What size socket for wheel nuts? This seemingly simple question holds the key to a safe and successful tire change. The right socket size ensures a secure connection, preventing accidents and damage to your vehicle. Whether you’re a seasoned mechanic or a novice driver, understanding the importance of proper socket selection is crucial.

This comprehensive guide will delve into the intricacies of wheel nut sizes, providing practical methods for identifying the correct socket for your vehicle. We’ll explore different types of sockets, safety precautions, and troubleshooting tips to ensure a smooth and efficient tire change experience.

Understanding Wheel Nut Sizes: What Size Socket For Wheel Nuts

Ensuring you use the correct socket size for your wheel nuts is crucial for safe and efficient tire changes. Using the wrong size can lead to various problems, potentially compromising your safety and causing damage to your vehicle.

Common Wheel Nut Sizes and Corresponding Vehicles

Knowing the correct wheel nut size for your vehicle is essential. Using the wrong size can result in stripping the nut, damaging the socket, or even causing the wheel to come loose while driving.

| Wheel Nut Size (mm) | Vehicle Makes and Models |

|---|---|

| 17 | Honda Civic, Toyota Corolla, Ford Focus |

| 19 | Chevrolet Silverado, Ford F-150, Toyota Tundra |

| 21 | Dodge Ram, Jeep Wrangler, Ford Mustang |

| 22 | Mercedes-Benz C-Class, BMW 3 Series, Audi A4 |

| 24 | Ford Expedition, Chevrolet Tahoe, Toyota Sequoia |

Identifying Your Vehicle’s Wheel Nut Size

Determining the correct wheel nut size is crucial for safely changing a tire. An incorrect socket size can damage the wheel nuts or prevent you from removing the wheel altogether. Fortunately, there are several methods for identifying your vehicle’s wheel nut size.

Checking the Owner’s Manual

The owner’s manual contains detailed information about your vehicle, including the wheel nut size. It is usually located in the “Maintenance and Care” or “Wheels and Tires” section. The manual will typically specify the size in millimeters or inches.

Examining the Spare Tire

If you have a spare tire, you can check its wheel nuts for the size. The spare tire’s wheel nuts are usually the same size as the ones on your main wheels.

Inspecting the Wheel Itself

The wheel itself can provide clues about the wheel nut size. Look for markings or stamps on the wheel’s surface. These markings may indicate the size or a code that can be used to identify the size.

Identifying the Socket Size from the Wheel Nut

Wheel nuts often have a specific size designation etched on their surface. This designation is usually a number followed by “mm” or “in,” indicating the socket size needed to loosen or tighten the nut.

Using a Socket Gauge

A socket gauge is a tool specifically designed for measuring wheel nut sizes. It features a series of sockets of varying sizes, allowing you to find the one that fits the wheel nut perfectly. Here’s how to use a socket gauge:

1. Select the appropriate socket gauge

Choose a socket gauge that covers the likely range of sizes for your vehicle.

2. Insert the wheel nut

Place the wheel nut into the socket gauge.

3. Identify the matching socket

Find the socket in the gauge that fits the wheel nut snugly.

4. Determine the socket size

The socket size will be marked on the gauge.

It is essential to use the correct socket size to avoid damaging the wheel nuts or the socket.

Choosing the Right Socket

Selecting the appropriate socket for your wheel nuts is crucial to ensure a safe and efficient tire change. The wrong socket can damage the wheel nut, making it difficult to remove or tighten in the future. This section explores the different types of sockets available and provides guidance on choosing the right one for your needs.

Types of Sockets

The most common types of sockets used for wheel nuts are standard, deep, and impact sockets. Each type has unique features and applications that make them suitable for different situations.

- Standard Sockets: These are the most common type of socket and are typically used for general-purpose applications. They have a shorter length and are suitable for wheel nuts that are easily accessible. However, they may not be suitable for wheel nuts that are recessed or have limited clearance.

- Deep Sockets: These sockets have a longer length than standard sockets, making them ideal for reaching recessed wheel nuts. They are often used on vehicles with larger wheel nuts or where access is limited. Deep sockets provide greater leverage and make it easier to loosen or tighten stubborn wheel nuts.

- Impact Sockets: These sockets are specifically designed for use with impact wrenches. They are made from durable materials that can withstand the high torque and impact forces generated by these tools. Impact sockets are essential for professional mechanics and are often used in automotive repair shops. They are not typically recommended for home use.

