A company makes bikes from recycled metal, a testament to innovation and sustainability. This endeavor transforms discarded metal into sleek, durable machines, offering a compelling alternative to traditional bike manufacturing. By embracing recycled materials, the company not only minimizes its environmental footprint but also contributes to a circular economy, where resources are valued and reused.

The company’s commitment to sustainability extends beyond simply using recycled metal. They carefully source their materials, ensuring ethical and responsible practices throughout the supply chain. This commitment resonates with environmentally conscious consumers who seek products that align with their values.

The Environmental Impact: A Company Makes Bikes From Recycled Metal

Our commitment to using recycled metal in our bike manufacturing process is not just about sustainability; it’s about actively contributing to a healthier planet. By choosing recycled materials, we’re taking a stand against the environmental damage associated with traditional metal extraction.

Reducing Mining and its Environmental Impact

Mining for raw materials is a resource-intensive process with significant environmental consequences. The extraction of metal ores can lead to deforestation, habitat destruction, soil erosion, and water pollution. By using recycled metal, we significantly reduce the demand for newly mined materials, thereby mitigating these negative impacts.

Carbon Footprint Reduction

Recycling metal requires significantly less energy than extracting new materials. This energy saving translates into a lower carbon footprint. According to the Aluminum Association, recycling aluminum cans saves 95% of the energy needed to produce aluminum from bauxite ore. This substantial energy reduction translates into a significant decrease in greenhouse gas emissions.

The Manufacturing Process

Our journey from recycled metal to sustainable bicycles is a testament to ingenuity and environmental responsibility. We meticulously transform discarded materials into durable and stylish bike frames and components, showcasing the transformative power of circular economy principles.

Transforming Recycled Metal into Bike Frames and Components

The process of transforming recycled metal into bike frames and components is a meticulous dance of precision and innovation. We begin by sourcing high-quality recycled aluminum, steel, and other metals from various sources. These materials are then carefully sorted and cleaned to remove impurities and ensure optimal quality.

- Melting and Casting: The recycled metal is melted down in specialized furnaces and poured into molds to create the desired shapes for bike frames, forks, handlebars, and other components.

- Machining and Shaping: Once the metal has cooled and solidified, it undergoes precise machining and shaping processes to achieve the exact dimensions and specifications required for each component.

- Welding and Assembly: The machined components are then carefully welded together to create the bike frame and other parts. This process requires skilled welders who can ensure strong and durable joints.

- Finishing and Painting: The completed frame and components are then finished with a variety of coatings and paints to provide durability, corrosion resistance, and a stylish aesthetic.

Challenges and Innovations in Using Recycled Materials

The use of recycled materials in bike manufacturing presents unique challenges and opportunities for innovation. One key challenge is ensuring the consistent quality of recycled metal, which can vary depending on the source and the recycling process.

- Material Purity and Consistency: Recycled metal often contains impurities that can affect its strength and durability. We address this challenge by employing rigorous quality control measures to ensure that only high-quality recycled metal is used in our manufacturing process.

- Advanced Manufacturing Techniques: To overcome the challenges of working with recycled materials, we have invested in advanced manufacturing techniques such as laser cutting, CNC machining, and robotic welding. These technologies allow us to achieve precise tolerances and ensure the quality of our products.

- Sustainable Sourcing: We prioritize sourcing recycled materials from responsible and ethical suppliers who share our commitment to sustainability. This helps to ensure that the materials we use are not only recycled but also produced in an environmentally friendly way.

Durability and Quality of Bikes Made from Recycled Metal

The durability and quality of bikes made from recycled metal are comparable to those made from virgin materials. In fact, some argue that recycled metal can be even more durable due to its unique properties.

- Strength and Durability: Recycled metal can be just as strong and durable as virgin metal, and in some cases, it may even be more resistant to fatigue and wear. This is because the recycling process can refine the metal, removing impurities and enhancing its structural integrity.

- Environmental Benefits: By using recycled materials, we significantly reduce the environmental impact of bike manufacturing. Recycling metals requires far less energy and resources than extracting and processing virgin materials.

- Circular Economy: Our commitment to using recycled materials is a cornerstone of our circular economy approach. We believe in creating a sustainable system where resources are used and reused effectively, minimizing waste and maximizing the lifespan of our products.

