What is ctr ring – What is a CTR ring? Imagine a circular tool, a precise ring, meticulously crafted to shape and refine materials with exceptional accuracy. This is the essence of a CTR ring, a specialized tool used in machining processes to create intricate designs and components. From the automotive industry to aerospace, CTR rings play a vital role in shaping the world around us.

These rings, available in various materials and configurations, are integral to the manufacturing process, enabling the creation of complex geometries and intricate details. They function as guides, ensuring consistent and accurate machining, ultimately contributing to the quality and reliability of finished products.

What is a CTR Ring?: What Is Ctr Ring

Okay, so CTR rings are basically the backbone of some pretty cool tech, especially when it comes to measuring stuff like speed, position, and even direction. They’re not just some random ring you find at a jewelry store, but a super precise component used in all sorts of applications. Think of them as tiny, super-smart sensors that can track and measure things with incredible accuracy.

Types of CTR Rings

CTR rings are available in different flavors, each designed for specific applications. These types vary based on their construction, size, and the kind of information they’re able to provide. Here’s a breakdown:

- Incremental CTR Rings: These are the basic building blocks, perfect for measuring linear displacement or rotation. They’re like the classic ruler of the CTR world, giving you precise measurements over a specific distance.

- Absolute CTR Rings: Imagine a ruler that can tell you your exact position, even if you’ve moved around. Absolute CTR rings do just that, providing a unique code for each position, eliminating the need for a reference point. They’re like having a built-in GPS for your machinery.

- Multi-Turn CTR Rings: Need to track rotations over multiple turns? These rings can handle it. They’re perfect for applications where a single revolution isn’t enough, like measuring the rotation of a motor shaft.

Applications of CTR Rings

CTR rings are pretty versatile, and you’ll find them in action across various industries. Here are a few examples:

- Manufacturing: Imagine robots in factories that can work with incredible precision. CTR rings help robots navigate, track their movements, and ensure everything is perfectly aligned. They’re crucial for tasks like assembly, welding, and quality control.

- Automotive: From your car’s speedometer to the advanced sensors in self-driving vehicles, CTR rings play a key role. They measure the rotation of wheels, engine speed, and even steering angles, ensuring smooth and safe driving.

- Aerospace: When it comes to planes and spacecraft, accuracy is paramount. CTR rings help control flight parameters, measure engine performance, and even track the position of landing gear. They’re essential for ensuring a safe and efficient flight.

- Medical Devices: CTR rings can be found in medical equipment like MRI machines, robotic surgery systems, and even prosthetic limbs. They help with precise positioning, tracking movement, and ensuring accurate diagnoses and treatments.