Socket Sizes and Applications

The size of the socket required for your wheel nuts is determined by the size of the nut itself. Wheel nut sizes vary depending on the vehicle make and model. Here is a table with examples of socket sizes, their applications, and their pros and cons:

| Socket Size | Application | Pros | Cons |

|---|---|---|---|

| 17mm | Common size for many vehicles, including sedans, SUVs, and trucks. | Widely available and affordable. | May not be suitable for vehicles with larger wheel nuts. |

| 19mm | Used on some vehicles with larger wheel nuts, including trucks and SUVs. | Provides greater leverage for larger wheel nuts. | May not be readily available in all sizes. |

| 21mm | Typically used on heavy-duty trucks and commercial vehicles. | Strong and durable for heavy-duty applications. | May be expensive and difficult to find. |

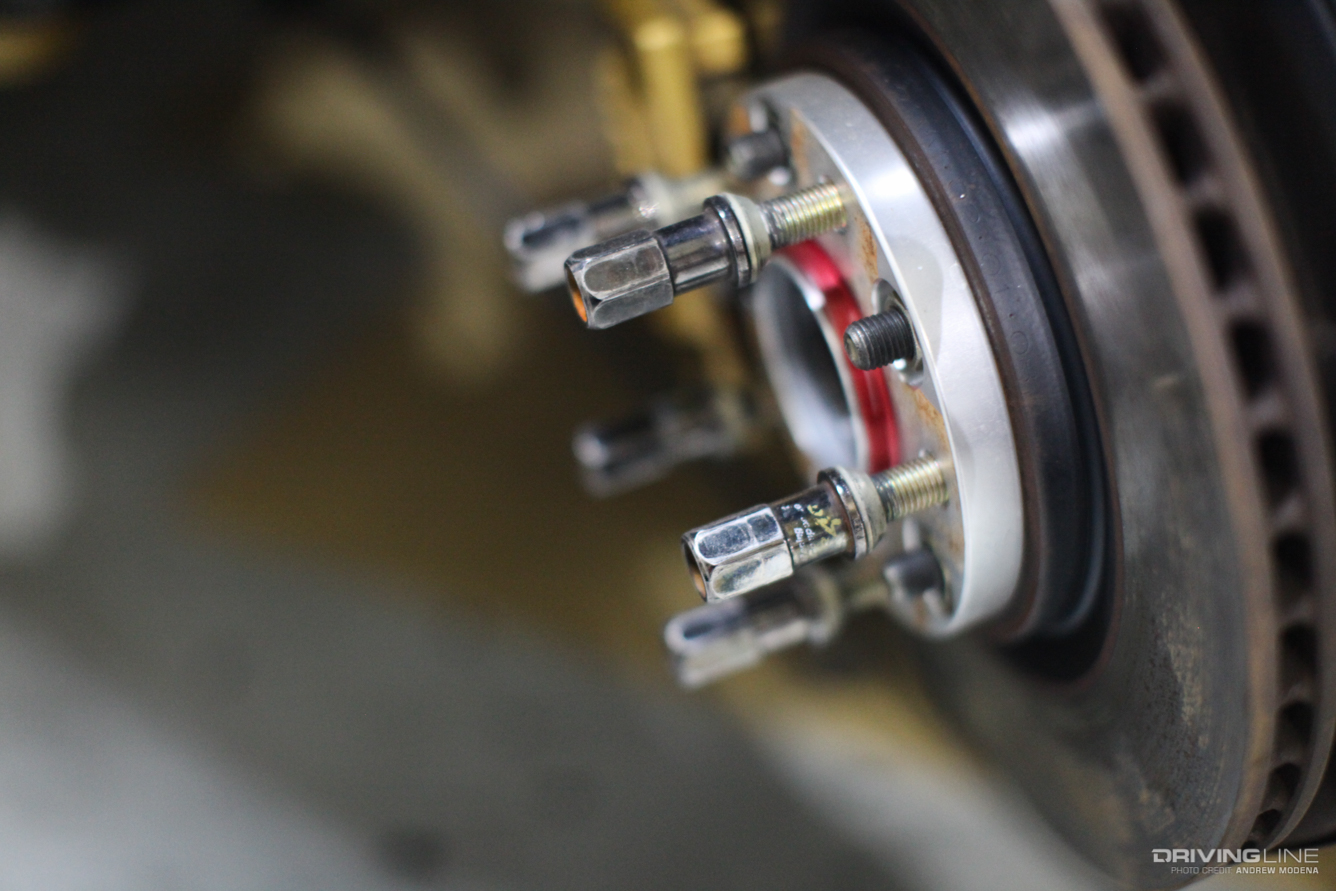

Importance of a Snug Fit

It is crucial to use a socket that fits snugly on the wheel nut to avoid damage. A loose-fitting socket can slip off the nut, causing damage to the nut or the socket itself. In some cases, a loose-fitting socket can even cause the wheel to come loose while driving, which can be extremely dangerous.

Always use a socket that fits the wheel nut snugly to avoid damage.

Using the Socket Safely

Working with wheel nuts requires a certain level of caution and awareness to prevent injuries and damage to your vehicle. Understanding the proper techniques and safety precautions is essential for a smooth and successful experience.

Safety Precautions When Using a Socket

It is crucial to prioritize safety when working with sockets and wheel nuts. Here are some key precautions to follow:

- Always ensure that the vehicle is securely parked on a level surface and engaged in park or with the emergency brake applied. This prevents the vehicle from rolling while you are working on the wheels.

- Use jack stands to support the vehicle securely after raising it with a jack. Never rely solely on the jack to hold the vehicle’s weight.

