How to tune a dirt bike carb – a phrase that echoes with the spirit of adventure and the thrill of pushing limits. It’s a journey into the heart of your engine, a dance between air and fuel, a symphony of power and precision. Every twist of the throttle, every surge of speed, is a testament to the intricate balance achieved within the carburetor.

But beyond the exhilarating rush, there’s a technical artistry involved, a deep understanding of how these components work in harmony to unleash the full potential of your dirt bike. This guide unveils the secrets of carburetor tuning, empowering you to unlock the true performance of your machine.

The carburetor, a vital organ in your dirt bike’s engine, acts as a maestro, orchestrating the perfect blend of air and fuel for combustion. It’s a complex system, comprised of elements like the air filter, float bowl, jetting system, and throttle mechanism, each playing a crucial role in the delicate dance of combustion. Understanding these components is the first step in mastering the art of carburetor tuning.

Understanding Your Dirt Bike Carb

The carburetor is the heart of your dirt bike’s fuel system, responsible for mixing air and fuel in the precise proportions needed for combustion. Understanding how your carburetor works is crucial for optimizing your bike’s performance and ensuring a smooth ride.

Key Components of a Dirt Bike Carburetor

The carburetor is a complex system with several key components that work together to deliver a combustible fuel-air mixture to the engine.

- Air Filter: The air filter is the first line of defense against dust and debris entering the carburetor. It’s typically made of foam or paper and needs to be cleaned or replaced regularly to maintain optimal airflow.

- Float Bowl: The float bowl houses the fuel and is responsible for maintaining a constant fuel level. It contains a float, a needle valve, and a jetting system.

- Jetting System: The jetting system consists of several small jets that control the flow of fuel into the carburetor. The main jet controls the amount of fuel delivered at full throttle, while the pilot jet regulates fuel flow at idle. The needle jet fine-tunes the fuel mixture at various throttle positions.

- Throttle Mechanism: The throttle mechanism allows the rider to control the amount of air entering the carburetor, which in turn regulates the fuel-air mixture. It consists of a throttle cable connected to a butterfly valve inside the carburetor.

How the Carburetor Mixes Air and Fuel

The carburetor works on the principle of venturi effect, where the speed of air flowing through a constricted passage increases, creating a low-pressure zone. This low-pressure zone draws fuel from the float bowl through the jets.

- Air Intake: Air enters the carburetor through the air filter and travels through the air intake.

- Venturi Effect: As air flows through the venturi, a low-pressure zone is created. This low pressure draws fuel from the float bowl through the jets.

- Fuel Mixing: The fuel and air mix inside the carburetor, forming a combustible mixture. The amount of fuel and air mixed is controlled by the throttle mechanism.

- Engine Intake: The fuel-air mixture is then drawn into the engine cylinder, where it ignites and powers the engine.

The ratio of air to fuel in the mixture is critical for optimal engine performance. Too much fuel will result in a rich mixture, leading to poor fuel economy and potential engine damage. Too little fuel will result in a lean mixture, causing overheating and potential engine damage.

