What are induction wheels? Imagine wheels that don’t rely on traditional friction, but instead harness the power of electromagnetic induction. These revolutionary wheels, a marvel of modern engineering, are poised to transform the way we move, offering a glimpse into a future where efficiency and performance are seamlessly intertwined.

Induction wheels, unlike their conventional counterparts, generate torque through the interaction of magnetic fields. This innovative approach opens up a world of possibilities, from enhancing electric vehicle capabilities to revolutionizing robotics and industrial applications.

Introduction to Induction Wheels

Induction wheels are a revolutionary technology that promises to transform the automotive industry. Unlike traditional wheels, which rely on mechanical contact with the road surface for traction, induction wheels utilize electromagnetic forces to propel and steer vehicles. This innovative approach offers a range of advantages, including increased efficiency, reduced wear and tear, and enhanced safety.Induction wheels are essentially electric motors integrated directly into the wheel hubs.

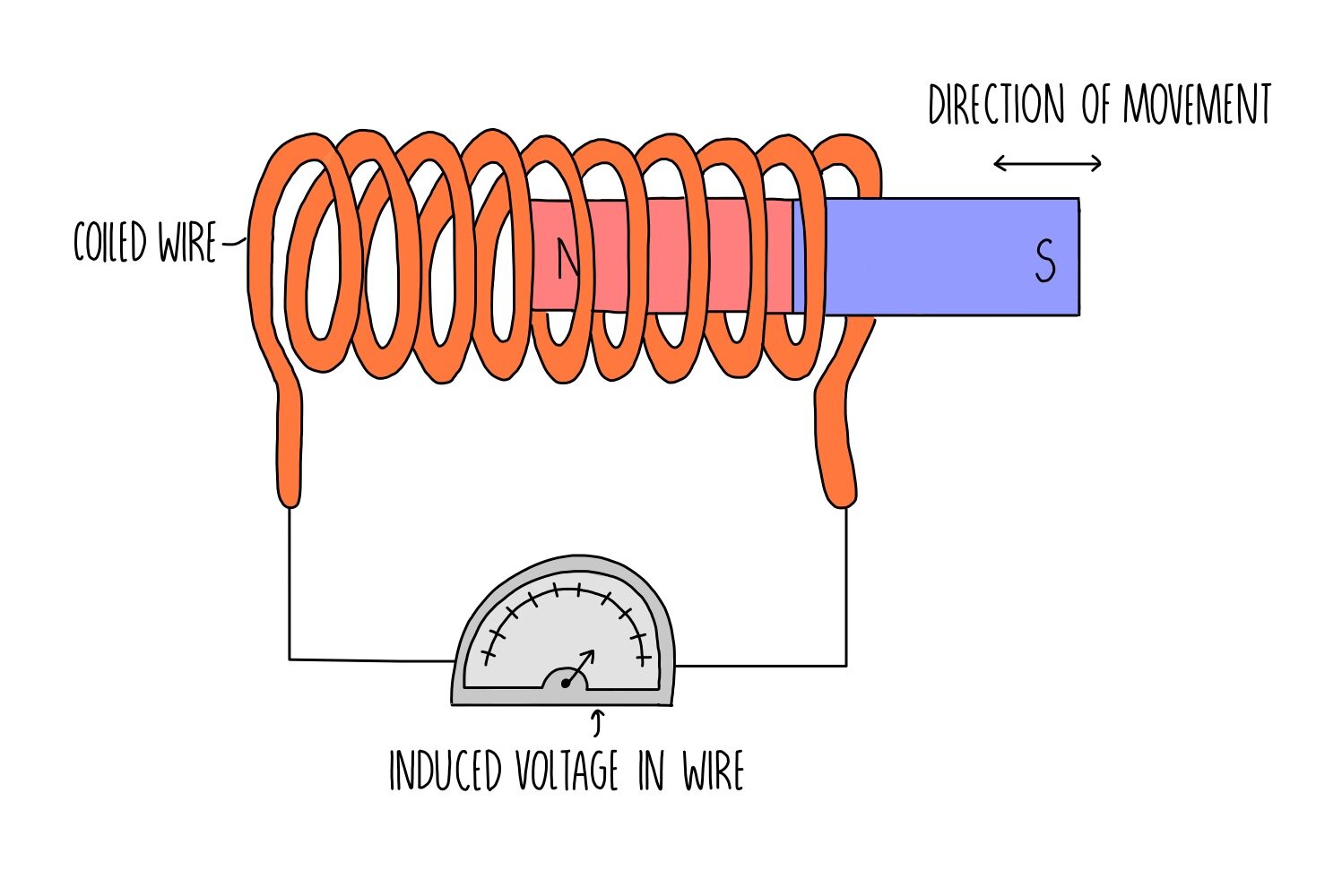

They operate on the principle of electromagnetic induction, where a rotating magnetic field induces currents in a conductive rotor, creating a force that propels the wheel. This process eliminates the need for a traditional transmission, axles, and differential, simplifying the vehicle’s drivetrain and reducing mechanical losses.

History and Evolution of Induction Wheel Technology

The concept of induction wheels has been around for several decades, with early research dating back to the 1970s. However, the technology has faced challenges in terms of power density, cost, and reliability. Recent advancements in materials science, electronics, and power electronics have led to significant progress in overcoming these obstacles.

- Early Research and Development: Initial research focused on developing proof-of-concept prototypes, exploring the feasibility of using electromagnetic induction for vehicle propulsion. These early iterations faced limitations in terms of power output, efficiency, and durability.

- Advancements in Materials and Electronics: Advancements in materials science, particularly the development of high-performance permanent magnets and conductive materials, have significantly improved the power density and efficiency of induction wheels. Similarly, advancements in power electronics have enabled more efficient and reliable control of the electromagnetic fields.

