How to remove wheel studs drum brakes – How to remove wheel studs from drum brakes, a task that may seem daunting, can be accomplished with the right tools and a methodical approach. This process, while demanding some mechanical know-how, is achievable for those willing to tackle the challenge.

From the initial safety precautions to the final brake test, this guide provides a comprehensive step-by-step breakdown of the process, ensuring a smooth and successful outcome. Whether you’re a seasoned mechanic or a novice DIY enthusiast, this guide will equip you with the knowledge and confidence to handle this essential automotive repair.

Safety Precautions

When working on your vehicle, safety should always be your top priority. It’s crucial to take the necessary precautions to prevent accidents and injuries. This section will highlight some essential safety measures you should follow while removing wheel studs and working with drum brakes.

Personal Protective Equipment

Wearing appropriate personal protective equipment (PPE) is vital to protect yourself from potential hazards.

- Safety Glasses: Always wear safety glasses to shield your eyes from flying debris, such as metal shavings or dirt particles, that can be ejected during the removal process.

- Gloves: Gloves protect your hands from cuts, scrapes, and grease. They also provide a better grip on tools and parts, especially when working with oily or rusty components.

Working with a Jacked-Up Vehicle

Working under a jacked-up vehicle can be dangerous.

- Jack Stands: Never rely solely on a jack to support the vehicle. Always use jack stands to securely hold the vehicle in place. Make sure the jack stands are rated for the weight of your vehicle and are placed on a solid, level surface.

- Chock the Wheels: To prevent the vehicle from rolling, use wheel chocks on the wheels that are still on the ground. Chocks should be placed in front of the front wheels and behind the rear wheels.

- Use Caution: When working under a jacked-up vehicle, exercise extreme caution. Avoid placing yourself directly under the vehicle. If possible, use a creeper to move around safely.

Tools Required

Having the right tools for the job makes the process easier and safer. Here’s a list of essential tools you’ll need:

- Lug Wrench: Used to loosen and tighten the lug nuts.

- Breaker Bar: A longer lever bar that provides extra torque for stubborn lug nuts.

- Socket Set: A set of sockets that fit various sizes of nuts and bolts, including the lug nuts and wheel stud nuts.

- Hammer: Used to tap on the wheel stud to loosen it if it’s stuck.

- Penetrating Oil: Helps to loosen rusted or seized nuts and bolts.

Removing the Wheel

Now that we’ve addressed safety, let’s move on to the exciting part – actually removing the wheel! This is where your mechanical prowess will truly shine.

Loosening the Lug Nuts

Before you start jacking up the car, it’s crucial to loosen the lug nuts. This will make it much easier to remove them later when the wheel is off the ground. First, grab your breaker bar and a socket that fits your lug nuts. Remember, you’re not trying to remove them entirely, just loosen them. To do this, place the socket onto the lug nut and use the breaker bar to apply force in a counter-clockwise direction.

The Importance of a Cross Pattern

Why a cross pattern? It’s all about distributing the force evenly across the lug nuts. Think of it like tightening the spokes of a bicycle wheel. You don’t want to tighten one side too much, or the wheel will be out of balance. The same principle applies to your car’s wheel.Here’s how it works:

- Loosen one lug nut a little bit.

- Move to the lug nut directly opposite it and loosen that one.

- Then, loosen the lug nut to the left or right of the first lug nut.

- Finally, loosen the last lug nut.

You’ll continue this pattern as you loosen the lug nuts, working your way around the wheel.

Jacking Up the Vehicle

Now, it’s time to lift the vehicle. Make sure you’re using a jack that’s rated for the weight of your car. Place the jack under the designated jack point on your vehicle’s frame. This is typically located near the wheel you’re working on. Consult your owner’s manual for the exact location.Once the jack is securely in place, begin to raise the vehicle.

Raise it just enough to take the weight off the tire. It’s important to raise the vehicle slowly and carefully.

Using Jack Stands

Never rely solely on the jack to hold the weight of your vehicle. Always use jack stands to support the car while you’re working on it. This is a crucial safety measure that can prevent the car from falling on you.Place the jack stands on a solid, level surface. Make sure they’re positioned under the frame of the vehicle, at a point that will support the weight.

Then, lower the vehicle onto the jack stands.

Removing the Wheel

With the vehicle safely secured, you can now remove the wheel. Grab your breaker bar and socket again, and finish loosening the lug nuts. Once they’re loose enough, you can use your hand to remove them.Now, carefully pull the wheel off the hub. You may need to wiggle it a little to get it off. Once it’s free, set it aside in a safe place.

