What should wheel speed sensor read sets the stage for this enthralling narrative, offering readers a glimpse into a story that is rich in detail and brimming with originality from the outset. The wheel speed sensor, a seemingly simple device, plays a crucial role in ensuring the safe and efficient operation of your vehicle. It silently gathers data about your car’s motion, relaying vital information to the braking and stability systems, ensuring your journey is smooth and secure.

This article delves into the world of wheel speed sensors, exploring their functions, workings, and the critical role they play in keeping you on the road.

Imagine a world where your car’s brakes respond unpredictably, where stability becomes a fleeting concept, and where the speedometer tells a tale of its own. This is the reality that unfolds when wheel speed sensors malfunction. They are the unsung heroes of your vehicle’s safety systems, providing the critical information that allows your car to respond appropriately to road conditions and driver input.

Understanding Wheel Speed Sensors

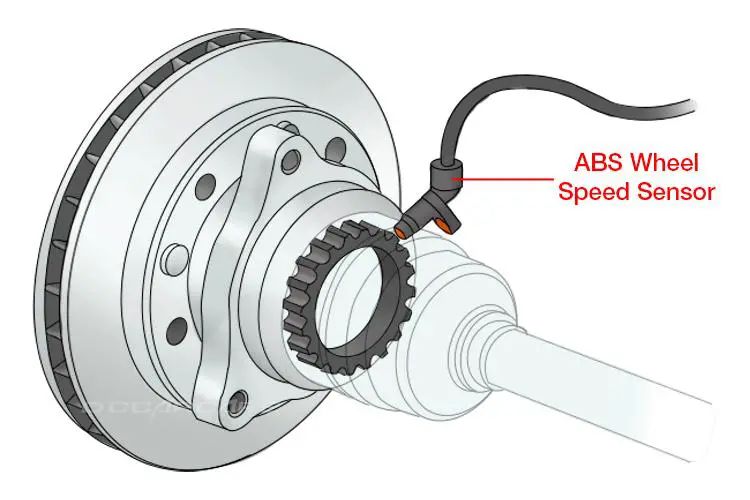

Wheel speed sensors are crucial components in a vehicle’s braking and stability systems, playing a vital role in ensuring safe and controlled driving. They monitor the rotational speed of each wheel, providing essential data to various electronic systems that control vehicle dynamics.

Types of Wheel Speed Sensors

Wheel speed sensors are designed to detect the rotation of the wheel and convert it into an electrical signal. This signal is then transmitted to the vehicle’s electronic control unit (ECU) for processing and subsequent action. Several types of wheel speed sensors are commonly used in automobiles, each employing a distinct mechanism to achieve this conversion.

- Passive Magnetic Sensors: These sensors are the most prevalent type. They consist of a magnet and a coil of wire positioned near a toothed wheel attached to the wheel hub. As the toothed wheel rotates, the magnetic field generated by the magnet changes, inducing a voltage in the coil. The frequency of this voltage signal is directly proportional to the wheel’s speed.

- Hall Effect Sensors: Hall effect sensors utilize a semiconductor device that generates a voltage when a magnetic field passes through it. They consist of a Hall-effect sensor chip positioned near a rotating magnet attached to the wheel hub. As the magnet rotates, the magnetic field changes, causing the Hall effect sensor to produce a voltage signal that is proportional to the wheel speed.

- Optical Sensors: Optical sensors employ a light source and a photodetector to detect wheel rotation. A light beam is directed onto a slotted disc attached to the wheel hub. As the disc rotates, the light beam is interrupted, generating a series of pulses that are detected by the photodetector. The frequency of these pulses is directly proportional to the wheel speed.

Working Principle of a Wheel Speed Sensor

The working principle of a wheel speed sensor relies on the conversion of mechanical rotation into an electrical signal. This conversion is achieved through various methods, as discussed above, but the underlying principle remains consistent.

The sensor detects the rotation of the wheel and generates a signal that is proportional to the wheel speed. This signal is then transmitted to the vehicle’s ECU, where it is processed and utilized by various electronic systems.

For instance, in anti-lock braking systems (ABS), the ECU uses the wheel speed sensor data to monitor the speed of each wheel during braking. If one wheel starts to lock up, the ECU can selectively reduce brake pressure to that wheel, preventing skidding and maintaining control. Similarly, in electronic stability control (ESC) systems, the ECU uses wheel speed sensor data to detect and correct oversteer or understeer by applying individual brakes or adjusting engine power.

