Can a bad wheel bearing cause vibration at high speeds – So, you’re feeling some serious vibrations when you’re hitting the gas, right? You might be thinking, “Is it just me, or is my car acting a bit dodgy?” Well, it could be your wheel bearings playing up, mate. Wheel bearings are like the little superheroes keeping your wheels spinning smoothly, but when they start to go kaput, you’ll feel the effects, especially at higher speeds.

Think of it like a wobbly wheel on a bike, but in your car, it can be a real pain.

Imagine driving down the motorway, and suddenly your steering wheel starts shaking like it’s having a fit. Or maybe you hear a weird grinding noise that gets louder as you speed up. These are all signs that your wheel bearings might be on the fritz. And if you ignore them, it can lead to some serious problems down the line, like a blown tyre or even a complete wheel failure.

Understanding Wheel Bearings: Can A Bad Wheel Bearing Cause Vibration At High Speeds

Wheel bearings are crucial components in a vehicle’s suspension system, playing a vital role in supporting the weight of the vehicle and allowing the wheels to rotate smoothly. They are essentially a set of rolling elements that enable the wheel to turn freely while reducing friction.

Types of Wheel Bearings

Wheel bearings can be broadly categorized into two main types:

- Ball Bearings: Ball bearings consist of a set of steel balls that are contained within a raceway. The balls roll between the inner and outer races, allowing for smooth rotation. These bearings are commonly used in older vehicles and are known for their simplicity and affordability.

- Tapered Roller Bearings: Tapered roller bearings, as the name suggests, use tapered rollers instead of balls. This design provides greater load-carrying capacity and better resistance to axial forces, making them suitable for heavier vehicles and applications where significant lateral loads are present. Tapered roller bearings are more complex and often require more maintenance than ball bearings.

Components of a Wheel Bearing Assembly

A wheel bearing assembly typically consists of several key components:

- Inner Race: The inner race is a circular ring that is fixed to the axle shaft. It provides a smooth surface for the rolling elements to rotate on.

- Outer Race: The outer race is another circular ring that is pressed into the hub. It also provides a smooth surface for the rolling elements to rotate on.

- Rolling Elements: These are the balls or rollers that allow the wheel to rotate smoothly. The rolling elements are typically made of hardened steel for durability and wear resistance.

- Cage: The cage, also known as a separator, is a component that keeps the rolling elements spaced evenly and prevents them from coming into contact with each other. It is typically made of plastic or metal.

- Grease: A thick lubricant, usually a grease, is applied to the bearing components to reduce friction and prevent wear. The grease also helps to protect the bearings from moisture and dirt.

- Seal: A seal is used to prevent contaminants, such as dirt and water, from entering the bearing assembly. The seal helps to ensure that the grease stays in place and the bearings continue to operate smoothly.

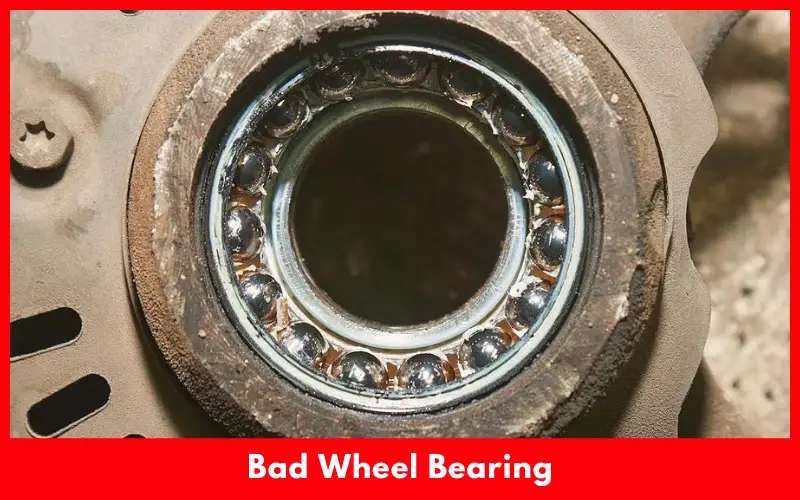

Signs of a Failing Wheel Bearing

A failing wheel bearing can cause a range of symptoms, from subtle noises to noticeable vibrations. These symptoms are often the first indication that your wheel bearing is wearing out and needs attention. Ignoring these signs can lead to more serious problems, including a complete bearing failure, which can result in loss of control and potentially a serious accident.

