How much to replace wheel studs? This question arises when you notice a wobble in your steering wheel, a persistent clunking sound, or even a loose wheel. These are signs that your vehicle’s wheel studs, those vital components that hold your wheels in place, might be nearing the end of their service life. Replacing them is crucial for your safety, but the cost can vary depending on several factors, from your vehicle’s make and model to the number of studs needing replacement.

Let’s delve into the world of wheel studs, exploring their importance, the telltale signs of damage, and the cost considerations involved in restoring your vehicle’s stability.

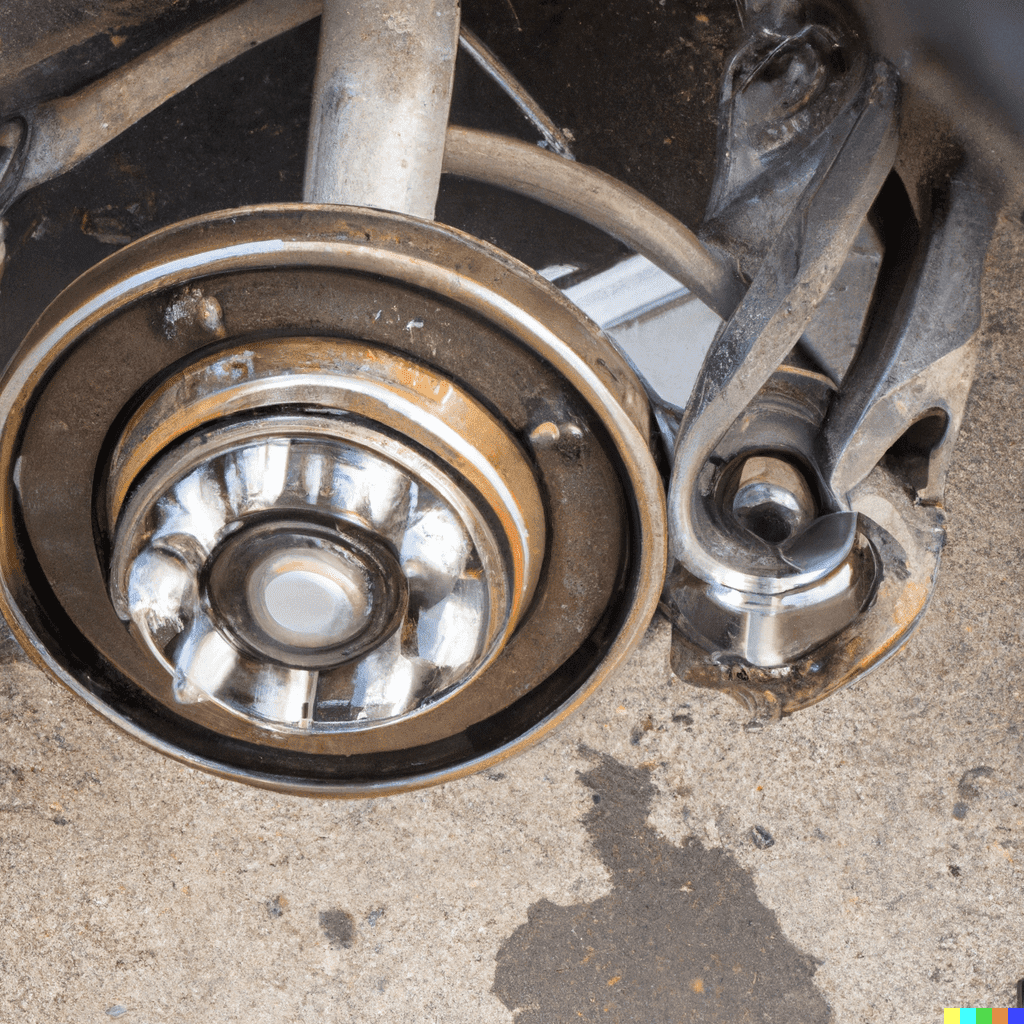

Wheel studs are the unsung heroes of your vehicle’s suspension system. They are the sturdy metal pins that anchor your wheels to the hub, ensuring a secure connection that keeps your vehicle safe and stable on the road. Understanding their function, the different types available, and the potential consequences of driving with faulty studs is crucial for every driver.

We’ll explore the factors that influence the cost of replacement, including labor, the number of studs needing replacement, and the type of vehicle. You’ll also learn how to identify signs of wear and tear, whether it’s time to call a professional, or if you can tackle the replacement yourself.