- Commercialization and Adoption: While induction wheels are still in their early stages of commercialization, several companies are actively developing and testing these technologies. The automotive industry is closely monitoring these developments, recognizing the potential of induction wheels to revolutionize vehicle design and performance.

Working Principle of Induction Wheels

Induction wheels operate on the principle of electromagnetic induction, harnessing the power of magnetic fields to generate torque and propel a vehicle. This technology is based on the interaction between magnetic fields and electric currents, resulting in a force that drives the wheels.

Components of an Induction Wheel System

The components of an induction wheel system work together to create a seamless and efficient driving experience. These components include:

- Stator: The stator is the stationary part of the induction wheel, comprising a series of electromagnets arranged in a specific configuration. It is responsible for generating the magnetic field that interacts with the rotor.

- Rotor: The rotor is the rotating part of the induction wheel, made of a conductive material like aluminum or copper. It is designed to be conductive but non-magnetic, allowing it to interact with the magnetic field generated by the stator.

- Power Electronics: This system manages the flow of electricity to the stator windings, controlling the strength and direction of the magnetic field.

- Control System: The control system monitors and regulates the performance of the induction wheel, ensuring optimal torque generation and efficient operation.

Generating Torque and Movement

The interaction between the stator’s magnetic field and the rotor’s conductive material creates a force that drives the wheel. The process can be described as follows:

- Electromagnetic Induction: When an alternating current flows through the stator windings, it creates a pulsating magnetic field. This changing magnetic field induces currents in the rotor, according to Faraday’s Law of electromagnetic induction.

- Rotor Currents: The induced currents in the rotor create their own magnetic field, which interacts with the stator’s magnetic field.

- Torque Generation: The interaction between the stator and rotor magnetic fields results in a force that attempts to align the rotor’s magnetic field with the stator’s field. This force manifests as torque, causing the rotor to rotate.

- Movement: As the rotor rotates, it transmits the torque to the wheel, propelling the vehicle forward.

Advantages of Induction Wheels

Induction wheels offer several advantages over traditional wheels, making them a promising technology for the future of transportation. These advantages stem from the unique principles of their operation, which allow for increased efficiency, performance, and environmental friendliness.