Wheel Speed Sensor Output Signals

Wheel speed sensors play a crucial role in modern vehicles by providing real-time information about the rotational speed of each wheel. This data is essential for various safety and performance-related systems, including anti-lock braking systems (ABS), traction control, and electronic stability control (ESC). Understanding the output signals generated by these sensors is essential for comprehending how these systems function.Wheel speed sensors generate output signals that are directly proportional to the speed of the wheel.

These signals can be analog or digital, depending on the sensor type.

Analog Output Signals

Analog wheel speed sensors produce a voltage output that varies continuously with the wheel’s rotational speed. The relationship between wheel speed and voltage output is typically linear.

As the wheel rotates faster, the voltage output increases proportionally.

For instance, a sensor might produce 0 volts at zero wheel speed and 5 volts at a specific speed. This voltage output is then processed by the vehicle’s control unit (ECU) to determine the actual wheel speed.

Digital Output Signals

Digital wheel speed sensors produce a square wave signal, where the frequency of the signal is directly proportional to the wheel’s rotational speed.

As the wheel rotates faster, the frequency of the square wave increases.

The number of pulses per second (Hz) is directly related to the wheel’s speed. For example, a sensor might produce 10 pulses per second (Hz) at a certain speed and 20 pulses per second (Hz) at double that speed.

Types of Wheel Speed Sensors and Output Signals

The type of output signal produced by a wheel speed sensor depends on its design. Here are some common types of wheel speed sensors and their corresponding output signals:

- Variable Reluctance (VR) Sensors: VR sensors generate a variable reluctance signal, which is an analog signal. This signal is produced by the changing magnetic field as the sensor’s magnet rotates past a toothed wheel. The voltage output varies depending on the distance between the magnet and the teeth.

- Hall Effect Sensors: Hall effect sensors generate a digital output signal. These sensors use a Hall effect device that produces a voltage output when exposed to a magnetic field. The magnetic field is generated by a permanent magnet on the sensor, and the output voltage changes as the magnet rotates past a toothed wheel.

- Inductive Sensors: Inductive sensors generate an analog output signal. These sensors use a coil that generates a magnetic field. As a toothed wheel rotates past the coil, the magnetic field changes, inducing a voltage in the coil. The voltage output varies depending on the speed of the wheel.

Interpreting Wheel Speed Sensor Readings: What Should Wheel Speed Sensor Read

The output signal from a wheel speed sensor provides valuable information about the vehicle’s speed. Understanding how to interpret these readings is crucial for accurate speed measurement and overall vehicle performance.

Units of Measurement, What should wheel speed sensor read

Wheel speed is typically measured in units of miles per hour (mph) or kilometers per hour (km/h). These units are commonly used in automotive applications and provide a standardized way to express vehicle speed.

Interpreting the Output Signal

The output signal from a wheel speed sensor is usually a series of pulses. The frequency of these pulses directly corresponds to the speed of the wheel. A higher frequency indicates a faster wheel speed, while a lower frequency indicates a slower wheel speed. The relationship between the pulse frequency and wheel speed is determined by the sensor’s calibration.

Factors Affecting Accuracy

Several factors can influence the accuracy of wheel speed sensor readings:

- Tire Size: The size of the tires affects the distance traveled per wheel revolution. Larger tires will cover more ground with each revolution, resulting in a higher speed reading for the same pulse frequency.

- Road Conditions: Uneven road surfaces, such as potholes or bumps, can cause the wheel to momentarily lose contact with the ground, resulting in inaccurate speed readings.

- Wheel Slip: When the wheels lose traction, such as during acceleration or braking, the wheel speed sensor may not accurately reflect the actual speed of the vehicle.

The accuracy of wheel speed sensor readings is essential for various vehicle functions, including the anti-lock braking system (ABS), traction control, and electronic stability control (ESC).

Common Wheel Speed Sensor Problems

Wheel speed sensors are crucial components in modern vehicles, playing a vital role in safety systems like anti-lock brakes (ABS) and traction control. These sensors monitor the speed of each wheel, providing data to the vehicle’s computer to ensure proper operation of these safety features. However, like any other electronic component, wheel speed sensors can malfunction, leading to various issues that can affect vehicle performance and safety.

