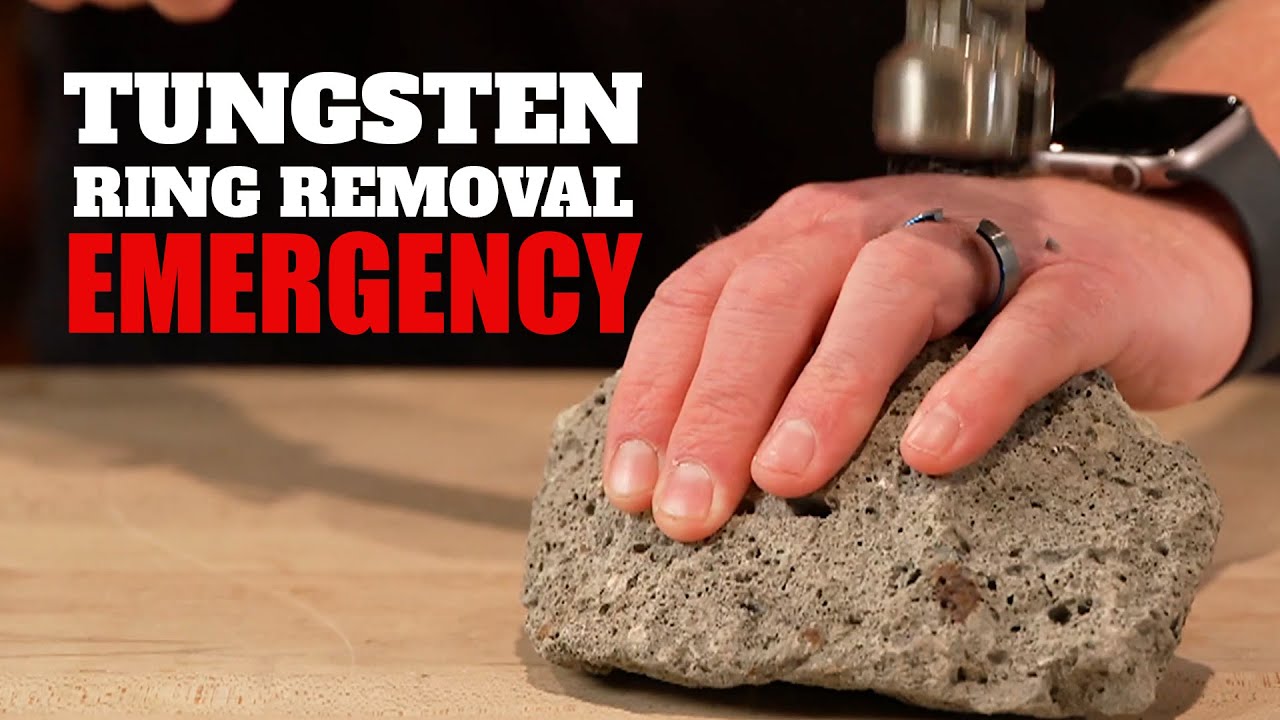

Can you cut a tungsten ring? You might be surprised to learn that it’s not as easy as slicing through butter. Tungsten carbide, the material used in these rings, is incredibly hard and durable. It’s so tough, in fact, that it can withstand scratches, abrasions, and even the occasional accidental drop. But what happens when you need to resize a tungsten ring or, heaven forbid, remove it in an emergency?

That’s where the real challenge comes in.

The hardness of tungsten carbide makes it a formidable foe for conventional cutting tools. You can’t just whip out a pair of pliers and expect to snip it in half. Special tools and techniques are required to tackle this task, and even then, there are risks involved. In this article, we’ll explore the challenges of cutting tungsten rings, delve into the various methods available, and highlight the importance of seeking professional assistance.

So, if you’re curious about the secrets of tungsten ring cutting, buckle up and prepare for a wild ride!

Tungsten Ring Properties

Tungsten carbide rings are known for their exceptional durability and unique properties. These rings are often chosen for their strength, scratch resistance, and distinctive appearance. Let’s delve into the key characteristics that make tungsten carbide such a popular choice for jewelry.

Hardness and Durability

Tungsten carbide is incredibly hard, ranking 9 out of 10 on the Mohs Hardness Scale, second only to diamond. This extreme hardness makes tungsten carbide rings highly resistant to scratches, dents, and wear and tear. They are virtually indestructible in everyday use, making them ideal for those seeking a ring that will last a lifetime.

Density and Weight

Tungsten carbide is a dense metal, meaning it has a high mass packed into a small volume. This density makes tungsten carbide rings heavier than rings made from other metals like gold or silver. However, the weight is often perceived as a positive attribute, as it provides a substantial feel and a sense of permanence.

Resistance to Scratching and Abrasion

Tungsten carbide’s exceptional hardness translates to outstanding resistance to scratching and abrasion. The smooth, polished surface of a tungsten carbide ring is highly resistant to daily wear and tear, ensuring that it maintains its shine and beauty for years to come.