Understanding Wheel Studs: How Much To Replace Wheel Studs

Wheel studs are essential components of a vehicle’s suspension system, playing a crucial role in securely attaching the wheels to the vehicle. They are responsible for transferring the vehicle’s weight and forces from the wheel to the hub, ensuring safe and stable driving.

Types of Wheel Studs

Wheel studs are available in various types, each with its own characteristics and applications. The choice of wheel stud type depends on the specific vehicle model, wheel size, and driving conditions.

- Standard Wheel Studs: These are the most common type of wheel studs, typically made from steel. They are cost-effective and suitable for most vehicles.

- Extended Wheel Studs: These studs are longer than standard studs, providing additional clearance for thicker wheel spacers or larger wheels. They are commonly used in off-road vehicles or when upgrading to larger wheels.

- Chrome Wheel Studs: These studs are made from chrome-plated steel, offering a more aesthetically pleasing appearance. They are often used on vehicles with custom wheels or for a more polished look.

- Forged Wheel Studs: These studs are made from high-strength steel and are designed to withstand higher stress levels. They are often used in performance vehicles or for applications requiring increased durability.

- Aluminum Wheel Studs: These studs are made from aluminum, offering a lighter weight alternative to steel studs. They are often used in racing applications or for weight reduction.

Wheel Studs vs. Lug Nuts

While both wheel studs and lug nuts are essential for securing the wheels, they serve different purposes.

Wheel studs are threaded rods that protrude from the wheel hub, while lug nuts are threaded nuts that screw onto the wheel studs.

The wheel studs provide a fixed point for the lug nuts to engage, ensuring a secure connection between the wheel and the hub. The lug nuts act as a clamping force, tightening the wheel onto the studs and maintaining a secure connection.

Determining the Need for Replacement

Wheel studs are essential components of your vehicle’s suspension system, connecting the wheels to the hubs. Over time, these studs can experience wear and tear, potentially leading to safety hazards. Recognizing the signs of damaged or worn wheel studs is crucial to ensure safe driving and prevent accidents.

Signs of Worn or Damaged Wheel Studs

Recognizing the signs of worn or damaged wheel studs is crucial to ensure safe driving and prevent accidents.

- Visible damage: Inspect the studs for any signs of bending, cracking, or rust. Bent or cracked studs are structurally compromised and can easily break, leading to wheel detachment. Excessive rust can weaken the stud’s strength and make it prone to failure.

- Loose wheel: A loose wheel is a clear indicator of a potential problem with the wheel studs. If you notice excessive play or movement in the wheel, it could indicate a worn or damaged stud.

- Unusual noises: Grinding or rattling noises while driving can indicate a loose wheel or a damaged stud. These sounds are often caused by the wheel contacting the brake rotor or other suspension components.

- Uneven tire wear: If you notice uneven tire wear, especially on one side of the vehicle, it could indicate a problem with the wheel alignment, which may be caused by worn or damaged wheel studs.

Consequences of Driving with Faulty Wheel Studs

Driving with faulty wheel studs poses significant safety risks, potentially leading to serious accidents.

- Wheel detachment: Worn or damaged studs can break under stress, causing the wheel to detach from the vehicle while driving. This can lead to a loss of control, resulting in a serious accident.

- Tire blowout: A loose wheel can cause the tire to rub against the brake rotor or other components, leading to a tire blowout. This can result in a sudden loss of control and potentially cause an accident.

- Suspension damage: Faulty wheel studs can put additional strain on other suspension components, leading to premature wear and tear. This can ultimately result in expensive repairs.

Inspecting Wheel Studs

Regularly inspecting your wheel studs is essential for maintaining safety and preventing potential issues.

- Visual inspection: Examine each stud for signs of bending, cracking, or excessive rust.

- Tightness check: Use a torque wrench to ensure all lug nuts are properly tightened to the manufacturer’s specifications.

- Wheel movement: Gently rock the wheel back and forth to check for excessive play or movement.

- Listen for noises: Pay attention to any grinding or rattling noises while driving, which may indicate a loose wheel or damaged stud.

Cost Factors

Replacing wheel studs is a relatively straightforward repair, but the cost can vary depending on several factors. Understanding these factors can help you budget for the repair and make informed decisions about whether to DIY or seek professional help.

Factors Influencing the Cost of Wheel Stud Replacement

The cost of replacing wheel studs is influenced by several factors, including:

- Vehicle Make and Model: Different vehicles have different wheel stud designs and sizes, which can affect the cost of replacement. Some vehicles may require specialized tools or parts, increasing the overall cost. For instance, a high-end luxury car may have more complex wheel stud designs, leading to higher replacement costs compared to a standard sedan.

