Where can I get a wheel bearing replaced? This question often arises when a car owner encounters the dreaded grinding noise, a sign of a failing wheel bearing. It’s a crucial component that keeps your wheels spinning smoothly, and a worn-out bearing can lead to serious safety issues. This guide will help you navigate the process of finding a reliable mechanic, understanding the costs involved, and ensuring a smooth repair.

Think of your car’s wheel bearings as the hinges that allow your wheels to rotate freely. Just like hinges on a door, these bearings wear down over time, and when they do, you’ll notice a distinct rumbling or grinding noise, especially when turning. It’s a sign that the bearing is no longer able to handle the stress of supporting your vehicle’s weight and movement.

Ignoring this issue can lead to more serious problems, including wheel damage and even a complete loss of control.

Understanding Wheel Bearings

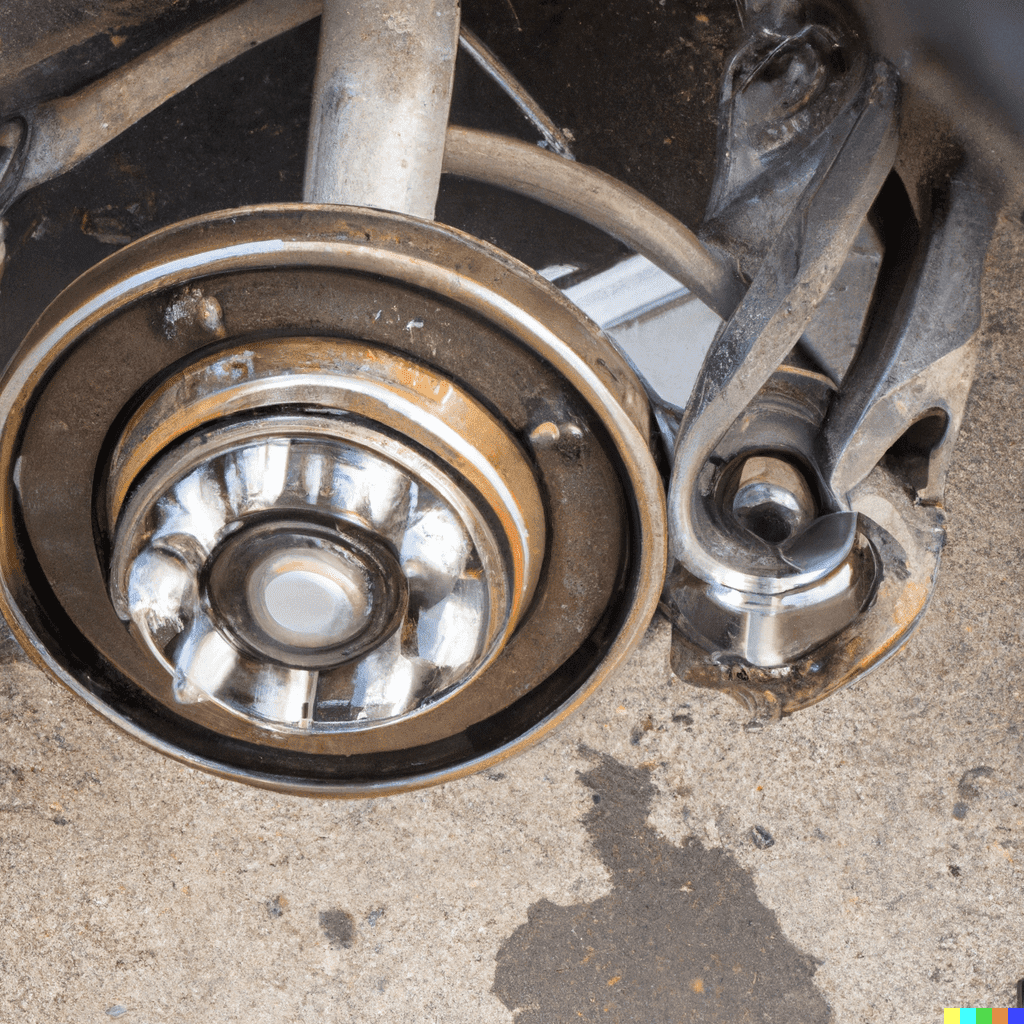

Wheel bearings are essential components in your vehicle’s suspension system, responsible for supporting the weight of your car and allowing the wheels to rotate smoothly. They act as the interface between the wheel hub and the axle, ensuring that the wheel can spin freely while maintaining proper alignment and stability.