How CTR Rings Work

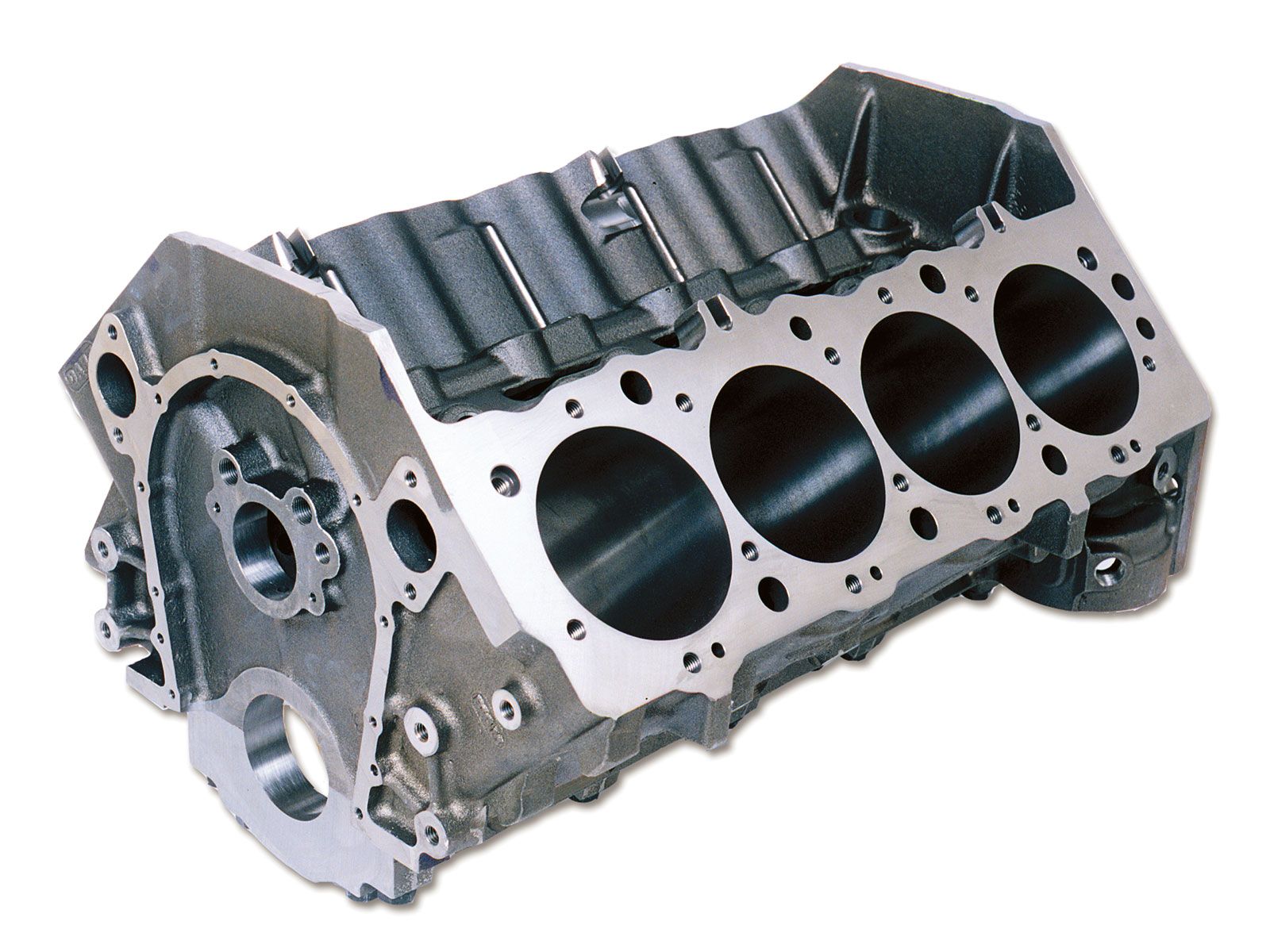

CTR rings are a crucial component in various machining processes, especially in turning operations. They provide a precise and rigid support system for the workpiece, ensuring high accuracy and surface finish during cutting. Understanding how CTR rings work is essential for optimizing machining processes and achieving desired results.

Relationship Between CTR Ring and Workpiece

The CTR ring plays a vital role in securing the workpiece during machining. The workpiece is typically mounted on a chuck, which is then attached to the CTR ring. The ring’s internal diameter is designed to fit snugly around the chuck, providing a strong and stable connection. This tight fit ensures that the workpiece remains securely fixed during cutting, minimizing vibration and ensuring accurate machining.

Role of the Cutting Tool

The cutting tool is responsible for removing material from the workpiece. The CTR ring, through its rigid support, allows the cutting tool to operate precisely and efficiently. The ring’s stability prevents the workpiece from shifting or vibrating during cutting, enabling the tool to follow the desired path and achieve the required dimensions and surface finish.

Advantages of Using CTR Rings

CTR rings offer a range of benefits that make them a valuable tool in manufacturing processes. Their unique design and functionality contribute to improved precision, accuracy, and overall efficiency. Let’s explore some of the key advantages of employing CTR rings in your manufacturing operations.

Increased Precision and Accuracy

CTR rings are renowned for their ability to achieve high levels of precision and accuracy. Their precise geometry and tight tolerances ensure consistent and repeatable results, minimizing errors and variations in the manufacturing process. This is particularly crucial in applications where dimensional accuracy is paramount, such as in the production of components for aerospace, automotive, and medical devices.

“The use of CTR rings in manufacturing processes has significantly improved the precision and accuracy of our products. We have seen a noticeable reduction in rejects and an overall increase in quality.”

Manufacturing Engineer, Aerospace Company

Improved Efficiency and Productivity

CTR rings streamline manufacturing processes by simplifying tooling setups and reducing the need for complex adjustments. Their ease of use and versatility allow for faster production cycles, contributing to increased efficiency and productivity. This is especially beneficial for high-volume manufacturing environments where time is of the essence.

Enhanced Tool Life and Durability

CTR rings are designed to withstand demanding manufacturing environments. Their robust construction and high-quality materials ensure long tool life and durability, minimizing downtime and maintenance costs. This translates into reduced operational expenses and a more sustainable manufacturing process.

Versatility and Adaptability

CTR rings are highly versatile and adaptable, making them suitable for a wide range of manufacturing applications. They can be used for various machining operations, including turning, milling, drilling, and grinding, providing flexibility and efficiency in tooling selection.

“We have been able to significantly reduce our tooling inventory by using CTR rings. Their versatility allows us to use a single tool for multiple applications, saving us time and resources.”

Manufacturing Manager, Automotive Company

Applications of CTR Rings

CTR rings are versatile tools used in various industries for machining different materials. They offer precision and efficiency in turning operations, making them ideal for a wide range of applications.

