How to adjust wheel bearings on a trailer – Taking care of your trailer’s wheel bearings is crucial for a safe and smooth journey. This guide will walk you through the process of adjusting trailer wheel bearings, from understanding their function to ensuring a proper reassembly. We’ll cover everything you need to know to keep your trailer rolling smoothly.

Whether you’re a seasoned trailer owner or a novice, this comprehensive guide will equip you with the knowledge and confidence to tackle this essential maintenance task. From identifying signs of worn bearings to the proper use of tools and materials, we’ll cover every step in detail. Let’s dive in and keep your trailer rolling safely.

Understanding Trailer Wheel Bearings

Imagine your trailer wheels as the feet of a giant, carrying all your precious cargo. Just like your own feet need support, these wheels rely on bearings to keep them spinning smoothly. Wheel bearings are the unsung heroes of trailer maintenance, ensuring a safe and enjoyable journey.

Types of Trailer Wheel Bearings

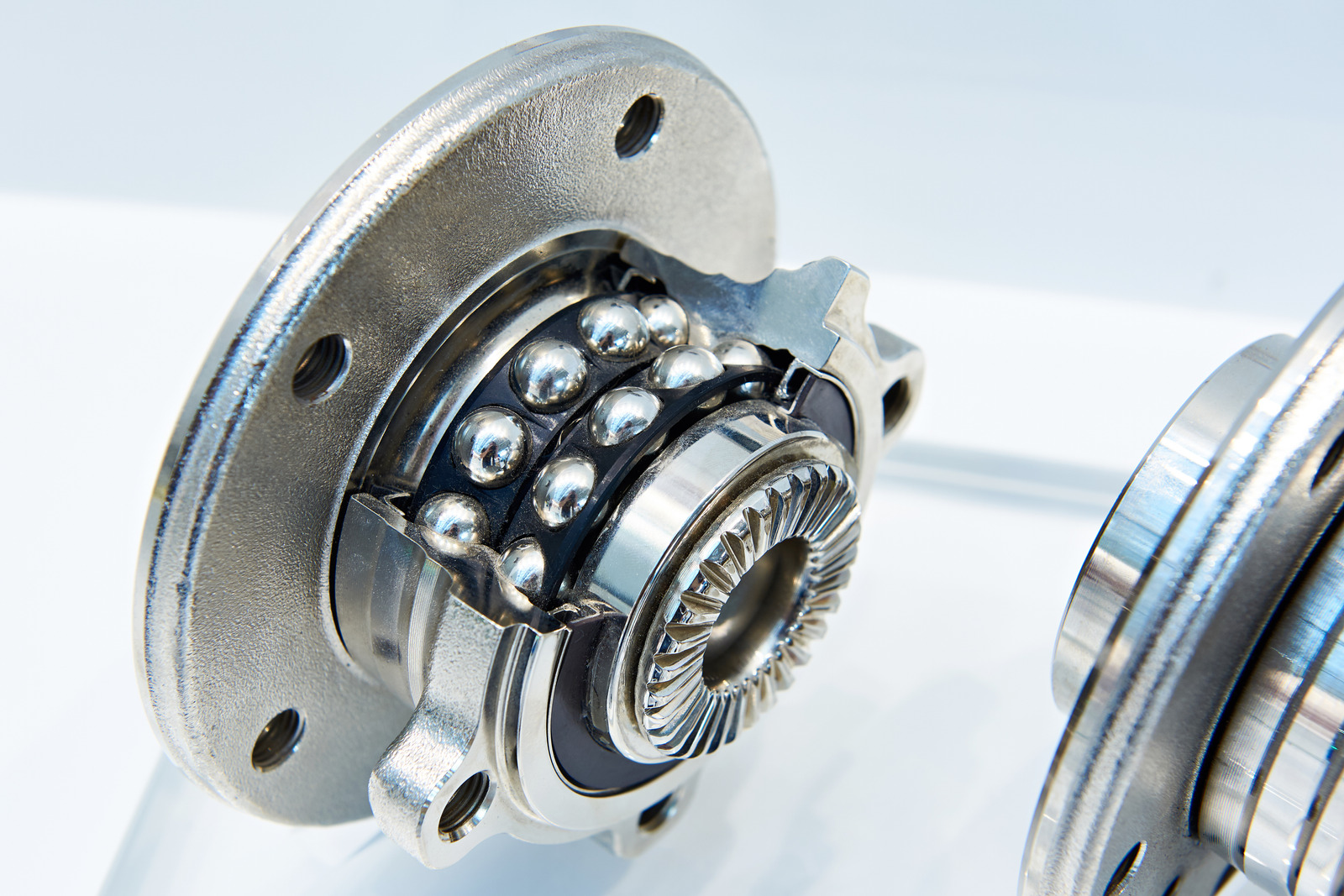

Wheel bearings are the vital components that allow your trailer wheels to rotate smoothly and efficiently. There are two primary types of wheel bearings used in trailers:

- Tapered Roller Bearings: These bearings are designed for heavy-duty applications and are commonly found in trailers carrying significant weight. Tapered roller bearings consist of conical rollers that fit between an inner and outer race, providing excellent radial and axial load capacity. They are known for their durability and ability to withstand high loads and speeds.

- Ball Bearings: Ball bearings are often used in lighter-duty trailers, such as utility trailers or small boat trailers. They feature small, hard spheres that roll between an inner and outer race. While ball bearings offer less load capacity than tapered roller bearings, they provide smoother operation and lower friction.

Signs of Worn or Damaged Wheel Bearings

Worn or damaged wheel bearings can lead to a range of problems, including:

- Unusual Noises: Grinding, rumbling, or clicking sounds when driving, especially at higher speeds or when turning, can indicate worn or damaged bearings.

- Wheel Wobble: If you notice your trailer wheel wobbling or shaking, it could be a sign of loose or damaged bearings.

- Increased Heat: Overheated wheels are a telltale sign of bearing failure. The excessive friction caused by worn bearings generates heat, which can be felt by touching the wheel.