- Number of Studs Needing Replacement: The number of studs that need replacement is a significant factor in determining the cost. Replacing a single stud is typically less expensive than replacing multiple studs. For example, if you need to replace all five studs on a wheel, the cost will be higher than replacing just one.

- Labor Costs: Labor costs can vary depending on your location and the mechanic’s experience. If you are having the work done at a dealership, the labor costs are likely to be higher than at an independent repair shop. For instance, a mechanic specializing in high-performance vehicles may charge more for labor than a general mechanic.

- Parts Cost: The cost of the replacement studs themselves can vary depending on the material, quality, and brand. Some studs are made of high-strength steel, while others are made of cheaper materials. The cost of the studs can also vary depending on the vehicle make and model.

Cost Comparison: DIY vs. Professional Service

You can choose to replace wheel studs yourself or hire a professional mechanic. The cost of DIY replacement is typically lower, as you only need to pay for the parts. However, it requires some mechanical knowledge and tools, which may not be readily available to everyone. Professional service offers convenience and expertise, but comes with higher labor costs.

DIY replacement can save money but requires mechanical knowledge and tools. Professional service offers convenience and expertise but costs more.

DIY Replacement Guide

Replacing wheel studs is a relatively straightforward DIY project that can save you money compared to having a mechanic do it. However, it’s essential to approach this task with caution and follow the correct procedures to ensure safety and a successful outcome. This guide will provide a step-by-step process, necessary tools, and safety tips for replacing wheel studs.

Tools and Materials

A successful DIY wheel stud replacement requires the right tools and materials. This list Artikels the essentials for a smooth and safe procedure:

- Jack and jack stands: Essential for safely lifting the vehicle off the ground.

- Lug wrench: Used to remove and tighten lug nuts.

- Breaker bar: A longer lever to loosen stubborn lug nuts.

- Socket set: To fit various sizes of lug nuts and wheel studs.

- Hammer: Used to drive out old studs and install new ones.

- Torque wrench: To tighten lug nuts to the manufacturer’s specifications.

- New wheel studs: Choose the correct size and thread pitch for your vehicle.

- Anti-seize compound: Apply to the threads of the new studs to prevent corrosion and make removal easier in the future.

- Penetrating fluid: Use to loosen stubborn lug nuts or studs.

- Safety glasses: Protect your eyes from flying debris.

- Gloves: Provide protection for your hands.

Safety Precautions

Safety should always be a top priority when working on your vehicle. Here are some important precautions to take:

- Park on a level surface: Ensure the vehicle is stable and won’t roll during the repair.

- Engage the parking brake: This adds an extra layer of security.

- Chock the wheels: Place chocks behind the remaining wheels to prevent the vehicle from rolling.

- Wear appropriate safety gear: Use safety glasses, gloves, and sturdy footwear.

- Never work under a vehicle supported only by a jack: Always use jack stands for stability.

- Be mindful of surrounding areas: Ensure there’s enough space to work safely and that no one is walking around the vehicle.

Step-by-Step Replacement Guide

Once you’ve gathered the necessary tools and taken safety precautions, you can proceed with the replacement process:

- Loosen the lug nuts: Using the breaker bar and the appropriate socket, loosen the lug nuts on the wheel with the damaged stud. Do not remove them completely at this stage.

- Jack up the vehicle: Place the jack under the designated jacking point for the wheel you’re working on and carefully raise the vehicle until the tire is slightly off the ground.

- Secure with jack stands: Position the jack stands under the vehicle’s frame or designated points, ensuring they are securely in place. Lower the vehicle onto the jack stands, removing the weight from the jack.

- Remove the lug nuts: Completely remove the lug nuts and set them aside.

- Remove the wheel: Carefully remove the wheel from the vehicle.

- Remove the old stud: Use a hammer and a punch or drift to drive out the old stud from the hub. Be careful not to damage the hub.

- Clean the hub: Remove any debris or rust from the hub hole where the stud sits. You can use a wire brush or a shop rag.

- Install the new stud: Apply anti-seize compound to the threads of the new stud. Carefully insert the new stud into the hub hole and tap it in with a hammer. Make sure the stud is fully seated and flush with the hub.

- Reinstall the wheel: Place the wheel back onto the hub, ensuring it is properly centered. Start the lug nuts by hand.

- Tighten the lug nuts: Use the torque wrench to tighten the lug nuts to the manufacturer’s specifications. Refer to your vehicle’s owner’s manual for the correct torque setting.

- Lower the vehicle: Remove the jack stands and lower the vehicle to the ground. Remove the jack.

- Final tightening: Once the vehicle is back on the ground, use the torque wrench to tighten the lug nuts to the final specified torque.