Cutting Tungsten Rings

Tungsten carbide rings are known for their durability and resistance to scratches, but this same characteristic makes them incredibly difficult to cut. The extreme hardness of tungsten carbide presents unique challenges for jewelers and metalworkers attempting to resize or alter these rings.

Challenges of Cutting Tungsten Rings

The exceptional hardness of tungsten carbide, ranking 9 on the Mohs Hardness Scale, makes it a formidable material to cut. This hardness translates to a high resistance to scratching and abrasion, making it ideal for jewelry but a nightmare for traditional cutting methods.

- Traditional cutting tools, like those used for softer metals, are simply not equipped to handle the strength of tungsten carbide. They tend to dull quickly or break, making the cutting process inefficient and potentially dangerous.

- The risk of damaging the ring during the cutting process is high. The force required to cut tungsten carbide can lead to chipping, cracking, or even breaking the ring, especially if the proper tools and techniques are not used.

Specialized Tools and Techniques

Cutting tungsten carbide rings requires specialized tools and techniques. Jewelers often use diamond-coated cutting blades or abrasive wheels specifically designed for this purpose. These tools are significantly harder than tungsten carbide and can effectively cut through the material without causing excessive damage.

- Diamond-coated blades are the most common tools used for cutting tungsten carbide rings. The diamond particles are incredibly hard and can effectively cut through the material without dulling quickly. These blades are often used in specialized cutting machines designed for precise cuts.

- Abrasive wheels are another option for cutting tungsten carbide. These wheels are made from a mixture of abrasive materials, like diamond dust, that can effectively grind away the material. The process can be time-consuming, but it can be effective for making precise cuts.

Cutting Methods

Cutting a tungsten ring is a challenging task due to its extreme hardness and durability. Several methods can be employed, each with its own advantages and disadvantages.

Comparison of Cutting Methods

The choice of cutting method depends on factors such as the desired precision, speed, and cost. Here’s a table comparing the most common methods:

| Method | Precision | Speed | Cost |

|---|---|---|---|

| Laser Cutting | High | Fast | High |

| Diamond Saw | Medium | Moderate | Medium |

| Abrasive Cutting | Low | Slow | Low |

Laser Cutting, Can you cut a tungsten ring

Laser cutting utilizes a high-powered laser beam to melt and vaporize the tungsten material. This method offers high precision and speed, making it suitable for intricate designs and complex cuts. However, it is a costly method due to the specialized equipment and expertise required.

Safety Precautions for Laser Cutting

- Wear appropriate eye protection to shield from the laser beam.

- Ensure proper ventilation to remove fumes and gases generated during cutting.

- Avoid direct contact with the laser beam or the workpiece.

Diamond Saw Cutting

Diamond saw cutting employs a saw blade with a diamond-coated edge to cut through the tungsten. This method offers moderate precision and speed, making it suitable for general cutting applications. It is less expensive than laser cutting but still requires specialized equipment.

Safety Precautions for Diamond Saw Cutting

- Wear appropriate eye protection to shield from flying debris.

- Use a stable platform to support the workpiece and prevent it from moving during cutting.

- Ensure proper ventilation to remove dust generated during cutting.

Abrasive Cutting

Abrasive cutting utilizes a rotating abrasive wheel to grind away the tungsten material. This method offers low precision and speed, making it suitable for simple cuts and rough shaping. It is the least expensive method, requiring only basic equipment.

Safety Precautions for Abrasive Cutting

- Wear appropriate eye protection to shield from flying debris.

- Use a stable platform to support the workpiece and prevent it from moving during cutting.

- Ensure proper ventilation to remove dust generated during cutting.

- Avoid prolonged exposure to the abrasive dust.

Professional Assistance: Can You Cut A Tungsten Ring

Tungsten rings are incredibly durable and resistant to scratches, but this same strength makes them extremely difficult to cut. Attempting to cut a tungsten ring at home can be dangerous and may lead to damage to the ring, your tools, or even yourself. It’s crucial to seek professional help from a qualified jeweler to ensure a safe and successful cutting process.

Expertise of a Professional Jeweler

Professional jewelers possess the specialized knowledge, tools, and experience necessary to safely and effectively cut tungsten rings. They understand the unique properties of tungsten and have access to high-quality equipment designed for this task.

- Specialized Tools: Jewelers use specialized tools like diamond-tipped saws, laser cutters, or high-speed grinding machines to cut through the hard metal. These tools are designed to withstand the extreme pressure and friction involved in cutting tungsten.

- Knowledge of Tungsten: Jewelers have a deep understanding of tungsten’s properties, including its hardness, brittleness, and heat resistance. They know how to manipulate the metal effectively and avoid causing damage during the cutting process.

- Experience: Jewelers have years of experience working with various metals, including tungsten. This experience allows them to assess the ring’s condition, choose the appropriate cutting method, and ensure a clean and precise cut.

