How to test a wheel speed sensor sets the stage for this enthralling narrative, offering readers a glimpse into a story that is rich in detail with creative twitter thread style and brimming with originality from the outset.

Ever wondered what makes your ABS and traction control systems work? It’s the wheel speed sensor, a crucial component that monitors your car’s wheel rotation. But what happens when it malfunctions? You might notice your ABS light flashing, traction control acting up, or even an inaccurate speedometer. This guide will walk you through testing a wheel speed sensor, so you can get back on the road safely and confidently.

Understanding Wheel Speed Sensors

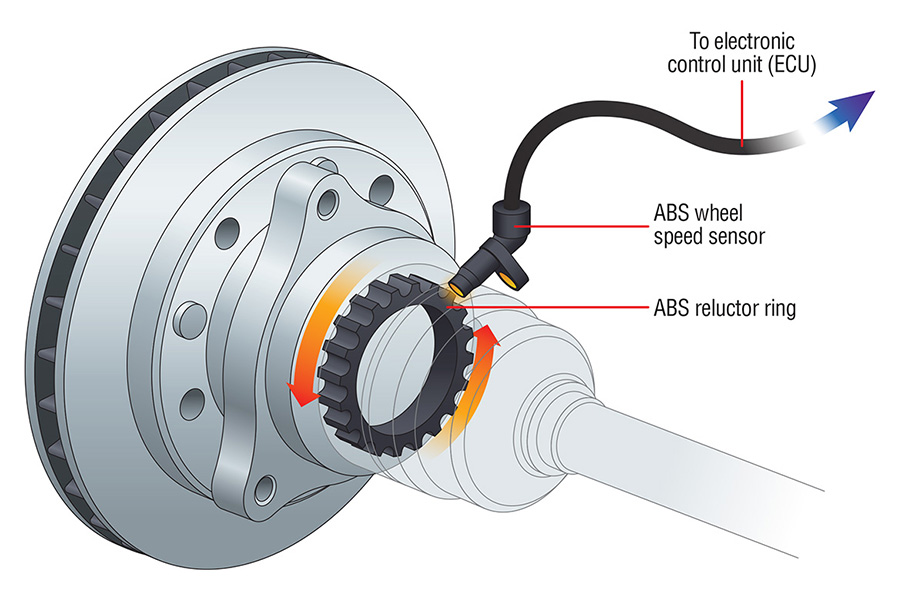

Wheel speed sensors are essential components in modern vehicles, playing a crucial role in various safety and performance systems. These sensors monitor the rotational speed of each wheel, providing vital information to the vehicle’s electronic control units (ECUs). This information is then used to regulate braking, traction control, and other critical functions.

Types of Wheel Speed Sensors

Wheel speed sensors are typically classified based on their operating principles. Each type utilizes a different method to generate a signal proportional to the wheel’s rotational speed.

- Magnetic Sensors: These sensors consist of a magnetic field generator and a coil. As the wheel rotates, the teeth on the wheel’s tone ring (a toothed metal ring attached to the wheel hub) interrupt the magnetic field, inducing a voltage in the coil. The frequency of these voltage pulses directly corresponds to the wheel’s speed.

- Optical Sensors: Optical sensors employ a light source and a photodetector. The light source emits a beam of light that shines through a slotted disc attached to the wheel hub. As the wheel rotates, the slots interrupt the light beam, creating a series of light pulses detected by the photodetector. The frequency of these pulses is directly proportional to the wheel’s speed.

- Hall Effect Sensors: Hall effect sensors use a semiconductor material that generates a voltage when subjected to a magnetic field. These sensors are typically embedded in the wheel hub and contain a permanent magnet. As the wheel rotates, the magnetic field from the magnet interacts with the semiconductor material, generating a voltage signal that varies with the wheel’s speed.

Signal Generation

Wheel speed sensors generate a signal that reflects the wheel’s rotational speed. The specific signal characteristics vary depending on the sensor type.

- Magnetic Sensors: Magnetic sensors produce a series of voltage pulses, with the frequency of the pulses directly proportional to the wheel’s speed. The higher the wheel speed, the more frequent the pulses.

- Optical Sensors: Optical sensors generate a series of light pulses, similar to magnetic sensors. The frequency of these pulses is also directly proportional to the wheel’s speed.

- Hall Effect Sensors: Hall effect sensors produce a voltage signal that varies continuously with the wheel’s speed. The higher the wheel speed, the higher the voltage signal.

Common Symptoms of a Faulty Wheel Speed Sensor

A faulty wheel speed sensor can cause a variety of problems with your vehicle’s performance and safety systems. These problems are often subtle and can be easily overlooked, but it’s important to be aware of the potential symptoms so you can get your vehicle repaired promptly.If you experience any of the following symptoms, it’s a good idea to have your wheel speed sensor checked by a qualified mechanic.