Tips for Successful Replacement

- Use a penetrating fluid: If the lug nuts or studs are particularly stubborn, apply penetrating fluid and let it sit for a few minutes before attempting to loosen them.

- Tap the stud with a hammer: If the stud is stuck, you can try tapping it lightly with a hammer to loosen it. Be careful not to damage the hub.

- Replace all studs on the same axle: Even if only one stud is damaged, it’s recommended to replace all the studs on the same axle for consistency and longevity.

- Use a torque wrench: Always use a torque wrench to tighten the lug nuts to the correct specifications. Overtightening can damage the studs or the hub.

Professional Replacement

While replacing wheel studs yourself can be a cost-effective option, there are several benefits to having a professional mechanic handle the job. Professional mechanics possess the expertise, tools, and experience necessary to ensure a safe and effective replacement, minimizing the risk of complications and potential damage to your vehicle.

Benefits of Professional Replacement

Professional mechanics offer several advantages over DIY replacement:

- Expertise and Experience: Professional mechanics have extensive training and experience in working with vehicle components, including wheel studs. They understand the proper procedures for removing and installing wheel studs, ensuring a secure and reliable fit.

- Specialized Tools and Equipment: Mechanics have access to specialized tools and equipment that are essential for safely removing and installing wheel studs. These tools ensure proper torque and alignment, preventing damage to the stud or surrounding components.

- Quality Parts and Warranty: Reputable mechanics use high-quality parts from trusted manufacturers, ensuring durability and longevity. They also offer warranties on their work, providing peace of mind in case of any issues.

- Safety and Accuracy: Professional mechanics prioritize safety and accuracy in their work. They understand the importance of properly torquing the wheel studs to prevent loosening or damage, ensuring the safe operation of your vehicle.

- Time Efficiency: Professional mechanics can complete the replacement process efficiently, saving you time and effort compared to DIY attempts. They have the experience and tools to perform the job quickly and accurately.

Process of Professional Replacement

The process of replacing wheel studs by a professional mechanic typically involves the following steps:

- Inspection: The mechanic will inspect the damaged or worn wheel studs to determine the extent of the issue and the necessary repairs.

- Removal: The mechanic will use specialized tools to safely remove the damaged or worn wheel studs from the hub. This process may require the use of a press or other specialized equipment to avoid damaging the surrounding components.

- Installation: New wheel studs will be installed into the hub, ensuring proper alignment and torque. The mechanic will use a torque wrench to tighten the studs to the manufacturer’s specifications.

- Testing and Finalization: After installation, the mechanic will test the new wheel studs to ensure they are securely fastened and properly aligned. They will also check for any signs of damage or wear on the surrounding components.

Choosing a Reputable Mechanic, How much to replace wheel studs

Choosing a reputable mechanic is crucial for ensuring a successful and safe wheel stud replacement. Consider the following factors when selecting a mechanic:

- Reputation and Experience: Look for a mechanic with a good reputation and experience in working on vehicles similar to yours. Ask for recommendations from friends, family, or online forums.

- Certifications and Training: Check if the mechanic is certified by reputable organizations, such as the National Institute for Automotive Service Excellence (ASE). This indicates they have met specific industry standards and training requirements.

- Customer Reviews: Read online reviews from previous customers to get an idea of the mechanic’s quality of work, customer service, and pricing.

- Warranty and Guarantees: Inquire about the mechanic’s warranty or guarantee on their work. This provides assurance and protection in case of any issues arising after the replacement.

The cost of replacing wheel studs can range significantly, but it’s an investment in your safety and peace of mind. Whether you choose to tackle the replacement yourself or enlist the expertise of a professional mechanic, understanding the factors that influence the cost is crucial for making informed decisions. Remember, neglecting worn or damaged wheel studs can lead to serious consequences, including wheel detachment and accidents.

Prioritizing your safety and understanding the intricacies of wheel studs will keep you rolling smoothly and confidently on the road.

Essential Questionnaire

How often should I inspect my wheel studs?

It’s recommended to inspect your wheel studs at least once a year, or more frequently if you often drive on rough roads or carry heavy loads.

Can I use a lug nut to replace a broken wheel stud?

No, using a lug nut as a temporary fix is extremely dangerous. It’s not designed to handle the same stresses as a wheel stud and could lead to wheel detachment.

Are there any signs of a damaged wheel stud that are not obvious?

Yes, even if a wheel stud doesn’t appear visibly damaged, it could be weakened from rust or corrosion. If you notice any unusual noises or vibrations, it’s best to have your wheel studs inspected by a professional.