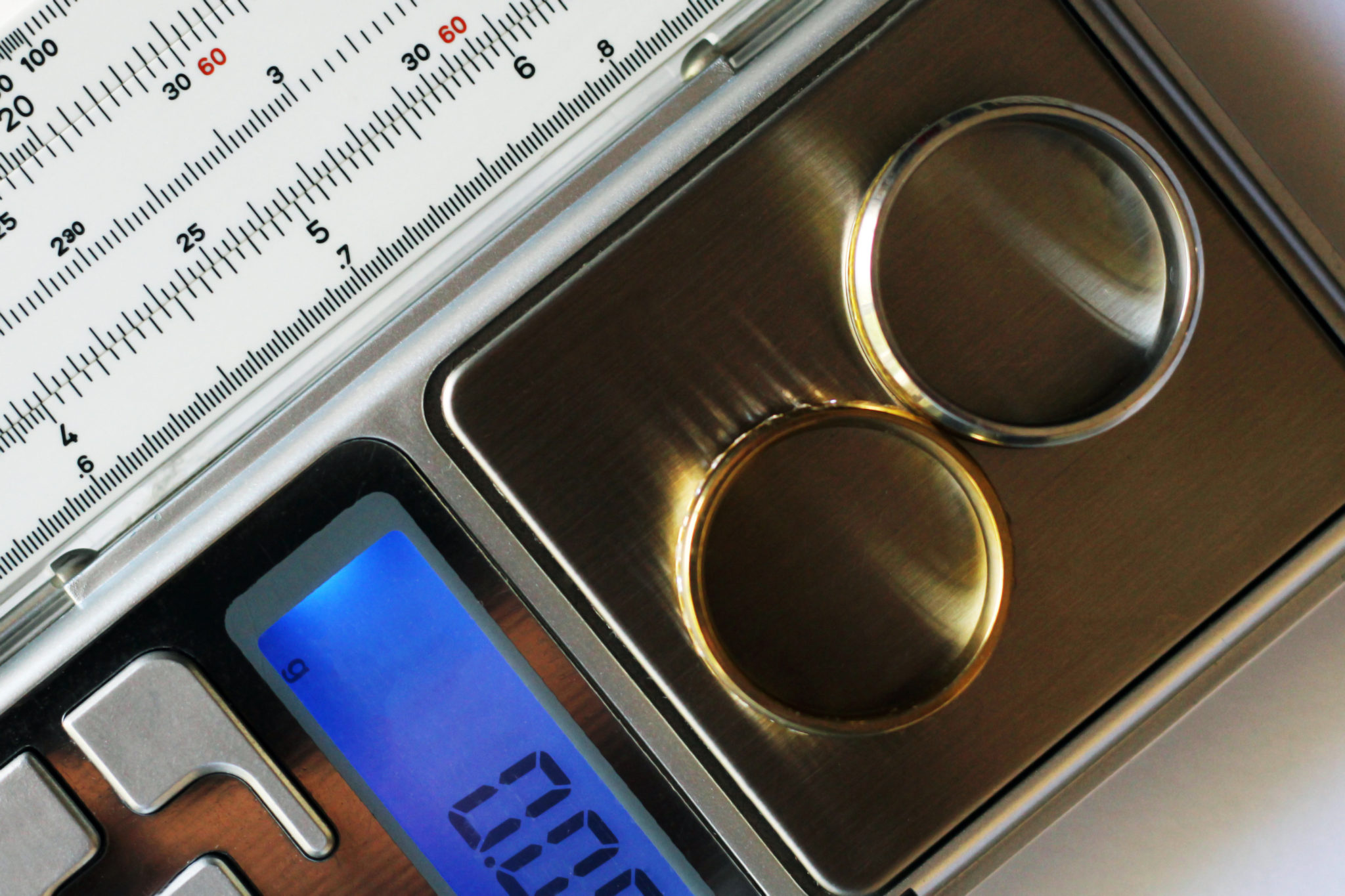

Can a tungsten ring be cut off? This question often arises when faced with a stuck ring, a common dilemma given the metal’s exceptional hardness. Tungsten carbide, the material used in these rings, boasts incredible durability, resisting scratches and even traditional ring cutters. However, specialized tools and techniques have emerged to address this challenge, ensuring safe and effective removal.

The strength of tungsten carbide stems from its unique properties. Its density and melting point are significantly higher than other metals, making it incredibly resistant to bending and breaking. This resilience, while desirable for jewelry, can pose difficulties when removing a ring.

Tungsten Ring Properties

Tungsten carbide is a popular material for jewelry, especially rings, due to its exceptional hardness, durability, and resistance to scratches. Its unique properties make it an ideal choice for those seeking a long-lasting and aesthetically pleasing ring.