- Grease Leakage: If you see grease leaking from the hub assembly, it could indicate a seal failure, which can lead to bearing damage.

Tools and Materials

Alright, brah, so you’re ready to get your hands dirty and adjust those wheel bearings? Let’s talk about the tools and materials you’ll need to make this happen. It’s all about having the right stuff to do the job properly, and trust me, it’s gonna be a smooth ride with the right tools.

Before you dive in, it’s crucial to understand that you’re dealing with some serious stuff here. You’re messing with the safety of your trailer and the people who ride in it. So, be sure to follow all the safety precautions and instructions. If you’re not comfortable doing this yourself, it’s always best to get a professional to help out.

It’s better to be safe than sorry, my friend.

Essential Tools

Let’s break down the tools you’ll need to adjust those trailer wheel bearings. These are your trusty companions for the job, and they’ll help you get the job done right.

- Jack: A jack is essential to lift your trailer and give you access to the wheels. Make sure you use a jack that’s rated for the weight of your trailer.

- Jack Stands: Once your trailer is lifted, you’ll need jack stands to support it safely. These are crucial for keeping your trailer stable and preventing any accidents while you work.

- Wheel Wrench: A wheel wrench is used to remove the lug nuts that hold your wheels in place. Make sure it’s the right size for your trailer’s lug nuts. You can find the size printed on the lug nuts.

- Torque Wrench: A torque wrench is a must-have for tightening the lug nuts to the correct specifications. You don’t want to overtighten them, or you might damage the wheel studs. Look up the recommended torque setting for your trailer’s lug nuts in the owner’s manual.

- Hammer: A hammer is used to remove the old wheel bearing races and install the new ones. You’ll also need it to tap the bearings onto the spindle.

- Bearing Race Tool: This special tool is used to remove and install the inner and outer wheel bearing races. It’s a specific tool for the job, and it makes the process much easier.

- Bearing Packer: This tool is used to pack the wheel bearings with grease. It helps to distribute the grease evenly and ensures that the bearings are properly lubricated.

- Bearing Grease: You’ll need a high-quality bearing grease specifically designed for trailers. Make sure you use the correct type of grease for your bearings. You can find recommendations in your trailer’s owner’s manual.