Consequences of Attempting to Cut a Tungsten Ring Without Professional Assistance

Attempting to cut a tungsten ring at home without professional expertise can have serious consequences. The following are some potential risks:

- Damage to the Ring: Using inappropriate tools or methods can damage the ring, leaving it unusable or requiring expensive repairs.

- Damage to Tools: Attempting to cut tungsten with tools not designed for the task can result in tool damage or breakage, potentially causing injury.

- Personal Injury: Tungsten is incredibly hard and can be difficult to cut. Attempting to cut it at home can result in serious injuries from flying debris, sharp edges, or tool malfunction.

- Ineffective Cutting: Using improper techniques or tools can lead to an incomplete or uneven cut, leaving the ring unusable or requiring further professional intervention.

Ring Sizing and Alterations

Choosing the right ring size is crucial, especially for a tungsten ring, as resizing can be challenging. A perfectly fitted ring ensures comfort and prevents potential issues.

Measuring Ring Size Accurately

Accurate ring size measurement is essential for a comfortable and well-fitting ring. Several methods can be used to determine your ring size.

- Using a Ring Sizer: This is the most accurate method. You can find ring sizers at jewelry stores or online. Simply slide the sizer onto your finger and note the corresponding size.

- Measuring with String or Tape: Wrap a piece of string or a measuring tape around the base of your finger, ensuring it’s snug but not too tight. Mark the string or tape where it meets, then measure the length against a ruler. Refer to a ring size chart to convert the measurement to your ring size.

- Measuring an Existing Ring: If you have a ring that fits well, you can use it to determine your size. Place the ring on a ruler or ring sizer and note the diameter. Use a ring size chart to find the corresponding size.

Resizing Tungsten Rings

Resizing a tungsten ring is a complex process due to the material’s hardness and durability. It’s recommended to get the ring size right the first time, as resizing may not always be possible or may result in damage to the ring.

- Limited Resizing Options: Tungsten rings can be resized, but the options are limited. Most jewelers can only resize the ring by a fraction of a size, and the process can be expensive.

- Potential for Damage: Resizing a tungsten ring requires specialized tools and techniques. The process can be risky, and there’s a chance of damage to the ring, especially if it’s a delicate or intricate design.

- Alternative Solutions: If you need to resize a tungsten ring, consider alternative solutions such as purchasing a new ring in the correct size or exploring ring bands with adjustable sizes.

Tungsten Ring Care and Maintenance

Tungsten rings are known for their durability and resistance to scratches, but they still require proper care and maintenance to maintain their beauty and longevity. Here’s a guide to help you keep your tungsten ring looking its best.

Cleaning and Polishing

Tungsten rings are relatively easy to clean. Here are some tips:

- Use a soft cloth: A microfiber cloth is ideal for removing dust, fingerprints, and everyday grime. Simply wipe the ring gently with the cloth.

- Mild soap and water: For deeper cleaning, you can use a mild dish soap and warm water. Gently scrub the ring with a soft-bristled toothbrush, then rinse thoroughly with water and dry with a soft cloth.

- Avoid harsh chemicals: Avoid using abrasive cleaners, bleach, or ammonia-based products on your tungsten ring, as these can damage the finish.

Potential Issues and Solutions

While tungsten rings are extremely durable, they can still experience some issues over time. Here are some common problems and how to address them:

- Scratches: While tungsten is scratch-resistant, deep scratches can occur. If you notice a scratch, you can try to polish it out with a fine-grit polishing cloth. However, deep scratches may require professional attention.

- Discoloration: Tungsten rings can sometimes develop a dull or discolored appearance due to exposure to chemicals or other environmental factors. To restore the shine, you can use a tungsten ring polishing cloth or have it professionally cleaned.

- Loss of Fit: Tungsten rings are generally very resistant to bending or warping, but it’s still possible for the ring to become slightly loose or tight over time. If this happens, you can have it professionally resized.

So, can you cut a tungsten ring? The answer is a resounding yes, but it’s not a simple task. While tungsten carbide is an incredibly durable material, with the right tools and expertise, it can be cut. However, due to the challenges and potential risks involved, it’s strongly advised to seek professional assistance. Remember, a professional jeweler has the experience, knowledge, and tools to ensure a safe and successful outcome.

So, the next time you find yourself with a tungsten ring that needs resizing or cutting, don’t try to tackle it yourself. Leave it to the professionals and enjoy the peace of mind that comes with knowing your ring is in good hands.

FAQ Explained

Can I cut a tungsten ring at home?

It’s not recommended. Attempting to cut a tungsten ring at home can be dangerous and may damage the ring.

What are the risks of cutting a tungsten ring?

Risks include damaging the ring, injury to yourself, and potential damage to surrounding surfaces.

How much does it cost to cut a tungsten ring?

The cost varies depending on the method used and the jeweler’s fees. Expect to pay anywhere from $50 to $150.

Can I resize a tungsten ring?

Yes, but it’s a specialized process. Tungsten rings can be resized, but it’s best to consult with a professional jeweler.