Can wheel bearing cause vibration? This question, while seemingly simple, delves into a complex world of automotive mechanics. Imagine a vehicle cruising down the road, its tires humming in perfect harmony with the asphalt. Suddenly, a rhythmic tremor begins to shake the car, a telltale sign that something is amiss. This unsettling vibration could be the result of a failing wheel bearing, a component that plays a crucial role in ensuring smooth and safe driving.

Understanding the intricate workings of wheel bearings and the subtle clues they offer when in distress can be the key to preventing potentially dangerous situations.

Wheel bearings, often overlooked but essential, act as the silent guardians of your vehicle’s wheels. They are the bearings that allow the wheels to rotate freely and smoothly, preventing friction and wear. A faulty wheel bearing can lead to a cascade of problems, including vibration, noise, and even loss of control. Recognizing the early warning signs of a failing wheel bearing is paramount, as it can help you address the issue before it escalates into a major safety hazard.

Diagnosing Wheel Bearing Vibration

Diagnosing a wheel bearing as the source of vibration requires a systematic approach to pinpoint the issue accurately. By understanding the symptoms, conducting a thorough inspection, and using appropriate tools, you can effectively determine if a faulty wheel bearing is causing the vibration.

Tools and Equipment

To effectively diagnose wheel bearing vibration, certain tools and equipment are essential. These tools assist in inspecting the wheel bearing and its components, enabling you to identify potential issues.

- Jack and Jack Stands: These are necessary to safely lift the vehicle and provide access to the wheel and suspension components.

- Lug Wrench: This tool is used to remove the lug nuts securing the wheel to the hub.

- Torque Wrench: After removing the lug nuts, a torque wrench ensures the proper tightening of the lug nuts to the manufacturer’s specifications.

- Pry Bar: A pry bar can be used to gently tap on the wheel hub to check for play or looseness in the wheel bearing.

- Inspection Mirror: A small inspection mirror can be helpful to see the condition of the wheel bearing and surrounding components.

- Digital Multimeter: While not always necessary, a digital multimeter can be used to test the electrical components associated with the wheel bearing, such as the wheel speed sensor.

Step-by-Step Guide for Diagnosing Wheel Bearing Vibration

To diagnose wheel bearing vibration effectively, follow these steps:

- Inspect the Wheel and Tire: Start by visually inspecting the wheel and tire for any signs of damage, wear, or uneven tire wear. These could indicate other issues contributing to the vibration.

- Check for Play in the Wheel Bearing:

- Safely lift the vehicle using a jack and jack stands.

- Remove the wheel.

- Gently grasp the top and bottom of the tire and try to move it in and out, or side to side. If you feel excessive play or looseness, this indicates a potential issue with the wheel bearing.

- Listen for Noise:

- With the wheel removed, rotate the tire by hand and listen for any grinding, roaring, or clicking sounds. These noises are often associated with a damaged wheel bearing.

- Inspect the Wheel Bearing:

- If you can visually inspect the wheel bearing, look for any signs of damage, wear, or corrosion.

- Examine the seals and grease to ensure they are intact and properly lubricated.

- Road Test:

- After inspecting the wheel bearing, take the vehicle for a test drive. Pay close attention to the vibration. Does it occur at specific speeds or when turning?

- If the vibration is more pronounced at higher speeds, it’s more likely a wheel bearing issue.

Impact of Vibration on Vehicle: Can Wheel Bearing Cause Vibration

Ignoring a vibrating wheel bearing can lead to a cascade of problems that can significantly impact your vehicle’s safety and performance. It’s crucial to address this issue promptly to avoid potential hazards and costly repairs.

Consequences of Neglecting a Vibrating Wheel Bearing

The consequences of neglecting a vibrating wheel bearing can be severe, ranging from discomfort to serious safety risks. Here’s a breakdown of the potential issues:

- Increased Vibration and Noise: As the bearing deteriorates, the vibration and noise will intensify, making driving unpleasant and potentially distracting.

- Premature Wear and Tear on Other Components: The vibration can stress other components of the suspension and drivetrain, leading to premature wear and tear, requiring additional repairs.

- Loss of Control: A severely damaged bearing can cause the wheel to seize, resulting in a sudden loss of control, increasing the risk of accidents.

- Wheel Separation: In extreme cases, a completely failed bearing can cause the wheel to detach from the vehicle, leading to a catastrophic accident.