Types of Wheel Bearings

Wheel bearings come in different types, each with its own characteristics and applications.

- Tapered Roller Bearings: These bearings are commonly used in heavy-duty vehicles and trucks. They consist of a set of tapered rollers that fit between a conical inner race and a conical outer race. This design provides high load capacity and excellent resistance to shock loads.

- Ball Bearings: Ball bearings are used in lighter vehicles, such as cars and SUVs. They consist of a set of steel balls that rotate between two races. Ball bearings are generally less expensive than tapered roller bearings, but they have a lower load capacity.

- Sealed Wheel Bearings: These bearings are pre-packed with grease and sealed to prevent contamination. They are generally maintenance-free and are becoming increasingly common in modern vehicles.

Signs of a Worn or Damaged Wheel Bearing

When wheel bearings wear out or get damaged, they can cause a range of symptoms, including:

- Grinding or roaring noise: This is often the most noticeable sign of a worn wheel bearing. The noise usually gets louder as the bearing deteriorates.

- Wobble or vibration: A worn wheel bearing can cause the wheel to wobble or vibrate, especially at higher speeds.

- Uneven tire wear: A worn wheel bearing can cause uneven tire wear, as the wheel is not rotating smoothly.

- Steering wheel pull: A worn wheel bearing can cause the steering wheel to pull to one side.

- Play in the wheel: If you can move the wheel up and down or side to side, this is a sign that the wheel bearing is worn or damaged.

Finding a Repair Shop

Finding a reliable mechanic to replace your wheel bearing can be a crucial step in ensuring a safe and smooth ride. It’s important to choose a shop that has the experience, expertise, and reputation to handle the job correctly.

Choosing a Repair Shop

It’s important to consider several factors when choosing a repair shop to replace your wheel bearing. These factors include:

- Experience: Look for a shop that has experience working on your specific vehicle make and model. Ask about their experience with wheel bearing replacements, and inquire about their success rate with similar repairs.

- Certifications: Look for shops with ASE (Automotive Service Excellence) certified technicians. ASE certification demonstrates a mechanic’s knowledge and expertise in automotive repair.

- Customer Reviews: Check online reviews from previous customers to get an idea of the shop’s reputation for quality work, customer service, and pricing.

Verifying Credentials

Once you’ve identified a few potential shops, it’s essential to verify their credentials.

- Ask for References: Request references from previous customers to confirm their satisfaction with the shop’s services.

- Check Online Resources: Use online resources like the Better Business Bureau (BBB) to check for any complaints or unresolved issues.

- Verify Licensing: Ensure the shop is properly licensed and insured to operate in your area.

Specialization in Wheel Bearings

While many repair shops can handle wheel bearing replacements, it’s beneficial to find a shop that specializes in this type of repair.

- Ask about Specific Experience: Inquire about the shop’s experience with different types of wheel bearings and their familiarity with the specific bearing needed for your vehicle.

- Check for Specialized Tools: Ask if the shop has specialized tools and equipment for replacing wheel bearings, such as bearing presses and hydraulic jacks.

Cost of Replacement

Replacing a wheel bearing can range in cost depending on several factors. These include the make and model of your vehicle, the labor costs charged by the repair shop, and the quality of the replacement part.

It’s important to note that replacing a wheel bearing is often a complex repair that requires specialized tools and knowledge. As a result, labor costs can vary significantly. It’s also essential to understand that replacing a wheel bearing may not be a standalone repair. Additional work, such as an alignment, may be necessary depending on the severity of the damage and the specific repair being performed.

Cost Breakdown

To understand the cost of replacing a wheel bearing, it’s helpful to break down the individual components:

- Part Cost: Wheel bearings can vary in price depending on the make and model of your vehicle, the quality of the part, and the source from which you purchase it. A basic wheel bearing can cost anywhere from $30 to $100, while premium parts can cost upwards of $200.

- Labor Cost: Labor costs for replacing a wheel bearing can vary significantly depending on the location of the repair shop, the experience of the mechanic, and the complexity of the repair. Labor costs can range from $100 to $300 or more.

Purchasing Parts

You have several options for purchasing replacement parts, each with its own advantages and disadvantages:

- Dealerships: Dealerships typically offer genuine OEM (Original Equipment Manufacturer) parts, which are designed specifically for your vehicle. However, these parts are often more expensive than aftermarket parts.

