Can a bad wheel bearing cause vibration? Absolutely! Imagine the intricate ballet of your car’s wheels, a symphony of motion orchestrated by the silent workhorses known as wheel bearings. These tiny, often overlooked components are crucial for smooth, safe driving. When they fail, the consequences can be dramatic, manifesting as unsettling vibrations that shake your vehicle and threaten your journey.

This article delves into the world of wheel bearings, exploring their vital role in your car’s performance and the telltale signs of their demise. We’ll dissect the symptoms of a failing wheel bearing, unravel the common causes of their failure, and equip you with the knowledge to identify and address this potentially dangerous issue.

What are Wheel Bearings?

Wheel bearings are essential components in a vehicle’s suspension system, responsible for supporting the weight of the vehicle and allowing the wheels to rotate smoothly. They are crucial for maintaining vehicle stability, handling, and ride comfort.

Types of Wheel Bearings

Wheel bearings are classified into two main types:

- Ball Bearings: These bearings consist of a set of steel balls that rotate between an inner and outer raceway. They are known for their low friction and high load-carrying capacity, making them suitable for high-speed applications.

- Roller Bearings: These bearings use cylindrical rollers instead of balls, providing greater load-carrying capacity in radial directions. They are commonly used in heavy-duty vehicles and applications where high radial loads are expected.

Wheel Bearing Construction Materials

Wheel bearings are typically constructed using high-quality materials to ensure durability and performance. Common materials include:

- Steel: The most common material for bearing races and balls, offering high strength and wear resistance.

- Ceramic: Ceramic bearings offer lower friction and higher heat resistance compared to steel bearings. They are often used in high-performance vehicles.

- Bronze: Bronze is used for bearing cages, providing resistance to wear and corrosion.

Symptoms of a Bad Wheel Bearing

A bad wheel bearing can cause a variety of symptoms that may seem subtle at first but become more pronounced as the bearing deteriorates. Recognizing these signs early is crucial for ensuring your safety and preventing further damage to your vehicle. These symptoms can range from a slight rumbling noise to a loud grinding sound, and even affect the way your vehicle handles.

Vibrations and Noise

A failing wheel bearing often manifests itself through vibrations and noises that you might feel or hear while driving. The vibrations can be felt in the steering wheel, the floorboard, or even the entire vehicle. These vibrations are often accompanied by a rumbling, grinding, or roaring noise, especially when turning or driving over bumps.

- Vibration at Speed: As the bearing deteriorates, the rolling elements inside the bearing start to wear down, creating uneven surfaces that cause the wheel to wobble. This wobble can be felt as a vibration that increases with speed, particularly noticeable when driving on a smooth surface.

- Noise When Turning: When turning, the load on the wheel bearing increases. A failing bearing will produce a louder grinding or roaring noise, especially when turning at low speeds. This is because the bearing’s internal components are forced to rub against each other more intensely.

- Noise When Driving Over Bumps: Driving over bumps can also exacerbate the symptoms of a bad wheel bearing. As the wheel impacts the bump, the bearing is subjected to a sudden force that can cause the worn components to grind against each other, producing a noticeable noise.

Causes of Wheel Bearing Failure

Wheel bearings are essential components of your vehicle’s suspension system, responsible for supporting the weight of your car and allowing the wheels to rotate smoothly. However, like any mechanical part, wheel bearings can wear out over time and require replacement. Several factors contribute to wheel bearing failure, understanding which can help you prevent premature wear and ensure a smooth and safe driving experience.

Driving Conditions and Road Surfaces

The conditions under which you drive can significantly impact the lifespan of your wheel bearings. Harsh driving environments, such as frequently driving on rough roads or roads with potholes, can put excessive stress on the bearings, leading to premature wear and tear.

- Rough Roads: Driving on roads with uneven surfaces or potholes can subject the wheel bearings to constant impacts and vibrations, causing them to wear down faster.

- Off-Road Driving: Off-road driving often involves navigating challenging terrain, including rocky surfaces and uneven paths. These conditions can place extreme stress on the wheel bearings, leading to rapid deterioration.

- Heavy Loads: Vehicles carrying heavy loads, such as towing trailers or hauling cargo, put additional stress on the wheel bearings. This increased load can accelerate wear and tear, leading to failure sooner.

Improper Maintenance

Neglecting regular maintenance can significantly contribute to wheel bearing failure. Proper lubrication and inspection are crucial for maintaining the health of your bearings.

- Insufficient Lubrication: Wheel bearings rely on lubrication to reduce friction and wear. Insufficient lubrication can lead to increased friction, causing the bearings to overheat and wear out prematurely.

- Contamination: Dirt, debris, and water can contaminate the wheel bearings, causing premature wear and tear. Regularly inspecting and cleaning the bearings helps to prevent contamination.

- Overtightening: Overtightening the wheel bearing nuts can damage the bearing races and seals, leading to premature failure.