Understanding common problems associated with wheel speed sensors is essential for diagnosing and resolving these issues promptly.

Sensor Failure

Sensor failure is a common problem that can occur with wheel speed sensors. Over time, these sensors can become damaged due to wear and tear, exposure to harsh environmental conditions, or physical impact. A faulty sensor may fail to produce a signal, resulting in an inaccurate or missing speed reading.

Symptoms of a Faulty Wheel Speed Sensor

- ABS light illumination: When a wheel speed sensor fails, the ABS system will likely detect a discrepancy in the wheel speed data and illuminate the ABS warning light on the dashboard.

- Traction control issues: Similarly, the traction control system relies on accurate wheel speed data to function effectively. A faulty sensor can cause the traction control system to malfunction, resulting in reduced traction and control, particularly on slippery surfaces.

- Inaccurate speedometer readings: The speedometer also relies on data from the wheel speed sensors to display the vehicle’s speed. A faulty sensor can lead to inaccurate speedometer readings, which can be dangerous for drivers.

Wiring Issues

Wiring issues can also contribute to wheel speed sensor problems. Damaged or corroded wiring can disrupt the signal transmission between the sensor and the vehicle’s computer, resulting in inaccurate or missing speed readings.

Diagnosing and Troubleshooting Wiring Issues

- Visual inspection: Inspect the wiring harness leading to the sensor for any signs of damage, corrosion, or loose connections. Look for broken wires, chafed insulation, or corrosion on the connector pins.

- Continuity test: Use a multimeter to check the continuity of the wiring circuit. Ensure there is a clear path for electrical signals to flow between the sensor and the vehicle’s computer.

- Resistance measurement: Measure the resistance of the wiring circuit to identify any potential resistance issues that could impede signal transmission.

Damage to the Sensor Housing

Physical damage to the sensor housing can also lead to sensor malfunctions. This damage can occur due to road debris, impacts, or even excessive heat exposure.

Diagnosing and Troubleshooting Damage to the Sensor Housing

- Visual inspection: Carefully examine the sensor housing for any signs of damage, such as cracks, dents, or loose components.

- Check for debris: Inspect the sensor housing for any debris that may have lodged inside, potentially obstructing the sensor’s operation.

- Verify proper mounting: Ensure the sensor is securely mounted and that the mounting bracket is not damaged or loose.

Diagnostic Tools and Techniques

Diagnosing wheel speed sensor issues involves utilizing specialized tools and techniques to accurately identify the problem and guide repair efforts. This section delves into the use of diagnostic tools, such as OBD-II scanners, and Artikels the procedures for testing wheel speed sensors using a multimeter or oscilloscope.

Using Diagnostic Scanners

Diagnostic scanners, such as OBD-II scanners, are invaluable tools for retrieving wheel speed sensor data and identifying potential problems. These scanners connect to the vehicle’s onboard diagnostics (OBD) system, allowing technicians to access real-time sensor readings, fault codes, and other diagnostic information.

- Retrieving Wheel Speed Sensor Data: OBD-II scanners can display the speed readings from each wheel sensor, enabling technicians to compare values and identify inconsistencies. This data can indicate a faulty sensor, a wiring issue, or a problem with the ABS module.

- Identifying Fault Codes: OBD-II scanners can retrieve diagnostic trouble codes (DTCs) related to the wheel speed sensors. These codes provide specific information about the nature of the problem, such as a sensor circuit malfunction or a signal loss.

- Analyzing Sensor Data: Scanners can graph the sensor readings over time, revealing patterns that may indicate a malfunctioning sensor. For example, a sensor with intermittent issues might show erratic or fluctuating readings.

Testing Wheel Speed Sensors with a Multimeter

A multimeter is a versatile tool for testing wheel speed sensors, allowing technicians to check for continuity, resistance, and voltage. The following steps Artikel the process of testing a wheel speed sensor using a multimeter:

- Disconnect the Sensor: Disconnect the electrical connector from the wheel speed sensor.

- Check for Continuity: Set the multimeter to the resistance mode (ohms). Place the probes on the sensor’s terminals, typically two wires. A reading within a specified range indicates continuity, while an infinite reading suggests an open circuit.