Hardness and Durability

Tungsten carbide is known for its extreme hardness, ranking 9 out of 10 on the Mohs Hardness Scale, second only to diamond. This hardness translates to exceptional durability, making tungsten carbide rings highly resistant to scratches, dents, and wear.

Specific Gravity and Density

Tungsten carbide has a specific gravity of approximately 15.6, meaning it is denser than most other metals. Its high density contributes to its weight, making tungsten carbide rings feel substantial and luxurious.

The density of tungsten carbide is approximately 15.6 g/cm3, which is significantly higher than other commonly used metals like gold (19.3 g/cm 3), silver (10.5 g/cm 3), and platinum (21.45 g/cm 3).

Melting Point and Resistance to Scratching

Tungsten carbide has an exceptionally high melting point of approximately 2,870°C (5,200°F), making it highly resistant to heat and melting. Its resistance to scratching and wear is attributed to its strong atomic bonds, which create a rigid and durable structure.

Cutting Methods

Cutting a tungsten ring presents a unique challenge due to its extreme hardness and durability. Traditional ring cutters, designed for softer metals, often struggle to make a clean cut through tungsten. However, specialized tools and techniques have been developed to effectively cut tungsten rings.

Traditional Ring Cutters

Traditional ring cutters, commonly used for gold and silver rings, rely on a cutting blade that shears through the metal. However, tungsten’s high hardness and tensile strength make it resistant to this method. The blade often slips or dulls quickly, rendering the cutter ineffective. While traditional cutters might leave a mark or a shallow groove on a tungsten ring, they are unlikely to completely sever it.

Specialized Tools for Cutting Tungsten Rings

Specialized tools designed for cutting tungsten rings utilize different approaches to overcome the material’s hardness. These tools are generally more expensive than traditional ring cutters but offer a higher success rate.

Diamond-Tipped Saws

Diamond-tipped saws are specifically designed for cutting hard materials like tungsten. The saw blade features a thin, abrasive diamond coating that can effectively cut through the metal. The saw’s rotation and the diamond coating’s abrasiveness allow for a precise and clean cut.

Laser Cutting

Laser cutting uses a focused beam of high-intensity light to melt and vaporize the tungsten material. This method is highly precise and can create intricate cuts. Laser cutting is often used for industrial applications but can also be employed for cutting tungsten rings. However, it requires specialized equipment and expertise.

Specialized Pliers

Specialized pliers designed for cutting tungsten rings feature hardened jaws and a unique gripping mechanism. These pliers are designed to apply significant pressure and force to the ring, gradually cutting through the material. The process may require multiple applications of force, and the resulting cut may not be as clean as other methods.

Comparison of Cutting Methods

| Method | Effectiveness | Advantages | Disadvantages |

|---|---|---|---|

| Traditional Ring Cutters | Ineffective | Low cost | May damage the ring, unlikely to completely cut through |

| Diamond-Tipped Saws | Highly effective | Precise, clean cut | Requires specialized equipment, may be expensive |

| Laser Cutting | Highly effective | Precise, clean cut, can create intricate designs | Requires specialized equipment and expertise, may be expensive |

| Specialized Pliers | Moderately effective | Relatively affordable | May not create a clean cut, requires multiple applications of force |

Safety Considerations

Cutting a tungsten ring poses inherent risks, necessitating careful consideration of safety protocols and equipment to prevent injuries. The high hardness and density of tungsten make it difficult to cut, requiring specialized tools and techniques. Proper safety measures are essential to minimize the risk of accidents.

Potential Hazards

Cutting a tungsten ring can expose individuals to various hazards, including:

- Sharp Edges: The cutting process can create sharp edges on the ring, posing a risk of cuts or punctures.

- Flying Debris: The force of cutting can cause small pieces of tungsten to fly off, potentially injuring eyes or skin.

- Heat Generation: Cutting tungsten generates heat, which can cause burns if not handled carefully.

- Tool Failure: Improper tools or techniques can lead to tool failure, resulting in broken tools or flying debris.

- Dust Inhalation: Cutting tungsten can generate fine dust particles that can be inhaled, potentially causing respiratory problems.

Safety Protocol

To ensure safety during the cutting process, a comprehensive safety protocol should be followed:

- Wear Protective Gear: Always wear safety glasses, gloves, and a dust mask to protect against flying debris, sharp edges, and dust inhalation.

- Secure Work Area: Work in a well-ventilated area with a stable work surface to prevent accidents caused by slipping or falling objects.

- Use Appropriate Tools: Employ tools specifically designed for cutting tungsten, ensuring they are in good working condition.

- Avoid Excessive Force: Apply steady pressure during cutting, avoiding sudden forceful movements that could lead to tool failure or flying debris.

- Take Breaks: Regular breaks during the cutting process can help prevent fatigue and improve focus, reducing the risk of accidents.