Vibrations at High Speeds, Can a bad wheel bearing cause vibration at high speeds

A bad wheel bearing can cause vibration at high speeds due to the uneven rotation of the wheel. As the bearing wears down, the balls or rollers inside the bearing begin to lose their smooth rolling motion, causing a slight wobble in the wheel. This wobble is amplified at higher speeds, leading to a noticeable vibration that can be felt in the steering wheel, the floorboard, or the entire car.

Noise from the Wheel

One of the most common signs of a failing wheel bearing is a noise coming from the wheel. This noise can be a variety of sounds, including:

- Grinding: This indicates that the bearing is severely worn and the metal parts are grinding against each other.

- Rumbling: This is a deeper, more consistent sound that can be heard even at low speeds.

- Whirring: This is a high-pitched sound that often gets louder as the wheel spins faster.

- Clicking: This sound can be intermittent and is often heard when turning the steering wheel.

Steering Wheel Shake

A failing wheel bearing can cause the steering wheel to shake, especially at high speeds. This is because the uneven rotation of the wheel is transmitted through the steering column to the steering wheel. The severity of the shake can vary depending on the severity of the bearing wear.

Other Symptoms

In addition to the symptoms mentioned above, a failing wheel bearing can also cause:

- Uneven tire wear: A bad wheel bearing can cause the tire to wear unevenly, leading to a decrease in tire life.

- Pulling to one side: A bad wheel bearing can cause the car to pull to one side, especially when braking.

- Loose or wobbly wheel: If the bearing is completely worn out, the wheel may become loose or wobbly.

Causes of Wheel Bearing Failure

Wheel bearing failure is a common automotive issue that can lead to dangerous driving conditions and costly repairs. Understanding the factors that contribute to wheel bearing wear and tear can help you prevent premature failure and ensure a smoother, safer driving experience.

Driving Conditions and Their Impact

The conditions under which you drive can significantly impact the lifespan of your wheel bearings. Rough roads, heavy loads, and frequent off-road driving can all accelerate wear and tear.

- Rough Roads: Constant exposure to bumps, potholes, and uneven surfaces creates significant stress on wheel bearings. The repeated impact can cause the bearing components to wear down prematurely.

- Heavy Loads: Carrying heavy loads, such as towing a trailer or hauling cargo, puts extra strain on the wheel bearings. The increased weight can lead to faster wear and tear, especially if the bearings are already nearing the end of their service life.

- Off-Road Driving: Off-road driving often involves navigating uneven terrain, which can expose wheel bearings to extreme forces and vibrations. This can lead to faster wear and tear, especially if the bearings are not properly lubricated.

Consequences of Neglecting Maintenance

Neglecting regular maintenance can significantly shorten the lifespan of your wheel bearings and lead to a cascade of problems.

- Premature Failure: Failing to lubricate wheel bearings regularly can cause them to wear down faster, leading to premature failure.

- Increased Wear and Tear: A worn-out wheel bearing can cause other components in the suspension system to wear down faster, resulting in more frequent repairs.

- Safety Hazards: A failed wheel bearing can cause the wheel to seize, leading to a loss of control and a potentially dangerous accident.

Diagnosing a Bad Wheel Bearing

Diagnosing a bad wheel bearing involves a systematic approach to identify the source of the vibration and confirm if it’s indeed a failing bearing. The process involves visual inspection, listening for sounds, and testing for play in the wheel.

Visual Inspection

A visual inspection can reveal signs of damage or wear on the wheel bearing. Look for:

- Grease leaks: Excess grease or signs of grease leakage around the bearing area indicate a potential problem.

- Damaged seals: Damaged or worn-out seals around the bearing can allow contaminants to enter and damage the bearing.

