Why do semi wheels have spikes? The answer lies in the need for enhanced traction, particularly in challenging weather conditions. These seemingly simple metal protrusions play a crucial role in ensuring the safe and efficient operation of large trucks, especially on icy or snowy roads. Throughout history, the evolution of semi-trailer tires has been driven by the constant pursuit of improved grip, and spikes represent a significant step in this journey.

From their origins in the early days of trucking to their continued use in specific environments, spikes have become an integral part of the trucking industry’s arsenal for navigating slippery surfaces. However, their impact extends beyond mere traction, raising concerns about road damage, environmental considerations, and even safety. This exploration delves into the world of semi-trailer spikes, uncovering their history, purpose, types, and the ongoing debate surrounding their use.

Purpose of Spikes

The spikes, or studs, found on semi-trailer tires are a common sight, particularly during winter months. These seemingly aggressive protrusions serve a crucial purpose: enhancing traction and safety on slippery surfaces.

Historical Development and Problem Solving

The use of studded tires dates back to the early 20th century. In the early days of motor vehicles, drivers often struggled with limited traction on icy roads. This led to the development of studded tires, which offered a more secure grip, reducing the risk of accidents. The initial studs were often made of metal, but over time, materials like carbide and tungsten carbide were adopted for their increased durability and resistance to wear.

These materials proved more effective in gripping ice and snow, significantly improving traction on slippery surfaces.

Effectiveness in Different Weather Conditions

The effectiveness of studded tires varies significantly depending on the road conditions.

Dry Roads

On dry roads, studded tires can actually decrease traction. The studs can create a slight drag, potentially reducing braking distance and making steering less responsive.

Wet Roads

In wet conditions, studded tires offer little advantage over regular tires. The presence of water on the road surface negates the benefits of the studs.

Snowy Roads

Studded tires are most effective on snowy roads. The spikes dig into the snow, providing superior grip compared to regular tires.

Icy Roads

On icy roads, studded tires are essential for safety. The studs bite into the ice, providing a secure grip that prevents skidding and loss of control.

