How to file piston rings is a crucial skill for anyone who wants to maintain or rebuild their engine. Piston rings are essential components that seal the combustion chamber, preventing blow-by and ensuring proper compression. They also play a vital role in controlling oil consumption by scraping excess oil off the cylinder walls. Understanding how to file piston rings correctly can help you achieve optimal engine performance and extend its lifespan.

This guide will walk you through the entire process, from understanding the purpose of piston rings to the final steps of reassembly and break-in. We’ll cover everything you need to know, including the tools and equipment required, safety precautions, and troubleshooting tips. Whether you’re a seasoned mechanic or a DIY enthusiast, this comprehensive guide will equip you with the knowledge and skills to file piston rings confidently.

Understanding Piston Rings

Piston rings are essential components in internal combustion engines, playing a crucial role in sealing the combustion chamber and controlling oil consumption. They’re like the engine’s little helpers, ensuring everything runs smoothly and efficiently.

Types of Piston Rings

Piston rings are classified based on their function and location within the piston groove. Here’s a breakdown of the different types:

- Compression Rings: These rings are the primary sealers of the combustion chamber, preventing gases from escaping into the crankcase. They are typically made of cast iron or steel, and their design can vary based on engine size and performance requirements.

- Oil Rings: Oil rings are responsible for controlling oil consumption by scraping excess oil from the cylinder walls and returning it to the sump. They usually consist of an expander ring and a scraper ring, both working together to maintain a thin oil film on the cylinder walls.

Materials Used in Piston Ring Construction

The choice of material for piston rings is critical for their performance and durability. Common materials include:

- Cast Iron: Cast iron is a popular choice for piston rings due to its high wear resistance and ability to withstand high temperatures. It’s also relatively inexpensive. However, cast iron rings can be prone to galling (sticking) if not properly lubricated.

- Steel: Steel piston rings offer superior strength and wear resistance compared to cast iron. They are often used in high-performance engines where temperatures and pressures are higher. Steel rings can also be heat-treated to enhance their properties.

- Other Materials: Some specialized piston rings are made from materials like molybdenum, chrome, or nickel alloys. These materials provide even better wear resistance and heat tolerance, often found in high-performance or racing applications.

Factors Influencing Piston Ring Wear and Failure

Several factors contribute to piston ring wear and eventual failure. Understanding these factors is crucial for maintaining engine health and longevity.

- Insufficient Lubrication: Proper lubrication is vital for piston ring performance. Insufficient oil supply can lead to excessive friction, heat, and wear. This can result in ring sticking, galling, and even ring breakage.

- Excessive Engine Temperature: High engine temperatures can cause piston rings to expand beyond their design limits, leading to increased wear and even ring breakage. Overheating can also contribute to ring sticking and galling.

- Improper Ring Installation: Installing piston rings incorrectly can cause them to wear prematurely or fail completely. This can involve improper ring gap setting, ring orientation, or even ring damage during installation.

- Cylinder Wall Wear: Worn cylinder walls can cause excessive ring wear. This is because the rings have less surface area to ride on, leading to increased friction and wear.

- Engine Deposits: Carbon buildup and other engine deposits can interfere with piston ring function. These deposits can increase friction, prevent proper sealing, and even cause ring sticking.

Preparing for Piston Ring Replacement

Yo, so you’re ready to swap out those worn-out piston rings, huh? That’s awesome, but before you get all hands-on, you gotta make sure you’re prepped for the job. Think of it like getting your game face on before a big test. It’s all about having the right tools, being safe, and knowing the steps.

Tools and Equipment

Alright, let’s get the basics down. You’re gonna need a bunch of tools to do this right. Think of it as your own personal mechanic’s toolkit. Here’s what you’ll need:

- Piston ring compressor: This tool is your best friend when it comes to installing new piston rings. It helps you compress the rings so you can get them in the cylinder without any damage. Think of it as a ring-holding device for a smooth installation.

- Torque wrench: This tool lets you tighten bolts and nuts to the exact specifications, which is super important to prevent damage to your engine. It’s all about getting that perfect amount of pressure.

