How to change wheel studs on drum brakes – Changing wheel studs on drum brakes is a crucial maintenance task that ensures the safe and reliable operation of your vehicle. Wheel studs, the metal pins that secure the wheels to the vehicle, are essential for proper wheel attachment and stability. Drum brakes, a traditional braking system found in many vehicles, rely on a drum and shoe mechanism to slow the wheels down.

Replacing worn or damaged wheel studs on drum brakes is a relatively straightforward process that can be accomplished with the right tools and knowledge. This guide provides a comprehensive overview of the steps involved in changing wheel studs on drum brakes, ensuring you have the necessary information to complete this important maintenance task.

This guide will walk you through the entire process, from preparing your vehicle to reassembling the brake drum and wheel. It will also provide valuable tips and troubleshooting advice to help you avoid common pitfalls and ensure a successful repair.

Wheel Stud Replacement on Drum Brakes

Your vehicle’s wheel studs are crucial for securely attaching the wheels to the hubs, ensuring a safe and stable ride. These studs are threaded metal rods that protrude from the hub and connect to the lug nuts. Over time, they can become worn or damaged, requiring replacement. Drum brakes, a common braking system in older vehicles, use a system of brake shoes and drums to slow the wheels.

Replacing wheel studs on drum brakes is a straightforward procedure, although it requires some mechanical knowledge and tools.

Understanding Wheel Stud Replacement

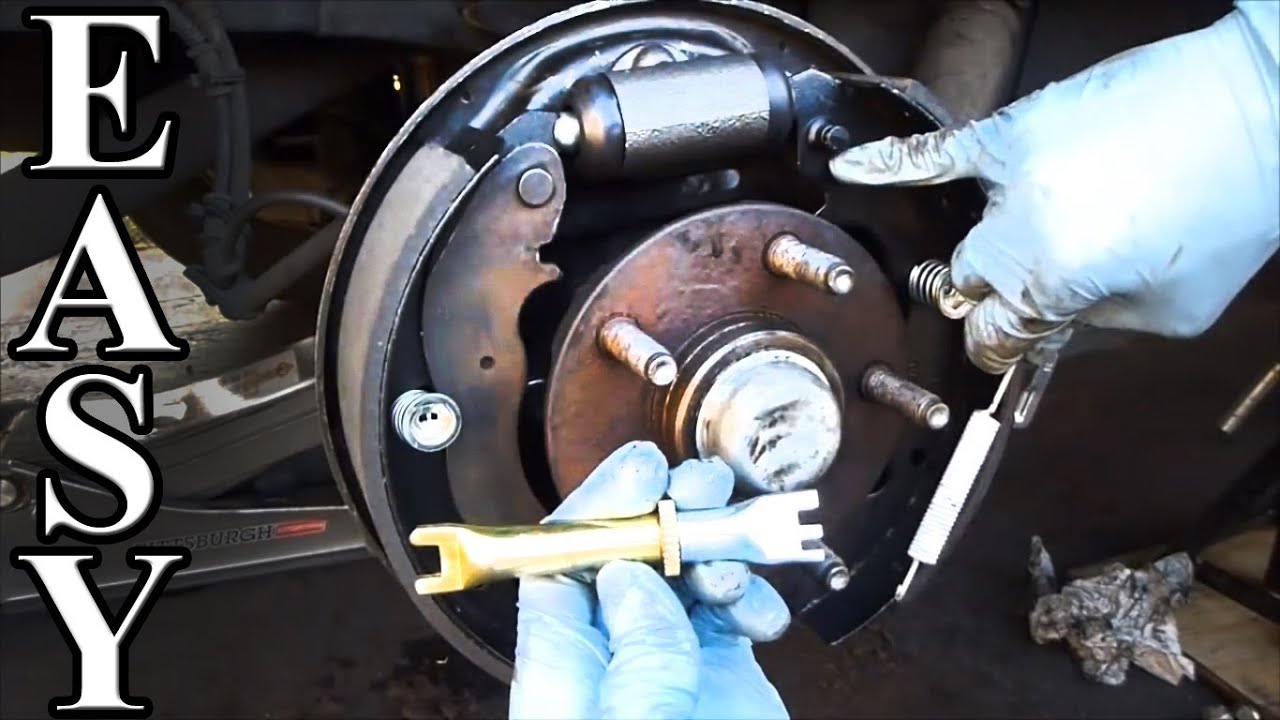

Replacing wheel studs on drum brakes is a necessary maintenance task that ensures the safe and secure attachment of your vehicle’s wheels. This procedure involves removing the old studs and installing new ones. The process requires the removal of the brake drum, which exposes the wheel studs. After removing the old studs, new studs are pressed into the hub using a specialized tool.