Efficiency and Performance

Induction wheels have the potential to significantly improve the efficiency and performance of vehicles. This is primarily due to the direct coupling of the motor to the wheel, eliminating the need for a transmission and reducing energy losses associated with mechanical components.

- Reduced Energy Consumption: The direct drive system eliminates energy losses from transmission systems, resulting in a more efficient use of energy. This translates to improved fuel economy for gasoline-powered vehicles and increased range for electric vehicles.

- Enhanced Acceleration and Torque: The direct drive system allows for faster acceleration and higher torque output compared to traditional wheels. This is because the motor can directly apply force to the wheel, without any power loss through a transmission.

- Improved Traction Control: Induction wheels can independently control the torque of each wheel, providing better traction control and stability, especially in challenging road conditions.

Environmental Impact

Induction wheels can contribute to a cleaner and more sustainable transportation system.

- Reduced Emissions: The increased efficiency of induction wheels can lead to lower fuel consumption, resulting in reduced greenhouse gas emissions for gasoline-powered vehicles.

- Quiet Operation: Induction motors are known for their quiet operation, which can significantly reduce noise pollution in urban areas.

Comparison with Other Wheel Technologies

Induction wheels offer advantages over other alternative wheel technologies, such as in-wheel motors and electric axles.

- Higher Efficiency: Compared to in-wheel motors, induction wheels have higher efficiency due to the elimination of transmission losses and the ability to directly couple the motor to the wheel.

- Improved Durability: Induction wheels are more durable than in-wheel motors, as they are less susceptible to wear and tear due to the absence of moving parts.

- Lower Cost: Induction wheels have the potential to be more cost-effective than electric axles in the long run, due to their simplified design and lower maintenance requirements.

Applications of Induction Wheels

Induction wheels, with their unique advantages, have the potential to revolutionize various industries. Their ability to provide torque directly to the wheel, eliminating the need for transmissions, makes them a compelling alternative to traditional mechanical systems.

Electric Vehicles

Induction wheels are a promising technology for electric vehicles (EVs). Their direct drive capability eliminates the need for a complex and heavy transmission system, which can significantly improve efficiency and reduce vehicle weight. This can lead to longer driving ranges and increased performance.

The elimination of the transmission also simplifies the design and manufacturing process, potentially reducing production costs.

Furthermore, the absence of mechanical components like gears and axles reduces friction and wear, extending the lifespan of the vehicle. This can lead to lower maintenance costs and a more sustainable transportation solution.

Robotics

Induction wheels are particularly well-suited for robotics applications. Their compact size and ability to provide precise torque control make them ideal for navigating complex environments and performing intricate tasks.

For example, they can be used to develop highly maneuverable robots for warehouse automation, search and rescue operations, or even space exploration.

Induction wheels can also be integrated with sensors and actuators to create intelligent robots that can adapt to changing environments and perform tasks autonomously.

Other Applications, What are induction wheels

Beyond EVs and robotics, induction wheels have potential applications in various industries:

- Industrial Equipment: Induction wheels can be used in forklifts, cranes, and other heavy machinery, improving efficiency and reducing energy consumption. They can also enhance maneuverability in tight spaces.

- Military Applications: The high torque and silent operation of induction wheels make them suitable for military vehicles, such as unmanned ground vehicles (UGVs) or stealthy reconnaissance vehicles.

- Renewable Energy: Induction wheels can be used in wind turbines and solar trackers to optimize energy generation by precisely adjusting the orientation of these devices.

Challenges and Future Developments

While induction wheels hold immense potential, they face certain challenges that need to be addressed for their widespread adoption. Ongoing research and development efforts are focused on overcoming these limitations and enhancing their performance.

Current Challenges and Limitations

Induction wheel technology, despite its potential, faces several challenges that hinder its widespread adoption. These challenges include:

- Efficiency and Power Consumption: The efficiency of induction wheels is a significant concern, particularly at low speeds. The energy losses due to magnetic fields and eddy currents can be substantial, leading to reduced efficiency and increased power consumption. This limitation is especially relevant in applications where energy efficiency is paramount, such as electric vehicles.