- Cleaning Supplies: It’s important to clean the wheel bearing components before you reassemble them. You’ll need a brush, a rag, and some degreaser to get the job done right.

Safety Gear

Now, let’s talk about safety. It’s always important to prioritize safety, and you’ll need some gear to keep yourself protected while working on your trailer.

- Safety Glasses: Protect your eyes from flying debris while working on the trailer. You don’t want to get any dirt or grease in your eyes.

- Gloves: Protect your hands from grease and dirt. It’s always a good idea to wear gloves when working on your trailer.

- Work Boots: Sturdy work boots will provide support and protection for your feet while you’re working on the trailer. It’s always better to be safe than sorry.

Tips for Choosing the Right Tools

Choosing the right tools is key to making this job easier and safer. Here are a few tips to help you make the right choices.

- Quality Over Quantity: Invest in quality tools that are built to last. They’ll make your job easier and save you money in the long run.

- Right Size: Make sure your tools are the right size for the job. This is especially important for the wheel wrench and the torque wrench.

- Read the Instructions: Before you start working, read the instructions for all of your tools. This will help you understand how to use them safely and effectively.

Safety Precautions

Adjusting trailer wheel bearings is a task that requires careful attention to safety. It involves working with heavy components, potentially hazardous tools, and a lifted trailer. Failing to take necessary precautions can lead to serious injuries.

Safety Checklist for Working on Trailer Wheel Bearings

It’s crucial to create a safe working environment before you start adjusting your trailer wheel bearings. Here’s a checklist to guide you:

- Park on a level surface: Ensure the trailer is parked on a level, solid surface, free from debris or obstacles. This prevents the trailer from rolling while you’re working on it.

- Engage the parking brake: Always engage the trailer’s parking brake to prevent it from moving.

- Chock the wheels: Use wheel chocks to prevent the trailer from rolling, even if the parking brake is engaged. Place chocks on the opposite side of the trailer from the wheel you’re working on.

- Wear appropriate safety gear: Protect yourself by wearing safety glasses, gloves, and sturdy closed-toe shoes.

- Use proper lifting equipment: Use a hydraulic jack rated for the weight of your trailer. Always use jack stands to support the trailer once it’s lifted, never rely solely on the jack.

- Clear the work area: Remove any tools or debris from the work area to prevent tripping or accidents.

- Be aware of surroundings: Pay attention to your surroundings and any potential hazards.

Using Proper Lifting Equipment and Jack Stands

Lifting a trailer is a critical part of the wheel bearing adjustment process. It’s essential to use the correct lifting equipment and jack stands to ensure safety and stability.

- Hydraulic Jack: Choose a hydraulic jack that’s rated for the weight of your trailer. The jack should be in good working condition, with no leaks or damage.

- Jack Stands: Always use jack stands to support the trailer once it’s lifted. Never rely solely on the jack. Place the jack stands on a solid, level surface, and make sure they are securely positioned under the trailer’s frame.

- Safety Tips:

- Always lift the trailer slowly and carefully.

- Never work under a trailer that is only supported by a jack.

- Ensure the jack stands are rated for the weight of the trailer.

- Double-check that the jack stands are securely in place before working under the trailer.

Always remember, safety should be your top priority when working on trailer wheel bearings. Following these precautions will help ensure a safe and successful adjustment process.

Jacking Up the Trailer

Okay, so now we’re gonna lift that trailer up, but let’s do it safely, right? It’s like a traditional Balinese dance – every move counts! First, we need to find a flat, solid surface to park the trailer. This will help us get a good grip with the jack.

Using Jack Stands

Jack stands are your best friends when lifting a trailer. They give you that extra support, making sure your trailer doesn’t decide to take a spontaneous trip down.

- Always use jack stands that are rated for the weight of your trailer. You don’t want to be caught in a sticky situation, especially when working on your bearings!

- Position the jack stands under the trailer’s frame rails, not the axles. The frame is stronger and will provide a more stable base.

- Make sure the jack stands are fully extended and locked into place. You want to be certain they’re not going to slip out on you.

