What is a fly wheel / flex plate – What is a flywheel/flex plate? These unassuming components, tucked away within the heart of your vehicle’s engine, play a crucial role in ensuring smooth, reliable power delivery. Imagine a symphony orchestra – the flywheel acts like the conductor, keeping the rhythm steady and the instruments in harmony. It absorbs and releases energy, ensuring a consistent flow of power to the wheels.

The flex plate, meanwhile, is the bridge between the engine and the transmission, accommodating slight movements and vibrations to prevent jarring and damage. These unsung heroes work tirelessly, often unseen, to make driving a smooth and enjoyable experience.

From the materials used in their construction to the intricacies of their design, we’ll delve into the world of flywheels and flex plates, exploring their function, maintenance, and even some advanced applications.

Introduction to Flywheels and Flex Plates

Flywheels and flex plates are essential components in internal combustion engines, playing crucial roles in smooth power delivery and engine operation. They are both designed to absorb and store energy, but they differ in their construction, function, and applications.

Materials Used in Flywheel and Flex Plate Construction

The choice of materials for flywheels and flex plates is crucial, influencing their durability, weight, and performance. Common materials include:

- Steel: Steel is a robust and widely used material for both flywheels and flex plates due to its high strength and affordability. It is a good choice for engines that experience high torque and stress, but its heavier weight can impact fuel efficiency.

- Cast Iron: Cast iron is another popular choice for flywheels, particularly in older engines. It offers good wear resistance and cost-effectiveness, but its heavier weight can affect engine performance.

- Aluminum: Aluminum is becoming increasingly popular for flywheels and flex plates, especially in performance applications. It offers significant weight savings compared to steel or cast iron, improving fuel efficiency and engine response. However, aluminum is less strong than steel and requires careful design to ensure durability.

- Composite Materials: Composite materials are used in some high-performance applications for their lightweight and high strength properties. However, they are more expensive than traditional materials and require specialized manufacturing processes.

Key Differences Between Flywheels and Flex Plates

Flywheels and flex plates serve distinct purposes in an engine’s operation.

- Design and Function:

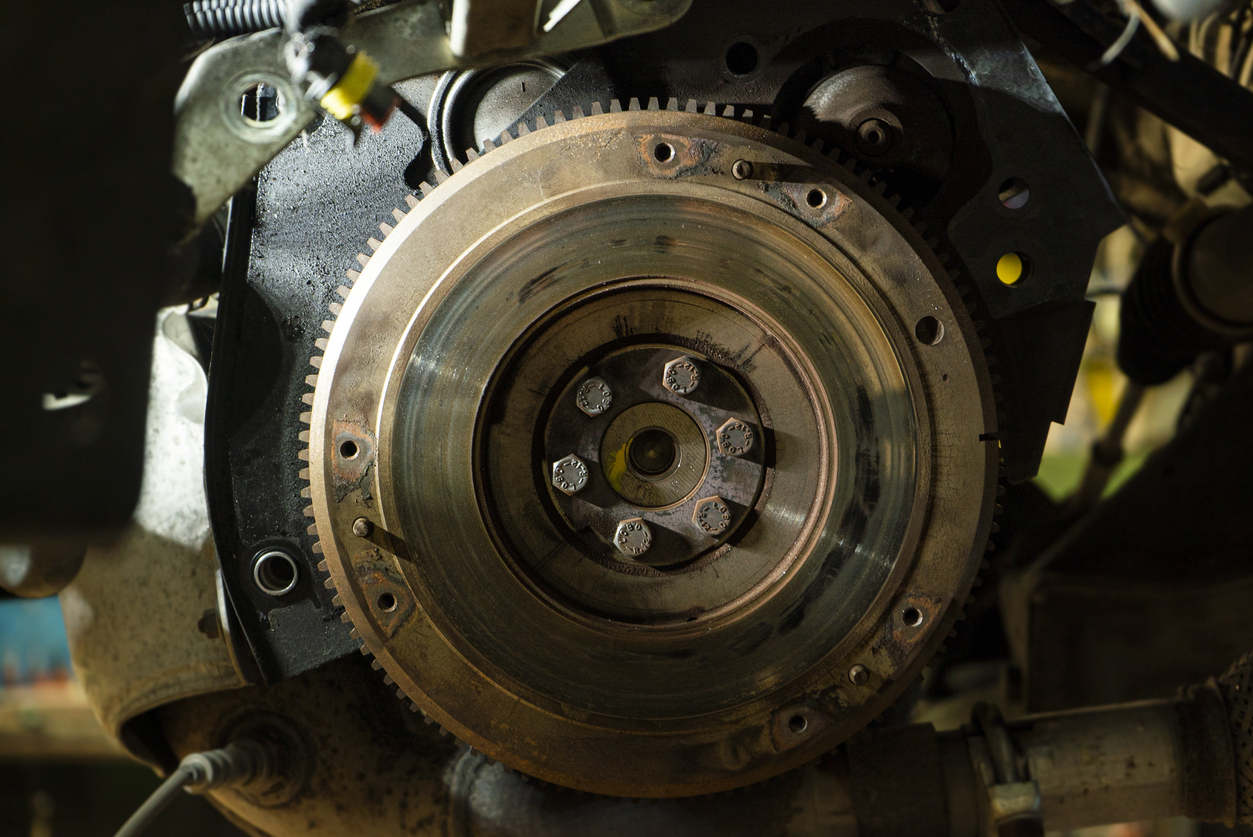

- Flywheel: A flywheel is a heavy, disc-shaped component that is attached to the crankshaft. It stores kinetic energy during the power stroke and releases it during the other strokes, smoothing out engine operation and reducing vibrations. Flywheels are typically found in manual transmission vehicles.

- Flex Plate: A flex plate is a thinner, lighter component with a series of holes that are bolted to the crankshaft and the torque converter. Its primary function is to connect the crankshaft to the transmission, allowing for the flexibility required during torque converter operation. Flex plates are used in automatic transmission vehicles.

- Applications:

- Flywheel: Flywheels are used in manual transmission vehicles, where the engine is directly connected to the transmission.

- Flex Plate: Flex plates are used in automatic transmission vehicles, where the torque converter acts as a fluid coupling between the engine and the transmission.

Factors Affecting Flywheel and Flex Plate Design

Several factors influence the design of flywheels and flex plates:

- Engine Size and Power: Larger and more powerful engines typically require heavier flywheels to absorb and store more energy.

- Transmission Type: Manual transmissions use flywheels, while automatic transmissions use flex plates.

- Vehicle Application: Performance vehicles may have lighter flywheels for quicker acceleration, while heavy-duty vehicles may have heavier flywheels for smoother operation.

Flywheel Function and Operation: What Is A Fly Wheel / Flex Plate

The flywheel is a critical component in an internal combustion engine, playing a crucial role in ensuring smooth and consistent power delivery. It acts as a reservoir of rotational energy, absorbing and releasing it as needed to maintain a steady engine speed.

Flywheel Inertia and Engine Performance

The flywheel’s inertia is its resistance to changes in rotational motion. This inertia is directly proportional to its mass and the distribution of that mass around its axis of rotation. A heavier flywheel possesses greater inertia, meaning it takes more energy to accelerate it and more energy to bring it to a stop. The flywheel’s inertia plays a vital role in maintaining consistent engine power delivery by:

- Smoothing out engine fluctuations: As the pistons move within the engine cylinders, the rotational speed of the crankshaft varies slightly. The flywheel’s inertia absorbs these fluctuations, preventing them from being transmitted to the drivetrain, resulting in a smoother engine operation.

- Maintaining engine speed during acceleration: When the engine is accelerating, the flywheel stores rotational energy, preventing the engine speed from dropping too rapidly. This stored energy is then released to help maintain the engine’s speed, ensuring a smoother and more consistent acceleration.