Removing the Drum Brake

The drum brake assembly is a critical component of your vehicle’s braking system, and removing it is a necessary step for many repairs and maintenance tasks. It’s important to understand how to remove the drum brake safely and efficiently to avoid damage to the brake shoes or other components.

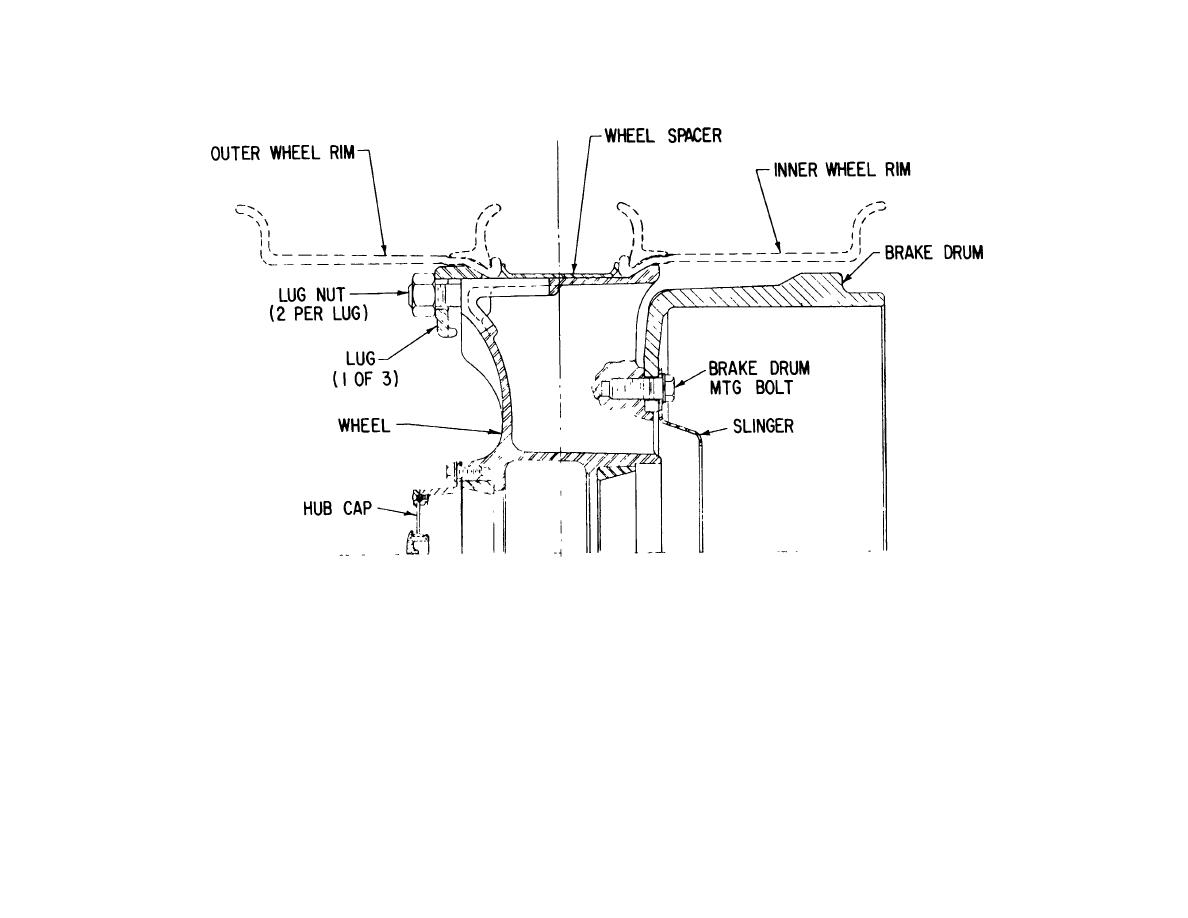

Identifying the Drum Brake Assembly and Wheel Studs

The drum brake assembly is typically located behind the wheel and is easily identifiable by its cylindrical shape. It houses the brake shoes and other components that work together to slow down your vehicle. The wheel studs are the threaded metal rods that protrude from the hub and hold the wheel in place. They are usually located on the back side of the hub, and you can see them when you remove the wheel.

Methods for Removing the Drum Brake

There are several methods for removing the drum brake, each with its own advantages and disadvantages. The most common methods include:

- Using a Hammer and Drift Punch: This method involves using a hammer and a drift punch to tap the drum brake off the hub. This method is often used when the drum brake is stuck or rusted in place. However, it’s important to use caution to avoid damaging the brake shoes or other components.

- Using a Drum Brake Puller: A drum brake puller is a specialized tool designed to remove drum brakes. It uses a set of arms that apply force to the drum brake, pulling it off the hub. This method is generally safer than using a hammer and drift punch, but it requires a dedicated tool.