Proper Placement of Jack Stands

Now, let’s talk about where to place those jack stands for maximum stability. Think of it like finding the perfect spot for a Balinese offering – you want to be precise.

- Front Jack Stand Placement: Place the jack stand under the front frame rail, just behind the front axle. This will give you a good balance point for lifting the front of the trailer.

- Rear Jack Stand Placement: The rear jack stand goes under the rear frame rail, just in front of the rear axle. This keeps the rear of the trailer stable while you’re working on the bearings.

Important Note: Always leave the trailer jack in place, even when using jack stands. It’s like having a safety net – just in case something unexpected happens.

Removing the Wheel

Alright, brah, now that you’ve got the trailer jacked up and the lug nuts are ready to go, it’s time to remove the wheel. This part’s pretty straightforward, but you gotta be careful, man. Safety first, always.

Removing the Wheel

Once you’ve got the trailer jacked up and the lug nuts are loose, you can start removing the wheel. Here’s the deal:* Use a breaker bar: This is a long bar that fits onto the lug nut socket. It gives you more leverage to break the lug nuts loose.

Break the lug nuts loose

You gotta apply some pressure here, brah. Rotate the breaker bar counterclockwise to loosen the lug nuts.

Remove the lug nuts

Once the lug nuts are loose, you can remove them completely using a lug wrench.

Remove the wheel

Now, you can gently pull the wheel off the axle. Tips for Safely Handling the Wheel and Tire:

Don’t drop the wheel

This could damage the wheel or the tire. Be careful when removing the wheel and set it down gently.

Handle the wheel by the tire

Don’t grab the wheel by the rim. This could damage the rim.

Wear gloves

This will protect your hands from dirt and grease.

Use a wheel dolly

This will make it easier to move the wheel around.

Inspecting the Wheel Bearings

Alright, brah, now that you’ve got the wheel off, it’s time to take a good look at those bearings. You wanna make sure they’re in tip-top shape, so you can cruise on down the road without any worries.

Inspecting the Bearings

Now, you’re gonna want to check for any signs of wear and tear. You’re looking for things like:

- Grooves or scoring on the bearing races: These are signs that the bearings have been rubbing against the races too hard.

- Pitting or flaking on the bearing balls: This indicates that the bearings are starting to wear down.

- Rust or corrosion: This can happen if the bearings haven’t been greased properly or if they’ve been exposed to the elements.

If you see any of these signs, it’s time to replace the bearings. You don’t want to risk a bearing failure while you’re on the road.

Inspecting the Grease Seal

The grease seal is what keeps the grease in and the dirt out. You wanna make sure it’s in good condition. If it’s cracked, torn, or missing, you’ll need to replace it.Here’s how to check it:

- Look for cracks or tears: If you see any cracks or tears, the seal is no longer doing its job.

- Check for wear and tear: If the seal is worn down, it’s not going to seal properly.

- Make sure it’s securely in place: If the seal is loose, it’s not going to seal properly.

If you see any signs of wear and tear, it’s time to replace the seal.

Inspecting the Bearing Races

The bearing races are the metal rings that the bearings roll on. You wanna make sure they’re in good condition. If they’re damaged, the bearings won’t be able to roll smoothly.Here’s how to check them:

- Look for grooves or scoring: If you see any grooves or scoring, the races are damaged.

- Check for rust or corrosion: If you see any rust or corrosion, the races are damaged.

- Make sure they’re securely in place: If the races are loose, they’re not going to support the bearings properly.

If you see any signs of wear and tear, it’s time to replace the races.

Adjusting the Wheel Bearings

Alright, brah, so you’ve got your bearings inspected, and now it’s time to get those bad boys adjusted. This is where you’ll ensure those wheels spin smoothly and your trailer stays safe and sound. Let’s get into it!

Tightening the Bearing Races

Before you start tightening anything, make sure you’ve got the right tools for the job. You’ll need a torque wrench, a bearing race tool, and a hammer. The bearing races are the metal rings that hold the bearings in place. To tighten them, you’ll need to use a bearing race tool. This tool will help you press the races into the hub.