- Measure Resistance: Some wheel speed sensors have a specific resistance value. Consult the manufacturer’s specifications or a repair manual to determine the expected resistance range. Compare the measured resistance with the specified value to identify any deviations.

- Test for Voltage: With the ignition key turned on, set the multimeter to the voltage mode. Connect the probes to the sensor’s terminals. A voltage reading within a specific range indicates a functional sensor, while a lack of voltage suggests a wiring issue or a problem with the ABS module.

Testing Wheel Speed Sensors with an Oscilloscope

An oscilloscope provides a visual representation of the electrical signal generated by a wheel speed sensor. This allows technicians to analyze the signal waveform and identify any abnormalities that may indicate a sensor malfunction.

- Connect the Oscilloscope: Connect the oscilloscope probes to the sensor’s terminals.

- Observe the Waveform: Observe the waveform displayed on the oscilloscope screen. A healthy sensor should produce a clean, square-wave signal with consistent frequency and amplitude.

- Identify Irregularities: Look for irregularities in the waveform, such as missing pulses, distorted waveforms, or variations in frequency or amplitude. These abnormalities can indicate a faulty sensor or a wiring problem.

Practical Tips and Tricks

- Inspect the Sensor and Wiring: Before performing any electrical tests, visually inspect the wheel speed sensor and its wiring for signs of damage, corrosion, or loose connections.

- Check for Obstructions: Ensure that the sensor is not obstructed by debris or other objects that could interfere with its operation.

- Verify Ground Connections: A good ground connection is crucial for the proper functioning of the wheel speed sensor. Verify the ground wire’s connection to the sensor and the vehicle’s chassis.

- Use a Reference Sensor: If possible, compare the readings from the suspect sensor with a known good sensor to confirm the diagnosis.

- Perform a Road Test: After repairing or replacing a wheel speed sensor, conduct a road test to ensure the ABS system is functioning properly.

Importance of Accurate Wheel Speed Data

Accurate wheel speed data is crucial for the safe and efficient operation of modern vehicles, especially those equipped with advanced safety systems like ABS and traction control. These systems rely on precise wheel speed information to effectively perform their functions, contributing significantly to the stability and control of the vehicle, particularly during braking and cornering.

Impact on Advanced Safety Systems

Accurate wheel speed data is fundamental for the proper functioning of advanced safety systems such as Anti-lock Braking Systems (ABS) and Traction Control Systems (TCS).

- ABS: ABS systems prevent wheel lock-up during braking by modulating brake pressure to each individual wheel. This is achieved by constantly monitoring wheel speed data and adjusting brake pressure accordingly. If the wheel speed data is inaccurate, the ABS system might misinterpret the situation, leading to ineffective braking or even wheel lock-up, compromising vehicle control and increasing the risk of accidents.

- TCS: Traction control systems aim to prevent wheel slip during acceleration by reducing engine power or applying brakes to individual wheels. Accurate wheel speed data is crucial for TCS to determine which wheels are slipping and to implement corrective measures. Inaccurate wheel speed data could result in ineffective traction control, leading to wheel spin and loss of control, particularly on slippery surfaces.

Understanding the workings of wheel speed sensors is essential for any car owner who values safety and performance. By recognizing the symptoms of a faulty sensor and employing the appropriate diagnostic tools, you can ensure that your vehicle’s safety systems are operating at peak efficiency. The next time you’re behind the wheel, take a moment to appreciate the silent guardian working tirelessly to ensure your journey is safe and secure.

It’s a reminder that even the smallest components can have a profound impact on your driving experience.

Questions and Answers

How often should I check my wheel speed sensors?

It’s recommended to have your wheel speed sensors checked as part of your regular vehicle maintenance schedule. If you experience any warning lights related to ABS, traction control, or the speedometer, it’s crucial to have your sensors inspected immediately.

Can I replace a wheel speed sensor myself?

While replacing a wheel speed sensor can seem straightforward, it’s best left to a qualified mechanic. Improper installation can lead to further complications and compromise the safety of your vehicle.

What is the typical lifespan of a wheel speed sensor?

Wheel speed sensors are generally designed to last the lifetime of the vehicle. However, factors such as environmental conditions, road hazards, and wear and tear can shorten their lifespan.