Applications of CTR Rings

CTR rings find their place in numerous industries, each with specific requirements. Here are some examples:

- Automotive Industry: CTR rings are used in the production of engine components, transmission parts, and other automotive components. They ensure precise machining of these parts, which is crucial for optimal engine performance and durability.

- Aerospace Industry: CTR rings are essential in machining aircraft components, such as turbine blades, engine casings, and landing gear parts. The high precision and efficiency offered by CTR rings are vital for the safety and performance of aircraft.

- Medical Industry: CTR rings are used in the production of medical implants, surgical instruments, and other medical devices. The precision and accuracy of CTR rings ensure the safety and effectiveness of these devices.

- Energy Industry: CTR rings are used in the manufacturing of components for power plants, wind turbines, and other energy infrastructure. The durability and reliability of CTR rings are crucial for the efficient operation of these systems.

- Manufacturing Industry: CTR rings are widely used in general manufacturing, including the production of tools, dies, molds, and other industrial components. They offer the precision and efficiency required for high-volume production.

Materials Machined with CTR Rings

CTR rings can be used to machine a wide range of materials, including:

- Metals: Steel, aluminum, brass, copper, titanium, and other metals can be machined using CTR rings. Different materials require specific cutting tools and machining parameters to achieve the desired results.

- Plastics: CTR rings can also be used to machine various types of plastics, including ABS, polycarbonate, and nylon. The machining parameters and cutting tools need to be adjusted based on the specific plastic material.

- Composites: CTR rings are used to machine composite materials, such as fiberglass, carbon fiber, and Kevlar. The ability of CTR rings to handle complex geometries and maintain precision is crucial for machining these materials.

CTR Ring Applications by Industry

The table below shows some specific applications of CTR rings in different industries:

| Industry | Application |

|---|---|

| Automotive | Engine Crankshafts, Connecting Rods, Transmission Gears |

| Aerospace | Turbine Blades, Engine Casings, Landing Gear Parts |

| Medical | Surgical Instruments, Medical Implants, Prosthetic Components |

| Energy | Turbine Blades, Generator Shafts, Power Plant Components |

| Manufacturing | Tools, Dies, Molds, Precision Components |

Choosing the Right CTR Ring

Choosing the right CTR ring is crucial for achieving optimal performance and ensuring the longevity of your application. It’s like picking the perfect outfit for a special occasion – you want it to fit right, be made of the right material, and complement your overall style.

Material Compatibility

The material of the CTR ring should be compatible with the materials used in your application. This ensures that the ring won’t react negatively with other components, leading to corrosion, wear, or other issues. For example, a CTR ring made of stainless steel would be a good choice for applications involving water or other corrosive environments, while a CTR ring made of PTFE would be ideal for applications involving chemicals or high temperatures.

- Stainless Steel: Offers excellent corrosion resistance, making it suitable for applications involving water, chemicals, and harsh environments.

- PTFE: Known for its high chemical resistance, making it ideal for applications involving chemicals, acids, and high temperatures.

- Nylon: Offers good wear resistance and electrical insulation, making it suitable for applications involving mechanical stress and electrical components.

Size Considerations

The size of the CTR ring is also critical. It needs to be the right size to fit the shaft or other component it’s being used with. Too small, and it won’t provide enough support. Too large, and it might cause damage or interfere with the operation of the application.

CTR Ring Types and Applications, What is ctr ring

Here’s a table summarizing the characteristics of different CTR ring types and their suitable applications:

| Type | Characteristics | Applications |

|---|---|---|

| Standard CTR Ring | Basic design, available in various materials. | General-purpose applications, including shaft support, sealing, and wear reduction. |

| Flanged CTR Ring | Features a flange that provides additional support and stability. | Applications requiring increased stability and resistance to axial loads. |

| Snap-Fit CTR Ring | Designed for easy installation and removal, featuring a snap-fit mechanism. | Applications where frequent assembly and disassembly are required. |

| Metric CTR Ring | Conforms to metric standards, ensuring compatibility with other metric components. | Applications requiring adherence to metric standards. |

Maintenance and Care of CTR Rings

CTR rings are precision components, and their performance depends heavily on their condition. Proper maintenance and care are essential to ensure their longevity and accuracy. This section will delve into the best practices for keeping your CTR rings in tip-top shape.

Regular Inspection and Cleaning

Regular inspection and cleaning are crucial for maintaining the performance of CTR rings. It helps identify potential issues early on and prevent them from escalating into major problems. Here’s what you need to know:

- Visual Inspection: Regularly inspect the CTR ring for any signs of damage, wear, or contamination. This includes checking for scratches, dents, cracks, or any buildup of debris.

- Cleaning: Clean the CTR ring with a soft, lint-free cloth and a mild cleaning solution. Avoid harsh chemicals or abrasive materials that could damage the surface. If necessary, use a compressed air source to remove any loose debris.