Here’s how to do it:

- Place the bearing race tool over the bearing race.

- Use a hammer to gently tap the bearing race tool, pressing the race into the hub.

- Make sure the race is seated evenly and flush with the hub.

- Repeat this process for the other bearing race.

Adjusting the Preload, How to adjust wheel bearings on a trailer

Once the bearing races are in place, you need to adjust the preload. This is the amount of tension on the bearings. Too much preload can cause the bearings to overheat, while too little preload can cause the bearings to wear out prematurely.Here’s how to adjust the preload:

- Install the spindle nut and tighten it until the wheel spins freely but with a slight drag.

- Use a torque wrench to tighten the spindle nut to the manufacturer’s specifications.

- You can test the preload by spinning the wheel and listening for any grinding or squeaking noises. If you hear any noises, you’ll need to adjust the preload again.

It’s important to note that the preload should be just enough to prevent the bearings from moving, but not so tight that they’re binding.

Tightening Components

You’ll need to use a torque wrench to tighten all the components. This will ensure that everything is securely fastened.

- Tighten the spindle nut to the manufacturer’s specifications.

- Tighten the lug nuts to the manufacturer’s specifications.

- Tighten the wheel studs to the manufacturer’s specifications.

Make sure to refer to your trailer’s owner’s manual for the specific torque specifications for your trailer.

Packing the Wheel Bearings

Packing the wheel bearings with grease is an important step in ensuring your trailer runs smoothly and safely. This process involves filling the bearing races with grease, creating a protective barrier between the moving parts and preventing wear and tear.

Choosing the Right Grease

Selecting the appropriate type of grease for your trailer bearings is crucial. Different greases have different properties and are designed for specific applications. Consider these factors when choosing a grease:

- Temperature Range: Trailer bearings experience a wide range of temperatures, from hot pavement to cold winters. Choose a grease that can withstand the temperature extremes you’ll encounter.

- Water Resistance: Trailer bearings are exposed to the elements, including rain and moisture. Opt for a grease with excellent water resistance to prevent corrosion and maintain lubrication.

- Load Capacity: Trailer bearings are subjected to significant loads, especially when hauling heavy cargo. Select a grease with high load capacity to handle the pressure.

Tip: Consult your trailer manufacturer’s manual for recommended grease types and specifications.

Packing the Bearings with Grease

Once you have the right grease, you can start packing the bearings. Here’s how:

- Remove the Bearing Races: Carefully remove the inner and outer bearing races from the hub assembly. Use a bearing race tool or a suitable punch to remove the races without damaging them.

- Clean the Bearings: Thoroughly clean the bearings and races with a suitable solvent, like kerosene or brake cleaner. Remove any old grease, dirt, or debris.

- Apply Grease to the Bearings: Use a grease gun to pack the bearings with fresh grease. Fill the inner and outer races with grease, ensuring they are completely packed. Avoid overpacking the bearings, as this can lead to overheating and premature failure.

- Reinstall the Bearing Races: Carefully reassemble the bearing races into the hub assembly, ensuring they are properly seated.

- Torque the Nuts: Tighten the axle nut to the manufacturer’s specified torque. Overtightening can damage the bearings, while undertightening can lead to loosening and premature failure.

Tip: Use a torque wrench to ensure proper tightening of the axle nut.

Reassembly and Testing: How To Adjust Wheel Bearings On A Trailer

Once you’ve adjusted the wheel bearings, it’s time to put everything back together and give those bearings a spin. It’s a good idea to double-check your work and make sure you’re ready to roll before you hit the road.

Reassembling the Wheel and Axle

With the bearings packed and the hub installed, you can now reassemble the wheel and axle. This process is pretty straightforward, but there are a few key points to keep in mind.

- Slide the wheel onto the axle. Make sure the wheel is properly seated on the hub.

- Install the lug nuts. Don’t tighten them all the way just yet.

- Lower the trailer to the ground. Once the trailer is on the ground, you can tighten the lug nuts.

- Tighten the lug nuts in a star pattern. This helps to ensure that the wheel is evenly seated on the hub.

