How to repair cast iron pipes is a question many homeowners face, especially in older homes. These pipes, while durable, are prone to corrosion and leaks over time. Understanding the causes of damage, assessing the severity, and choosing the right repair method are crucial steps in addressing this issue.

This guide will equip you with the knowledge and practical steps to tackle cast iron pipe problems, from simple repairs to complete replacement.

We’ll explore the common issues that lead to cast iron pipe failure, including corrosion, cracks, and leaks. You’ll learn how to visually inspect your pipes for damage, identify the severity of the problem, and choose the best repair method based on your specific situation.

We’ll also cover preventive measures to extend the lifespan of your cast iron pipes and avoid future problems.

Understanding Cast Iron Pipes

Cast iron pipes have been a staple in plumbing systems for centuries due to their durability and resistance to corrosion. However, with time, these pipes can succumb to wear and tear, leading to various issues. Understanding the characteristics, common problems, and risks associated with cast iron pipes is crucial for homeowners and property managers.

Characteristics of Cast Iron Pipes

Cast iron pipes are known for their robust nature, offering longevity and resistance to high pressures. Their heavy-duty construction makes them suitable for underground installations and transporting water under significant pressure. However, their inherent characteristics also contribute to their vulnerabilities.

Common Issues Leading to Cast Iron Pipe Failure

- Corrosion:Cast iron pipes are susceptible to rusting, especially in areas with high moisture content. This corrosion weakens the pipe walls, making them prone to leaks and eventual failure.

- Scale Buildup:Mineral deposits from hard water can accumulate inside the pipes, reducing water flow and increasing pressure. This buildup can lead to pipe blockages and even burst pipes.

- Cracks and Breaks:Over time, the constant pressure and vibrations can cause cracks and breaks in the pipe, leading to leaks and water damage.

- Joint Failure:The joints in cast iron pipes are often made with lead or other materials that can deteriorate over time, leading to leaks and water damage.

Potential Risks Associated with Damaged Cast Iron Pipes

- Water Damage:Leaking cast iron pipes can cause significant water damage to property, leading to mold growth, structural damage, and costly repairs.

- Health Hazards:Rust and lead from damaged cast iron pipes can contaminate the water supply, posing health risks, particularly to children and pregnant women.

- Structural Damage:Severe leaks from cast iron pipes can weaken the foundation of a building, leading to structural instability and safety concerns.

Assessing the Damage

Before attempting any repairs, it’s crucial to thoroughly assess the extent of the damage to your cast iron pipe. This involves a visual inspection and careful consideration of the type and severity of the damage.

Visual Inspection

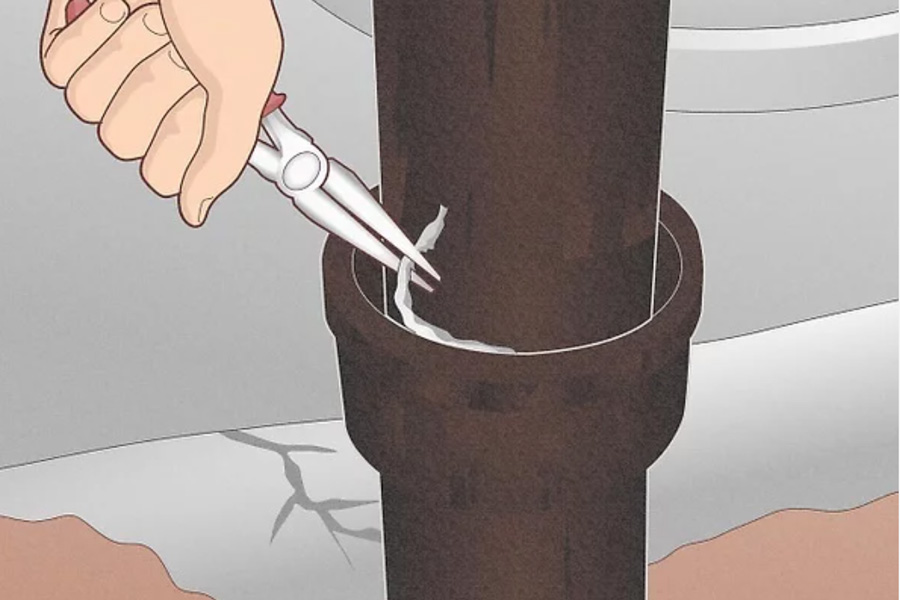

A visual inspection is the first step in assessing the damage to a cast iron pipe. It involves looking for signs of corrosion, cracks, leaks, and other damage.