Types of Spikes

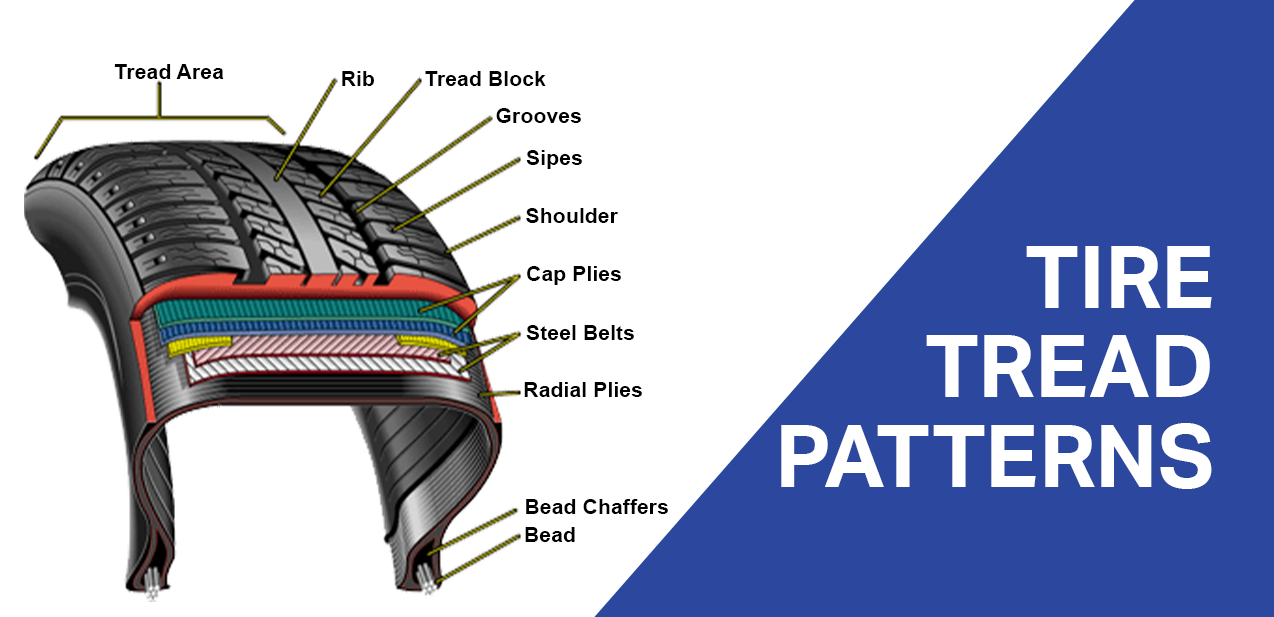

Semi-trailer tires are equipped with various types of spikes, each designed to enhance traction and control on icy and snowy surfaces. These spikes are typically made from hardened steel or carbide and are embedded into the tire tread.The choice of spike type depends on factors like the type of vehicle, driving conditions, and the intended application.

Types of Spikes

- Studded Spikes: These are the most common type of spikes used on semi-trailers. They are made from hardened steel and have a cylindrical or conical shape with a pointed tip. Studded spikes are typically installed in a staggered pattern across the tire tread to provide optimal traction.

- Carbide Spikes: Carbide spikes are made from tungsten carbide, a material known for its exceptional hardness and durability. They are often used in applications where extreme traction is required, such as heavy-duty trucking and off-road driving. Carbide spikes are typically smaller and more pointed than studded spikes, providing superior grip on icy surfaces.

- Screw-In Spikes: These spikes are designed to be screwed into the tire tread. They are typically made from hardened steel and have a threaded shank that allows them to be easily installed and removed. Screw-in spikes are often used in applications where the tire tread needs to be replaced frequently, such as in mining or construction.

- Clip-On Spikes: Clip-on spikes are a relatively new type of spike that is designed to be easily attached and removed from the tire tread. They are typically made from hardened steel or carbide and have a clip mechanism that allows them to be securely fastened to the tire. Clip-on spikes are often used in applications where the tire tread needs to be replaced frequently, such as in snow removal or ice road driving.

Spike Designs and Advantages, Why do semi wheels have spikes

- Conical Spikes: These spikes have a conical shape with a pointed tip. Conical spikes are known for their excellent penetration and grip on icy surfaces. They are also relatively durable and can withstand high levels of wear and tear.

- Cylindrical Spikes: Cylindrical spikes have a cylindrical shape with a rounded tip. They are typically less aggressive than conical spikes but can still provide good traction on icy surfaces. Cylindrical spikes are also less likely to damage the road surface.

- Triangular Spikes: Triangular spikes have a triangular shape with a pointed tip. They are known for their aggressive grip on icy surfaces but can also be more prone to wear and tear. Triangular spikes are typically used in applications where extreme traction is required, such as in heavy-duty trucking or off-road driving.

Comparison of Spike Types

| Spike Type | Material | Traction | Wear | Noise | Applications |

|---|---|---|---|---|---|

| Studded Spikes | Hardened Steel | Good | Moderate | Moderate | Heavy-duty trucking, passenger vehicles |

| Carbide Spikes | Tungsten Carbide | Excellent | High | High | Heavy-duty trucking, off-road driving |

| Screw-In Spikes | Hardened Steel | Good | Moderate | Moderate | Mining, construction |

| Clip-On Spikes | Hardened Steel or Carbide | Good | Moderate | Moderate | Snow removal, ice road driving |

Impact on Road Surfaces

Spiked tires, while offering advantages in specific conditions, can have a detrimental impact on road surfaces. The sharp metal projections penetrate and damage asphalt and concrete, leading to accelerated wear and tear, requiring more frequent repairs and maintenance. This section explores the potential damage caused by spikes and the regulations governing their use.

Regulations and Restrictions

The use of spiked tires is subject to regulations and restrictions in various regions due to their potential to damage road surfaces. These regulations are designed to balance the need for traction in specific conditions with the need to protect road infrastructure.

- In many countries, spiked tires are prohibited on public roads during the warmer months when road surfaces are less prone to freezing. This restriction is intended to minimize damage to roads during periods when spikes are less necessary for traction.

- Some regions may allow spiked tires only on designated routes or during specific time periods, often during the winter months when icy conditions prevail. These regulations ensure that the use of spikes is limited to situations where their benefits outweigh the risks to road surfaces.