Tightening Lug Nuts to Correct Torque Specifications

The torque specifications for lug nuts vary depending on the size and type of lug nuts.

Check your trailer’s owner’s manual or consult a reputable online resource for the correct torque specification.

You want to make sure the lug nuts are tight enough to hold the wheel securely, but not so tight that you damage the threads or the wheel.

If you don’t have a torque wrench, you can use a breaker bar to tighten the lug nuts. Be careful not to overtighten them.

Testing the Adjusted Bearings

Now that everything is back together, it’s time to test your work. Here’s how:

- Jack up the trailer.

- Spin the wheel by hand. Listen for any unusual noises, like grinding or squeaking. If you hear anything, you may need to readjust the bearings.

- Check the wheel for excessive play. If the wheel moves back and forth more than a few millimeters, the bearings are likely too loose.

- Lower the trailer to the ground.

- Drive the trailer a short distance. Listen for any unusual noises.

- Check the wheel bearings again. If the bearings are still making noise, you may need to readjust them.

Maintenance and Troubleshooting

It’s super important to keep your trailer wheel bearings in tip-top shape. This will ensure a smooth and safe ride for your next adventure. By following some simple maintenance tips and knowing how to troubleshoot any issues, you can avoid any unexpected breakdowns and keep your trailer rolling for years to come.

Recommended Maintenance Schedule

Regular maintenance is the key to keeping your trailer wheel bearings running smoothly. Here’s a schedule to follow:

- Every 12,000 kilometers or annually: This is a good time to check your wheel bearings for signs of wear or damage. This includes inspecting the grease, bearings, and races for any signs of damage or excessive wear. You should also repack the bearings with fresh grease at this time.

- Every 24,000 kilometers or every two years: This is a good time to replace your wheel bearings. Even if they don’t show any signs of wear, it’s best to replace them before they fail. Replacing your bearings before they fail will prevent any potential problems on the road.

Common Problems

There are a few common problems that can arise with wheel bearings. Here are some of the most frequent issues:

- Overheated bearings: This is a common problem, especially if you’re towing heavy loads or driving in hot weather. Overheated bearings can cause premature wear and tear. If you notice your wheel bearings are getting hot, you should stop and check them.

- Worn bearings: This is another common problem that can be caused by a number of factors, including overheated bearings, lack of lubrication, or rough roads. Worn bearings can cause a number of problems, including noise, vibration, and a rough ride.

- Loose bearings: This is a serious problem that can lead to bearing failure. If you notice any play in your wheel bearings, you should stop and check them.

Troubleshooting Tips

If you suspect that your wheel bearings are experiencing problems, here are some tips to help you diagnose and resolve the issue:

- Listen for any unusual noises: If you hear a grinding, roaring, or clicking sound coming from your trailer wheels, this could indicate a problem with your wheel bearings.

- Check for excessive heat: If you feel any heat coming from your wheels, this could also be a sign of a problem with your bearings.

- Inspect the wheel for any play: If you notice any play in the wheel, this is a sure sign that your bearings are worn out or damaged.

By following this guide, you’ll be equipped to handle your trailer’s wheel bearing adjustments with confidence. Remember, regular maintenance and proper care are key to ensuring your trailer’s safety and longevity. So, get your tools ready and keep those wheels turning!

FAQ Insights

How often should I adjust my trailer wheel bearings?

It’s generally recommended to adjust your trailer wheel bearings every 12,000 miles or annually, whichever comes first. However, it’s important to inspect your bearings regularly for signs of wear and damage, and adjust them as needed.

What type of grease should I use for my trailer wheel bearings?

Use a high-quality, waterproof grease specifically designed for trailer wheel bearings. Check your trailer owner’s manual for recommended grease type or consult with a professional mechanic.

What are the signs of worn or damaged wheel bearings?

Common signs include:

-Unusual noise or grinding when the trailer is moving

-Excessive heat in the wheel area

-Play or looseness in the wheel

-Grease leaking from the bearing seals

What if I don’t have a torque wrench?

It’s highly recommended to use a torque wrench for accurate tightening. If you don’t have one, consult with a professional mechanic or a trusted automotive parts store for assistance.