Basic Carburetor Adjustment

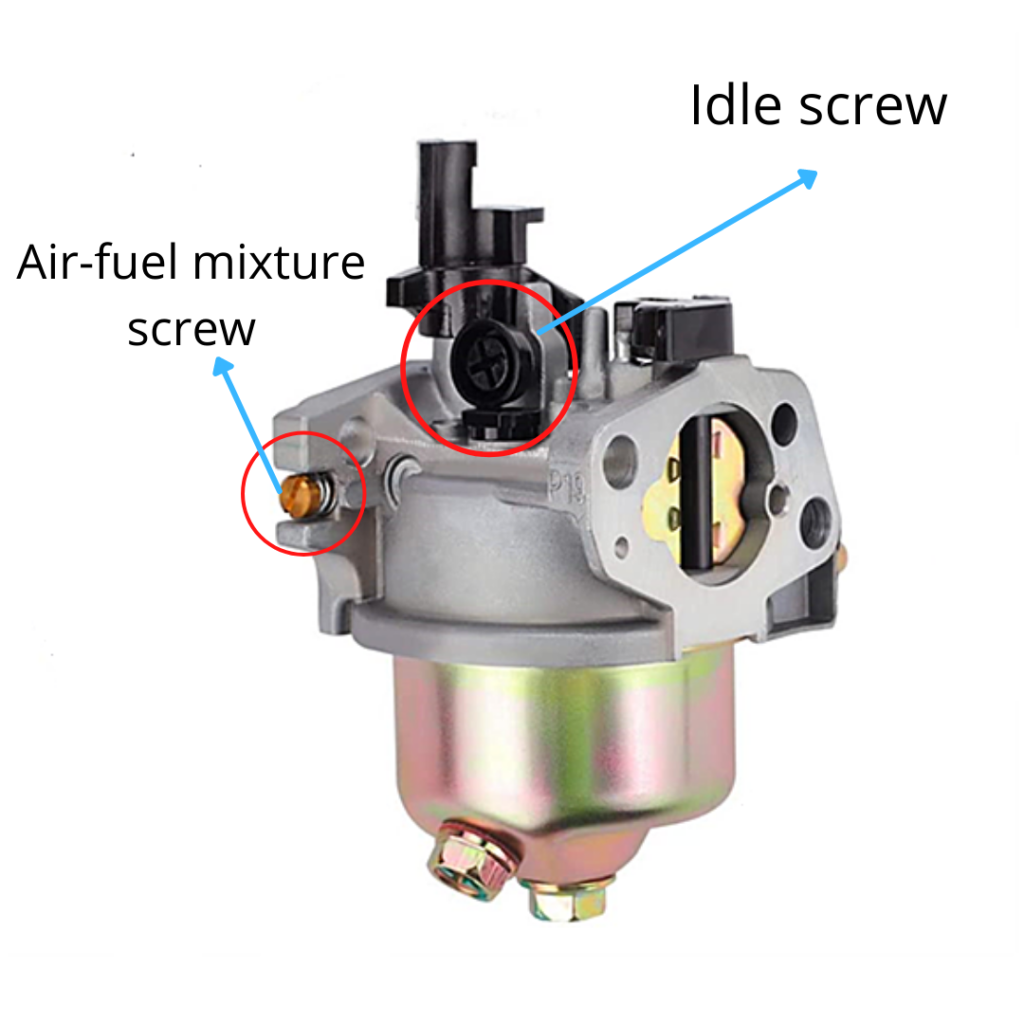

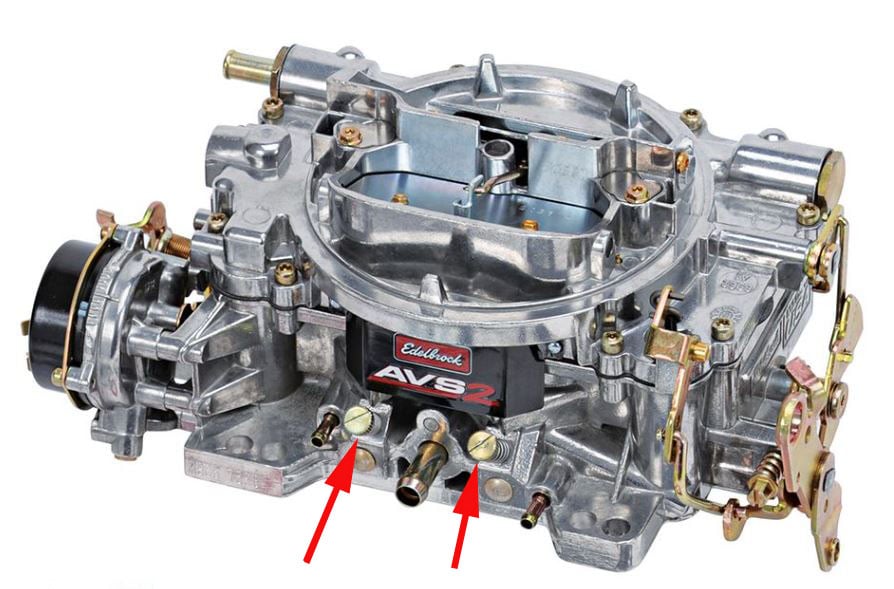

Carburetor adjustment is a crucial aspect of tuning a dirt bike, as it directly affects the engine’s performance and drivability. The two main screws on a dirt bike carburetor are the idle mixture screw and the throttle screw. Adjusting these screws allows you to fine-tune the fuel-air mixture entering the engine, resulting in a smooth idle, optimal throttle response, and overall better performance.