- Specific restrictions may apply to the types of spikes allowed, their size, and the number of spikes per tire. These regulations aim to minimize the severity of damage caused by spikes while still providing sufficient traction.

Pros and Cons of Spiked Tires from a Road Maintenance Perspective

| Pros | Cons |

|---|---|

| Enhanced traction on icy and snowy surfaces, improving safety and reducing accidents. | Increased wear and tear on road surfaces, requiring more frequent repairs and maintenance. |

| Potentially beneficial for specific applications, such as heavy-duty vehicles operating in extreme winter conditions. | Potential for damage to asphalt and concrete, leading to costly repairs and disruptions to traffic flow. |

| May be necessary for certain industries or activities where traction is critical. | Noise pollution caused by spikes impacting road surfaces, contributing to community disturbances. |

Alternatives to Spikes: Why Do Semi Wheels Have Spikes

While spikes offer a reliable solution for enhancing traction on semi-trailers, their drawbacks, including road damage and noise pollution, have prompted the search for alternative solutions. Several innovations have emerged, offering comparable or even superior traction capabilities while minimizing environmental impact.

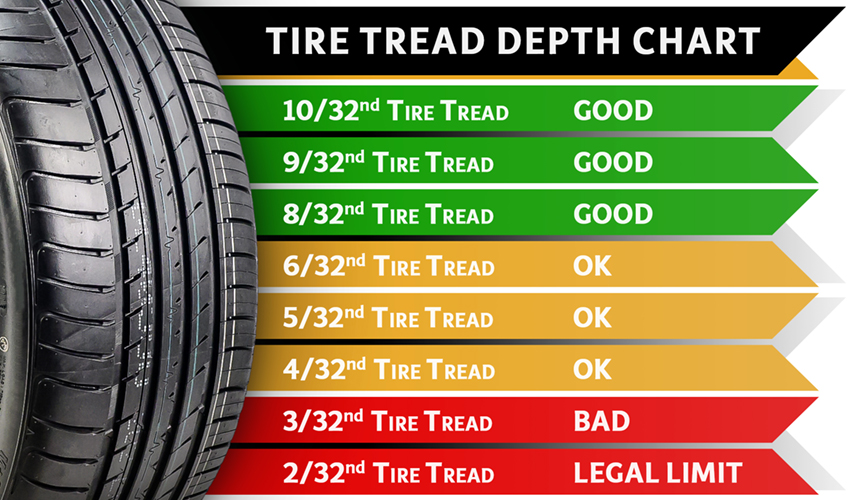

Specialized Tire Tread Patterns

Specialized tire tread patterns are designed to provide increased grip on various road surfaces, particularly in challenging conditions. These patterns feature deeper grooves, wider spacing, and strategically placed lugs, which enhance the tire’s ability to grip the road surface, effectively replacing the need for spikes.

Benefits of Specialized Tread Patterns

- Enhanced Traction: These patterns offer significant traction improvement on both dry and wet surfaces, ensuring safe and reliable braking and acceleration.

- Reduced Wear: The absence of spikes minimizes the wear and tear on both tires and road surfaces, extending tire lifespan and reducing maintenance costs.

- Lower Noise Pollution: Specialized tread patterns significantly reduce the noise generated by tires, improving the overall driving experience and minimizing environmental impact.

Chains

Chains are a traditional solution for enhancing traction on semi-trailers, particularly during winter conditions. They are typically installed on drive tires and provide additional grip on snow and ice.

Types of Chains

- Standard Chains: These chains are commonly used and offer a reliable solution for increasing traction on snow and ice. They are relatively inexpensive and widely available.

- Cable Chains: Cable chains are lighter and more flexible than standard chains, offering better maneuverability and less wear on tires.

- Tire Spikes: Tire spikes are a relatively new innovation that combines the benefits of chains with the ease of installation of spikes. They are typically installed on the drive tires and offer excellent traction on snow and ice.

Benefits of Chains

- Excellent Traction: Chains provide superior traction on snow and ice compared to spikes, significantly improving braking and acceleration performance.

- Versatility: Chains can be installed and removed quickly and easily, making them adaptable to various weather conditions.

- Cost-Effective: Chains are relatively inexpensive compared to other traction-enhancing solutions, making them a budget-friendly option.