- Corrosion:Look for rust or pitting on the surface of the pipe. This is a common sign of corrosion and can weaken the pipe over time.

- Cracks:Check for any cracks or fissures in the pipe. These can be caused by stress, impact, or corrosion. Even small cracks can lead to leaks and eventually pipe failure.

- Leaks:Look for signs of water leaking from the pipe. This can be a clear indication of a damaged pipe, especially if the leak is consistent or increasing in size.

- Other Damage:Inspect the pipe for any other damage, such as dents, holes, or broken sections. This type of damage can also weaken the pipe and lead to leaks or failure.

Types of Damage, How to repair cast iron pipe

Cast iron pipes can suffer from various types of damage. Knowing the different types of damage helps you understand the severity of the problem and determine the appropriate repair strategy.

- Corrosion:This is the most common type of damage to cast iron pipes. Corrosion occurs when the iron in the pipe reacts with oxygen and water, forming rust. This rust can weaken the pipe and eventually cause it to leak or break.

- Cracks:These can be caused by a variety of factors, including stress, impact, and corrosion. Cracks can be small and hairline or large and gaping. Cracks can weaken the pipe and allow water to leak out.

- Leaks:Leaks can occur at any point along a cast iron pipe, but they are most common at joints and fittings. Leaks can be caused by corrosion, cracks, or other damage.

- Broken Sections:In severe cases, a cast iron pipe can break completely. This is often caused by severe corrosion, impact damage, or earthquakes. A broken section of pipe will require immediate repair or replacement.

Severity of Damage

The severity of damage to a cast iron pipe can range from minor to severe. The severity of the damage will determine the type of repair that is needed.

- Minor Damage:Minor damage includes small cracks, surface corrosion, and small leaks. These types of damage can often be repaired with simple methods, such as using epoxy or sealant.

- Moderate Damage:Moderate damage includes larger cracks, deeper corrosion, and larger leaks. These types of damage may require more complex repairs, such as using a pipe clamp or sleeve.

- Severe Damage:Severe damage includes broken sections of pipe, extensive corrosion, and major leaks. These types of damage may require the replacement of the entire pipe section.

Repairing Cast Iron Pipes: How To Repair Cast Iron Pipe

Repairing cast iron pipes is a common task for homeowners and plumbers, as these pipes are prone to corrosion and leaks. Several repair methods are available, each with its pros and cons, and the best choice depends on the severity of the damage, the location of the pipe, and the budget.

Methods for Repairing Cast Iron Pipes

Choosing the right repair method is crucial for ensuring a long-lasting and safe solution. Here’s a comparison of different methods:

| Repair Method | Pros | Cons | Cost | Durability | Complexity | Tools and Materials |

|---|---|---|---|---|---|---|

| Epoxy Patch | Easy to apply, relatively inexpensive, quick fix. | Not as durable as other methods, may not be suitable for large holes or cracks, can be prone to leaks if not applied correctly. | Low | Medium | Low | Epoxy resin, mixing container, trowel, sandpaper, cleaning solution. |

| Clamp Repair | Quick and easy, can be used for small leaks, relatively inexpensive. | Not as durable as other methods, may not be suitable for large holes or cracks, can be prone to leaks if not installed correctly. | Medium | Medium | Medium | Pipe clamp, gasket, bolts, wrench, cleaning solution. |

| Pipe Sleeve | Durable, can be used for larger holes or cracks, can be installed without cutting the pipe. | More expensive than other methods, requires specialized tools, may be difficult to install in tight spaces. | High | High | High | Pipe sleeve, sealant, cutting tool, welding machine (for some sleeves). |

| Pipe Replacement | Most durable solution, eliminates the risk of future leaks, can be used for extensive damage. | Most expensive option, requires significant labor and time, may involve disrupting other plumbing systems. | Very High | Very High | Very High | New pipe, cutting tools, welding machine, plumbing fixtures, pipe sealant, drain cleaner, gloves, safety glasses. |

Choosing the Right Repair Method

The best repair method depends on the severity of the damage, the location of the pipe, and the homeowner’s budget.

For small leaks or minor damage, an epoxy patch or clamp repair may be sufficient. However, for larger holes or cracks, a pipe sleeve or pipe replacement is recommended.