Properly installed wheel studs are essential for maintaining the integrity of your vehicle’s braking system and overall safety.

Tools and Materials: How To Change Wheel Studs On Drum Brakes

Changing wheel studs on drum brakes is a relatively straightforward task, but it requires the right tools and materials to ensure a safe and successful repair. Having the right tools and materials will make the job easier and prevent unnecessary delays.

Tools

Here are the tools you will need:

- Jack and Jack Stands: A jack is essential for lifting the vehicle to provide clearance for working underneath. Jack stands are crucial for supporting the vehicle securely and preventing it from falling while you work. Make sure the jack stands are rated for the weight of your vehicle and are placed on a solid, level surface.

- Lug Wrench: A lug wrench is used to loosen and tighten the lug nuts that hold the wheel to the vehicle. Ensure you have the correct size lug wrench for your vehicle.

- Socket Wrench Set: A socket wrench set is needed to remove and install the wheel studs. You will need sockets that fit the size of the wheel studs and the size of the lug nuts.

- Hammer: A hammer is used to tap the wheel studs out of the hub and into the brake drum. Use a rubber mallet or a hammer with a soft-faced head to prevent damaging the studs or the hub.

- Torque Wrench: A torque wrench is essential for tightening the lug nuts to the correct specifications. This ensures the wheel is securely attached to the hub and prevents premature wear and tear on the wheel bearings.

Materials

Here are the materials you will need:

- New Wheel Studs: The most important material is the new wheel studs. Purchase studs that are the correct size and thread pitch for your vehicle.

- Grease: Apply grease to the threads of the new wheel studs before installation. This helps to prevent corrosion and makes it easier to remove the studs in the future.

- Penetrating Fluid: If the old studs are difficult to remove, use penetrating fluid to loosen them up. Apply the fluid to the threads of the studs and allow it to sit for a few minutes before attempting to remove them.

Safety Precautions

When working on your vehicle’s brakes, safety should be your top priority. Even a seemingly simple task like replacing wheel studs can be dangerous if you’re not careful.

Using Safety Glasses and Gloves

Always wear safety glasses to protect your eyes from flying debris. Wheel studs are made of hardened steel, and when you’re hammering them out or hammering them in, there’s a chance that small pieces of metal could break off and fly towards your face. Gloves are also essential to protect your hands from cuts and scrapes, especially when working with sharp tools like a hammer or a wrench.

Safely Lifting and Supporting the Vehicle

Before you start working on your vehicle, it’s important to make sure it’s properly lifted and supported. This will prevent the vehicle from falling on you and causing serious injury. Use a jack that’s rated for the weight of your vehicle and place it on a solid, level surface. Always use jack stands to support the vehicle once it’s lifted.

Never work under a vehicle that is only supported by a jack.

Using a Parking Brake and Chocks

Always engage the parking brake before lifting the vehicle. This will help to prevent the vehicle from rolling. In addition to the parking brake, you should also use wheel chocks to further secure the vehicle. Place chocks behind the wheels that are still on the ground to prevent the vehicle from rolling forward or backward.

Removing the Wheel and Brake Drum

With the car safely secured, you’re ready to remove the wheel and brake drum. This step requires some physical effort and patience, but it’s manageable with the right tools and technique.

Removing the Wheel

Before you can access the brake drum, you need to remove the wheel. This is a straightforward process, but it’s crucial to follow these steps to avoid damaging the wheel or lug nuts.

- Loosen the Lug Nuts: Using your lug wrench, break the lug nuts loose while the car is still on the ground. This will prevent the lug nuts from becoming too tight when the car is lifted. You may need to apply significant force, especially if the lug nuts haven’t been loosened in a while.