- Allowing for smooth gear changes: During gear changes, the flywheel helps to maintain the engine speed, preventing stalling and ensuring a smoother transition.

Flywheel Weight and Engine Performance

The weight of the flywheel has a significant impact on engine performance. A heavier flywheel:

- Improves acceleration: A heavier flywheel stores more rotational energy, making it easier to accelerate the vehicle, particularly from a standstill.

- Enhances fuel efficiency: A heavier flywheel can improve fuel efficiency by reducing the number of times the engine needs to accelerate and decelerate, minimizing fuel consumption.

- Reduces engine vibrations: A heavier flywheel helps to dampen engine vibrations, resulting in a smoother and quieter ride.

However, a heavier flywheel also:

- Slows down acceleration: While it helps with acceleration from a standstill, a heavier flywheel can make it harder to accelerate quickly at higher speeds.

- Reduces responsiveness: A heavier flywheel can make the engine feel less responsive, particularly at lower engine speeds.

Therefore, the optimal flywheel weight is a compromise between acceleration, fuel efficiency, and engine responsiveness. In general, high-performance engines often use lighter flywheels to enhance acceleration and responsiveness, while engines designed for fuel efficiency may utilize heavier flywheels to improve smoothness and reduce fuel consumption.

Flex Plate Function and Operation

The flex plate, a critical component in rear-wheel drive vehicles, serves as the interface between the engine crankshaft and the transmission torque converter. Unlike the flywheel used in manual transmissions, the flex plate is designed with flexibility to accommodate the slight misalignment and vibrations that occur between the engine and transmission. This flexibility plays a crucial role in ensuring smooth power transfer and minimizing transmission wear.

Flex Plate’s Role in Accommodation

The flex plate’s primary function is to absorb the slight misalignment and vibrations that naturally occur between the engine and transmission. This misalignment can arise from variations in engine mounting, engine torque fluctuations, and the inherent flexibility of the transmission mount. The flex plate’s flexibility allows it to bend slightly, accommodating these variations and preventing excessive stress on the transmission input shaft.

Importance of Flex Plate Integrity

A flex plate’s integrity is essential for smooth power transfer and minimizing transmission wear. A damaged or cracked flex plate can cause vibrations, noise, and even transmission damage. The flex plate’s flexibility allows for slight misalignment and vibrations between the engine and transmission. This flexibility is achieved through the use of a ring gear with a specific number of teeth, typically 164 or 168.

The ring gear is bolted to the flex plate and engages with the torque converter’s stator. As the engine rotates, the flex plate transmits power to the torque converter, which in turn transfers it to the transmission.

The flex plate’s flexibility allows for slight misalignment and vibrations between the engine and transmission.

Flex Plate Wear and Replacement

Over time, the flex plate can wear out due to repeated flexing and vibrations. This wear can lead to cracks or warping, which can compromise the flex plate’s ability to absorb misalignment and vibrations. A worn flex plate can cause noise, vibration, and even transmission damage.

A worn flex plate can cause noise, vibration, and even transmission damage.

Signs of Flex Plate Issues

There are several signs that may indicate a problem with the flex plate. These include:

- A rattling or clunking noise coming from the transmission area, especially during acceleration or deceleration.

- Vibrations in the vehicle, particularly at idle or when the engine is under load.

- A slipping transmission, which can be caused by a damaged flex plate that is not transferring power efficiently.

- A leaking transmission, which can be caused by a cracked flex plate that is allowing transmission fluid to leak out.

If you experience any of these symptoms, it is important to have your vehicle inspected by a qualified mechanic to determine the cause of the problem.

Flywheel and Flex Plate Design Considerations

The design of flywheels and flex plates is crucial for engine performance, durability, and noise levels. These components are subject to significant forces and stresses, and their design must carefully consider factors such as engine type, power output, and intended application.