Drawbacks of Chains

- Road Damage: Chains can cause damage to road surfaces, particularly when used on dry pavement.

- Noise Pollution: Chains generate significant noise, which can be disruptive to other road users and contribute to environmental pollution.

- Limited Use: Chains are primarily effective on snow and ice, making them less suitable for other road conditions.

Safety Considerations

While spiked tires offer traction benefits, they also pose safety risks that should be carefully considered. The unique design of spiked tires, with their protruding metal studs, can lead to various issues that compromise vehicle safety and potentially cause accidents.

Potential Safety Hazards

- Punctures: Spiked tires are more susceptible to punctures than regular tires due to the protruding studs. These studs can easily snag on debris, road imperfections, or even potholes, leading to punctures and tire damage.

- Blowouts: The constant stress and wear on the tire caused by the spikes can weaken the tire structure, increasing the risk of blowouts. This is especially true if the spikes are not properly installed or maintained.

- Reduced Traction on Dry Surfaces: While spiked tires provide excellent traction on ice and snow, they can actually reduce traction on dry surfaces. The studs can dig into the pavement, causing the tires to lose grip and potentially leading to skidding or loss of control.

- Increased Risk of Accidents: The combination of punctures, blowouts, and reduced traction on dry surfaces significantly increases the risk of accidents. Spiked tires can also make it difficult to steer and brake effectively, particularly on dry roads.

Situations Where Spiked Tires Might Be Unsafe or Impractical

- Dry Road Conditions: Spiked tires are designed for winter conditions and can be detrimental to driving on dry roads. The studs can cause excessive wear on the pavement and increase the risk of skidding.

- High-Speed Driving: The increased friction and potential for instability caused by spiked tires can make them unsuitable for high-speed driving. The studs can also cause vibrations and noise at higher speeds, making the ride uncomfortable.

- Urban Areas: Spiked tires are generally not recommended for driving in urban areas. The studs can damage roads and sidewalks, and they can also be a safety hazard to pedestrians and cyclists.

- Limited Tire Life: Spiked tires typically have a shorter lifespan than regular tires due to the wear and tear caused by the studs. Replacing spiked tires more frequently can be an added expense.

Examples of Accidents Involving Spiked Tires

- Case 1: A truck driver lost control of his vehicle on a dry road due to the reduced traction of his spiked tires. The truck veered off the road and collided with a tree, resulting in significant damage and injuries. The accident was attributed to the driver’s failure to switch to regular tires when road conditions improved.

- Case 2: A passenger car with spiked tires experienced a blowout on a highway. The driver lost control of the vehicle and collided with a guardrail, causing serious injuries to the occupants. The blowout was caused by the constant wear and tear on the tires due to the studs.

The use of spikes on semi-trailer tires remains a complex issue, balancing the need for enhanced traction with concerns about road damage, environmental impact, and safety. While spikes provide a crucial advantage in specific weather conditions, their effectiveness comes at a cost. Alternative traction-enhancing solutions, such as specialized tire tread patterns and chains, are continuously evolving, offering potentially safer and more environmentally friendly options.

As the trucking industry navigates the ever-changing landscape of road conditions and regulations, the debate surrounding spikes will likely continue, prompting ongoing research and innovation in the pursuit of safer and more sustainable transportation solutions.

FAQ Section

Are spikes still used on semi-trailers today?

Yes, spikes are still used on semi-trailers in certain regions and situations, particularly in areas with frequent snowfall or icy conditions. However, their use is becoming less common due to regulations and the development of alternative traction-enhancing solutions.

What are the main disadvantages of using spikes on semi-trailer tires?

The main disadvantages of using spikes include road damage, noise pollution, increased tire wear, and potential safety hazards. Spikes can damage asphalt and concrete surfaces, leading to costly repairs. They also generate significant noise, contributing to noise pollution, and can lead to punctures or blowouts if not properly maintained.

Are spikes legal in all areas?

No, regulations regarding the use of spiked tires vary depending on the region. Some areas have outright bans on spikes, while others restrict their use to specific times of the year or require special permits.

What are some alternatives to using spikes on semi-trailers?

Alternative traction-enhancing solutions include specialized tire tread patterns designed for winter conditions, chains, and tire-mounted traction devices. These options offer comparable traction benefits with reduced road damage and noise pollution.