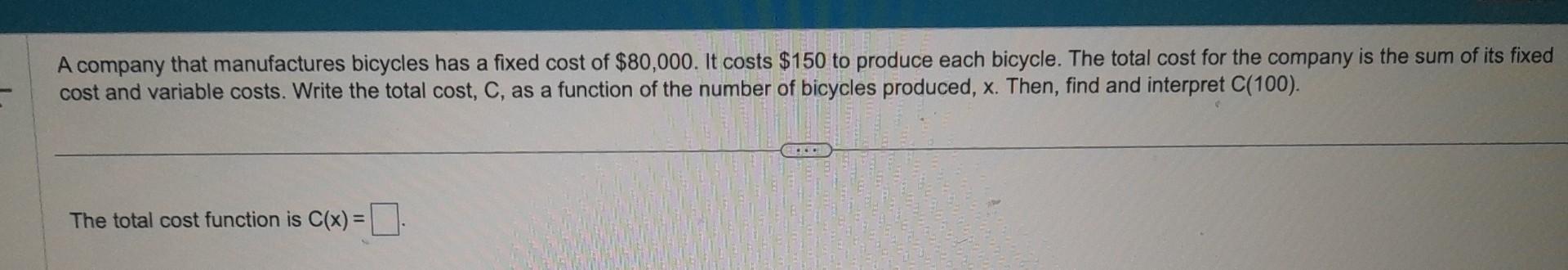

The Business Model

The business model of a company that makes bikes from recycled metal is based on sustainability, affordability, and appealing to a growing market of environmentally conscious consumers.

Sourcing Recycled Materials

The company prioritizes sourcing recycled materials from responsible and ethical sources. They often collaborate with local scrap metal dealers, recycling centers, and even industrial partners who have surplus metal. This ensures the materials are sourced sustainably and contribute to a circular economy.

Sustainability Practices

To ensure sustainability, the company implements various practices:

- Minimizing waste: The company strives to minimize waste during the manufacturing process by utilizing scrap metal efficiently and implementing recycling programs for leftover materials.

- Energy efficiency: The company invests in energy-efficient equipment and technologies to reduce its carbon footprint. This includes using solar panels for electricity generation and implementing energy-saving measures in its facilities.

- Fair labor practices: The company adheres to fair labor standards and ethical sourcing practices, ensuring that workers are treated fairly and their rights are respected.

Pricing Strategies

The company adopts a competitive pricing strategy that balances affordability with the value proposition of sustainability. They offer their bikes at prices comparable to traditional bikes made from new materials, while highlighting the environmental benefits of their products.

Target Market

The target market for these bikes is diverse and includes:

- Environmentally conscious consumers: Individuals who prioritize sustainability and are willing to pay a premium for products that align with their values.

- Budget-conscious consumers: People who are looking for affordable and durable bikes that are also environmentally friendly.

- Urban commuters: Individuals who use bikes for daily transportation and appreciate the durability and low maintenance of recycled metal bikes.

- Outdoor enthusiasts: Adventure seekers who value the unique aesthetic and sustainable aspect of recycled metal bikes.

The Consumer Perspective

For environmentally conscious consumers, choosing a bike made from recycled metal offers a unique opportunity to align their purchase with their values. These bikes represent a sustainable alternative to traditional manufacturing methods, appealing to those who prioritize reducing their environmental footprint. However, it is essential to understand the consumer perspective, encompassing both the motivations for purchasing recycled bikes and any potential concerns that may arise.

Reasons for Choosing Recycled Bikes

Consumers are increasingly interested in products made from recycled materials, driven by a growing awareness of environmental issues. This trend is reflected in the increasing popularity of recycled bikes, which offer a range of benefits:

- Environmental Sustainability: By choosing a recycled bike, consumers contribute to reducing the demand for new materials and minimizing waste. This aligns with their commitment to sustainable living and reducing their environmental impact.

- Reduced Carbon Footprint: Manufacturing bikes from recycled metal requires less energy and produces fewer emissions compared to using virgin materials. This translates to a lower carbon footprint, appealing to consumers seeking to minimize their impact on climate change.

- Unique Style and Design: Bikes made from recycled metal often feature distinctive designs and finishes, showcasing the unique character of the materials used. This appeals to consumers who appreciate individuality and craftsmanship.

- Support for Ethical Practices: Purchasing from a company that uses recycled materials and prioritizes sustainability often aligns with consumers’ ethical values. They support businesses that contribute to a more responsible and circular economy.

Potential Challenges and Concerns

While the benefits of recycled bikes are clear, consumers may have certain concerns that need to be addressed:

- Durability and Reliability: Some consumers may be concerned about the durability and reliability of bikes made from recycled metal. It is important to emphasize that recycled metal can be just as strong and durable as virgin materials, particularly when using high-quality recycled materials and appropriate manufacturing processes.

- Availability and Price: The availability of recycled bikes may be limited compared to traditional bikes, and the price may be higher. The company can address this by building strong partnerships with suppliers, optimizing production processes, and promoting the value proposition of their sustainable products.

- Lack of Awareness: Consumers may not be fully aware of the benefits and advantages of recycled bikes. The company needs to educate consumers about the environmental and social benefits of their products through effective marketing campaigns and public awareness initiatives.

