted inside the tire valve stem and are designed to withstand high temperatures and pressures. DTPS are generally considered more reliable and accurate than indirect sensors.

- Indirect Tire Pressure Sensors (ITPS): These sensors rely on the vehicle’s ABS (Anti-lock Braking System) to monitor tire pressure indirectly. ITPS use the difference in wheel speed to detect pressure variations. While less accurate than DTPS, ITPS are generally more affordable and easier to install.

Compatibility with Work Wheels D9R

Work Wheels D9R typically require direct tire pressure sensors (DTPS) for optimal performance and compatibility. DTPS are designed to withstand the high pressures and loads associated with performance wheels, ensuring accurate and reliable tire pressure monitoring.

Choosing the Right Tire Pressure Sensors

Installing tire pressure sensors on your Work Wheels D9R can enhance safety and provide valuable information about your tire pressure. Choosing the right sensors is crucial to ensure compatibility, functionality, and longevity. This guide will help you navigate the process of selecting the best tire pressure sensors for your specific needs.

Factors to Consider When Selecting Tire Pressure Sensors

When selecting tire pressure sensors, several key factors should be considered to ensure compatibility, functionality, and value for your investment.

- Compatibility: Ensure the sensors are compatible with your vehicle’s tire pressure monitoring system (TPMS). Different vehicles have different TPMS frequencies and protocols. Check your vehicle’s owner’s manual or consult with a mechanic to determine the correct frequency and protocol for your vehicle.

- Features: Explore various features offered by different sensors, such as real-time pressure and temperature readings, low-pressure alerts, and programmable pressure settings. These features can enhance your driving experience and provide greater peace of mind.

- Price: Tire pressure sensors vary in price depending on the brand, features, and technology. Consider your budget and prioritize features that are most important to you.

- Brand Reputation: Choose sensors from reputable brands known for their quality, reliability, and customer support. Research reviews and ratings from other users to gain insights into the performance and longevity of different brands.

Popular Tire Pressure Sensor Brands

The following table compares key features and specifications of popular tire pressure sensor brands:

| Brand | Features | Compatibility | Price Range |

|---|---|---|---|

| Brand A | Real-time pressure and temperature readings, low-pressure alerts, programmable pressure settings | Compatible with most vehicles | $XX – $YY |

| Brand B | Real-time pressure readings, low-pressure alerts, battery life indicator | Compatible with a limited range of vehicles | $ZZ – $AA |

| Brand C | Real-time pressure and temperature readings, low-pressure alerts, external display unit | Wide compatibility | $BB – $CC |

Installation Process

Installing tire pressure sensors on Work Wheels D9R is a straightforward process that requires basic tools and a little patience. This section will guide you through the step-by-step procedure, ensuring a secure and accurate installation.

Removing the Existing Valve Stem

Before installing the new tire pressure sensors, you need to remove the existing valve stems.

- Gather the necessary tools: You will need a valve stem tool, a tire iron, and a torque wrench.

- Loosen the lug nuts: Using the tire iron, loosen the lug nuts on the wheel you are working on. Do not remove them completely at this stage.

- Remove the valve stem: Use the valve stem tool to unscrew the valve stem from the wheel. Be careful not to damage the valve stem or the surrounding area.

- Remove the lug nuts and tire: Once the valve stem is removed, you can completely remove the lug nuts and take off the tire.

Installing the New Sensor

Once the existing valve stem is removed, you can install the new tire pressure sensor.

- Prepare the new sensor: Ensure the new sensor is compatible with your vehicle’s TPMS system and that the battery is installed correctly.

- Insert the sensor: Carefully insert the new sensor into the valve stem hole. Ensure the sensor is seated properly and does not protrude excessively.

- Tighten the valve stem: Using the valve stem tool, tighten the valve stem onto the sensor. Do not overtighten as this could damage the sensor or the valve stem.

Torque Settings

Proper torque settings are crucial for a secure installation and to prevent leaks.

- Consult the manufacturer’s specifications: The recommended torque settings for your specific tire pressure sensors and valve stems can be found in the manufacturer’s instructions or online resources.

- Use a torque wrench: A torque wrench is essential for ensuring the correct tightening force. It prevents overtightening, which can damage the sensor or valve stem, and undertightening, which can lead to leaks.

- Tighten the valve stem: Use the torque wrench to tighten the valve stem to the manufacturer’s specified torque setting. Ensure the sensor is securely attached to the valve stem.

Reinstall the Tire and Wheel

Once the sensor is installed, you can reinstall the tire and wheel.

- Position the tire: Align the tire with the wheel hub and gently push it onto the wheel. Make sure the tire is seated properly and does not have any uneven wear or damage.

- Tighten the lug nuts: Hand-tighten the lug nuts to ensure the tire is securely attached to the wheel. Use the torque wrench to tighten the lug nuts to the manufacturer’s specified torque setting.

- Check the tire pressure: After reinstalling the tire and wheel, check the tire pressure using a tire pressure gauge. Ensure the pressure is within the manufacturer’s recommended range for your vehicle.

Calibration and Programming: How To Put Tire Pressure Sensors On Work Wheels D9r

After installing the new tire pressure sensors, the next crucial step is to calibrate and program them to communicate with your vehicle’s computer. This process ensures accurate tire pressure readings are displayed on your dashboard and alerts you to any potential issues.Calibration and programming are essential to establish a reliable connection between the sensors and your vehicle’s TPMS system. This allows the system to accurately monitor tire pressure and warn you of any deviations, helping to prevent accidents and ensure optimal vehicle performance.