- Raise the Vehicle: Using a jack, safely lift the vehicle until the tire is a few inches off the ground. Ensure the jack is properly positioned on a sturdy part of the vehicle frame.

- Remove the Lug Nuts: Now that the car is lifted, you can easily remove the lug nuts. Use the lug wrench to loosen and remove each lug nut.

- Remove the Wheel: Carefully pull the wheel straight off the hub. It may require a gentle tug, but avoid using excessive force, as this could damage the wheel or hub.

Removing the Brake Drum

With the wheel removed, you can now access the brake drum. The brake drum is a metal cylinder that houses the brake shoes and is attached to the wheel hub.

- Locate the Drum’s Retention Clips: Most brake drums are held in place by a few small retention clips or spring clips. These clips can be found on the outside edge of the drum, near the wheel hub.

- Remove the Retention Clips: Use a small screwdriver or a pair of pliers to carefully remove the retention clips. Once the clips are removed, the brake drum should be free to slide off the hub.

- Tap the Drum Gently: If the drum doesn’t come off easily, you can gently tap the drum with a rubber mallet or a hammer wrapped in a cloth. Avoid hitting the drum directly with a hammer, as this could damage it.

- Inspect the Brake Shoes: Once the drum is off, take a moment to inspect the brake shoes for wear and tear. If they are worn down, they will need to be replaced.

Removing the Old Wheel Studs

Now that you have the brake drum off, you can remove the old wheel studs. You will need to be careful not to damage the brake drum while removing the studs.

Removing the Old Wheel Studs

To remove the old wheel studs, you will need a socket wrench and a hammer. First, place the socket wrench over the top of the wheel stud and give it a few good whacks with the hammer. This should loosen the stud. Once the stud is loose, you can remove it from the brake drum by hand.If the stud is stubborn and won’t budge, you can try using a stud remover.

A stud remover is a specialized tool that is designed to remove stubborn wheel studs. You can purchase a stud remover at most auto parts stores. Here are some tips for removing old wheel studs:

- Use a socket wrench that is the correct size for the wheel studs.

- If the stud is stuck, try using a penetrating oil to loosen it up.

- If the stud is damaged, you will need to replace it.

- Be careful not to damage the brake drum while removing the studs.

It is important to remove the old wheel studs carefully, as they can be brittle and break easily.

Installing the New Wheel Studs

Now that you’ve removed the old wheel studs, it’s time to install the new ones. This process is the reverse of removal, but it’s crucial to do it correctly to ensure the new studs are securely in place.

Applying Grease to the Threads of the New Studs

Applying grease to the threads of the new wheel studs is important for several reasons. First, it helps to prevent the studs from seizing in the brake drum. Second, it makes it easier to install the studs and prevents them from galling during installation. Third, it reduces friction, which can help to prevent premature wear on the studs and the threads in the brake drum.

Installing the Studs into the Brake Drum

Installing the new studs into the brake drum is a simple process. Simply thread the studs into the holes in the brake drum until they are snug. It’s important to ensure that the studs are installed straight to prevent any damage to the brake drum. If you’re having trouble threading the studs, you can use a small hammer to tap them in gently.

Tightening the Studs to the Correct Torque Specifications

Once the studs are installed, you need to tighten them to the correct torque specifications. This ensures that the studs are securely in place and that they will not come loose during driving. The torque specifications for wheel studs vary depending on the make and model of your vehicle. You can find the correct torque specifications in your vehicle’s owner’s manual or online.

It is important to use a torque wrench to tighten the studs to the correct specifications. Over-tightening the studs can damage the brake drum and cause the studs to break. Under-tightening the studs can cause them to loosen and come loose during driving, which can be dangerous.

Use a torque wrench to tighten the studs to the specified torque. Once the studs are tightened to the correct torque, you can install the wheel and tighten the lug nuts to the correct torque specifications.

Reassembling the Brake Drum and Wheel

Now that the new wheel studs are securely in place, it’s time to put everything back together. We’ll be reassembling the brake drum and wheel, making sure everything is properly aligned and tightened.