Educating and Engaging Consumers, A company makes bikes from recycled metal

To address potential concerns and highlight the benefits of recycled bikes, the company can implement a comprehensive strategy for consumer education and engagement:

- Transparent Information: Provide detailed information about the sourcing of recycled materials, the manufacturing process, and the environmental impact of their bikes. This transparency builds trust and demonstrates the company’s commitment to sustainability.

- Educational Campaigns: Launch campaigns to raise awareness about the benefits of recycled bikes, emphasizing their environmental impact, durability, and unique style. Utilize online platforms, social media, and partnerships with environmental organizations to reach a wider audience.

- Customer Testimonials: Feature stories and testimonials from satisfied customers who have chosen recycled bikes. This provides social proof and demonstrates the real-world benefits of these products.

- Interactive Experiences: Organize events, workshops, or test rides where consumers can experience recycled bikes firsthand and learn more about the company’s sustainable practices. This provides a tangible connection with the product and its values.

Design and Aesthetics

The use of recycled materials in bike design presents a unique opportunity to create visually appealing and sustainable products. While the raw materials may have an industrial past, they can be transformed into bikes that are both functional and aesthetically pleasing.

Design Considerations and Aesthetic Choices

The inherent characteristics of recycled metal, such as its texture, color, and shape, can be incorporated into the design to create a distinct aesthetic. For example, the use of reclaimed steel with its inherent imperfections can create a rustic and industrial look, while polished aluminum can provide a sleek and modern feel.

Incorporating Recycled Metal into Bike Designs

Companies can incorporate recycled metal into various aspects of bike design:* Frames: The use of recycled steel or aluminum in bike frames can be visually striking. Some companies utilize the inherent texture and color variations of recycled metal to create unique frame designs, highlighting the material’s history and sustainability.

Components

Recycled metal can be used in components like handlebars, stems, seatposts, and even wheels. These components can be designed to complement the frame’s aesthetic or create a distinct contrast.

Finishing Touches

The use of recycled metal can extend beyond structural components. For example, recycled metal can be used to create custom accents like badges, chain guards, or even decorative elements on the frame.

Sustainability and Eco-friendliness

The use of recycled metal contributes to the overall sustainability of the bike by:* Reducing Environmental Impact: Using recycled metal reduces the demand for virgin materials, lowering the energy consumption and emissions associated with mining and processing.

Promoting Circular Economy

Recycling metal promotes a circular economy, where materials are reused and repurposed, minimizing waste and resource depletion.

Creating Unique Products

The use of recycled metal can create a unique selling proposition for bikes, appealing to environmentally conscious consumers who value sustainable and ethically produced products.

Community Engagement

A company that manufactures bikes from recycled metal has a unique opportunity to connect with local communities and foster a shared commitment to sustainability. Engaging with local communities can be a powerful tool for promoting recycling, responsible metal sourcing, and building a strong brand identity.

Building Community Partnerships

Collaborating with local organizations can significantly amplify the company’s sustainability efforts and create a positive impact within the community.

- Partnering with local recycling centers and scrap metal yards can help secure a consistent supply of recycled materials while supporting local businesses and promoting responsible metal sourcing.

- Working with schools and educational institutions can provide opportunities to educate youth about the importance of recycling and sustainable practices. The company can offer workshops, tours of its manufacturing facility, and educational materials that highlight the environmental benefits of using recycled metal.

- Collaborating with community groups and non-profit organizations focused on environmental conservation and urban renewal can provide valuable insights and resources for promoting sustainable practices and community engagement.

The company’s dedication to creating bikes from recycled metal presents a compelling case for sustainable practices in the manufacturing industry. By demonstrating that environmentally conscious choices can lead to high-quality products, they inspire others to adopt similar approaches. As the demand for sustainable products grows, the company’s model serves as a blueprint for a future where environmental responsibility and innovation go hand in hand.

FAQ Resource

What are the benefits of buying a bike made from recycled metal?

Buying a bike made from recycled metal supports sustainable practices, reduces environmental impact, and often comes with a unique design aesthetic.

Are bikes made from recycled metal as durable as those made from virgin materials?

Yes, bikes made from recycled metal can be just as durable as those made from virgin materials. The company utilizes advanced manufacturing techniques to ensure the quality and strength of their products.

How does the company ensure the sustainability of their recycled metal sourcing?

The company works with certified suppliers who adhere to ethical and responsible sourcing practices. They also implement rigorous quality control measures to ensure the recycled metal meets their high standards.

What is the price difference between a recycled metal bike and a traditional bike?

The price of a recycled metal bike can vary depending on the model and features, but it is generally comparable to traditional bikes in the same category.