Diagnosing a Bad Wheel Bearing: Can A Bad Wheel Bearing Cause Vibration

Diagnosing a bad wheel bearing is a critical step in ensuring the safety and smooth operation of your vehicle. Mechanics use a combination of techniques to pinpoint the issue, from visual inspections to utilizing specialized tools. Understanding these methods empowers you to recognize the signs of a failing wheel bearing and seek professional help promptly.

Visual Inspection

Visual inspection plays a crucial role in diagnosing a bad wheel bearing. It involves carefully examining the bearing and its surrounding components for signs of wear, damage, or abnormalities.

- Inspecting the Bearing Raceways: Mechanics meticulously examine the raceways, the circular tracks on which the bearing balls or rollers rotate. Signs of damage, such as grooves, pitting, or rust, indicate wear and potential failure.

- Checking for Bearing Play: The presence of excessive play or looseness in the bearing is a clear indication of a problem. This can be observed by gently rocking the wheel back and forth while holding the brake caliper or rotor.

- Examining the Bearing Seals: The seals surrounding the bearing are designed to prevent dirt and debris from entering. If the seals are damaged or cracked, it allows contaminants to enter the bearing, leading to premature wear.

Using Diagnostic Tools

Diagnostic tools provide mechanics with valuable insights into the condition of wheel bearings, allowing them to identify issues that may not be readily apparent through visual inspection alone.

- Stethoscope: This tool amplifies sounds, enabling mechanics to listen closely for unusual noises emanating from the bearing. A grinding or rumbling sound, particularly when turning or braking, is a strong indicator of a bad wheel bearing.

- Vibration Analyzer: This tool measures and analyzes vibrations in the wheel and suspension components. A high level of vibration, particularly at certain speeds, suggests a faulty bearing.

- Torque Wrench: This tool is used to ensure the proper tightness of the wheel bearing nuts. If the nuts are too loose, the bearing may be damaged. If they are too tight, they can also cause problems.