- Auto Parts Stores: Auto parts stores offer a wide selection of aftermarket parts at a lower price than dealerships. However, the quality of aftermarket parts can vary, so it’s important to choose a reputable brand.

- Online Retailers: Online retailers offer a convenient way to purchase parts, often at competitive prices. However, it’s important to ensure that the retailer is reputable and that the parts are compatible with your vehicle.

Additional Costs

In addition to the cost of the part and labor, there may be additional costs associated with replacing a wheel bearing. These costs can include:

- Alignment: After replacing a wheel bearing, it’s often necessary to have your vehicle’s wheels aligned to ensure proper handling and tire wear. Alignment costs can range from $50 to $150.

- Other Repairs: In some cases, replacing a wheel bearing may reveal other underlying problems with your vehicle’s suspension or braking system. These problems may require additional repairs, which can add to the overall cost.

The Repair Process

Replacing a wheel bearing is a complex procedure that requires specialized tools and knowledge. It involves removing the old bearing, installing the new one, and ensuring proper alignment and balancing of the wheel. This process is essential for maintaining the safety and smooth operation of your vehicle.

Removing the Old Bearing

The first step in replacing a wheel bearing is to remove the old one. This process typically involves:

- Jacking up the vehicle and securing it with jack stands.

- Removing the wheel.

- Removing the brake caliper and rotor.

- Removing the hub assembly from the axle.

- Using a bearing puller to remove the old bearing from the hub assembly.

It is crucial to be careful during this process to avoid damaging the axle or other components.

Installing the New Bearing

Once the old bearing is removed, the new one can be installed. This process typically involves:

- Cleaning the hub assembly and axle shaft thoroughly.

- Applying grease to the new bearing and race.

- Pressing the new bearing into the hub assembly using a bearing press.

- Installing the hub assembly onto the axle shaft.

- Re-installing the brake rotor, caliper, and wheel.

It is essential to use the correct type of bearing press and ensure that the new bearing is properly seated.

Adjusting the Wheel Bearing Preload

After installing the new bearing, it is important to adjust the wheel bearing preload. This refers to the amount of tension applied to the bearing when the wheel is in place.

- The preload must be within the manufacturer’s specifications to ensure proper operation and prevent premature bearing failure.

- This adjustment is typically done by tightening the axle nut to a specific torque value.

- A torque wrench is essential for this step, as it ensures that the nut is tightened to the correct amount.

Alignment and Wheel Balancing

After replacing a wheel bearing, it is essential to have the vehicle’s wheels aligned and balanced.

- Wheel alignment ensures that the wheels are properly positioned relative to each other and the vehicle’s frame.

- Wheel balancing ensures that the weight of each wheel is evenly distributed.

- Both alignment and balancing are crucial for safe and smooth driving, as they help to prevent uneven tire wear and improve handling.

Potential Complications

While replacing a wheel bearing is a relatively straightforward procedure, there are some potential complications that may arise.

- The bearing may be damaged during removal or installation, requiring replacement.

- The axle shaft or hub assembly may be damaged, requiring repair or replacement.

- The brake system may need to be bled after the repair.

To avoid these complications, it is essential to have the repair performed by a qualified mechanic who has experience with wheel bearing replacement.

Preventive Maintenance

Just like any other car part, wheel bearings need proper care to ensure they last as long as possible. Neglecting maintenance can lead to premature wear and tear, resulting in costly repairs and potential safety hazards. By following a few simple steps, you can significantly extend the life of your wheel bearings and avoid unexpected breakdowns.

Regular Inspections

Regularly inspecting your wheel bearings is crucial for detecting early signs of wear and tear. This helps you address issues before they escalate into major problems. Here’s what to look for during your inspections:

- Unusual noises: Listen for any grinding, humming, or roaring sounds, especially when turning or driving at higher speeds. These noises often indicate worn-out bearings.

- Vibration: If you feel a vibration in the steering wheel or through the vehicle, it could be a sign of a damaged bearing.

- Play in the wheel: Check for excessive movement in the wheel when you try to shake it back and forth. If you notice any significant play, it’s a clear indication that the bearing needs replacement.

- Grease leaks: Inspect the wheel hub for any signs of grease leakage. This indicates that the bearing seal is damaged and needs attention.

It’s recommended to perform a visual inspection of your wheel bearings at least once a month. If you notice any of these signs, take your car to a trusted mechanic for a professional inspection and repair.

