What makes wheel bearings go bad? This question, often whispered in the language of grinding and clunking, speaks to the heart of automotive reliability. Wheel bearings, those silent guardians of smooth motion, are the unsung heroes of our journeys. They carry the weight of our vehicles, absorbing the relentless forces of the road, and silently guide our wheels with unwavering precision.

But even these robust components can succumb to the relentless march of time and wear and tear.

Understanding the intricate dance between these bearings and the forces they encounter is crucial for maintaining the health of our vehicles. From the type of bearing used to the conditions they face, a myriad of factors can influence their lifespan. This exploration delves into the common causes of wheel bearing failure, providing insights into how to identify the warning signs, prevent premature wear, and ultimately, ensure a smoother, more reliable driving experience.

Understanding Wheel Bearings

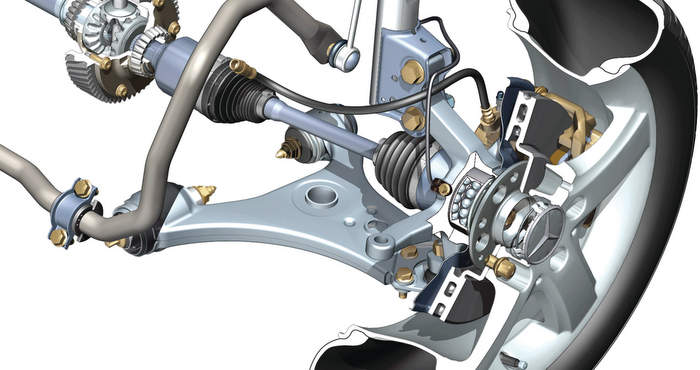

Wheel bearings are essential components in any vehicle, playing a crucial role in supporting the weight of the vehicle and allowing the wheels to rotate smoothly. They are responsible for reducing friction between the rotating wheel hub and the stationary axle, enabling smooth and efficient movement.

Types of Wheel Bearings

Wheel bearings are classified into different types based on their design and construction. The two primary types are:

- Tapered Roller Bearings: These bearings consist of tapered rollers that fit between a conical inner race and a conical outer race. They are known for their high load-carrying capacity and ability to handle both radial and axial loads. Tapered roller bearings are commonly found in heavy-duty vehicles and trucks.

- Ball Bearings: These bearings use steel balls that rotate between two races, one inner and one outer. Ball bearings are designed to handle primarily radial loads and are typically used in passenger cars and lighter vehicles.

Components of a Wheel Bearing Assembly

A typical wheel bearing assembly consists of several key components:

- Outer Race: This component is typically pressed into the hub of the wheel. It provides a smooth surface for the bearing elements to roll on.

- Inner Race: The inner race is mounted on the axle shaft. It also provides a smooth surface for the bearing elements to roll on.

- Bearing Elements: These are the rolling elements, such as balls or rollers, that facilitate smooth rotation between the inner and outer races.

- Cage: The cage is a separator that keeps the bearing elements evenly spaced and prevents them from coming into contact with each other.

- Seal: The seal is a component that prevents contaminants, such as dirt and water, from entering the bearing assembly and causing damage.

Causes of Wheel Bearing Failure

Wheel bearings, those silent workhorses in your car, play a crucial role in ensuring smooth and safe driving. But just like any mechanical component, they can wear out over time, leading to a variety of problems. Understanding the common culprits behind wheel bearing failure can help you take preventive measures and extend their lifespan.

Factors Contributing to Wheel Bearing Wear

The wear and tear on wheel bearings is a natural consequence of their function. They constantly endure the forces of weight, friction, and impact. However, certain factors can accelerate this process, leading to premature failure.

- Road Conditions: Rough roads, potholes, and uneven surfaces can exert excessive stress on wheel bearings, leading to accelerated wear. The constant jarring and impact can damage the bearing components, especially the balls or rollers.

- Driving Habits: Aggressive driving, including hard braking and cornering, can put significant strain on wheel bearings. These actions can cause the bearings to overheat, leading to premature wear and tear.

- Vehicle Load: Overloading a vehicle can place additional stress on wheel bearings, especially the front ones. The increased weight can cause the bearings to wear out faster, particularly if the vehicle is frequently carrying heavy loads.

- Environmental Factors: Exposure to harsh weather conditions, such as extreme temperatures, moisture, and dirt, can accelerate bearing wear. Moisture can corrode the bearing components, while dirt and debris can act as abrasive particles, leading to premature failure.

Premature Wheel Bearing Failure

While wear and tear are inevitable, certain conditions can significantly shorten the lifespan of wheel bearings. These conditions often involve improper maintenance or installation, or external factors that can accelerate the wear process.

- Improper Installation: Incorrect installation, such as over-tightening the bearing races or using the wrong type of grease, can lead to premature bearing failure. These errors can cause the bearing components to bind, overheat, and wear out quickly.