- Socket set: You’ll need different sizes of sockets to remove and install bolts and nuts on the engine. It’s like having a whole bunch of different keys for all the different bolts.

- Wrenches: You’ll need a variety of wrenches for loosening and tightening bolts and nuts. It’s like having the right tools to unlock all the different parts of your engine.

- Screwdrivers: You’ll need both flathead and Phillips screwdrivers for removing and installing screws. It’s like having a couple of handy tools to help you get the job done.

- Piston ring gap gauge: This tool is used to measure the gap between the ends of the piston rings. It’s like a measuring tape for your rings, making sure they’re the right size.

- Micrometer: This tool is used to measure the diameter of the cylinder walls. It’s like a super-accurate ruler for your engine, making sure everything fits perfectly.

- Cleaning supplies: You’ll need a few cleaning supplies, like brake cleaner and a rag, to clean up the engine before reassembly. It’s like giving your engine a good scrub down before putting it back together.

Safety Precautions

Safety first, right? You don’t want to end up with a nasty surprise while you’re working on your engine. Here’s a rundown of some important safety tips:

- Wear safety glasses: You’ll be dealing with metal parts and fluids, so protect your eyes from any flying debris. Think of it as your eye insurance while you’re working on your engine.

- Wear gloves: Protect your hands from cuts, scrapes, and oil. It’s like giving your hands a little extra armor while you’re working on your engine.

- Work in a well-ventilated area: Engine fluids and cleaning supplies can be dangerous if inhaled, so make sure you have plenty of fresh air. It’s like giving your lungs a breath of fresh air while you’re working on your engine.

- Use a jack stand: If you’re working on the engine while the car is lifted, make sure you use a jack stand to support the car. It’s like giving your car a little extra support while you’re working on it.

- Disconnect the battery: Before you start working on the engine, disconnect the battery to prevent electrical shock. It’s like turning off the power to your engine before you start working on it.

Removing the Old Piston Rings

Okay, now that you’re all geared up and ready to go, it’s time to get those old piston rings out. Think of it like removing the old parts of your engine so you can put in the new ones. Here’s how to do it:

- Remove the cylinder head: This is the first step, and it’s important to do it carefully. It’s like opening up the top of your engine to get to the piston rings.

- Remove the pistons: Once the cylinder head is off, you can remove the pistons. This involves carefully pulling them out of the cylinders. It’s like taking the pistons out of their little homes.

- Remove the old piston rings: Now that the pistons are out, you can remove the old piston rings. This is where you’ll use your piston ring compressor to help you. It’s like taking off the old rings that are worn out and ready to be replaced.

Inspecting the Cylinder Walls

Before you install the new piston rings, it’s important to inspect the cylinder walls for any wear or damage. Think of it as giving your engine a checkup before putting in the new parts. Here’s what to look for:

- Scratches: If you see any scratches on the cylinder walls, it means the cylinder is damaged and needs to be honed or replaced. It’s like finding a scratch on your favorite piece of furniture. You might need to fix it or replace it.

- Grooves: If you see any grooves on the cylinder walls, it means the cylinder is worn and needs to be honed or replaced. It’s like finding a groove in your favorite record. You might need to fix it or replace it.

- Corrosion: If you see any corrosion on the cylinder walls, it means the cylinder is damaged and needs to be replaced. It’s like finding rust on your car. You might need to fix it or replace it.

Installing New Piston Rings

Installing new piston rings is a crucial step in rebuilding an engine. It requires precision and care to ensure proper ring seal and engine performance. The process involves cleaning and lubricating the rings, carefully installing them in the piston grooves, and measuring ring gaps.

Installing the Piston Rings

Before installing the piston rings, it’s essential to clean and lubricate them. This ensures smooth installation and prevents damage to the rings or the cylinder walls.

- Use a clean, lint-free cloth to wipe down the piston rings, removing any dirt, debris, or oil residue.

- Apply a thin coat of clean engine oil to the piston rings, ensuring the entire surface is coated.