Installing the Brake Drum, How to change wheel studs on drum brakes

Before installing the brake drum, it’s important to inspect the drum’s surface for any signs of damage or wear. If you find any damage, you’ll need to replace the drum. Once you’ve confirmed the drum is in good condition, you can proceed with installation. Align the drum’s mounting holes with the wheel studs. Slide the drum onto the wheel studs, ensuring it seats properly against the backing plate.

Tightening the Lug Nuts

With the brake drum in place, it’s time to tighten the lug nuts. This is a crucial step, as properly tightened lug nuts ensure the wheel is securely attached to the vehicle.

It’s essential to tighten the lug nuts in a star pattern. This ensures even pressure across all lug nuts, preventing the wheel from becoming loose.

Start by tightening each lug nut just a little bit. Then, go back and tighten each lug nut in a star pattern, moving from one lug nut to the next in a diagonal sequence. Continue tightening the lug nuts until they are snug.

Lowering the Vehicle and Testing the Brakes

Once all the lug nuts are properly tightened, you can lower the vehicle. Use a jack to slowly lower the vehicle until the wheel is back on the ground. After lowering the vehicle, it’s important to test the brakes. Drive the vehicle slowly and apply the brakes gently to ensure they are working properly. If you hear any unusual noises or feel any vibrations, you may need to re-inspect the brake system.

Troubleshooting and Tips

Even the most experienced DIYer can encounter challenges when changing wheel studs. Understanding common problems and having a plan to address them can make the process smoother. Here’s a breakdown of some potential issues and tips to help you overcome them.

Stripped Threads

Stripped threads can occur when removing the old wheel studs or installing the new ones. If the threads in the axle housing are damaged, the new studs will not seat properly, potentially leading to a loose wheel and safety concerns.

- Identify the Problem: Inspect the threads in the axle housing for any signs of damage. Look for stripped threads, burrs, or any other irregularities.

- Repairing Damaged Threads: If the threads are slightly damaged, you may be able to repair them using a thread chaser or a tap. For severe damage, you may need to replace the axle housing.

- Prevention: Use a high-quality wrench or socket that fits the stud snugly. Avoid excessive force when tightening or loosening the studs.

Broken Studs

A broken wheel stud can be a frustrating and potentially dangerous situation. This can happen due to over-tightening, corrosion, or simply age.

- Removing a Broken Stud: Use a stud extractor tool to remove the broken stud. If the stud is completely broken off, you may need to drill it out and use a bolt extractor to remove the remaining piece.

- Preventing Broken Studs: Use a torque wrench to tighten the wheel studs to the manufacturer’s specifications. This will help prevent over-tightening and ensure the studs are properly secured. Regular inspection of the studs for signs of wear or corrosion can help prevent future problems.

Difficulty Removing the Brake Drum

Removing the brake drum can be challenging, especially if the drum is rusted or seized.

- Loosening a Seized Drum: Use a penetrating oil or lubricant to loosen the drum. Tap the drum gently with a hammer to help break the rust. If the drum is still stuck, you may need to use a drum puller to remove it.

- Preventing Seized Drums: Regularly inspect the brake drums for rust and corrosion. Apply a light coating of lubricant to the drum’s contact surfaces to prevent seizing.

By following the steps Artikeld in this guide, you can confidently change wheel studs on drum brakes and ensure the safe and reliable operation of your vehicle. Remember to always prioritize safety by using the proper tools, taking necessary precautions, and following the instructions carefully. With the right approach, this maintenance task can be completed successfully, ensuring your vehicle remains roadworthy and safe for many miles to come.

Top FAQs

What are the signs that my wheel studs need to be replaced?

Signs of worn or damaged wheel studs include loose wheels, rattling noises while driving, or visible damage to the studs themselves. If you notice any of these signs, it’s crucial to inspect the studs and replace them if necessary.

How often should I replace my wheel studs?

Wheel studs generally have a long lifespan, but they can wear down over time, especially if subjected to excessive stress or damage. It’s recommended to inspect your wheel studs regularly and replace them as needed. There’s no specific time frame for replacement, as it depends on usage and driving conditions.

Can I reuse old wheel studs?

It’s not recommended to reuse old wheel studs, as they may be worn or damaged. Replacing them with new studs ensures a secure and reliable connection between the wheel and the vehicle.