- Wear safety glasses to protect your eyes from flying debris or loose nuts.

- Avoid using damaged or worn-out sockets, as they can slip and cause injury or damage to the wheel nuts.

- Use the appropriate size socket for the wheel nuts on your vehicle. A socket that is too small can strip the nut, while one that is too large can damage the nut or the socket itself.

- Never use a hammer or other forceful methods to loosen or tighten wheel nuts. This can damage the nuts and make them difficult to remove in the future.

- Always use a torque wrench to tighten the wheel nuts to the manufacturer’s specifications. Overtightening can damage the wheel studs or the nuts, while undertightening can cause the wheels to loosen and potentially detach while driving.

Using a Breaker Bar and Socket to Loosen Wheel Nuts

- Position the breaker bar over the socket, ensuring a secure fit. Apply pressure to the end of the breaker bar in a counter-clockwise direction to loosen the wheel nut. Use a firm but controlled force, avoiding sudden or excessive force that could damage the nut or the socket.

- If the nut is particularly stubborn, try using a lubricant like penetrating oil to loosen it. Allow the lubricant to penetrate the threads for a few minutes before attempting to loosen the nut again.

- If the nut is still stuck, you may need to use a longer breaker bar or a cheater pipe for added leverage. However, exercise caution when using extra leverage to avoid overstressing the socket or the wheel stud.

Using a Torque Wrench to Tighten Wheel Nuts, What size socket for wheel nuts

- Select a torque wrench that is appropriate for the size and type of wheel nuts on your vehicle. The torque wrench should have a range that covers the manufacturer’s specified torque for your vehicle.

- Set the torque wrench to the manufacturer’s recommended torque value for your vehicle. This information can typically be found in the owner’s manual or online resources.

- Place the socket on the wheel nut and engage the torque wrench. Tighten the nut until the torque wrench clicks, indicating that the desired torque has been reached.

- Repeat this process for each wheel nut, ensuring that they are all tightened to the same torque value. Do not overtighten the nuts, as this can damage the wheel studs or the nuts themselves.

Troubleshooting Socket Issues

Even with the correct socket size, you might encounter problems while removing or tightening wheel nuts. Understanding common issues and their solutions can save you time and frustration.

Stripped Wheel Nuts

Stripped wheel nuts are a common problem, especially if the nuts have been overtightened or if the wrong socket size has been used.

- Signs of a stripped wheel nut: The socket spins freely on the nut without engaging the flats. The nut may have visible damage, such as rounded edges or a deformed shape.

- Solutions:

- Use a larger socket: A larger socket may be able to grip the nut more securely, but it should only be used if the nut has not been severely damaged.

- Use a nut extractor: Nut extractors are specialized tools designed to remove stripped nuts. They come in various sizes and designs, but they all work by gripping the inside of the nut and applying torque to loosen it.

- Drill out the nut: In extreme cases, you may need to drill out the nut. This should only be done as a last resort, as it can damage the wheel stud.

Stuck Socket

A stuck socket can be frustrating, but it’s often a result of rust or corrosion on the wheel nut.

- Signs of a stuck socket: The socket is tightly attached to the nut, and you cannot remove it by hand.

- Solutions:

- Use a penetrating oil: Apply penetrating oil to the nut and allow it to soak for several minutes. This will help loosen the rust and make it easier to remove the socket.

- Tap the socket: Use a hammer to gently tap the socket, which may help to break the bond between the socket and the nut.

- Use a breaker bar: A breaker bar is a longer wrench that provides more leverage, which can be helpful for loosening stuck sockets.

Broken Socket

A broken socket can happen if you apply too much force or if the socket is of poor quality.

- Signs of a broken socket: The socket may crack, chip, or break completely.

- Solutions:

- Use a new socket: If the socket is broken, you’ll need to use a new one. Make sure to choose a socket that is made of high-quality material and is the correct size for the wheel nuts.

- Use a socket extractor: A socket extractor is a specialized tool designed to remove broken sockets. They work by gripping the inside of the socket and applying torque to loosen it.

From understanding the importance of using the correct socket size to navigating potential issues, this guide empowers you with the knowledge to confidently tackle tire changes. By employing the right tools and techniques, you can ensure a safe and secure experience, minimizing the risk of accidents and maximizing the longevity of your vehicle’s components. Remember, a properly fitted socket is not just a matter of convenience, it’s a vital element of vehicle safety and maintenance.

FAQ Section

What if I can’t find the correct socket size?

If you’re unable to determine the correct socket size, it’s best to consult a professional mechanic or visit a reputable auto parts store. They can help you identify the appropriate size and provide any necessary assistance.

How often should I check my wheel nut size?

While it’s not necessary to check your wheel nut size regularly, it’s a good practice to do so during routine maintenance checks or whenever you replace a tire. This ensures that the socket size remains compatible with your vehicle.

What if I damage a wheel nut while using a socket?

If you encounter a stripped or damaged wheel nut, it’s crucial to seek professional assistance. A mechanic can use specialized tools to remove the damaged nut and replace it with a new one.