Next, carefully install the piston rings in the piston grooves. The rings should be installed in the correct order and orientation.

- The top compression ring is typically the thickest and has a beveled edge. It should be installed with the beveled edge facing the top of the piston.

- The second compression ring is usually thinner than the top ring and may have a different shape or design. Its orientation should be determined by the manufacturer’s instructions.

- The oil ring is typically a three-piece design, consisting of two rails and an expander. The rails should be installed with the gaps aligned and the expander should be positioned correctly.

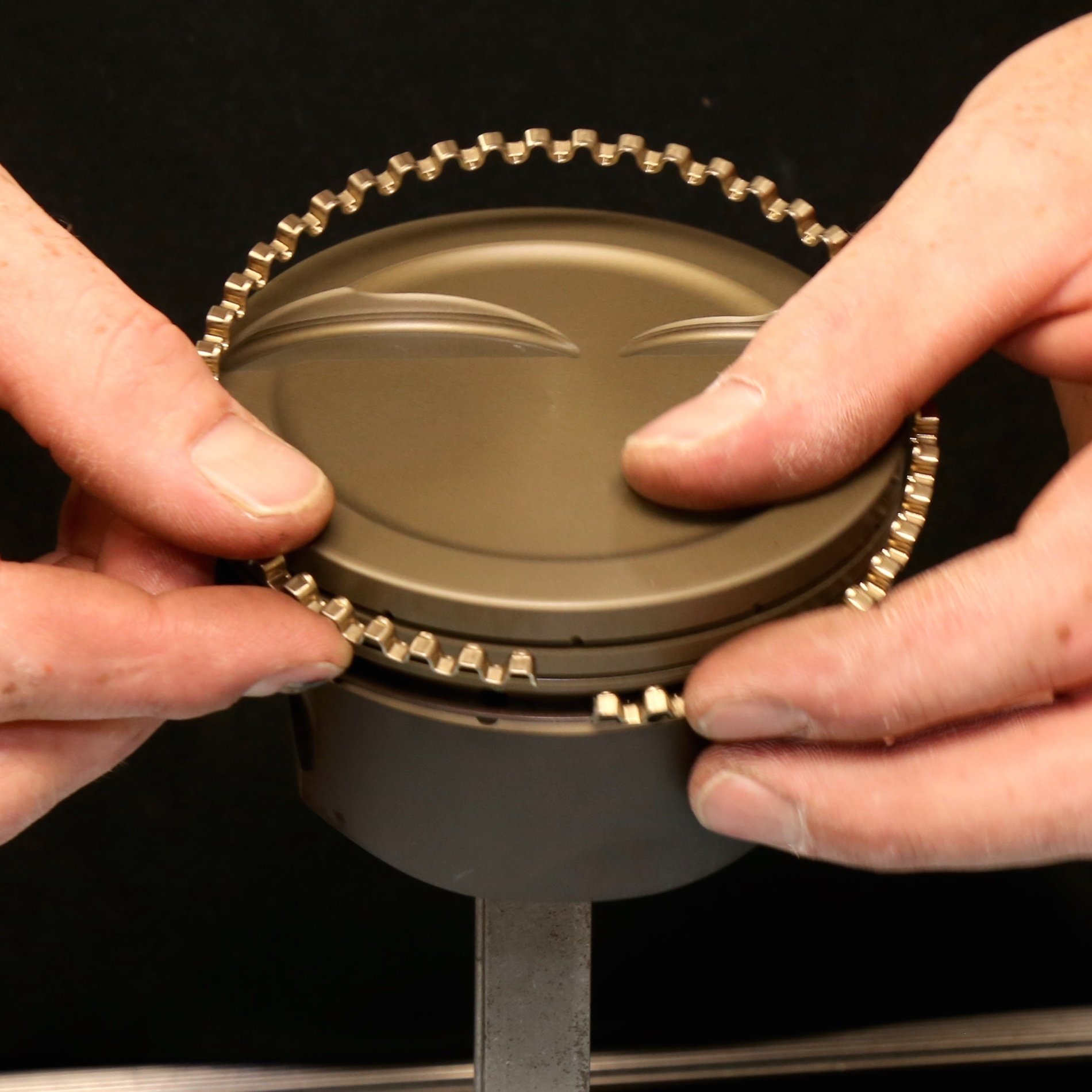

When installing the piston rings, ensure they are properly seated in the grooves. Use a ring compressor tool to gently push the rings into the grooves. Avoid using excessive force, as this can damage the rings or the piston.