Risks Associated with Driving with a Faulty Wheel Bearing, Can wheel bearing cause vibration

Driving with a faulty wheel bearing presents significant safety risks, putting both the driver and other road users in danger. Here’s a closer look at the risks:

- Loss of Steering Control: A damaged bearing can affect the steering mechanism, making it difficult to control the vehicle’s direction.

- Uneven Tire Wear: Vibration can cause uneven tire wear, leading to reduced traction and handling.

- Increased Braking Distance: A faulty bearing can affect the braking system, leading to increased stopping distances and reduced braking effectiveness.

- Accident Risk: The combination of reduced control, uneven tire wear, and increased braking distances significantly increases the risk of accidents.

Impact on Vehicle Safety and Performance

A vibrating wheel bearing directly affects vehicle safety and performance in multiple ways. Here’s a detailed explanation:

- Safety:

- Loss of Control: A damaged bearing can cause the wheel to lock up or seize, leading to a sudden loss of steering control.

- Increased Braking Distance: Vibration can affect the braking system, resulting in longer braking distances and reduced stopping power.

- Wheel Separation: A completely failed bearing can cause the wheel to detach from the vehicle, posing a serious safety hazard.

- Performance:

- Reduced Fuel Efficiency: Vibration can increase drag and resistance, leading to decreased fuel efficiency.

- Uneven Tire Wear: Vibration can cause uneven tire wear, affecting traction and handling.

- Increased Noise and Discomfort: The constant vibration and noise can be distracting and uncomfortable for the driver and passengers.