It’s important to note that while some repair methods may seem easier or more cost-effective, they may not provide a long-term solution. A professional plumber can assess the damage and recommend the most appropriate repair method for your specific situation.

Replacing Cast Iron Pipes

Replacing a damaged section of cast iron pipe is a significant undertaking, but it’s often necessary to ensure the long-term integrity of your plumbing system. This process involves removing the damaged section, installing a new pipe, and connecting it to the existing plumbing.

Choosing the Right Replacement Pipe Material

The choice of replacement pipe material is crucial for the longevity and performance of your plumbing system.

- Copper:Copper pipes are known for their durability, resistance to corrosion, and ability to withstand high water pressure. They are a good choice for hot and cold water lines, but they can be more expensive than other options.

- PEX:Cross-linked polyethylene (PEX) pipes are flexible, corrosion-resistant, and relatively easy to install. They are a popular choice for both hot and cold water lines, but they may not be as durable as copper.

- PVC:Polyvinyl chloride (PVC) pipes are a cost-effective option for cold water lines, but they are not suitable for hot water due to their susceptibility to heat damage. They are also less durable than copper or PEX.

- CPVC:Chlorinated polyvinyl chloride (CPVC) pipes are a more durable option for hot water lines than PVC, but they are still not as durable as copper or PEX.

Safety Precautions During Pipe Replacement

Safety should be a top priority during any plumbing work.

- Turn off the water supply:Before beginning any work on your plumbing system, ensure the water supply to the affected area is turned off at the main valve. This will prevent water damage and potential injury.

- Wear appropriate safety gear:Wear protective eyewear, gloves, and sturdy footwear to protect yourself from potential hazards during the pipe replacement process.

- Work in a well-ventilated area:If you are working with any chemicals or materials that release fumes, ensure adequate ventilation to prevent potential health issues.

- Be aware of potential hazards:Be mindful of potential hazards, such as sharp edges on pipes, exposed wiring, and slippery surfaces. Exercise caution and take necessary precautions to prevent injuries.

Preventing Future Damage

Cast iron pipes, despite their durability, are susceptible to wear and tear over time. Taking proactive measures to prevent damage can significantly extend their lifespan and minimize the risk of costly repairs or replacements.

Regular Inspections and Cleaning

Regular inspections are crucial for early detection of any potential problems with cast iron pipes. This helps identify issues before they escalate and become major repairs.

- Visual Inspection:A visual inspection of the pipes should be conducted at least once a year. Look for signs of corrosion, leaks, cracks, or any other visible damage.

- Internal Inspection:For a more thorough assessment, a professional plumber can perform an internal inspection using a camera to detect internal corrosion, blockages, or other issues.

- Cleaning:Regular cleaning of cast iron pipes helps prevent buildup of sediment and debris that can lead to blockages and corrosion.

Avoiding Common Pipe Damage Issues

Several factors contribute to the deterioration of cast iron pipes. Understanding these factors can help homeowners take preventive measures to avoid common damage issues.

- Corrosion:Cast iron is susceptible to corrosion, especially in areas with acidic water.

- Electrolysis:This occurs when dissimilar metals are in contact with each other in the presence of water.

- Tree Roots:Tree roots can grow into cast iron pipes, causing cracks and leaks.

- Improper Installation:Poorly installed pipes are more prone to leaks and damage.

Final Wrap-Up

Repairing or replacing cast iron pipes is a significant undertaking, but with the right information and approach, it can be done successfully. By understanding the intricacies of cast iron pipes, assessing the damage, and choosing the appropriate repair method, you can ensure a safe and reliable plumbing system for your home.

Remember, prevention is key. Regular inspections and maintenance can help prevent costly repairs down the line.

Common Queries

How long does it typically take to repair a cast iron pipe?

The time required for a cast iron pipe repair varies depending on the severity of the damage and the chosen repair method. Simple repairs, such as patching a small leak, can be completed in a few hours. However, replacing a large section of pipe can take several days.

What are the signs of a leaking cast iron pipe?

Common signs of a leaking cast iron pipe include dripping water, damp spots on walls or ceilings, a musty smell, and a decrease in water pressure. If you notice any of these signs, it’s important to address the problem as soon as possible to prevent further damage.

Is it safe to use chemicals to repair cast iron pipes?

While some chemicals are marketed as pipe repair solutions, it’s generally not recommended to use them on cast iron pipes. These chemicals can be corrosive and damage the pipe further, leading to more significant problems down the line.