Key Design Features

Several key design features influence the performance and durability of flywheels and flex plates. These include:

- Number of Bolts: The number of bolts securing the flywheel or flex plate to the crankshaft determines the load distribution and overall strength of the connection. More bolts generally provide greater strength and distribute the load more evenly.

- Diameter: The diameter of the flywheel or flex plate influences its moment of inertia. A larger diameter increases the moment of inertia, which helps to smooth out engine operation and reduce vibration. However, a larger diameter can also increase weight and rotational inertia, potentially affecting acceleration and fuel efficiency.

- Weight: The weight of the flywheel or flex plate plays a significant role in engine performance and durability. A heavier flywheel provides greater inertia, smoothing out engine operation and reducing vibration. However, a heavier flywheel can also increase rotational inertia, impacting acceleration and fuel efficiency.

- Material: The material used to manufacture flywheels and flex plates significantly affects their durability, weight, and cost. Cast iron is a common material for flywheels due to its strength and low cost. However, lighter materials like aluminum are used in some applications to reduce weight and improve acceleration.

Design Considerations for Different Applications

Flywheel and flex plate designs vary depending on the engine type, power output, and intended application.

- High-Performance Engines: High-performance engines often use lighter flywheels to improve acceleration and responsiveness. These flywheels are typically made from aluminum or other lightweight materials. They may also feature a smaller diameter to reduce rotational inertia.

- Diesel Engines: Diesel engines typically have heavier flywheels due to their higher torque and slower rotational speeds. These flywheels help to smooth out the engine’s power delivery and reduce vibration.

- Manual Transmissions: Manual transmissions typically use flywheels with a higher moment of inertia to provide smoother gear changes. The higher inertia helps to absorb the shock of the clutch engagement and disengagement, reducing wear and tear on the transmission.

- Automatic Transmissions: Automatic transmissions typically use flex plates with a lower moment of inertia to allow for faster gear changes. The lower inertia allows the transmission to shift gears more quickly and efficiently.

Impact of Design Choices on Engine Performance

The design choices made for flywheels and flex plates have a significant impact on engine performance, durability, and noise levels.

- Engine Smoothness: Heavier flywheels provide greater inertia, smoothing out engine operation and reducing vibration. This is particularly important for engines with high torque output or those operating at lower speeds.

- Acceleration: Lighter flywheels reduce rotational inertia, improving acceleration and responsiveness. This is beneficial for high-performance engines and vehicles where quick acceleration is desired.

- Fuel Efficiency: A lighter flywheel can improve fuel efficiency by reducing the energy required to accelerate the rotating mass. However, this effect is generally small and can be offset by other factors, such as engine load and driving style.

- Durability: Flywheel and flex plate design also affects durability. A heavier flywheel can withstand higher torque loads and reduce wear on the crankshaft and other components. However, a heavier flywheel can also increase stress on the crankshaft and other components.

- Noise Levels: The design of flywheels and flex plates can also affect engine noise levels. A heavier flywheel can help to dampen vibrations and reduce noise, while a lighter flywheel may result in higher noise levels.

Maintenance and Replacement

Flywheels and flex plates, though durable components, require regular inspection and maintenance to ensure optimal engine performance and longevity. Neglecting these components can lead to premature wear, damage, and potential engine failure.

Inspection Procedures

Inspecting flywheels and flex plates for signs of wear, damage, or cracks is crucial for maintaining engine health. Regular visual inspection and proper handling are essential.

- Visually inspect the flywheel or flex plate for any cracks, chips, or other damage. Pay close attention to the ring gear, which is responsible for engaging the starter motor.

- Check for excessive wear on the friction surface of the flywheel or flex plate. This wear can cause slippage and reduce the efficiency of the transmission.

- Inspect the bolts that secure the flywheel or flex plate to the crankshaft for any signs of loosening or damage. These bolts are crucial for maintaining the integrity of the connection.