Measuring Ring Gaps

After installing the piston rings, it’s essential to measure the ring gaps. The ring gaps should be within the manufacturer’s specifications to ensure proper ring seal and prevent blow-by.

- Use a ring gap tool to accurately measure the gaps between the ends of the rings.

- The ring gaps should be measured at the top and bottom of the piston groove.

- If the ring gaps are too large, the rings may leak and cause blow-by. If the gaps are too small, the rings may bind and damage the cylinder walls.

If the ring gaps are not within the manufacturer’s specifications, you may need to adjust the gaps by filing the rings.

Cleaning and Lubricating the Piston Rings, How to file piston rings

Before installing the piston rings, it’s important to clean and lubricate them. This helps ensure smooth installation and prevents damage to the rings or the cylinder walls.

- Use a clean, lint-free cloth to wipe down the piston rings, removing any dirt, debris, or oil residue.

- Apply a thin coat of clean engine oil to the piston rings, ensuring the entire surface is coated.

This process ensures that the rings are free of any contaminants that could interfere with their proper function. Lubricating the rings helps them slide smoothly into the piston grooves and reduces friction during operation.

Post-Installation Procedures

Yo, so now that you’ve swapped out those rings, it’s time to put everything back together and get your engine purring like a kitten. But hold your horses, there are a few things you gotta do before you crank it up. We’re gonna talk about putting your engine back together, making sure those cylinder head bolts are tight, and how to break in those new rings.

Get ready to learn some cool stuff!

Reassembling the Engine

Alright, let’s get this engine back in shape. It’s time to put everything back together. Here’s the deal:

- Cleanliness is key: Make sure everything is super clean before you start. Any dirt or debris can mess things up. Wipe down all the parts with a clean rag and some degreaser.

- Reinstall the pistons and connecting rods: Carefully slide the pistons back into the cylinders, making sure the rings are properly seated. Don’t forget to put the connecting rods back on, too.

- Install the crankshaft: Now, slide the crankshaft back into the block and make sure the bearings are properly seated.

- Install the cylinder head: Now, it’s time to put the cylinder head back on. Make sure the head gasket is in place and that the head bolts are properly torqued. We’ll talk about that in the next section.

- Install the valve train: Once the head is on, put the valve train back together. Make sure the valves are adjusted correctly and that the camshaft is properly timed.

Torqueing Cylinder Head Bolts

Yo, tightening those cylinder head bolts is serious business. You don’t want to over-tighten them and crack the head, or under-tighten them and have them loosen up. Here’s the lowdown:

- Use a torque wrench: This is a must-have tool. A torque wrench allows you to apply the exact amount of force to each bolt.

- Follow the manufacturer’s specifications: Every engine is different, so you need to follow the manufacturer’s torque specs for your specific engine. You can find these specs in your engine’s repair manual.

- Tighten in stages: Don’t just crank down on those bolts all at once. You need to tighten them in stages, using a specific pattern. This ensures that the head is evenly compressed and that the bolts are properly seated.

Breaking in New Piston Rings

Breaking in new piston rings is like training a puppy. You gotta take it slow and easy so they don’t get messed up.

- The first 500 miles are crucial: During this time, the rings are still seating themselves into the cylinder walls. You need to be gentle with the engine and avoid high RPMs and heavy loads.

- Use the right oil: Using a high-quality break-in oil is important. This oil will help to lubricate the rings and cylinder walls, preventing excessive wear. Check your engine’s manual for recommendations.

- Vary your RPMs: Don’t just drive at a constant speed. Vary your RPMs to help the rings seat properly.