- Weight and Size: The bulky nature of induction motors used in induction wheels contributes to increased weight and size. This can be a challenge in applications where space and weight constraints are crucial, such as in smaller vehicles or robotics.

- Cost: The production cost of induction wheels is currently higher compared to traditional wheel systems. This is mainly due to the complex design and manufacturing processes involved in creating the induction motors and the associated power electronics.

- Durability and Maintenance: The long-term durability and maintenance requirements of induction wheels are still under investigation. The constant exposure to wear and tear, especially in harsh environments, can affect the lifespan of the system.

- Thermal Management: Induction motors generate significant heat during operation. Effective thermal management systems are essential to prevent overheating and ensure optimal performance. This requires efficient cooling solutions, which can add to the complexity and cost of the system.

Potential Future Developments

Researchers and engineers are actively working on addressing these challenges and advancing induction wheel technology. Future developments are likely to focus on:

- Improved Efficiency and Power Management: Ongoing research aims to enhance the efficiency of induction wheels by optimizing the design of the induction motor, reducing energy losses, and implementing advanced power management systems. This includes exploring new materials, innovative winding configurations, and advanced control algorithms to minimize energy consumption.

- Lightweight Materials and Design: The development of lightweight materials and improved design techniques can significantly reduce the weight and size of induction wheels. This is crucial for applications where weight and space are critical factors.

- Cost Reduction: Efforts are underway to reduce the production cost of induction wheels through streamlined manufacturing processes, automation, and the use of more affordable materials. This is essential to make induction wheels more competitive with traditional wheel systems.

- Enhanced Durability and Reliability: Improving the durability and reliability of induction wheels involves developing more robust materials, optimizing the design for wear resistance, and incorporating self-monitoring and fault-detection systems. This ensures the longevity and safe operation of the system.

- Advanced Thermal Management: Future developments in thermal management systems will focus on improving the efficiency of cooling solutions and developing integrated thermal management systems. This can be achieved through innovative cooling techniques, such as liquid cooling, and the use of heat-resistant materials.

Integration with Other Advanced Technologies

Induction wheels have the potential to be integrated with other advanced technologies, further enhancing their capabilities and expanding their applications. Some promising areas include:

- Integration with Artificial Intelligence (AI): AI algorithms can be employed to optimize the performance of induction wheels, predict potential failures, and enhance their adaptability to different terrains and driving conditions. This can improve the efficiency, safety, and overall driving experience.

- Integration with Renewable Energy Sources: Induction wheels can be integrated with solar panels or other renewable energy sources to create self-powered systems. This can significantly reduce reliance on fossil fuels and promote sustainable transportation.

- Integration with Smart Grids: Induction wheels can be incorporated into smart grids, allowing them to act as energy storage devices. This can improve grid stability and optimize energy distribution, contributing to a more sustainable and efficient energy system.

As we stand on the cusp of a new era in mobility, induction wheels hold the key to unlocking unprecedented levels of efficiency and performance. With their ability to overcome the limitations of traditional wheels, these cutting-edge systems are poised to reshape industries, revolutionize transportation, and propel us towards a future where movement is both sustainable and powerful.

FAQ Explained: What Are Induction Wheels

How do induction wheels work?

Induction wheels utilize electromagnetic induction to generate torque. They consist of a stator with windings that produce a magnetic field, and a rotor that interacts with this field to create movement.

What are the advantages of induction wheels?

Induction wheels offer advantages such as increased efficiency, reduced friction, enhanced performance, and potential for regenerative braking.

What are some challenges associated with induction wheels?

Challenges include the need for advanced materials, complex control systems, and the development of robust power electronics.

What are some potential applications of induction wheels?

Induction wheels have potential applications in electric vehicles, robotics, industrial machinery, and even high-speed transportation systems.