What is wheel cylinder – What is a wheel cylinder? It’s a small but crucial component hidden within your car’s braking system, playing a vital role in converting the hydraulic pressure from your brake pedal into the mechanical force needed to stop your vehicle. Think of it like a tiny hydraulic jack, using fluid pressure to push out pistons that engage the brake shoes or pads, clamping them against the brake rotors or drums.

Understanding how a wheel cylinder works is essential for anyone who wants to keep their car running safely and efficiently. It’s not just a matter of knowing what it is, but also recognizing its importance in the overall braking system. We’ll delve into the details of its construction, operation, and potential problems, giving you the knowledge to confidently maintain your car’s braking system.

What is a Wheel Cylinder?

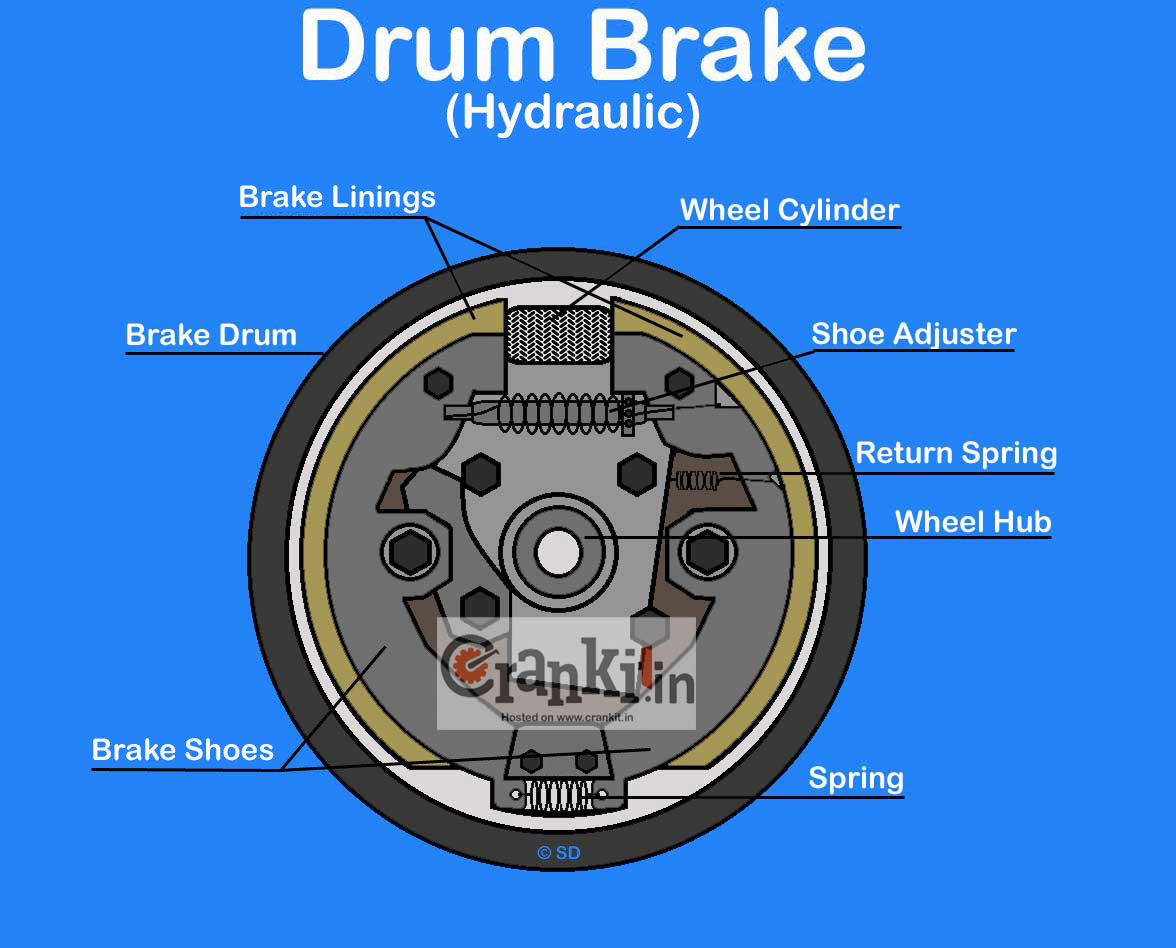

The wheel cylinder is a crucial component in a hydraulic braking system. It converts hydraulic pressure from the master cylinder into mechanical force, which is then used to activate the brake shoes or pads, ultimately stopping the vehicle.