- Frequency: The frequency of inspection and cleaning depends on the environment in which the CTR ring is used. In a clean, controlled environment, inspection and cleaning can be done less frequently. However, in a harsh or dirty environment, more frequent maintenance is recommended.

Potential Issues from Improper Handling or Maintenance

Improper handling or maintenance can lead to various issues with CTR rings, affecting their accuracy and longevity. Here are some common problems that can arise:

- Damage: Dropping or mishandling the CTR ring can lead to scratches, dents, or cracks, affecting its dimensional accuracy and performance.

- Contamination: Exposure to dirt, dust, or other contaminants can lead to buildup on the surface of the CTR ring, interfering with its smooth operation.

- Wear and Tear: Continuous use without proper maintenance can lead to wear and tear on the CTR ring, reducing its accuracy and lifespan.

- Corrosion: Exposure to corrosive environments can lead to rust or corrosion on the CTR ring, affecting its functionality.

Safety Considerations with CTR Rings

CTR rings, while incredibly useful in various applications, do present certain safety hazards. It’s crucial to be aware of these potential risks and implement appropriate safety measures to ensure a safe working environment. This section will delve into the potential hazards, essential precautions, and proper handling techniques for minimizing risks associated with CTR rings.

Identifying Potential Hazards

It’s important to recognize the potential hazards associated with using CTR rings. These hazards can arise from various factors, including:

- Electrical Shock: CTR rings can be used in applications involving high voltage, increasing the risk of electrical shock. This risk is particularly prominent when working with energized circuits or systems.

- Mechanical Injuries: The sharp edges and moving parts of CTR rings can cause cuts, punctures, or other mechanical injuries. This risk is heightened during installation, removal, or handling of the rings.

- Thermal Hazards: CTR rings can generate heat during operation, especially in high-power applications. This heat can pose a burn risk if proper safety precautions are not taken.

- Fire Hazards: In certain applications, CTR rings can create sparks or ignite flammable materials. This risk is elevated in environments with combustible substances or where electrical faults occur.

Precautions to Take

To minimize the risks associated with CTR rings, it’s essential to take the following precautions:

- Use Personal Protective Equipment (PPE): Wear appropriate PPE, including insulated gloves, safety glasses, and fire-resistant clothing, to protect yourself from electrical shock, mechanical injuries, and thermal hazards.

- Work in a Safe Environment: Ensure a safe working environment by providing adequate lighting, ventilation, and space for movement. This will minimize the risk of accidents and injuries.

- De-energize Circuits: Always de-energize circuits before working on or near CTR rings. This will eliminate the risk of electrical shock and prevent accidental energization during maintenance or repair.

- Use Insulated Tools: Employ insulated tools and equipment when working with CTR rings, especially in applications involving high voltage. This will further reduce the risk of electrical shock.

- Follow Manufacturer’s Instructions: Always adhere to the manufacturer’s instructions for installation, operation, and maintenance of CTR rings. This will ensure safe and proper usage.

Proper Handling Techniques

Proper handling techniques are crucial for minimizing the risks associated with CTR rings. Here are some essential tips:

- Use Lifting Devices: When handling heavy CTR rings, use appropriate lifting devices, such as hoists or cranes, to avoid manual lifting and potential injuries.

- Wear Gloves: Always wear insulated gloves when handling CTR rings to protect your hands from electrical shock and potential mechanical injuries.

- Use Caution with Sharp Edges: Be cautious of sharp edges and moving parts when handling CTR rings. Avoid touching these areas to prevent cuts or punctures.

- Avoid Direct Contact with Hot Surfaces: Do not touch hot surfaces on CTR rings during or after operation. Allow them to cool down before handling to prevent burns.

- Maintain a Safe Distance: Maintain a safe distance from CTR rings, especially during operation, to avoid contact with moving parts or potential hazards.

CTR rings are more than just tools; they represent precision, efficiency, and innovation in the world of manufacturing. Their ability to achieve intricate designs and deliver high-quality results has solidified their place as essential components in various industries. Understanding the workings, benefits, and applications of CTR rings provides valuable insights into the intricate world of precision machining.

FAQ Summary

What are the most common materials used for CTR rings?

CTR rings are typically made from durable materials like hardened steel, carbide, or ceramics, chosen based on the specific application and the material being machined.

How do I determine the correct size of a CTR ring for my application?

The size of the CTR ring depends on the diameter of the workpiece and the desired machining process. Consulting with a tooling specialist or referring to the manufacturer’s specifications is crucial for accurate selection.

Are there any safety precautions to consider when using CTR rings?

Yes, safety is paramount when working with CTR rings. Always wear appropriate personal protective equipment, such as safety glasses and gloves, and follow the manufacturer’s instructions for proper handling and operation.