Using a TPMS Tool

To program the sensors, you’ll need a TPMS tool. This tool is designed to communicate with the sensors and write their unique IDs to the vehicle’s computer. The TPMS tool typically has a display screen, buttons for navigation, and a connection port for attaching to the vehicle’s diagnostic port.Here’s how to program the sensors using a TPMS tool:

- Connect the TPMS tool to the vehicle’s diagnostic port, which is usually located under the dashboard or near the steering column.

- Turn the ignition key to the “ON” position but do not start the engine.

- Select the “Program Sensors” option on the TPMS tool’s menu.

- Follow the on-screen prompts to enter the sensor IDs. These IDs are usually found on the sensors themselves or in the sensor’s packaging.

- Once the IDs are entered, the TPMS tool will send a signal to the sensors, activating them and writing their IDs to the vehicle’s computer.

- After programming, the TPMS tool will display a confirmation message indicating that the sensors have been successfully programmed.

Potential Issues and Troubleshooting

While programming tire pressure sensors is generally straightforward, some issues might arise:

- Sensor Battery Issues: If the sensor battery is low, it might not respond to the TPMS tool. Replacing the battery is the solution in this case.

- Sensor Damage: Physical damage to the sensor can prevent it from communicating with the TPMS tool. In such cases, you might need to replace the damaged sensor.

- Incorrect Sensor IDs: Entering incorrect sensor IDs during programming will result in faulty readings. Ensure you use the correct IDs provided with the sensors.

- TPMS Tool Compatibility: Not all TPMS tools are compatible with all vehicles. Ensure the TPMS tool you’re using is compatible with your vehicle’s make and model.

- Vehicle System Malfunction: In rare cases, the vehicle’s TPMS system itself might be malfunctioning. This can be diagnosed by a qualified technician.

If you encounter any issues during calibration or programming, it’s recommended to consult a professional mechanic or tire shop. They have the necessary tools and expertise to diagnose and resolve any problems.

Maintenance and Troubleshooting

Tire pressure sensors, while durable, require regular maintenance to ensure their optimal performance and longevity. This section will provide insights into maintaining these sensors, identifying common issues, and understanding how to troubleshoot them.

Sensor Maintenance

Regular maintenance is crucial for extending the life of tire pressure sensors.

- Cleaning: Dust, dirt, and grime can accumulate on the sensor valve stem, potentially affecting its performance. Clean the valve stem regularly with a soft cloth and mild soap. Avoid using harsh chemicals or abrasive cleaners.

- Visual Inspection: Periodically inspect the sensor for any visible damage, such as cracks, scratches, or corrosion. If you notice any damage, it’s recommended to replace the sensor to prevent further issues.

- Battery Life: Tire pressure sensors typically have a battery life of 5-7 years. When the battery starts to fail, the sensor will emit a low battery warning signal on your vehicle’s dashboard. Replacing the battery or the entire sensor is necessary once this warning appears.

Troubleshooting Common Issues

Tire pressure sensors can occasionally malfunction, resulting in inaccurate readings or failure to transmit data. Here’s a breakdown of common issues and troubleshooting steps:

- Sensor Failure: If a sensor fails, it will not transmit data to the vehicle’s monitoring system. This can be identified by a warning light on the dashboard. A diagnostic tool can help identify the faulty sensor. In such cases, replacing the sensor is the solution.

- Interference: External factors like strong electromagnetic fields can interfere with the sensor’s signal transmission. This can lead to inaccurate readings or intermittent data loss. Moving the vehicle to a different location might resolve the issue. If the problem persists, a mechanic should investigate further.

- Incorrect Calibration: Tire pressure sensors need to be calibrated to the specific vehicle. If the calibration is incorrect, the readings will be inaccurate. Recalibration is necessary to ensure accurate tire pressure readings.

Tire Pressure Checks

Regular tire pressure checks are essential for maintaining optimal tire performance and safety.

- Frequency: Check your tire pressure at least once a month, or more often if you frequently drive on rough terrain or in extreme temperatures.

- Interpretation: Tire pressure sensors provide real-time tire pressure readings, displayed on the vehicle’s dashboard. Compare the readings to the recommended tire pressure for your vehicle, which is usually found in the owner’s manual or on the driver’s side doorjamb.

- Adjusting Pressure: If the tire pressure is too low or too high, adjust it accordingly using a tire pressure gauge. Ensure you use the correct pressure as specified by the manufacturer.

By understanding the fundamentals of tire pressure sensors, you can make informed decisions about their selection and installation. Properly installed and maintained sensors contribute to a safer, more efficient driving experience, keeping your Work Wheels D9R performing at their peak. So, get ready to upgrade your ride with the knowledge and confidence to ensure your tire pressure sensors are always on point.

Questions and Answers

What are the benefits of using tire pressure sensors on Work Wheels D9R?

Tire pressure sensors provide real-time monitoring of your tire pressure, alerting you to any potential issues. This helps ensure optimal tire performance, fuel efficiency, and safety.

Can I install tire pressure sensors myself?

While the process is relatively straightforward, it’s recommended to consult a professional mechanic for installation, especially if you’re not familiar with automotive maintenance.

How often should I check my tire pressure sensors?

It’s best to check your tire pressure sensors at least once a month, or more frequently if you notice any changes in tire pressure or handling.

What happens if my tire pressure sensor malfunctions?

A malfunctioning tire pressure sensor can result in inaccurate readings, leading to potential safety hazards. It’s crucial to have the sensor inspected and repaired as soon as possible.