Are there wheel bearings in the rear – Do rear wheels have bearings? The answer is a resounding yes! Just like their front counterparts, rear wheels rely on bearings to facilitate smooth rotation and support the weight of the vehicle. These essential components ensure a comfortable and safe driving experience, but understanding their function and maintenance is crucial.

Wheel bearings are a vital part of any vehicle’s suspension system, allowing the wheels to rotate freely and efficiently. They are typically housed within the wheel hub and consist of a set of steel balls or rollers that allow the wheel to spin smoothly on the axle. These bearings are designed to withstand significant loads and friction, but over time, wear and tear can occur, leading to a variety of issues that can impact your vehicle’s performance and safety.

Wheel Bearing Basics: Are There Wheel Bearings In The Rear

:max_bytes(150000):strip_icc()/car-wheel-bearing-diagram-how-to-repair-wheel-bearings-of-car-wheel-bearing-diagram-5bafa1a6c9e77c00514cb94a.jpg)

Wheel bearings are essential components in a vehicle’s suspension system, playing a crucial role in supporting the weight of the vehicle and allowing the wheels to rotate smoothly. They act as a vital link between the wheel hub and the axle, enabling the wheels to turn freely while maintaining stability and control.

Types of Wheel Bearings

Wheel bearings are classified into two main types:

- Ball Bearings: These bearings consist of steel balls that rotate between two raceways, one on the inner race and one on the outer race. Ball bearings are commonly found in older vehicles and are known for their simplicity and affordability.

- Tapered Roller Bearings: These bearings utilize tapered rollers that are arranged in a cage and roll between a conical inner race and a conical outer race. