A bicycle wheel is 63 centimeters from top to bottom, a measurement that holds profound significance in the world of cycling. This seemingly simple dimension governs a multitude of factors, from the wheel’s construction and performance to the rider’s experience on the road. Understanding this measurement unlocks a deeper appreciation for the intricate design and mechanics of a bicycle wheel, revealing the delicate balance between efficiency, strength, and control.

This measurement, the diameter of the wheel, directly influences its circumference, the distance covered in one complete rotation. The circumference, in turn, dictates the speed at which the bicycle travels for a given pedal stroke. This fundamental relationship highlights the critical role that wheel size plays in determining a cyclist’s performance, emphasizing the importance of choosing the right wheel for a specific riding style and terrain.

Dimensions and Measurement

The 63-centimeter measurement refers to the overall height of a bicycle wheel, encompassing both the rim and the tire. This measurement is crucial for understanding the wheel’s size and its impact on the bicycle’s performance.

Determining the Diameter

The 63-centimeter measurement represents the wheel’s diameter, which is the straight line distance across the circle passing through its center. To calculate the diameter, we simply divide the overall height by 2:

Diameter = Overall Height / 2 = 63 cm / 2 = 31.5 cm

Calculating the Circumference

The circumference of a circle is the distance around its outer edge. It is calculated using the following formula:

Circumference = π – Diameter

Where π (pi) is a mathematical constant approximately equal to 3.

Therefore, the circumference of a bicycle wheel with a 63-centimeter height is:

Circumference = 3.14159

31.5 cm ≈ 98.96 cm

Practical Implications for Cyclists

The circumference of a bicycle wheel directly influences the distance traveled with each rotation. Larger wheels have a greater circumference, meaning the bike travels further with each pedal stroke. This can be advantageous for covering longer distances with less effort, particularly on flat terrain. However, larger wheels can also make the bike heavier and less maneuverable.Conversely, smaller wheels require more pedal strokes to cover the same distance but offer greater maneuverability and agility, particularly in urban environments.Wheel size also influences the frame size of a bicycle.

Larger wheels generally require a larger frame to accommodate their size and provide proper geometry for comfortable and efficient riding.In summary, the 63-centimeter measurement provides essential information about a bicycle wheel’s size and its impact on performance. Understanding these dimensions allows cyclists to choose the appropriate wheel size and frame size for their specific needs and riding style.

Wheel Construction

A bicycle wheel is a marvel of engineering, seamlessly integrating multiple components to facilitate efficient and safe movement. Its construction involves a delicate balance of strength, flexibility, and weight, crucial for its performance and durability.

Components of a Bicycle Wheel

The components of a bicycle wheel are intricately connected, each playing a vital role in its functionality.

- Rim: The rim forms the outer circle of the wheel, providing the foundation for the tire to sit upon. It is typically made from aluminum, steel, or carbon fiber, each offering distinct advantages. Aluminum rims are lightweight and durable, while steel rims are robust and affordable. Carbon fiber rims are exceptionally lightweight and stiff, making them ideal for high-performance bicycles.

- Spokes: Spokes are thin, tensioned wires that connect the rim to the hub, transferring the rider’s weight and power to the ground. They are usually made of steel, stainless steel, or sometimes aluminum, depending on the desired strength and weight. The number and arrangement of spokes influence the wheel’s stiffness and responsiveness.

- Hub: The hub is the central component of the wheel, acting as the pivot point for the spokes. It houses the bearings that allow the wheel to rotate smoothly. Hubs are typically made of aluminum or steel, with bearings made of steel or ceramic.

- Tire: The tire encases the rim and provides the contact point with the road surface. Tires are made of rubber, with a variety of tread patterns and materials designed to optimize grip, rolling resistance, and puncture resistance.

Materials and Properties

The materials used in bicycle wheel construction are carefully chosen to meet specific performance requirements.

- Aluminum: Aluminum is lightweight, strong, and corrosion-resistant, making it a popular choice for rims, hubs, and spokes. It is also relatively affordable.

- Steel: Steel is a strong and durable material, often used for rims, hubs, and spokes. It is less expensive than aluminum but heavier.

- Carbon Fiber: Carbon fiber is exceptionally lightweight and stiff, making it ideal for high-performance rims. It is also corrosion-resistant, but it is more expensive than aluminum or steel.

- Rubber: Rubber is a flexible and resilient material, making it ideal for tires. It provides grip and cushioning, absorbing road vibrations and bumps.

Visual Representation of a Bicycle Wheel

Imagine a bicycle wheel as a circular frame, the rim, with numerous spokes radiating from its center, the hub. The hub is connected to the bike’s frame through an axle. The tire encases the rim, providing the contact point with the road surface. The spokes are arranged in a specific pattern, typically radial, crossed, or tangential, to distribute stress evenly and enhance the wheel’s strength and stiffness.

Relationship Between Wheel Size and Component Strength

The size of a bicycle wheel directly influences the strength and durability of its components. Larger wheels, with larger rims and longer spokes, generally require stronger and more robust components to withstand the increased stress and weight. This is especially true for mountain bikes, where larger wheels are essential for navigating rough terrain. Conversely, smaller wheels, found on road bikes, can utilize lighter and more flexible components, resulting in a lighter and more responsive wheel.

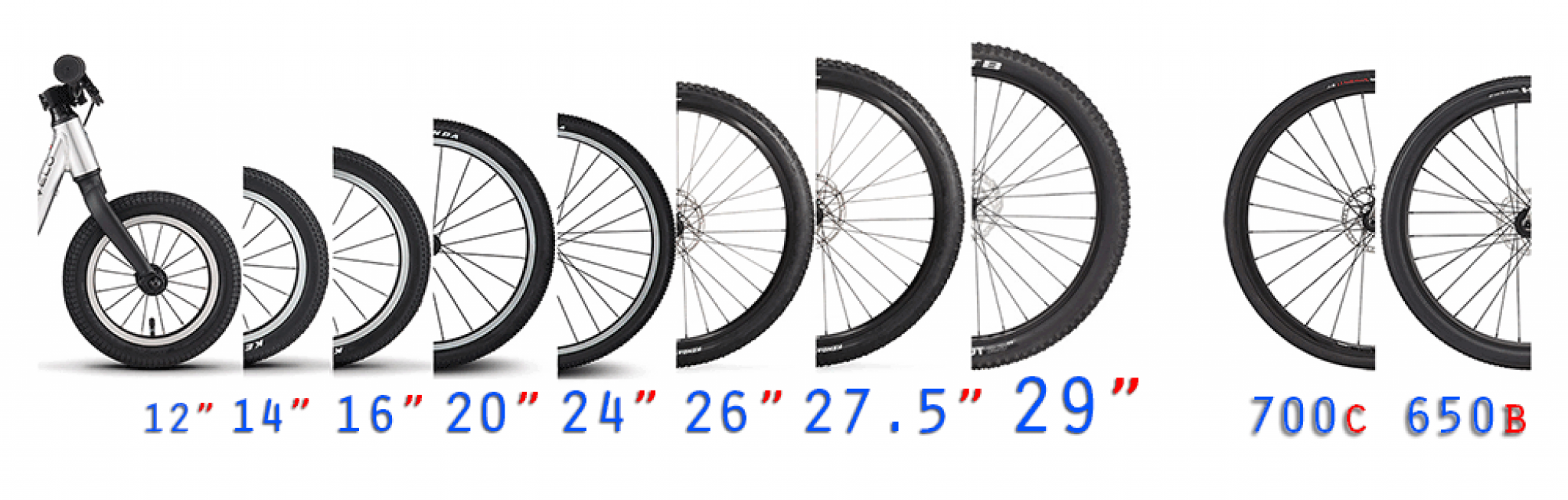

Types of Bicycle Wheels

Bicycle wheels are not all the same. Their design and construction are tailored to meet the specific demands of different cycling disciplines. From the smooth asphalt of road cycling to the rugged terrain of mountain biking, the choice of wheel type significantly impacts a cyclist’s performance and riding experience.

Wheel Types and Their Applications

The choice of wheel type depends largely on the intended use of the bicycle. Here are some common types of bicycle wheels and their applications:

- Road Wheels: These wheels are designed for speed and efficiency on paved surfaces. They typically feature narrow rims, high spoke counts, and lightweight hubs. The narrow rim allows for low rolling resistance, while the high spoke count provides lateral stiffness and durability. The lightweight hubs reduce rotational inertia, further contributing to efficiency.

- Mountain Bike Wheels: Mountain bike wheels are built for durability and traction on rough terrain. They have wider rims to accommodate wider tires with knobby treads for grip. The spoke count is often lower than road wheels, providing greater strength and resilience to impacts. The hubs are typically stronger and more robust to withstand the rigors of off-road riding.

- BMX Wheels: BMX wheels are designed for strength and agility in freestyle riding and racing. They feature small diameters and wide rims to accommodate thick tires with knobby treads. The hubs are often sealed and robust, designed to withstand high impacts and repeated landings.

- Gravel Wheels: Gravel wheels are a hybrid between road and mountain bike wheels. They are designed for mixed-surface riding, combining the speed and efficiency of road wheels with the durability and traction of mountain bike wheels. They feature wider rims than road wheels but narrower than mountain bike wheels, and the spoke count is typically moderate.

Key Differences in Wheel Design, A bicycle wheel is 63 centimeters from top to bottom

| Wheel Type | Rim Width (mm) | Spoke Count | Hub Design | Typical Diameter (inches) | Applications |

|---|---|---|---|---|---|

| Road | 17-25 | 16-24 (each side) | Lightweight, low-friction bearings | 700c (29 inches) | Road cycling, time trials, criteriums |

| Mountain Bike | 25-35 | 24-36 (each side) | Strong, durable bearings | 26, 27.5, or 29 inches | Cross-country, trail, enduro, downhill |

| BMX | 20-25 | 36 (each side) | Sealed, robust bearings | 20 inches | Freestyle, racing |

| Gravel | 23-30 | 24-32 (each side) | Lightweight, durable bearings | 700c (29 inches) | Gravel riding, adventure cycling |

Impact of Wheel Type on Cycling Performance

The choice of wheel type significantly impacts a cyclist’s performance and riding experience.

- Road wheels offer the lowest rolling resistance and the highest efficiency on paved surfaces, making them ideal for speed and distance.

- Mountain bike wheels provide excellent traction and durability on rough terrain, allowing riders to tackle challenging trails with confidence.

- BMX wheels offer the agility and strength needed for freestyle riding and racing, enabling riders to perform tricks and navigate tight corners with ease.

- Gravel wheels provide a balance of speed, efficiency, and durability, making them suitable for a wide range of riding conditions.

Wheel Size and Performance

Wheel size plays a crucial role in a bicycle’s performance, influencing rolling resistance, speed, acceleration, and overall handling. Larger wheels generally offer advantages in terms of efficiency and speed, while smaller wheels excel in agility and maneuverability.

Rolling Resistance

Rolling resistance is the force that opposes the motion of a wheel as it rolls on a surface. Larger wheels generally exhibit lower rolling resistance compared to smaller wheels. This is because larger wheels have a larger contact patch with the ground, distributing the weight more evenly and reducing the amount of friction. The larger circumference of larger wheels also allows them to roll over obstacles and imperfections in the road surface more easily, further minimizing rolling resistance.

Impact on Speed and Acceleration

Wheel size significantly impacts a bicycle’s speed and acceleration. Larger wheels have a greater circumference, meaning they cover more ground with each revolution. This translates to higher speeds at a given cadence, but also requires more effort to accelerate. Smaller wheels, on the other hand, require less effort to accelerate but reach lower top speeds.

Wheel Size and Cycling Disciplines

The optimal wheel size varies depending on the cycling discipline.

Road Racing

Road racing bikes typically feature large, thin wheels with a diameter ranging from 700c (28 inches) to 29 inches. This larger wheel size minimizes rolling resistance, enabling riders to maintain high speeds on smooth paved surfaces.

Mountain Biking

Mountain bikes typically employ smaller wheels, ranging from 26 inches to 29 inches. The smaller wheel size offers better maneuverability and agility on challenging terrain, allowing riders to navigate tight turns and technical obstacles with ease.

Other Disciplines

Other cycling disciplines, such as cyclocross, gravel riding, and urban commuting, utilize a range of wheel sizes depending on the specific demands of the terrain and riding style.

Optimizing Wheel Size for Terrain and Riding Style

Wheel size can be optimized for various terrain types and riding styles.

Smooth Surfaces

For smooth paved surfaces, such as roads and tracks, larger wheels with a diameter of 700c or 29 inches are generally preferred. They offer lower rolling resistance, enabling riders to achieve higher speeds with less effort.

Rough Terrain

On rough terrain, such as trails and gravel roads, smaller wheels, typically 26 inches or 27.5 inches, are often favored. Their smaller diameter and wider tires provide greater traction and control, making it easier to navigate obstacles and maintain stability.

Urban Environments

In urban environments, where agility and maneuverability are essential, smaller wheels, ranging from 20 inches to 26 inches, are often preferred. They allow for easier maneuvering in tight spaces and provide a more responsive ride.

Wheel Maintenance

Maintaining your bicycle wheels is crucial for a safe and enjoyable riding experience. Regular inspections, cleaning, and lubrication can help prevent problems and extend the lifespan of your wheels.

Wheel Inspection

Regularly inspecting your wheels for signs of wear and tear is essential.

- Spoke Tension: Check for loose or broken spokes, which can cause the wheel to wobble or become out of true. Loose spokes can be tightened with a spoke wrench. Broken spokes need to be replaced.

- Rim Damage: Inspect the rim for dents, cracks, or other damage. Damaged rims can weaken the wheel and make it unsafe to ride. If you notice any damage, it’s best to have the rim repaired or replaced by a professional.

- Tire Wear: Examine the tire for wear and tear, including tread depth, sidewall cracks, and punctures. Worn tires can lead to flat tires and poor handling.

- Hub Bearings: Check the hub bearings for signs of wear or play. A smooth, quiet rotation indicates healthy bearings. A rough or noisy rotation suggests that the bearings need to be cleaned, lubricated, or replaced.

Wheel Cleaning

Cleaning your wheels regularly helps prevent dirt and grime from accumulating, which can cause premature wear and tear.

- Cleaning Method: Use a soft brush and a mild soap solution to clean the rim, spokes, and hub. Avoid using harsh chemicals or abrasive cleaners, which can damage the wheel.

- Drying: After cleaning, dry the wheel thoroughly with a clean cloth to prevent rust.

Wheel Lubrication

Lubricating the wheel bearings and moving parts helps to reduce friction and wear.

- Lubricant Type: Use a light oil, such as bicycle chain lube, to lubricate the hub bearings. Avoid using heavy grease, which can attract dirt and grime.

- Lubrication Frequency: Lubricate the bearings every few weeks or after riding in wet conditions.

Truing a Wheel

Truing a wheel involves adjusting the spoke tension to ensure that the rim is perfectly round and centered in the frame.

- Tools: You’ll need a spoke wrench, a truing stand, and a tire lever to true a wheel.

- Procedure:

- Remove the tire and tube from the wheel.

- Secure the wheel in the truing stand.

- Rotate the wheel and observe the rim for any wobbles or deviations from true.

- Use the spoke wrench to tighten or loosen spokes to adjust the rim’s position.

- Continue adjusting the spokes until the rim is perfectly round and centered in the frame.

- Reinstall the tire and tube.

Preventing Wheel Problems

- Proper Inflation: Maintain the correct tire pressure as recommended by the tire manufacturer. Overinflation can cause the rim to bend, while underinflation can lead to pinch flats and increased rolling resistance.

- Avoiding Obstacles: Avoid riding over sharp objects, potholes, and curbs, which can damage the rim or spokes.

- Regular Maintenance: Regularly inspect, clean, and lubricate your wheels to prevent problems and extend their lifespan.

As we delve deeper into the intricacies of a bicycle wheel, we uncover a fascinating interplay of engineering principles and practical applications. The 63-centimeter measurement, while seemingly straightforward, acts as a gateway to a world of technical details and performance considerations. From the wheel’s construction to its impact on riding experience, every aspect is intricately linked to this crucial dimension.

By appreciating the significance of this measurement, we gain a deeper understanding of the bicycle as a marvel of design and engineering, a testament to human ingenuity and the pursuit of efficient motion.

Clarifying Questions: A Bicycle Wheel Is 63 Centimeters From Top To Bottom

How does wheel size affect a bicycle’s handling?

Larger wheels generally provide greater stability and roll over obstacles more easily, while smaller wheels offer better maneuverability and agility.

What is the relationship between wheel size and gear ratios?

Larger wheels require a lower gear ratio to maintain the same speed as smaller wheels, as they cover more distance per revolution.

Are there any disadvantages to using larger wheels?

Larger wheels can be heavier and less responsive, potentially affecting acceleration and maneuverability in tight spaces.

What are the different types of bicycle tires available?

There are various tire types, including road tires for paved surfaces, mountain bike tires for off-road use, and hybrid tires for a mix of both.

How often should I inspect my bicycle wheels?

It’s recommended to inspect your wheels regularly, especially after riding on rough terrain or encountering any impact.