Solutions for Wheel Bearing Vibration

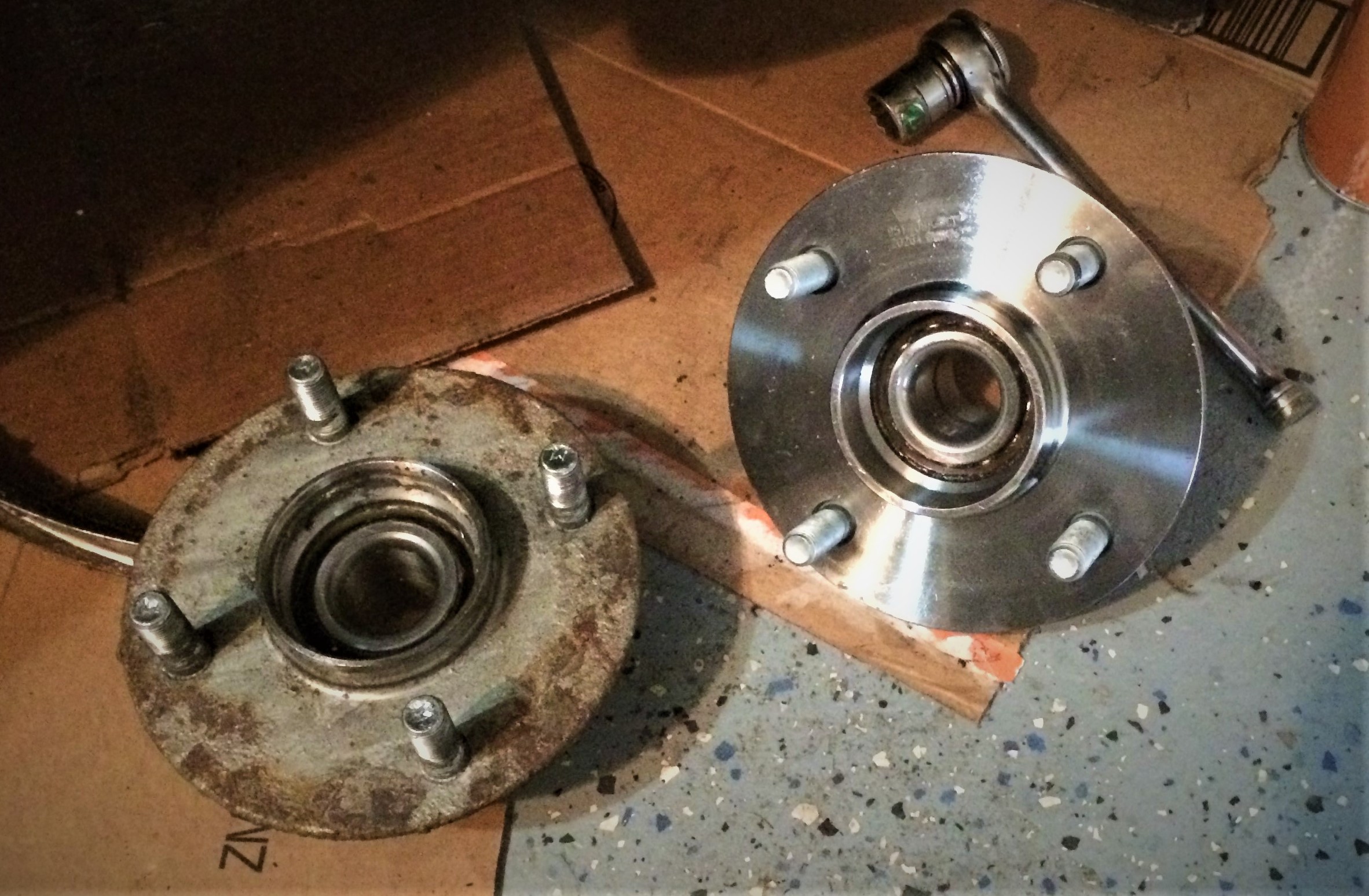

The only way to resolve the vibration caused by a failing wheel bearing is to replace it. While there might be temporary fixes like tightening the bearing or adding grease, these solutions are not permanent and can even worsen the problem. Replacing the wheel bearing is the most effective and permanent solution to eliminate the vibration and ensure the safety and stability of your vehicle.

Replacing a Failing Wheel Bearing

Replacing a wheel bearing is a relatively straightforward process, but it requires specialized tools and a certain level of mechanical expertise. It involves removing the old bearing and installing a new one.

Tools and Equipment

- Jack and jack stands

- Lug wrench

- Wheel bearing race and seal remover

- Wheel bearing race and seal installer

- Torque wrench

- Hammer

- Socket set

- Pry bar

- Grease gun

- New wheel bearing

Steps for Replacing a Wheel Bearing

- Raise and Secure the Vehicle: Use a jack to lift the vehicle and secure it with jack stands. Ensure the vehicle is stable and safe before proceeding.

- Remove the Wheel: Remove the lug nuts using a lug wrench and take off the wheel.

- Remove the Brake Caliper: Remove the brake caliper and hang it securely using a wire or rope to prevent damage to the brake hose.

- Remove the Rotor: Remove the rotor, which is attached to the wheel hub. It might be necessary to use a hammer and a pry bar to loosen it.

- Remove the Old Bearing: Use a wheel bearing race and seal remover to remove the old bearing from the hub. This tool helps to safely and efficiently remove the bearing without damaging the hub.

- Clean the Hub: Clean the hub thoroughly using a wire brush or a cleaning cloth to remove any dirt or debris. This ensures a smooth surface for the new bearing.

- Install the New Bearing: Use a wheel bearing race and seal installer to press the new bearing onto the hub. This tool ensures the bearing is properly seated and secured in place.

- Install the Rotor: Reinstall the rotor and tighten it securely. Make sure it is properly aligned with the hub.

- Install the Brake Caliper: Reinstall the brake caliper and tighten the bolts. Make sure the caliper is properly positioned and secured.

- Install the Wheel: Install the wheel and tighten the lug nuts using a torque wrench to the manufacturer’s specifications.

- Lower the Vehicle: Lower the vehicle and remove the jack stands. Make sure the vehicle is safely on the ground before proceeding.

- Test Drive: Take the vehicle for a test drive to ensure the vibration is gone. If the vibration persists, there might be another issue, and further diagnosis is required.

As we journey through the intricate workings of wheel bearings and the subtle signs they reveal when in distress, a crucial message emerges: never underestimate the importance of maintaining your vehicle’s health. A slight vibration, a faint humming, or a disconcerting wobble could be the first whispers of a failing wheel bearing. Heeding these early warnings can save you from potential danger and costly repairs down the road.

So, the next time you feel a tremor beneath your feet while driving, take a moment to reflect on the silent guardians that keep your wheels turning, and ensure their well-being for a smooth and safe journey.

Essential FAQs

What are the most common causes of wheel bearing failure?

Common causes include wear and tear, damage from road debris, improper installation, and lack of lubrication.

How often should I have my wheel bearings inspected?

It’s recommended to have your wheel bearings inspected during regular maintenance checks, typically every 50,000 to 75,000 miles.

Can I drive with a vibrating wheel bearing?

While it might be tempting to ignore a vibrating wheel bearing, it’s strongly advised against. Driving with a faulty bearing can worsen the problem, potentially leading to a catastrophic failure.