Proper Lubrication

Proper lubrication is vital for the smooth operation and longevity of your wheel bearings. The grease inside the bearing helps reduce friction and wear.

- Type of grease: Use a high-quality grease specifically designed for wheel bearings. Consult your vehicle’s owner’s manual for the recommended grease type.

- Grease frequency: The frequency of greasing depends on the type of bearing and driving conditions. Typically, it’s recommended to repack the bearings with fresh grease every 30,000 to 50,000 miles.

- Grease application: When greasing your wheel bearings, make sure to pack the grease evenly and completely fill the bearing cavity. Avoid over-greasing, as it can cause damage to the bearing.

Regularly greasing your wheel bearings ensures proper lubrication and reduces friction, which can significantly extend their lifespan.

Avoiding Harsh Driving Conditions

Harsh driving conditions can accelerate wear and tear on your wheel bearings. Here are some tips to minimize stress on your bearings:

- Avoid potholes: Hitting potholes can put immense stress on your wheel bearings, potentially causing damage.

- Reduce heavy loads: Carrying heavy loads can increase the pressure on your wheel bearings, leading to faster wear.

- Minimize off-road driving: Driving off-road exposes your wheel bearings to dirt, debris, and harsh terrain, which can cause premature wear.

- Avoid excessive braking: Frequent hard braking can generate excessive heat, which can damage your wheel bearings.

By driving cautiously and avoiding harsh conditions, you can significantly reduce the wear and tear on your wheel bearings and extend their lifespan.

Using High-Quality Parts, Where can i get a wheel bearing replaced

Choosing high-quality wheel bearings is crucial for their long-term performance and reliability.

- OEM parts: Original Equipment Manufacturer (OEM) parts are designed specifically for your vehicle and are generally of high quality. They are typically more expensive but offer the best fit and performance.

- Aftermarket parts: Aftermarket parts are manufactured by companies other than the original car manufacturer. They can be a more affordable option, but it’s important to choose reputable brands with a good track record.

- Bearing materials: Wheel bearings are typically made of steel or ceramic. Ceramic bearings are known for their superior performance and durability, but they are also more expensive.

Investing in high-quality wheel bearings can save you money in the long run by preventing premature failures and costly repairs.

Maintenance Schedules

Following manufacturer recommendations for maintenance schedules is essential for keeping your wheel bearings in optimal condition.

- Owner’s manual: Consult your vehicle’s owner’s manual for the recommended maintenance intervals for your wheel bearings.

- Service reminders: Many vehicles have service reminders that alert you when it’s time for routine maintenance, including wheel bearing inspections and greasing.

- Professional inspections: Regularly schedule professional inspections with a trusted mechanic to ensure your wheel bearings are in good working order.

Adhering to these schedules can help prevent costly repairs and ensure the safety and reliability of your vehicle.

Expected Lifespan of Different Wheel Bearing Types

| Bearing Type | Expected Lifespan (Miles) |

|---|---|

| Tapered Roller Bearings | 50,000 – 100,000 |

| Ball Bearings | 30,000 – 70,000 |

| Ceramic Bearings | 100,000 – 150,000 |

These are just estimates, and the actual lifespan can vary depending on factors such as driving conditions, maintenance practices, and the quality of the bearings.

Finding a trusted mechanic, understanding the costs involved, and ensuring a smooth repair process are essential when it comes to replacing your wheel bearings. Remember, preventative maintenance, such as regular inspections and lubrication, can significantly extend the lifespan of your wheel bearings. By taking proactive steps, you can ensure a safe and enjoyable driving experience.

Helpful Answers: Where Can I Get A Wheel Bearing Replaced

What are the signs of a bad wheel bearing?

Besides the grinding noise, you might notice a vibration in the steering wheel, a feeling of looseness in the steering, or a pulling sensation when driving straight.

How long does it take to replace a wheel bearing?

The time required for a wheel bearing replacement can vary depending on the vehicle and the complexity of the job. It can take anywhere from a couple of hours to a full day.

Can I replace a wheel bearing myself?

While it’s possible to replace a wheel bearing yourself, it’s a complex task that requires specialized tools and knowledge. It’s generally recommended to have a qualified mechanic perform the repair.

What kind of warranty do I get on a new wheel bearing?

The warranty on a new wheel bearing will vary depending on the manufacturer and the retailer. Some parts come with a 1-year warranty, while others may have a lifetime warranty.