Engine Break-in Procedures

Breaking in your engine is like teaching a new puppy to sit. You gotta be patient and consistent. Here’s the deal:

- Start with a warm-up: Before you hit the road, let the engine warm up for a few minutes. This will help to lubricate the parts and prevent excessive wear.

- Avoid high RPMs: For the first 500 miles, keep the engine RPMs below 3,000. This will help to prevent the rings from getting damaged.

- Avoid heavy loads: Don’t tow anything or put a lot of stress on the engine during the break-in period. Let it take it easy.

- Change the oil early: After the first 500 miles, change the oil and filter. This will remove any metal shavings or debris that may have been generated during the break-in process.

Troubleshooting Piston Ring Problems

Yo, so you’ve replaced your piston rings, but your engine’s still acting up? Don’t worry, it’s not always a smooth ride. Sometimes, you gotta dig deeper to figure out what’s going on. This section will help you troubleshoot those pesky piston ring problems.

Common Piston Ring Problems and Causes

Okay, so first things first, let’s break down some of the most common piston ring problems and why they happen.

| Problem | Cause |

|---|---|

| Excessive Oil Consumption |

|

| Loss of Compression |

|

| Engine Knocking or Detonation |

|

| Blue Smoke from Exhaust |

|

Diagnosing Piston Ring Issues

Alright, now that you know what to look for, let’s talk about how to diagnose those problems. Here are some tips:

- Listen to your engine: Does it sound rough? Any knocking or rattling? This could be a sign of piston ring problems.

- Check for oil leaks: Oil leaks around the engine block or valve covers can indicate worn or damaged piston rings.

- Look for smoke: Blue smoke from the exhaust is a dead giveaway for oil consumption, often caused by piston ring issues.

- Perform a compression test: A compression test is the most reliable way to assess the condition of your piston rings. If you have low compression in one or more cylinders, it’s a good sign that your piston rings might be worn or damaged.

- Inspect the spark plugs: Oil deposits on the spark plugs can indicate oil consumption, which could be due to worn or damaged piston rings.

Using Diagnostic Tools

Yo, sometimes you need a little help from your friends, or in this case, some tools. A compression test is your go-to for diagnosing piston ring issues.

A compression test measures the pressure inside the cylinder when the piston is at the top of its stroke. Low compression readings indicate a problem with the piston rings, cylinder walls, or valves.

Seeking Professional Assistance

Listen, if you’re not comfortable tackling piston ring issues yourself, don’t be afraid to ask for help. A mechanic can diagnose the problem and recommend the best course of action. Especially if you’re dealing with a complex issue or have limited experience, it’s best to leave it to the pros. They’ve got the tools, knowledge, and experience to get the job done right.

Filing piston rings is a complex task that requires precision and attention to detail. By following the steps Artikeld in this guide, you can ensure that your piston rings are properly filed, resulting in optimal engine performance and longevity. Remember to prioritize safety, use the correct tools and equipment, and seek professional assistance if you encounter any difficulties. With proper care and maintenance, your engine will continue to run smoothly for years to come.

Query Resolution: How To File Piston Rings

What are the signs that my piston rings need to be filed?

Excessive oil consumption, loss of compression, blue smoke from the exhaust, and a knocking sound from the engine are common signs that your piston rings may need to be filed or replaced.

What tools are essential for filing piston rings?

You’ll need a set of ring gap tools, a file, a honing tool, a micrometer, a cleaning cloth, and a lubricant. It’s also recommended to have a torque wrench for tightening the cylinder head bolts.

How often should piston rings be filed?

Piston rings typically don’t need to be filed unless they are worn or damaged. The frequency of filing depends on factors like engine wear, driving conditions, and maintenance practices.

Can I file piston rings without removing the engine?

It’s generally not recommended to file piston rings without removing the engine. This process requires specialized tools and expertise, and it’s best to consult a professional mechanic.

What are the risks of improperly filing piston rings?

Improperly filed piston rings can lead to engine damage, including reduced compression, increased oil consumption, and even engine failure. It’s crucial to follow the correct procedures and use the appropriate tools.