- Proper Disposal: Dispose of cutting debris safely, ensuring it does not pose a hazard to others.

Essential Safety Equipment

Essential safety equipment for cutting a tungsten ring includes:

- Safety Glasses: Protect eyes from flying debris.

- Gloves: Protect hands from sharp edges and heat generated during cutting.

- Dust Mask: Prevent inhalation of fine tungsten dust particles.

- Cutting Tool: A specialized tool designed for cutting tungsten, such as a tungsten ring cutter or a diamond-tipped saw.

- Work Surface: A stable and secure surface to prevent accidents caused by slipping or falling objects.

- First Aid Kit: Available in case of minor injuries.

Alternative Solutions: Can A Tungsten Ring Be Cut Off

While cutting a tungsten ring is generally not recommended due to the material’s hardness and potential safety risks, there are alternative solutions to remove a ring that has become too tight. These methods focus on adjusting the ring or reducing swelling, providing a safer approach than cutting.

Using Lubricant or Soap

Applying a lubricant, such as soap or hand lotion, can help to reduce friction between the ring and the finger, making it easier to slide off. This method is particularly effective if the ring is slightly tight but not significantly constricting blood flow.

- Wash your hands thoroughly with soap and water. This will help to lubricate the ring and your finger.

- Apply a generous amount of soap or lotion to the ring and the affected finger.

- Gently twist or rotate the ring while simultaneously pulling it towards the tip of your finger.

- Continue applying lubricant as needed, and be patient as you try to slide the ring off.

Using a Ring Sizer

A ring sizer is a tool designed to adjust the size of rings, including tungsten rings. This method involves gently stretching or compressing the ring to make it slightly larger or smaller.

- Locate a reputable jeweler who offers ring sizing services.

- Bring the ring to the jeweler for inspection and assessment.

- The jeweler will use specialized tools to resize the ring, taking into account the material and design of the ring.

- Ensure the jeweler has experience with resizing tungsten rings, as it requires specialized techniques and equipment.

Gently Twisting or Rotating the Ring

If the ring is only slightly tight, you might be able to remove it by gently twisting or rotating it. This method relies on the slight elasticity of the ring and the possibility of a small gap between the ring and your finger.

- Start by gently twisting the ring in one direction, while simultaneously pulling it towards the tip of your finger.

- If this doesn’t work, try twisting in the opposite direction.

- Be careful not to apply excessive force, as this could damage the ring or your finger.

- If the ring is stuck, stop and seek professional help from a jeweler or emergency medical personnel.

Professional Assistance

When faced with a tungsten ring stuck on a finger, seeking professional help is the safest and most effective approach. Attempting to remove the ring yourself can lead to injury and complications.

Professional jewelers and emergency medical personnel possess the specialized tools, expertise, and knowledge to safely remove a tungsten ring without causing harm.

Jeweler’s Procedures

Jewelers have the necessary tools and experience to remove tungsten rings. They can use specialized techniques like ring cutters, which are designed to cut through tungsten without damaging the finger.

Here’s a typical procedure at a jeweler’s shop:

- The jeweler will assess the situation and determine the best course of action.

- They will use a ring cutter to carefully cut the ring at the base of the finger.

- The jeweler will then remove the ring with a pair of pliers.

- Once the ring is removed, the jeweler may smooth the edges of the cut to prevent any discomfort.

Potential Risks of Removing a Tungsten Ring Without Professional Assistance, Can a tungsten ring be cut off

Attempting to remove a tungsten ring on your own can be dangerous and lead to serious complications.

Here are some potential risks:

- Injury to the finger: Using improper tools or techniques can cause cuts, bruises, or even broken bones.

- Tissue damage: Attempting to force the ring off can cause damage to the soft tissues of the finger, leading to swelling, pain, and infection.

- Circulatory compromise: If the ring is too tight, it can restrict blood flow to the finger, leading to numbness, tingling, and even permanent damage.

- Amputation: In extreme cases, if the ring is not removed quickly, it can lead to tissue death and amputation of the finger.

While tungsten rings may seem impossible to remove, various solutions exist, ranging from specialized tools to professional assistance. Understanding the properties of tungsten carbide and the available cutting methods empowers individuals to make informed decisions regarding ring removal. Remember, safety should always be prioritized, and seeking professional help when necessary is crucial.

Frequently Asked Questions

What are the most common reasons for needing to remove a tungsten ring?

Common reasons include swelling due to injury or medical conditions, ring size changes, and accidental trapping of the ring.

Can I use a lubricant like soap to remove a tungsten ring?

While lubricants can sometimes help, they are unlikely to be effective for tungsten rings due to their tight fit and the metal’s resistance.

Is it safe to attempt removing a tungsten ring myself?

Attempting to remove a tungsten ring without proper tools and knowledge can be dangerous. Consult a professional for safe and effective removal.