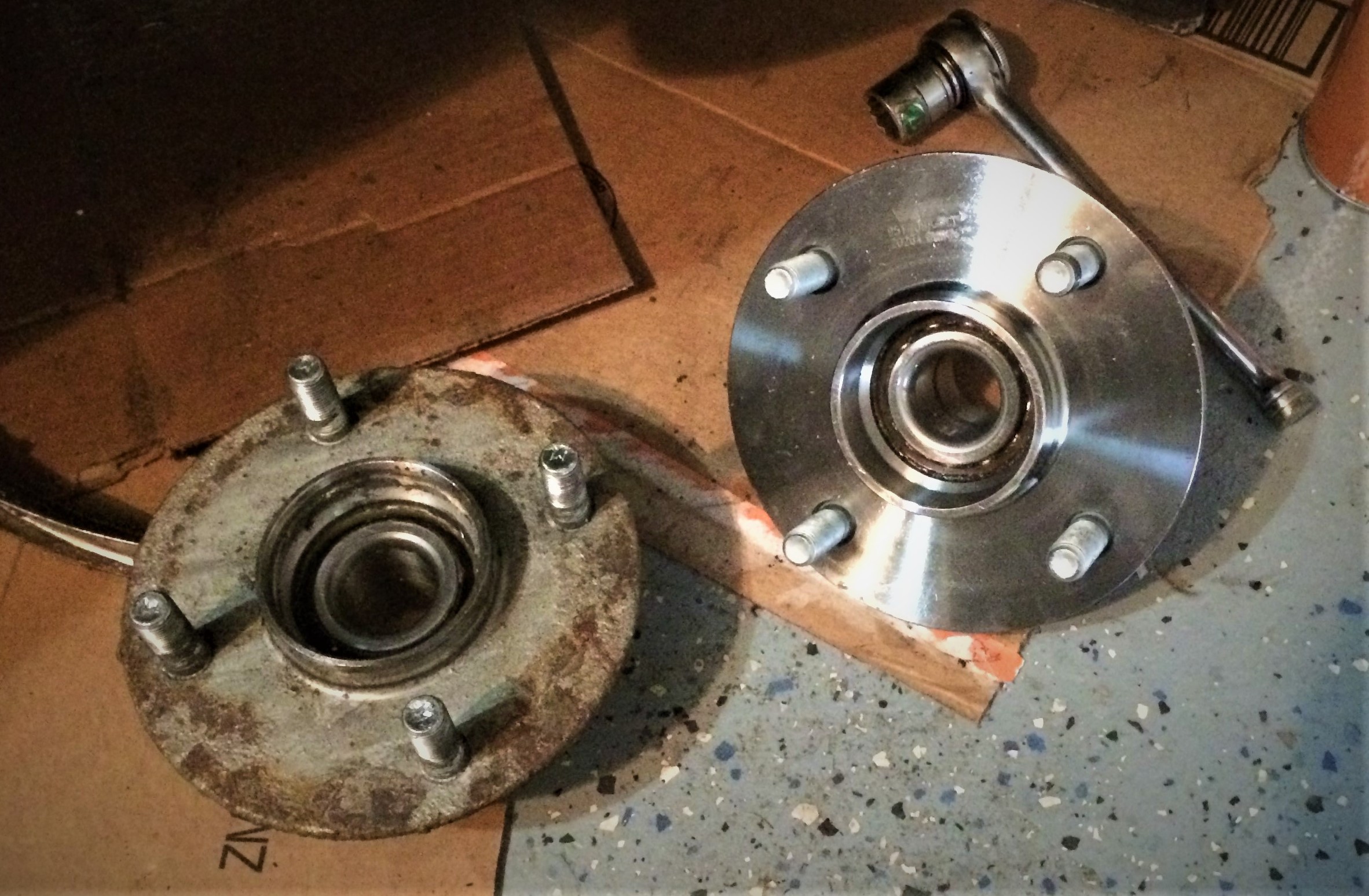

Replacing a Wheel Bearing

Replacing a wheel bearing is a complex repair that requires a combination of mechanical skills and specialized tools. It is not recommended for beginners, as improper installation can lead to further damage or even safety hazards. It’s always a good idea to consult with a qualified mechanic if you’re unsure about the process.

Tools and Equipment, Can a bad wheel bearing cause vibration

To successfully replace a wheel bearing, you will need a collection of specialized tools and equipment.

- Jack and Jack Stands: These are essential for safely lifting the vehicle and securing it while working on the wheel.

- Wheel Wrench: Used to loosen and tighten the lug nuts on the wheel.

- Torque Wrench: A torque wrench is crucial for tightening the lug nuts to the correct specifications, ensuring proper wheel attachment and preventing damage to the wheel studs.

- Hydraulic Press: A hydraulic press is used to remove and install the wheel bearing race and the bearing itself. This is a specialized tool that requires careful handling and operation.

- Bearing Race Installer and Remover: These tools are designed specifically for removing and installing the bearing races, ensuring a proper fit and preventing damage to the hub assembly.

- Impact Wrench: An impact wrench can be helpful for loosening stubborn lug nuts, but it’s important to use it with caution to avoid damaging the wheel studs.

- Socket Set: A socket set is essential for working on various nuts and bolts during the repair process.

- Hammer: A hammer is needed for tapping the bearing race into place and for other minor adjustments during the installation process.

- Pry Bar: A pry bar can be used to help separate components during the disassembly process.

- Cleaning Supplies: Cleanliness is essential for proper installation. You’ll need brake cleaner, rags, and a cleaning brush to remove dirt and debris from the components.

Proper Alignment and Torque Specifications

Proper alignment and torque specifications are crucial for ensuring the safe and efficient operation of the wheel bearing.

- Wheel Alignment: After replacing a wheel bearing, it’s important to have the vehicle’s wheel alignment checked and adjusted by a qualified mechanic. This ensures that the wheels are properly aligned and that the vehicle drives straight and safely.

- Torque Specifications: The lug nuts must be tightened to the correct torque specifications, which are specific to the vehicle make and model. This ensures that the wheel is securely attached to the hub without damaging the wheel studs. Consult your vehicle’s owner’s manual or a reputable repair manual for the correct torque specifications.

Preventive Measures for Wheel Bearing Failure

Just like any mechanical component, wheel bearings require care and attention to ensure they function optimally and last their intended lifespan. Taking proactive steps to prevent bearing failure can save you from costly repairs and potential safety hazards.

Regular Maintenance

Regular maintenance is crucial for preventing premature wheel bearing failure. A simple visual inspection during routine checks can often identify signs of wear or damage.

- Inspect for Grease Leaks: Wheel bearings rely on grease to lubricate and protect their moving parts. If you notice any grease leaks around the bearing area, it indicates a potential problem.

- Check for Loose or Damaged Components: Inspect the bearing housing, mounting bolts, and surrounding components for any signs of looseness, damage, or corrosion.

- Listen for Unusual Noises: Pay attention to any unusual noises coming from your wheels, especially when turning or driving at higher speeds. A grinding, humming, or roaring sound could indicate a failing bearing.

Understanding the intricacies of wheel bearings and their potential for causing vibration is essential for any car owner. By recognizing the symptoms, understanding the causes, and taking proactive steps, you can ensure the safety and longevity of your vehicle. Whether you’re a seasoned mechanic or a novice driver, this knowledge empowers you to maintain a smooth ride and a worry-free journey.

So, the next time you feel a vibration, pay attention – it might be your wheel bearings sending a crucial message.

Helpful Answers

How often should I inspect my wheel bearings?

It’s recommended to inspect your wheel bearings during every oil change or at least once a year. This allows you to catch any early signs of wear or damage.

Can I replace a wheel bearing myself?

While it’s possible to replace a wheel bearing yourself, it’s a complex and potentially dangerous procedure. It’s best left to a qualified mechanic to ensure proper installation and alignment.

How much does it cost to replace a wheel bearing?

The cost of replacing a wheel bearing varies depending on the make and model of your vehicle and the labor costs in your area. Expect to pay anywhere from $100 to $500 or more for the entire repair.