- If the flywheel or flex plate is removed for inspection, ensure that the balance is not compromised. Any imbalance can lead to excessive vibration and damage to the engine.

Maintenance Schedule

While flywheels and flex plates are typically designed for long service life, regular maintenance can extend their lifespan and prevent premature failure.

- Cleaning: Periodically clean the flywheel and flex plate to remove any dirt, debris, or oil buildup. This helps maintain optimal performance and prevents corrosion.

- Lubrication: If applicable, apply a thin layer of lubricant to the friction surface of the flywheel or flex plate to reduce wear and friction. Consult the vehicle’s owner’s manual for specific recommendations.

Replacement Procedures, What is a fly wheel / flex plate

Replacing a damaged flywheel or flex plate requires specialized tools and technical expertise. It’s crucial to follow proper safety procedures and consult a qualified mechanic for assistance.

- Safety Precautions: Ensure the vehicle is securely supported on jack stands and the engine is cool before attempting any work. Disconnect the battery to prevent electrical hazards. Wear appropriate safety gear, including gloves and eye protection.

- Tools and Equipment: You’ll need a variety of tools, including a torque wrench, breaker bar, and specialized socket for the flywheel or flex plate bolts. A transmission jack may be required to support the transmission during the removal and installation process.

- Removal Process: Remove the transmission, then carefully remove the flywheel or flex plate. Ensure that all bolts are removed and the component is free from the crankshaft.

- Installation Process: Install the new flywheel or flex plate, ensuring it is properly aligned with the crankshaft. Tighten the bolts to the specified torque using a torque wrench. Reinstall the transmission and reconnect the battery.

Common Issues and Troubleshooting

Flywheels and flex plates are essential components in the powertrain of internal combustion engines, playing a crucial role in smooth engine operation. However, these components are subject to wear and tear over time, leading to various issues that can affect engine performance and longevity. This section delves into common problems associated with flywheels and flex plates, along with their symptoms and troubleshooting steps.

Common Issues and Symptoms

Understanding the common issues that arise with flywheels and flex plates is essential for timely diagnosis and repair. These problems can manifest in various ways, affecting the engine’s performance and potentially causing further damage if left unchecked.

- Cracks: Cracks in the flywheel or flex plate can develop due to fatigue, excessive stress, or impact. These cracks can propagate over time, leading to catastrophic failure.

- Warping: Heat cycling and uneven loading can cause warping in the flywheel or flex plate. Warping disrupts the smooth transfer of power and can lead to vibrations and noise.

- Bolt Failure: The bolts that secure the flywheel or flex plate to the crankshaft can loosen or fail due to fatigue, improper torque, or corrosion.

This can cause the flywheel or flex plate to detach, resulting in severe engine damage.

These issues often present themselves through various symptoms that can alert drivers to potential problems. These symptoms include:

- Engine Vibration: A noticeable vibration in the engine, especially at idle or under acceleration, can indicate a problem with the flywheel or flex plate.

- Noise: Unusual noises coming from the engine, such as clunking, rattling, or grinding, can be a sign of a damaged flywheel or flex plate.

- Power Loss: A decrease in engine power or difficulty accelerating can be a symptom of a faulty flywheel or flex plate, especially if accompanied by other symptoms.

Troubleshooting Steps

Diagnosing and addressing issues with flywheels and flex plates require a systematic approach. Here are some troubleshooting steps that can help pinpoint the problem:

Visual Inspection: A visual inspection of the flywheel or flex plate is a crucial first step. Look for cracks, warping, and signs of wear or damage. Use a flashlight and a mirror to inspect hard-to-reach areas.

Torque Check: Verify that the bolts securing the flywheel or flex plate to the crankshaft are properly torqued. Use a torque wrench to ensure that the bolts are tightened to the manufacturer’s specifications.

Engine Vibration Analysis: If the engine exhibits excessive vibration, use a vibration analyzer to identify the frequency and amplitude of the vibrations. This can help determine the source of the problem.