- Insufficient Lubrication: Wheel bearings require regular lubrication to prevent friction and wear. If the grease is old, insufficient, or contaminated, it can no longer provide adequate lubrication, leading to increased friction and premature failure.

- Corrosion: Exposure to moisture and salt can cause corrosion on the bearing components, leading to increased friction and premature failure. Regular cleaning and lubrication can help prevent corrosion.

- Damaged Components: External damage to the bearing components, such as a bent axle or a damaged hub, can cause premature failure. These issues can lead to misalignment and increased stress on the bearings.

Effects of Improper Installation and Maintenance

The consequences of improper installation and maintenance extend beyond premature bearing failure. They can also have a significant impact on the overall performance and safety of your vehicle.

- Reduced Vehicle Handling: Worn wheel bearings can cause a noticeable decrease in vehicle handling. The loose bearings can result in a wandering steering wheel, increased tire wear, and a feeling of instability.

- Noise and Vibration: A common sign of worn wheel bearings is a grinding, humming, or roaring noise, especially when turning or driving over bumps. This noise is caused by the bearing components rubbing against each other.

- Safety Risks: Severe wheel bearing failure can lead to a loss of control of the vehicle. The wheel can detach from the axle, causing a dangerous situation.

Symptoms of Bad Wheel Bearings

Your car’s wheel bearings are crucial for smooth and safe driving. They support the weight of your vehicle and allow the wheels to rotate freely. When these bearings start to fail, they can cause a variety of symptoms that can significantly impact your driving experience.

Noises Associated with Failing Wheel Bearings

When wheel bearings start to wear down, they can produce distinct noises that are often the first indication of a problem. These sounds can vary depending on the severity of the damage and the speed at which you are driving.

- Grinding Noise: A grinding noise, especially when turning or braking, is a common symptom of a failing wheel bearing. This noise is often described as a “rough” or “scratchy” sound.

- Rumbling Noise: A rumbling noise, similar to a low-pitched growl, can also be a sign of a failing wheel bearing. This noise is often more noticeable at higher speeds.

- Clicking or Popping Noise: A clicking or popping noise, especially when turning, can indicate that the wheel bearing is loose or damaged. This noise is often accompanied by a feeling of “play” in the steering wheel.

- Whistling Noise: A high-pitched whistling noise, particularly when driving at high speeds, could be a sign of a failing wheel bearing. This noise is often caused by friction between the bearing components.

Unusual Vibrations or Shaking in the Vehicle

Another common symptom of bad wheel bearings is unusual vibrations or shaking in the vehicle. These vibrations can be felt in the steering wheel, the floorboard, or even the entire vehicle.

- Steering Wheel Vibration: A noticeable vibration in the steering wheel, especially at higher speeds, is a strong indicator of a failing wheel bearing. This vibration is often accompanied by a feeling of looseness or “play” in the steering wheel.

- Floorboard Vibration: Vibrations in the floorboard, particularly on the side of the vehicle where the bad bearing is located, can also be a sign of a failing wheel bearing. This vibration is often felt as a rhythmic pulsing or shaking.

- Vehicle Shaking: In severe cases, a failing wheel bearing can cause the entire vehicle to shake or vibrate. This is a clear sign that the bearing is severely damaged and needs immediate attention.

Other Signs of Wheel Bearing Problems

In addition to noises and vibrations, there are other signs that can indicate a problem with your wheel bearings.

- Excessive Play in the Wheel: If you can move the wheel back and forth with your hand, this indicates excessive play in the wheel bearing. This play is often noticeable when you try to shake the wheel at the top and bottom.

- Uneven Tire Wear: Failing wheel bearings can cause uneven tire wear, particularly on the inside or outside edges of the tire. This is because the wheel is not rotating smoothly and evenly.

- Hot Wheels: A failing wheel bearing can generate heat, which can cause the wheel to become hot to the touch.

Preventing Wheel Bearing Failure: What Makes Wheel Bearings Go Bad

Wheel bearings are critical components in your vehicle’s suspension system, ensuring smooth and safe driving. While they are designed to withstand significant stress, wear and tear are inevitable. However, by implementing regular maintenance practices and avoiding harsh driving conditions, you can significantly extend their lifespan and prevent premature failure.

Regular Maintenance Practices

Regular maintenance plays a crucial role in preventing wheel bearing failure. By adhering to a schedule of inspections and lubrication, you can identify potential issues early on and address them before they escalate into major problems.

- Visual Inspection: Regularly inspect your wheel bearings for signs of damage, such as cracks, rust, or excessive wear. Pay attention to the condition of the seals, as they prevent contaminants from entering the bearing.

- Lubrication: Wheel bearings require regular lubrication to maintain smooth operation and prevent premature wear. Consult your vehicle’s owner’s manual for recommended lubrication intervals and the type of grease to use.

- Wheel Bearing Replacement: Over time, wheel bearings will eventually wear out and need replacement. If you notice any signs of bearing failure, such as noise or vibration, it’s important to have them inspected and replaced promptly.