Adjusting the Idle Mixture Screw

The idle mixture screw controls the amount of air entering the carburetor at idle. Turning the screw clockwise increases the air-fuel ratio, while turning it counter-clockwise decreases it. Adjusting the idle mixture screw impacts the engine’s idle speed and smoothness.

- Start with the screw fully seated. This is the starting point for most carburetors.

- Turn the screw counter-clockwise approximately 1 1/2 to 2 turns. This will allow a small amount of air to enter the carburetor.

- Start the engine and let it warm up to operating temperature.

This ensures the engine is running at its optimal temperature for adjustment.

- Slowly turn the idle mixture screw clockwise until the engine reaches a smooth idle. As you turn the screw, listen for changes in engine sound and observe the RPM gauge.

- Once you reach a smooth idle, continue turning the screw clockwise until the engine starts to stumble or die. This is the point where the air-fuel mixture is too lean.

- Turn the screw back counter-clockwise a quarter turn. This will ensure the engine is running slightly rich, which is generally better for idle stability.

Adjusting the Throttle Screw

The throttle screw controls the amount of throttle opening at idle. Turning the screw clockwise increases the idle speed, while turning it counter-clockwise decreases it. This adjustment helps set the engine’s idle speed and ensure a smooth transition from idle to acceleration.

- Start with the throttle screw fully seated. This is the starting point for most carburetors.

- Turn the screw counter-clockwise approximately 1/4 to 1/2 turn. This will allow the throttle to open slightly at idle.

- Start the engine and let it warm up to operating temperature.

This ensures the engine is running at its optimal temperature for adjustment.

- Adjust the throttle screw until the engine reaches a smooth idle speed. You can use an RPM gauge to measure the idle speed, which is typically around 1,500 to 1,800 RPM for most dirt bikes.

- Ensure the engine idles smoothly without stalling. If the engine stalls or has an unstable idle, you may need to adjust the idle mixture screw again.

Advanced Tuning Techniques

Once you’ve mastered the basics of carburetor adjustment, you can delve into more advanced techniques to fine-tune your dirt bike’s performance for specific riding styles and terrains. These techniques involve adjusting the needle position and experimenting with different air filters.

Needle Position Adjustment, How to tune a dirt bike carb

The needle position plays a crucial role in controlling fuel delivery throughout the engine’s RPM range. Adjusting the needle height can alter the fuel-air mixture, impacting throttle response, acceleration, and overall performance.

- Raising the needle: This leans out the fuel-air mixture at mid-range RPMs, resulting in improved throttle response and acceleration. However, it may lead to a lean condition at high RPMs, potentially causing engine damage.

- Lowering the needle: This enriches the fuel-air mixture at mid-range RPMs, improving performance at higher RPMs. However, it can lead to a rich condition at lower RPMs, resulting in poor throttle response and fuel consumption.

Air Filter Selection

The type of air filter you use can significantly affect engine performance and fuel consumption.

- Foam filters: These are commonly used on dirt bikes and offer excellent filtration and durability. They are also relatively easy to clean and maintain.

- Paper filters: These are more restrictive than foam filters and provide less airflow. They are typically used on street bikes and are less prone to clogging.

Tuning for Specific Riding Styles and Terrains

- Trail riding: A slightly richer fuel-air mixture is generally preferred for trail riding, as it provides more torque and power for climbing hills and navigating technical sections. A lower needle position and a foam air filter with a slightly higher airflow can help achieve this.

- Motocross: For motocross, a leaner fuel-air mixture is typically desired for maximum power and acceleration. A higher needle position and a foam air filter with a higher airflow can help achieve this. However, it is crucial to ensure the mixture remains within safe limits to prevent engine damage.

- Enduro: Enduro riding often involves a mix of terrain, from tight woods to open trails. A balanced fuel-air mixture is generally recommended for enduro riding, ensuring good throttle response and fuel economy. This can be achieved by adjusting the needle position and air filter to strike a balance between power and fuel efficiency.