Components of a Wheel Cylinder

The wheel cylinder is a compact device containing several essential components:

- Cylinder Body: The main housing of the wheel cylinder, typically made of cast iron or aluminum, with two chambers separated by a piston.

- Piston: A movable component that seals the cylinder chambers and transfers hydraulic pressure to the brake shoes or pads.

- Piston Cups: Rubber seals that prevent fluid leakage and create a tight seal between the piston and the cylinder walls.

- Return Springs: Springs that retract the pistons after the brake pedal is released, allowing the brake shoes or pads to move away from the brake drum or rotor.

- Bleed Screw: A small valve used to remove air bubbles from the hydraulic system during brake fluid replacement.

- Brake Shoes/Pads: The friction materials that press against the brake drum or rotor to slow the vehicle down.

- Wheel Cylinder Mounting Brackets: These brackets secure the wheel cylinder to the vehicle’s axle or suspension.

How a Wheel Cylinder Works

Imagine a simple lever system where pushing down on one end causes the other end to lift a heavy object. In a wheel cylinder, hydraulic pressure acts as the force applied to the lever, and the brake shoes or pads are the object being lifted.

When the brake pedal is pressed, the master cylinder sends hydraulic pressure through the brake lines to the wheel cylinders. This pressure acts on the pistons inside the wheel cylinder, forcing them outward. The pistons push against the brake shoes or pads, which in turn press against the brake drum or rotor, creating friction that slows down the wheel. When the brake pedal is released, the return springs pull the pistons back, releasing the pressure on the brake shoes or pads.

Types of Wheel Cylinders

Wheel cylinders are crucial components of a vehicle’s braking system, responsible for converting hydraulic pressure into mechanical force that activates the brake shoes. Different types of wheel cylinders are designed to meet the specific requirements of various vehicle applications.

Wheel Cylinder Construction

The construction of a wheel cylinder plays a vital role in its performance and durability. Different types of wheel cylinders are categorized based on their construction features, including:

- Single-piston wheel cylinders are the simplest and most common type. They feature a single piston that pushes out the brake shoes when hydraulic pressure is applied. These cylinders are typically used in rear brake systems of older vehicles.

- Two-piston wheel cylinders are more common in modern vehicles. They utilize two pistons that work in tandem to push out the brake shoes. This design provides greater braking force and better distribution of pressure.

- Self-adjusting wheel cylinders are equipped with an automatic adjustment mechanism that compensates for wear on the brake shoes. This feature ensures consistent brake performance and reduces the need for manual adjustments.

Wheel Cylinder Material

The material used to construct a wheel cylinder also affects its performance and durability. Common materials include:

- Cast iron is a durable and cost-effective material, but it can be susceptible to corrosion. Cast iron wheel cylinders are often used in older vehicles.

- Aluminum is a lightweight and corrosion-resistant material. Aluminum wheel cylinders are becoming increasingly popular in modern vehicles due to their durability and weight-saving benefits.

Wheel Cylinder Applications

The type of wheel cylinder used in a vehicle depends on the specific application and requirements. For example:

- Single-piston wheel cylinders are commonly used in rear brake systems of older vehicles with drum brakes. They offer a simple and cost-effective solution for basic braking needs.

- Two-piston wheel cylinders are typically found in modern vehicles with drum brakes. They provide increased braking force and better pressure distribution, enhancing overall braking performance.

- Self-adjusting wheel cylinders are commonly used in rear brake systems to ensure consistent brake performance and reduce the need for manual adjustments. This type of cylinder is particularly beneficial in vehicles that experience frequent brake wear.

Wheel Cylinder Operation

The wheel cylinder is a crucial component in a hydraulic braking system, responsible for converting hydraulic pressure into mechanical force that applies the brake shoes or pads to the brake drum or rotor. This process involves the flow of brake fluid through the wheel cylinder, the interaction of the piston and cup, and the resulting mechanical force.

Brake Fluid Flow

The brake fluid flow through the wheel cylinder is a vital part of the braking process. When the brake pedal is pressed, the master cylinder pushes brake fluid through the brake lines to the wheel cylinders.