Importance of High-Quality Lubricants, What makes wheel bearings go bad

Using high-quality lubricants is essential for extending the life of your wheel bearings. The right lubricant provides a protective barrier between the bearing components, reducing friction and wear.

- Grease Type: Choose a grease specifically designed for wheel bearings, as it will have the appropriate viscosity and additives to withstand the high temperatures and loads experienced in this application.

- Grease Application: Apply the grease evenly and generously to the bearing surfaces. Ensure that the grease is packed into the bearing races and seals to provide adequate lubrication.

Avoiding Harsh Driving Conditions

Harsh driving conditions can accelerate wheel bearing wear and increase the risk of failure. By minimizing exposure to these conditions, you can significantly extend the life of your bearings.

- Heavy Loads: Avoid overloading your vehicle, as excessive weight puts additional stress on the wheel bearings.

- Off-Road Driving: Driving on rough terrain can subject your wheel bearings to severe shock and vibration, increasing the risk of damage.

- High Speeds: Driving at high speeds generates increased heat and centrifugal forces, which can accelerate bearing wear.

Replacing Wheel Bearings

Replacing a failed wheel bearing is a complex procedure that requires a combination of mechanical skills, specialized tools, and a safe working environment. This process involves removing the old bearing, inspecting associated components, and installing a new bearing, ensuring proper lubrication and alignment.

Tools and Equipment

Having the right tools is crucial for a successful and safe wheel bearing replacement.

- Jack and Jack Stands: Safely lift the vehicle and secure it on jack stands to provide a stable working platform.

- Lug Wrench: Loosen and remove the lug nuts securing the wheel to the hub.

- Wheel Bearing Puller: A specialized tool designed to remove the old bearing from the hub.

- Torque Wrench: Ensure proper tightening of the lug nuts and other fasteners to the manufacturer’s specifications.

- Hammer and Chisel: Used to remove the bearing race from the hub, if necessary.

- Grease Gun: Apply fresh grease to the new bearing and other moving parts.

- Socket Set: For removing and installing various bolts and nuts.

- Breaker Bar: Used for loosening stubborn bolts and nuts.

- Pry Bar: Helps to separate components during disassembly.

- Cleaning Supplies: Thoroughly clean the hub and bearing housing before installing the new bearing.

Safety Precautions

Working on a vehicle requires prioritizing safety.

- Secure the Vehicle: Ensure the vehicle is properly supported on jack stands before starting any work underneath. Never rely solely on a jack to support the vehicle.

- Use Protective Gear: Wear safety glasses, gloves, and sturdy footwear to protect yourself from potential hazards.

- Work in a Well-Lit Area: Ensure you have adequate lighting to see clearly what you are doing.

- Be Mindful of Moving Parts: Take caution when working near rotating components like the wheel hub. Ensure the vehicle is in park and the emergency brake is engaged.

- Avoid Distractions: Focus on the task at hand and avoid distractions that could lead to accidents.

Best Practices

Following best practices ensures a successful and long-lasting repair.

- Inspect Components: Thoroughly inspect the hub, spindle, and other associated components for any signs of damage or wear. Replace any damaged parts to prevent future issues.

- Clean Thoroughly: Clean all parts before installing the new bearing. Remove any debris or old grease to ensure proper lubrication and prevent contamination.

- Use Proper Grease: Apply a generous amount of high-quality wheel bearing grease to the new bearing and other moving parts. Ensure the grease is compatible with the bearing type.

- Tighten Components to Specifications: Use a torque wrench to tighten all fasteners to the manufacturer’s specifications. Over-tightening can damage components, while under-tightening can lead to looseness and premature failure.

- Test Drive: After the repair, test drive the vehicle to ensure the new bearing is functioning properly and there are no unusual noises or vibrations.

The lifeblood of a vehicle’s smooth operation, wheel bearings are a testament to engineering prowess. Yet, like all components, they too have their limitations. Understanding the factors that contribute to their wear and tear empowers us to extend their lifespan and ensure the safety and reliability of our journeys. By embracing preventive measures, recognizing the telltale signs of trouble, and addressing issues promptly, we can ensure that our vehicles continue to roll smoothly and safely, leaving the worries of wheel bearing failure behind.

Helpful Answers

What are the most common signs of a bad wheel bearing?

The most common signs include a rumbling or grinding noise that increases with speed, a vibration in the steering wheel, or a feeling of looseness or play in the wheel.

Can I drive with a bad wheel bearing?

It is not recommended to drive with a bad wheel bearing. It can lead to further damage to the bearing and other components, potentially causing a loss of control or a dangerous situation.

How often should I have my wheel bearings inspected?

It is generally recommended to have your wheel bearings inspected every 30,000 miles or as part of your regular maintenance schedule. However, if you notice any of the warning signs of a bad bearing, you should have it inspected immediately.

What are the different types of wheel bearings?

There are two main types of wheel bearings: tapered roller bearings and ball bearings. Tapered roller bearings are more common in modern vehicles, while ball bearings are typically found in older vehicles.