- Rust or corrosion: Rust or corrosion on the bearing race or other bearing components can indicate water ingress and damage.

Differentiating from Other Causes

Vibrations at high speeds can be caused by various factors. To differentiate a bad wheel bearing from other potential causes, consider the following:

- Tire balance: Unbalanced tires can cause vibration at high speeds. Check if the vibration occurs at specific speeds or if it changes when driving at different speeds.

- Tire condition: Worn-out or damaged tires can also cause vibrations. Check for uneven wear, bulges, or cuts on the tires.

- Wheel alignment: Misaligned wheels can cause vibrations, especially at high speeds. Check if the steering wheel is straight when driving straight.

- Suspension components: Worn-out or damaged suspension components, such as shock absorbers, struts, or ball joints, can also cause vibrations. Inspect these components for signs of wear or damage.

Testing for Play or Looseness

Testing for play or looseness in the wheel bearing can confirm if it’s damaged. To test for play:

- Jack up the vehicle: Safely lift the vehicle using a jack and secure it with jack stands.

- Grab the tire at the top and bottom: Gently rock the tire back and forth. If you feel any play or movement in the wheel bearing, it’s likely damaged.

- Check for noise: Listen carefully for any grinding or rumbling sounds while rocking the tire. These sounds indicate a damaged bearing.