- The brake fluid enters the wheel cylinder through an inlet port.

- The fluid pressure acts on the piston, which is sealed by a cup.

- The pressure pushes the piston outward, expanding the brake shoes or pads against the brake drum or rotor.

Role of the Piston and Cup

The piston and cup within the wheel cylinder are essential for the efficient operation of the braking system.

- The piston is a cylindrical component that moves within the wheel cylinder.

- The cup is a rubber seal that fits around the piston and creates a tight seal within the wheel cylinder.

- The cup prevents brake fluid leakage and ensures that the hydraulic pressure is effectively transmitted to the piston.

Conversion of Hydraulic Pressure to Mechanical Force

The wheel cylinder’s primary function is to convert hydraulic pressure into mechanical force.

- When brake fluid pressure acts on the piston, the piston moves outward.

- The outward movement of the piston pushes the brake shoes or pads against the brake drum or rotor.

- This creates friction, which slows down or stops the vehicle.

Wheel Cylinder Failure

Wheel cylinders are crucial components of a vehicle’s braking system, responsible for converting hydraulic pressure into mechanical force that actuates the brake shoes or pads. Over time, these cylinders can wear out or fail, leading to compromised braking performance and potential safety hazards.

Signs of a Failing Wheel Cylinder

A failing wheel cylinder can manifest itself through several noticeable symptoms. Early detection and prompt repair are essential to prevent further damage and ensure safe driving.

- Brake Fluid Leaks: One of the most common signs of a failing wheel cylinder is brake fluid leakage. This can be observed as a wet spot on the wheel rim or brake drum/rotor, often accompanied by a noticeable brake fluid odor. The leak is typically caused by a worn-out or damaged cylinder seal.

- Spongy Brake Pedal: A soft or spongy brake pedal is another indicator of a failing wheel cylinder. This occurs when the cylinder’s internal seals deteriorate, allowing brake fluid to bypass the piston and reduce pressure.

- Uneven Brake Application: If one or more wheel cylinders fail, it can result in uneven brake application. This can manifest as a pulling sensation when braking or a noticeable difference in braking force between the wheels.

- Dragging Brakes: A failing wheel cylinder can cause the brakes to drag, resulting in excessive heat and wear on the brake pads or shoes. This is usually due to a sticking piston within the cylinder, preventing it from fully retracting.

- Grinding or Squealing Noise: A grinding or squealing noise during braking could indicate a failing wheel cylinder. This is often caused by worn-out brake pads or shoes scraping against the brake rotor or drum, which can be exacerbated by a sticking piston within the wheel cylinder.

Causes of Wheel Cylinder Failure

Wheel cylinder failure can be attributed to several factors, including:

- Corrosion: Wheel cylinders are susceptible to corrosion, especially in areas prone to moisture or salt exposure. Corrosion can damage the cylinder’s seals and internal components, leading to leaks and malfunctions.

- Wear and Tear: Like any mechanical component, wheel cylinders are subject to wear and tear over time. The constant pressure and friction associated with braking can cause the cylinder’s seals and pistons to wear out, eventually leading to failure.

- Contamination: Contamination of brake fluid with moisture, dirt, or other debris can accelerate wear and tear on wheel cylinder seals and pistons. This can lead to premature failure and compromise braking performance.

- Heat: Excessive heat generated by the braking system can also contribute to wheel cylinder failure. The seals and other internal components can become damaged or deteriorate under prolonged high temperatures.

Consequences of a Failed Wheel Cylinder

A failed wheel cylinder can have several serious consequences, including:

- Reduced Braking Performance: A failing wheel cylinder can significantly reduce braking performance, making it difficult to stop the vehicle safely.

- Uneven Braking: A failed wheel cylinder can lead to uneven braking, causing the vehicle to pull to one side when braking or resulting in unpredictable braking behavior.

- Brake Fluid Leaks: A leaking wheel cylinder can deplete the brake fluid reservoir, leading to complete brake failure.

- Damage to Other Components: A failed wheel cylinder can cause damage to other braking system components, such as brake pads or shoes, rotors or drums, and even the brake lines.

- Increased Risk of Accidents: A failed wheel cylinder can significantly increase the risk of accidents due to compromised braking performance and unpredictable vehicle behavior.