Engine Noise Analysis: Listen carefully to the engine for any unusual noises. A mechanic’s stethoscope can help pinpoint the location of the noise.

Compression Test: Perform a compression test to assess the engine’s health. A low compression reading can indicate a problem with the flywheel or flex plate.

Dynamic Balancing: If the flywheel or flex plate is suspected of being warped or unbalanced, it can be dynamically balanced to restore proper operation.

Advanced Applications and Modifications

Flywheels and flex plates are essential components in internal combustion engines, but their applications extend beyond traditional automotive uses. Advancements in materials science, manufacturing techniques, and energy storage technologies have opened doors to innovative applications and modifications for these components.

Flywheels in Hybrid Vehicles and Energy Storage

Flywheels have emerged as a promising technology for energy storage in hybrid vehicles and other applications. Their ability to efficiently store and release kinetic energy makes them suitable for regenerative braking systems, where energy generated during deceleration is captured and stored for later use.

- Regenerative Braking: In hybrid vehicles, flywheels act as a buffer to store energy recovered during braking. This stored energy can then be used to assist the engine during acceleration, improving fuel efficiency and reducing emissions.

- Grid-Scale Energy Storage: Large-scale flywheels are being used in power grids to provide short-term energy storage. They can quickly respond to fluctuations in demand, improving grid stability and reliability.

- Uninterruptible Power Supplies (UPS): Flywheels can provide backup power in case of power outages. They are particularly valuable for critical applications like data centers and hospitals, where uninterrupted power is essential.

Modifications for Enhanced Performance and Durability

Flywheels and flex plates can be modified to improve engine performance, durability, and efficiency. These modifications can involve material selection, design changes, and advanced manufacturing techniques.

- Lightweight Materials: Replacing traditional steel flywheels with lighter materials like aluminum or composites can reduce rotational inertia, leading to faster engine response and improved acceleration.

- Dual-Mass Flywheels: These flywheels incorporate two masses separated by a spring-damped system. This design reduces vibrations and noise, improving ride comfort and engine smoothness.

- Surface Treatments: Applying surface treatments like shot peening or nitriding can enhance the fatigue strength and wear resistance of flywheels and flex plates.

Aftermarket Upgrades and Custom Designs

The aftermarket offers a range of upgrades and custom designs for flywheels and flex plates, catering to specific engine types and performance goals.

- High-Performance Flywheels: These flywheels are typically made from lightweight materials and optimized for high-revving engines. They can significantly improve acceleration and engine responsiveness.

- Flex Plate Upgrades: Some aftermarket flex plates are designed to enhance engine durability and reduce vibrations. They may feature reinforced materials or improved balancing.

- Custom Designs: For unique engine applications or performance goals, custom-designed flywheels and flex plates can be fabricated to meet specific requirements.

Understanding the critical role of flywheels and flex plates in your vehicle’s engine is essential for informed maintenance and troubleshooting. Knowing how these components work can help you identify potential issues early, preventing costly repairs and ensuring a smooth ride. Whether you’re a seasoned mechanic or a curious car enthusiast, appreciating the mechanics of these often overlooked components will deepen your understanding of the intricate workings of your vehicle.

FAQs

What are the signs of a failing flywheel or flex plate?

Symptoms can include excessive engine vibration, unusual noises during acceleration or deceleration, and even a loss of power. If you notice any of these, it’s crucial to have your vehicle inspected by a qualified mechanic.

Can I replace a flywheel myself?

While it’s possible, replacing a flywheel or flex plate is a complex task that requires specialized tools and expertise. It’s best left to a professional mechanic to ensure proper installation and prevent damage to other engine components.

How often should I have my flywheel or flex plate inspected?

Regular inspections are recommended as part of your vehicle’s routine maintenance. The frequency will depend on factors such as driving conditions, vehicle age, and mileage. Consult your owner’s manual for specific recommendations.