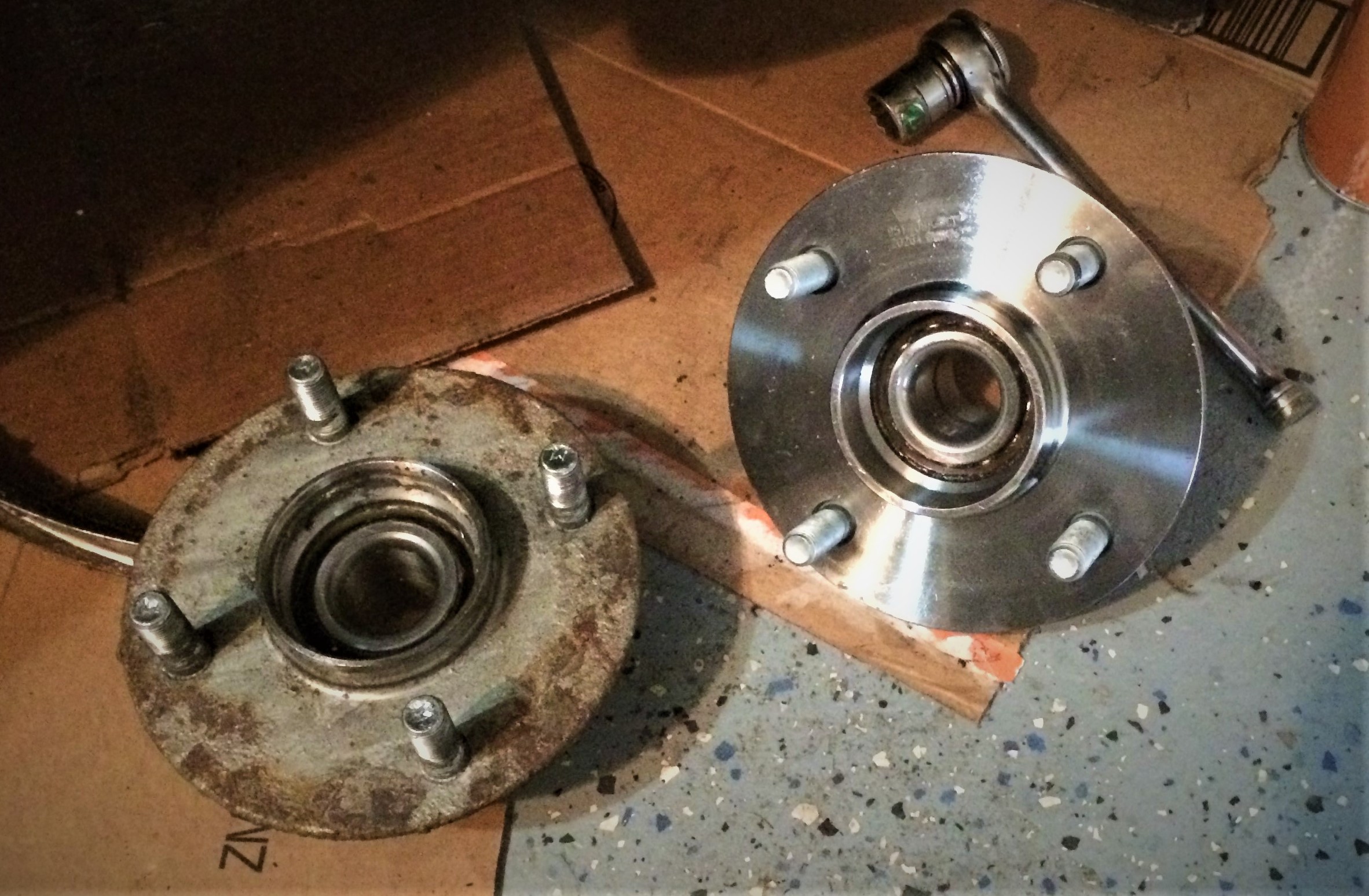

Replacing a Wheel Bearing

Replacing a worn or damaged wheel bearing is a necessary repair to ensure your vehicle’s safety and smooth operation. This process requires careful attention to detail and the use of appropriate tools and techniques.

Removing the Old Bearing

Before you begin, ensure you have a safe and well-lit workspace. It is recommended to consult your vehicle’s service manual for specific instructions and torque specifications for your particular model.

- Jack up the vehicle and secure it with jack stands. Never work under a vehicle supported only by a jack.

- Remove the wheel. This will give you access to the hub assembly.

- Remove the brake caliper and rotor. Be careful not to damage the brake lines or caliper.

- Remove the hub nut. This will require a large socket and a breaker bar. You may need to use a hammer and a chisel to break the nut loose if it is stuck.

- Remove the hub assembly from the spindle. This may require some force, but avoid using excessive force to prevent damaging the spindle. Use a puller if necessary.

- Press out the old bearing. This will require a bearing press or a suitable alternative tool. Use caution to avoid damaging the bearing race or the hub assembly.

Installing the New Bearing

Once the old bearing is removed, you can proceed with installing the new one.

- Clean the hub assembly and spindle. Remove any debris or rust to ensure a clean and secure fit for the new bearing.

- Press in the new bearing. Use a bearing press or a suitable alternative tool to press the new bearing into the hub assembly. Ensure the bearing is properly seated and that the race is flush with the hub.

- Install the hub assembly onto the spindle. Make sure the hub is properly aligned with the spindle and that the bearing races are seated correctly.

- Tighten the hub nut. Use a torque wrench to tighten the nut to the manufacturer’s specifications. Over-tightening the nut can damage the bearing.

- Reinstall the rotor, caliper, and wheel. Ensure the brake caliper is properly secured and that the wheel is properly tightened.

- Lower the vehicle. Remove the jack stands and carefully lower the vehicle.

- Test drive the vehicle. Drive the vehicle at different speeds to ensure the vibration is gone.

Basically, if you’re experiencing any kind of vibration or weird noises coming from your wheels, it’s best to get it checked out by a mechanic ASAP. It could be a simple fix, or it could be something more serious. But the sooner you get it sorted, the better. And remember, keeping your car in good nick isn’t just about making it look good, it’s about keeping you safe on the road.

Answers to Common Questions

How do I know if it’s definitely a bad wheel bearing?

A mechanic can do a proper inspection, but you can also try to identify the problem by jacking up your car and checking for play in the wheel. If the wheel wobbles or moves freely, it’s a strong sign of a bad bearing.

Can I drive with a bad wheel bearing?

It’s not ideal, but you can probably get away with it for a short distance. However, it’s best to get it fixed as soon as possible to avoid any further damage or a complete breakdown.

How much does it cost to replace a wheel bearing?

The cost of replacing a wheel bearing can vary depending on the make and model of your car. It’s best to get a quote from a mechanic before you proceed with any repairs.