- Using a Lug Wrench: If the drum brake is stuck or rusted, you can try using a lug wrench to loosen it. This method involves using the lug wrench to tap the drum brake from the outside, trying to break it free. However, it’s important to use caution to avoid damaging the drum brake or other components.

Removing the Drum Brake Safely

Before removing the drum brake, ensure the parking brake is disengaged and the vehicle is securely supported on jack stands. Here’s a step-by-step guide for safely removing the drum brake:

- Locate the Emergency Brake Cable: The emergency brake cable connects to the brake shoes inside the drum. Identify the cable and release any tension by loosening the adjustment nut on the cable.

- Loosen the Drum Brake: If the drum brake is stuck, try using a hammer and drift punch or a drum brake puller to loosen it. Use a hammer and drift punch by tapping gently on the edge of the drum brake. If using a puller, ensure it’s properly positioned and tighten the arms evenly.

- Remove the Drum Brake: Once the drum brake is loosened, you can remove it by pulling it off the hub. Be careful not to drop it, as it can be heavy.

- Inspect the Drum Brake: Once the drum brake is removed, inspect it for any damage or wear. Replace the drum brake if necessary.

It’s important to remember that removing the drum brake is a complex procedure that requires specialized tools and knowledge. If you’re not comfortable performing this task, it’s best to consult a professional mechanic.

Removing the Wheel Studs

Now, with the drum brake assembly removed, we can tackle the wheel studs. These studs are the critical connection points between the wheel and the hub, and they need to be removed carefully to avoid damaging the threads or the surrounding components.

Removing the Wheel Studs

Removing the wheel studs is a relatively straightforward process, but it requires the right tools and a bit of patience. You’ll need a stud remover, which is a specialized tool designed to grip and remove the studs. The stud remover comes in various sizes, so it’s crucial to select the correct size for your vehicle. Using the wrong size stud remover can damage the stud or the brake drum, making the repair more difficult.

Always choose a stud remover that is specifically designed for your vehicle’s wheel studs.

Here’s a step-by-step guide on how to safely remove the wheel studs:

1. Locate the stud remover

Ensure you have the correct size stud remover for your vehicle’s wheel studs.

2. Position the stud remover

Align the stud remover over the wheel stud, ensuring the center pin of the remover is properly positioned over the stud.

3. Tighten the stud remover

Using a wrench or socket, tighten the stud remover until it securely grips the stud.

4. Apply leverage

Apply steady and controlled pressure to the stud remover handle to loosen the stud.

5. Remove the stud

Once the stud is loosened, continue turning the stud remover until the stud is completely removed.It’s important to note that the stud remover should be applied with care to avoid damaging the surrounding components. If the stud is stuck or difficult to remove, consider using a penetrating oil to loosen it.

Replacing the Wheel Studs

Now that the old wheel studs are removed, you can install the new ones. This is a crucial step, and you need to be careful to ensure the new studs are the correct size and type for your vehicle.

Installing New Wheel Studs

Installing new wheel studs is a relatively straightforward process, but it’s essential to do it correctly. Here are the steps involved:

- Clean the Stud Holes: Before installing the new studs, ensure the holes in the hub are clean and free of any debris. This will prevent the studs from being installed incorrectly or damaged.

- Lubricate the Studs: Applying a thin layer of anti-seize compound to the threads of the new studs will help prevent them from seizing in the hub.

- Insert the New Studs: Carefully insert the new studs into the holes in the hub. Make sure they are fully seated and flush with the hub surface.

- Tighten the Studs: Use a torque wrench to tighten the studs to the manufacturer’s specifications. This is critical for ensuring the wheels are securely attached and prevent them from coming loose.

Correct Size and Type of Wheel Studs

Using the correct size and type of wheel studs is essential for safe and reliable operation of your vehicle. Here’s why:

- Wheel Fitment: The wrong size studs can cause the wheels to fit improperly, potentially leading to wheel wobble or even wheel separation.

- Lug Nut Compatibility: Wheel studs are designed to work with specific lug nuts. Using the wrong type of stud can prevent the lug nuts from seating correctly, compromising the wheel’s attachment.

- Strength and Durability: Wheel studs are designed to withstand the stresses of driving. Using studs that are too small or weak can result in premature failure, potentially leading to a wheel detaching from the vehicle.

Torqueing the Wheel Studs, How to remove wheel studs drum brakes

Torqueing the wheel studs to the correct specifications is crucial for ensuring the wheels are securely attached to the vehicle.

The torque specifications for wheel studs are typically found in your vehicle’s owner’s manual or a repair manual specific to your vehicle.