Replacing a Wheel Cylinder

Replacing a wheel cylinder is a common maintenance task for vehicles, especially older ones. It involves removing the old cylinder and installing a new one. This procedure requires basic mechanical skills and appropriate tools.

Tools and Materials, What is wheel cylinder

The tools and materials needed for replacing a wheel cylinder include:

- Jack and jack stands

- Lug wrench

- Wheel cylinder wrench

- Socket set

- Wrench set

- Pliers

- Brake fluid

- New wheel cylinder

- Brake line wrench

- Cleaning rags

- Safety glasses

- Gloves

It’s crucial to use the correct tools and materials for this task. Using the wrong tools can damage the parts or cause injury.

Safety Precautions

Before starting the replacement process, it’s essential to take the following safety precautions:

- Park the vehicle on a level surface and engage the parking brake.

- Chock the front and rear wheels to prevent the vehicle from rolling.

- Wear safety glasses and gloves to protect your eyes and hands.

- Avoid touching brake fluid as it can damage your skin and clothing.

- Do not work on the vehicle while the engine is running.

- Make sure the brake system is properly bled after replacing the wheel cylinder.

Wheel Cylinder Maintenance: What Is Wheel Cylinder

Wheel cylinders are a critical component of your vehicle’s braking system, responsible for converting hydraulic pressure into mechanical force that pushes the brake shoes or pads against the brake drum or rotor. Ensuring their proper functioning is essential for safe and reliable braking.

Routine Maintenance Schedule

A regular maintenance schedule can help to prevent wheel cylinder failure and extend their lifespan. Here’s a recommended schedule:

- Visual Inspection: Inspect wheel cylinders for signs of leaks, corrosion, or damage during every routine brake inspection, typically every 6 months or 5,000 miles.

- Fluid Level Check: Check the brake fluid level in the master cylinder reservoir regularly. Low fluid levels can indicate a leak in the system, including a leaking wheel cylinder.

- Brake Pad/Shoe Inspection: Inspect brake pads/shoes for wear and tear. Worn pads/shoes can lead to increased pressure on the wheel cylinders, potentially causing damage.

- Wheel Cylinder Replacement: Replace wheel cylinders every 50,000 to 70,000 miles, or sooner if signs of wear or damage are detected.

Importance of Regular Inspection

Regular inspections are crucial for early detection of problems that could lead to catastrophic brake failure.

- Leaks: Leaking wheel cylinders can cause a loss of brake fluid, reducing braking effectiveness and potentially leading to brake failure.

- Corrosion: Corrosion can damage the internal components of the wheel cylinder, causing them to seize or leak.

- Damage: Physical damage to the wheel cylinder can compromise its ability to function properly.

Tips for Extending Lifespan

- Use High-Quality Brake Fluid: Using high-quality brake fluid helps prevent corrosion and ensures proper lubrication of the wheel cylinder components.

- Avoid Overheating: Overheating brakes can damage wheel cylinders. Avoid prolonged braking or excessive downhill driving.

- Proper Maintenance: Regularly inspecting and maintaining your brake system can help prevent premature wheel cylinder failure.

Wheel Cylinder in Different Vehicle Types

Wheel cylinders are essential components of a vehicle’s braking system, and their design and function can vary depending on the type of vehicle. Understanding these differences is crucial for proper maintenance and repair.Wheel cylinder designs and maintenance considerations differ significantly across various vehicle types. This variation is influenced by factors such as vehicle weight, braking system design, and intended usage.

Wheel Cylinder Designs in Different Vehicle Types

The design of a wheel cylinder can vary depending on the vehicle type. Here’s a breakdown of common variations:* Passenger Cars: Passenger cars typically employ smaller wheel cylinders due to their lighter weight and smaller braking system demands. They often feature single-piston designs for simplicity and cost-effectiveness.

Trucks and SUVs

Heavier vehicles, like trucks and SUVs, require larger wheel cylinders to handle the increased braking forces. They often feature dual-piston designs for greater braking power and improved heat dissipation.

Sports Cars

High-performance sports cars may utilize larger wheel cylinders with specialized materials to handle the extreme braking forces generated during spirited driving. They may also feature advanced features like vented rotors for better cooling.