ABS Light Illumination, How to test a wheel speed sensor

A faulty wheel speed sensor can trigger the ABS light on your dashboard. The ABS system relies on accurate speed readings from each wheel to properly engage the brakes in slippery conditions. If the system detects a discrepancy between the speed readings, it will illuminate the ABS light as a warning. The ABS system will likely be disabled, which means you won’t have the benefit of anti-lock braking if you need it.

Traction Control Malfunction

Traction control systems also rely on accurate wheel speed readings to determine when the wheels are slipping and to intervene to regain traction. A faulty wheel speed sensor can cause the traction control system to malfunction, making it difficult to control your vehicle on slippery surfaces.

Speedometer Inaccuracy

The speedometer gets its information from the wheel speed sensors. If a sensor is faulty, your speedometer may read inaccurately. You might find that your speedometer is reading slower or faster than your actual speed.

Consequences of Ignoring a Faulty Wheel Speed Sensor

Ignoring a faulty wheel speed sensor can lead to a number of problems, including:

- Reduced braking performance: Without accurate wheel speed readings, the ABS system may not be able to function properly, leading to a longer stopping distance in emergency situations.

- Loss of traction control: A faulty sensor can prevent the traction control system from working properly, making it more difficult to maintain control of your vehicle on slippery surfaces.

- Increased fuel consumption: A faulty sensor can cause the engine to run less efficiently, resulting in reduced fuel economy.

- Potential damage to other components: A faulty wheel speed sensor can cause damage to other components in the braking system, such as the ABS module.

Tools and Equipment Needed for Testing: How To Test A Wheel Speed Sensor

Testing a wheel speed sensor requires a few essential tools and equipment. These tools allow you to safely and effectively diagnose the sensor and its associated wiring.

Multimeter

A multimeter is an indispensable tool for testing a wheel speed sensor. It measures various electrical parameters, including voltage, current, and resistance.

The multimeter allows you to check for continuity in the sensor’s wiring, measure the sensor’s output signal, and test the sensor’s resistance.

When using a multimeter, ensure it’s set to the appropriate range for the measurement you’re taking.

Diagnostic Scanner

A diagnostic scanner, also known as an OBD-II scanner, is a device that communicates with your vehicle’s onboard computer system.

It can retrieve diagnostic trouble codes (DTCs) stored in the computer’s memory.

These codes provide valuable information about potential problems with the wheel speed sensor or other related components.

Wiring Diagram

A wiring diagram for your specific vehicle is crucial for testing a wheel speed sensor.

It shows the location of the sensor, its wiring path, and its connection points.

This information helps you trace the wiring, identify potential problems, and ensure proper connections.

Safety Precautions

When working with automotive electrical systems, it’s essential to take the following safety precautions:

- Disconnect the battery before working on any electrical components to prevent electric shock.

- Use insulated tools to avoid contact with live wires.

- Be aware of the location of the vehicle’s fuse box and disconnect the appropriate fuse before working on any electrical components.

- Never work on electrical systems while the vehicle is running.

Testing Procedures

Alright, now that you’ve got your tools ready, let’s get down to the nitty-gritty of testing the wheel speed sensor. We’ll use a multimeter to check the sensor’s voltage, resistance, and signal output.

Measuring Voltage

To measure the voltage, you’ll need to connect the multimeter to the sensor’s wires. The sensor typically has two wires: one for power and one for signal. Here’s how to do it:* Locate the sensor wires. These wires will be connected to the sensor on one end and to the vehicle’s wiring harness on the other.

- Disconnect the sensor connector. This will prevent any accidental short circuits.

- Set your multimeter to DC voltage. You’ll need to measure the voltage in direct current (DC).

- Connect the positive lead of the multimeter to the power wire. This is usually the wire with a solid color, like black or red.

- Connect the negative lead of the multimeter to the signal wire. This is usually the wire with a striped color, like white with a black stripe.

- Turn the ignition key to the “ON” position. This will provide power to the sensor.

- Read the voltage reading on the multimeter. The voltage should be between 9 and 15 volts.

If the voltage reading is outside of this range, it could indicate a problem with the sensor’s power supply or a faulty sensor.

Measuring Resistance

The resistance of the sensor can be measured using a multimeter. Here’s how to do it:* Set your multimeter to ohms. This is usually indicated by the Ω symbol.

- Connect the positive and negative leads of the multimeter to the sensor wires. It doesn’t matter which wire you connect to which lead.

- Read the resistance reading on the multimeter. The resistance should be between 500 and 1500 ohms.

If the resistance reading is outside of this range, it could indicate a faulty sensor.