Troubleshooting Common Carburetor Problems: How To Tune A Dirt Bike Carb

Even with proper tuning, dirt bike carburetors can experience issues. Recognizing and addressing these problems is crucial for optimal engine performance. This section explores common carburetor malfunctions and provides troubleshooting steps for resolving them.

Fuel Leaks

Fuel leaks are a common problem with dirt bike carburetors. They can be caused by a variety of factors, including worn-out seals, loose fittings, or a damaged float valve. Fuel leaks can be dangerous and should be addressed immediately. Here are some steps for troubleshooting fuel leaks:

- Inspect the carburetor for visible leaks. Look for wet spots or dripping fuel around the carburetor body, float bowl, or fuel lines.

- Check the fuel lines for cracks or leaks. Examine the fuel lines for any signs of damage, such as cracks, splits, or loose connections.

- Inspect the float valve. The float valve is responsible for regulating the fuel level in the float bowl. A damaged or worn-out float valve can cause fuel to leak from the carburetor. To inspect the float valve, remove the float bowl and examine the float valve for damage or debris.

- Replace worn-out seals. The carburetor contains several seals that can wear out over time, leading to fuel leaks. Inspect the seals for damage and replace them as needed.

- Tighten loose fittings. If the carburetor has any loose fittings, tighten them to prevent fuel leaks.

Engine Flooding

Engine flooding occurs when too much fuel enters the combustion chamber, preventing the engine from starting or running smoothly. This can be caused by a variety of factors, including a stuck float valve, a faulty choke, or a clogged carburetor jet.Here are some steps for troubleshooting engine flooding:

- Check the float valve. A stuck float valve can cause the float bowl to overfill, leading to engine flooding. To check the float valve, remove the float bowl and examine the float valve for damage or debris. If the float valve is stuck, it will need to be replaced.

- Inspect the choke. The choke is used to enrich the fuel mixture during cold starts. If the choke is stuck in the open position, it can cause the engine to flood. To check the choke, make sure it is fully closed when the engine is warm.

- Clean the carburetor jets. Clogged carburetor jets can restrict fuel flow, leading to engine flooding. To clean the carburetor jets, remove the carburetor from the engine and disassemble it. Use a carburetor cleaning kit to clean the jets and other carburetor components.

Poor Idle

A poor idle can be caused by a variety of factors, including a dirty carburetor, a lean fuel mixture, or a vacuum leak.Here are some steps for troubleshooting a poor idle:

- Clean the carburetor. A dirty carburetor can cause a poor idle. To clean the carburetor, remove it from the engine and disassemble it. Use a carburetor cleaning kit to clean the carburetor components.

- Adjust the idle speed screw. The idle speed screw controls the engine’s idle speed. If the idle is too low, adjust the idle speed screw to increase the idle speed. If the idle is too high, adjust the idle speed screw to decrease the idle speed.

- Check for vacuum leaks. A vacuum leak can cause a poor idle. To check for vacuum leaks, spray carburetor cleaner around the carburetor and intake manifold while the engine is running. If the engine speed increases, there is a vacuum leak. Repair the vacuum leak by replacing any damaged hoses or gaskets.

Tuning a dirt bike carburetor is a rewarding endeavor, a testament to your mechanical prowess and a gateway to unlocking the full potential of your machine. It’s a journey of discovery, a process of fine-tuning and optimization. By understanding the nuances of carburetor function, the art of jetting, and the importance of regular maintenance, you can transform your dirt bike into a symphony of power and performance.

Each ride becomes an exhilarating testament to your expertise, a testament to the power of mastering the art of carburetor tuning.

FAQ Guide

What are the most common signs of a carburetor problem?

Common signs include poor acceleration, engine hesitation, backfiring, stalling, and excessive fuel consumption.

How often should I clean my carburetor?

It’s recommended to clean your carburetor every 50-100 hours of riding or at least once a year.

What type of cleaning solvent should I use?

Use a carburetor cleaning solvent specifically designed for motorcycles. Avoid using harsh chemicals that can damage the carburetor.

What are the risks of improper carburetor tuning?

Improper tuning can lead to engine damage, decreased fuel efficiency, and poor performance.