Commercial Vehicles

Commercial vehicles, such as buses and delivery trucks, require robust wheel cylinders capable of withstanding heavy loads and frequent braking. They often feature heavy-duty designs with larger pistons and reinforced components.

Wheel Cylinder Maintenance in Different Vehicle Types

Maintaining wheel cylinders is essential for ensuring safe and reliable braking performance. However, the frequency and specifics of maintenance can vary depending on the vehicle type:* Passenger Cars: Passenger cars typically require wheel cylinder inspection and maintenance every 2-3 years or 30,000 miles.

Trucks and SUVs

Heavier vehicles, due to their higher braking loads, may require more frequent inspection and maintenance, potentially every 1-2 years or 20,000 miles.

Sports Cars

Sports cars, with their more demanding braking systems, often require more frequent inspections and potentially earlier replacement of wheel cylinders compared to other vehicle types.

Commercial Vehicles

Commercial vehicles, with their heavy-duty use, require regular inspections and maintenance schedules based on mileage or time, often at shorter intervals than passenger vehicles.

Impact of Vehicle Weight and Braking System Design

Vehicle weight and braking system design have a significant impact on wheel cylinder performance:* Vehicle Weight: Heavier vehicles require larger wheel cylinders to generate sufficient braking force to stop the vehicle effectively. Larger wheel cylinders have larger pistons and can handle higher hydraulic pressure.

Braking System Design

The design of the braking system, including the type of calipers, rotors, and brake lines, also influences wheel cylinder performance. For example, vehicles with disc brakes typically require larger wheel cylinders than those with drum brakes.

The weight of the vehicle and the braking system design directly influence the size and performance of the wheel cylinders.

Wheel Cylinder and Safety

The wheel cylinder is a critical component in your vehicle’s braking system, playing a vital role in stopping your car safely and effectively. A properly functioning wheel cylinder ensures that your brakes engage promptly and consistently, providing you with the stopping power you need to avoid accidents. However, a failing wheel cylinder can severely compromise your braking system, putting you and other road users at risk.

Impact of a Failing Wheel Cylinder on Braking Performance

A malfunctioning wheel cylinder can lead to various braking issues, significantly affecting your vehicle’s ability to stop safely. Here’s how a failing wheel cylinder can impact braking performance:

- Reduced Braking Force: A failing wheel cylinder might not generate enough hydraulic pressure to push the brake shoes or pads against the brake drum or rotor. This results in a diminished braking force, making it harder to stop your vehicle in time, especially during emergency braking situations.

- Uneven Braking: If one or more wheel cylinders fail, the braking force may become uneven across the wheels. This can lead to the vehicle pulling to one side during braking, making it difficult to maintain control, particularly at higher speeds.

- Spongy or Soft Brake Pedal: A failing wheel cylinder can cause a spongy or soft brake pedal feel. This indicates a leak in the hydraulic system, reducing the pressure required to engage the brakes. A soft brake pedal means that more pressure is needed to stop the vehicle, which can be dangerous in emergency situations.

- Brake Fluid Leaks: A damaged wheel cylinder can leak brake fluid, which is essential for proper braking function. As brake fluid leaks, the system’s hydraulic pressure decreases, leading to diminished braking performance and potential damage to other brake components.

So, next time you hit the brakes, take a moment to appreciate the little wheel cylinder diligently working behind the scenes. Understanding its function and maintenance is key to ensuring safe and reliable braking. By recognizing the signs of a failing wheel cylinder and addressing them promptly, you can prevent potential hazards and maintain the peace of mind that comes with knowing your vehicle is in good working order.

Popular Questions

How often should I inspect my wheel cylinders?

It’s recommended to inspect your wheel cylinders at least once a year or whenever you’re servicing your brakes.

What are the signs of a leaking wheel cylinder?

Look for brake fluid leaks around the wheel cylinder, brake pedal going to the floor, a spongy brake pedal feel, and a grinding or squealing noise when braking.

Can I replace a wheel cylinder myself?

While it’s possible, replacing a wheel cylinder requires some mechanical skills and specialized tools. If you’re not comfortable, it’s best to take it to a qualified mechanic.

What type of brake fluid should I use?

Consult your vehicle’s owner’s manual for the recommended brake fluid type. Using the wrong fluid can damage your braking system.