- Use a Torque Wrench: A torque wrench is an essential tool for tightening wheel studs. It allows you to apply the precise amount of torque required, ensuring the studs are properly tightened without being over-tightened.

- Tighten in a Star Pattern: To evenly distribute the load on the wheel studs, tighten them in a star pattern, moving from one stud to the next in a diagonal pattern.

- Check Torque After Driving: It’s a good practice to check the torque on the wheel studs after driving a short distance. This ensures that the studs have not loosened due to vibrations or other factors.

Reinstalling the Drum Brake and Wheel

Now that you’ve successfully removed and replaced the wheel studs, it’s time to put everything back together. This process requires precision and care to ensure your brakes function correctly and safely.

Reinstalling the Drum Brake Assembly

Before reinstalling the drum brake, ensure the brake shoes are properly aligned and adjusted. This step is crucial for maintaining proper braking performance.

- Align the brake shoes: Make sure the brake shoes are properly seated in their respective positions within the drum brake assembly. The shoes should be aligned with the drum, ensuring even contact with the drum’s surface.

- Adjust the brake cable: The brake cable connects the brake pedal to the brake shoes. Ensure the cable is adjusted correctly, providing sufficient tension to engage the brakes effectively.

A loose cable will result in a spongy brake pedal and reduced braking power.

- Install the drum brake: Once the brake shoes are aligned and the cable is adjusted, carefully slide the drum brake assembly back onto the axle. Make sure the drum is properly seated and aligned with the wheel studs.

Reinstalling the Wheel

Now that the drum brake is back in place, you can reinstall the wheel. It’s essential to tighten the lug nuts correctly to ensure the wheel is securely attached to the axle.

- Place the wheel: Position the wheel over the wheel studs, ensuring it’s correctly aligned with the axle.

- Tighten the lug nuts: Start tightening the lug nuts by hand, ensuring they are evenly distributed around the wheel.

- Use a torque wrench: Once the lug nuts are hand-tightened, use a torque wrench to tighten them to the manufacturer’s specifications. The torque specifications for your vehicle can be found in your owner’s manual or online.

- Tighten the lug nuts in a star pattern: Tighten the lug nuts in a star pattern (e.g., top, bottom, left, right) to ensure even pressure on the wheel. This pattern helps prevent the wheel from warping or becoming misaligned.

Testing the Brakes

After replacing the wheel studs, it is absolutely crucial to test the brakes to ensure they are functioning correctly and safely. This is because the wheel studs play a vital role in securing the wheels to the vehicle, and any issues with the studs could compromise the brakes’ effectiveness.

Testing the brakes after replacing the wheel studs is essential to ensure your safety and the safety of others on the road.

Testing Methods

There are several methods to test the brakes, each offering a unique perspective on their performance.

- Road Test: This involves driving the vehicle at a safe speed and applying the brakes progressively to assess their responsiveness and stopping power.

- Brake Pedal Test: This involves pumping the brake pedal several times to check for a firm pedal feel and ensure the brakes are engaging properly.

Identifying Problems

While testing the brakes, it’s essential to be aware of potential problems that may arise.

- Spongy Brake Pedal: This indicates air in the brake lines, requiring bleeding to restore proper brake fluid pressure.

- Hard Brake Pedal: This could indicate a problem with the master cylinder or a blockage in the brake lines.

- Uneven Braking: If one side of the vehicle brakes harder than the other, it could indicate a problem with the brake calipers or pads on that side.

- Grinding or Squealing Noise: This could indicate worn-out brake pads or rotors, requiring replacement.

- Vibration or Pulsating Brake Pedal: This could indicate warped brake rotors, which may need to be resurfaced or replaced.

By carefully following these instructions, you can safely and effectively remove wheel studs from drum brakes. Remember, safety is paramount, so always prioritize proper tools and techniques. The satisfaction of successfully completing this task will be a testament to your mechanical prowess, enhancing your automotive knowledge and skills.

General Inquiries: How To Remove Wheel Studs Drum Brakes

What tools do I need to remove wheel studs from drum brakes?

You’ll need a lug wrench, breaker bar, socket set, hammer, drift punch, stud remover, and penetrating oil.

Can I reuse old wheel studs?

It’s generally not recommended. Old studs can be damaged or weakened, potentially leading to future issues.

What is the correct torque for wheel studs?

Consult your vehicle’s owner’s manual for the specific torque specifications. Using a torque wrench is essential to ensure proper tightness.

What if I damage the brake drum while removing the wheel studs?

If you damage the drum, it may need to be replaced. Take care to use the correct tools and techniques to avoid damage.