Measuring Signal Output

The signal output of the sensor can be measured using a multimeter, but it’s a bit more involved. Here’s how to do it:* Set your multimeter to AC voltage. You’ll need to measure the voltage in alternating current (AC).

- Connect the positive lead of the multimeter to the signal wire.

- Connect the negative lead of the multimeter to a good ground point on the vehicle.

- Rotate the wheel that the sensor is attached to. You should see a fluctuating voltage reading on the multimeter.

The voltage reading should fluctuate with the speed of the wheel rotation. If the reading is constant or not fluctuating, it could indicate a faulty sensor.

Troubleshooting Faulty Wheel Speed Sensors

Once you’ve gone through the testing procedures and confirmed that a wheel speed sensor is faulty, you’ll need to figure out why it’s failing. Understanding the cause of the problem is crucial for fixing the issue correctly and preventing it from happening again.

Common Causes of Wheel Speed Sensor Failure

There are a few common reasons why a wheel speed sensor might go bad. Knowing these potential causes can help you diagnose the problem efficiently.

- Damage to the Sensor Itself: The most common cause of failure is physical damage to the sensor. This can happen due to road debris, impacts, or even just the wear and tear of normal driving. The sensor is often located in a vulnerable position, making it susceptible to damage.

- Wiring Problems: Another frequent issue is damage to the sensor’s wiring. This could be caused by chafing, corrosion, or even a broken wire. A damaged wire can disrupt the signal flow, leading to sensor malfunction.

- ABS Module Malfunctions: In some cases, the problem might not be with the sensor itself, but with the ABS module. The ABS module receives signals from the wheel speed sensors and controls the braking system. If the ABS module is faulty, it can cause issues with the wheel speed sensors.

Troubleshooting Wheel Speed Sensor Issues

After identifying a faulty wheel speed sensor, the next step is to determine the root cause of the problem. This process involves a systematic approach to eliminate potential issues.

- Inspect the Sensor: Begin by carefully inspecting the sensor for any signs of damage. Look for cracks, broken wires, or debris lodged in the sensor. If you find any damage, you’ll need to replace the sensor.

- Check the Wiring: Examine the wiring leading to the sensor. Look for signs of chafing, corrosion, or broken wires. If you find any issues with the wiring, repair or replace the damaged section.

- Test the ABS Module: If the sensor and wiring appear to be in good condition, the issue might lie with the ABS module. You can test the ABS module using a diagnostic scanner. If the ABS module is faulty, it will need to be replaced.

Replacing a Faulty Wheel Speed Sensor

Once you’ve determined that the sensor is faulty, you’ll need to replace it. Here’s a step-by-step guide on how to do so:

- Disconnect the Battery: Before you start working on the sensor, disconnect the battery to prevent any electrical shocks.

- Locate the Sensor: Find the faulty wheel speed sensor. It’s usually located near the wheel hub, often attached to the suspension arm or brake caliper.

- Remove the Sensor: Depending on the vehicle, you might need to remove the wheel or other components to access the sensor. Once you have access, disconnect the electrical connector and remove the sensor from its mounting point.

- Install the New Sensor: Install the new sensor in the same location as the old one. Make sure the sensor is securely mounted and the electrical connector is properly connected.

- Reconnect the Battery: Reconnect the battery and test the sensor using a diagnostic scanner or by driving the vehicle. If the sensor is working properly, you’ve successfully replaced the faulty sensor.

Testing a wheel speed sensor isn’t as daunting as it might seem. With the right tools and a little knowledge, you can diagnose the issue and get back to enjoying your ride. Remember, a faulty sensor can lead to serious safety concerns, so don’t ignore those warning signs. Take the time to understand how it works and troubleshoot any problems.

And if you’re ever unsure, consult a qualified mechanic. Happy driving!

FAQ Guide

What are the most common signs of a faulty wheel speed sensor?

The most common signs are a flashing ABS light, traction control malfunction, and an inaccurate speedometer. You may also notice a grinding or clicking noise coming from the wheels.

Can I test a wheel speed sensor without a multimeter?

While a multimeter is the most accurate tool, you can sometimes test the sensor using a simple continuity test with a test light. However, this method is less reliable and may not provide accurate readings.

How often should I check my wheel speed sensors?

It’s recommended to check your wheel speed sensors as part of your regular car maintenance routine, especially if you notice any of the symptoms mentioned above. However, if your sensors are working correctly, they typically don’t need to be replaced unless they are damaged.

Can I replace a wheel speed sensor myself?

Replacing a wheel speed sensor is a relatively straightforward task, but it requires some mechanical knowledge and tools. If you’re not comfortable working on your car, it’s best to consult a professional mechanic.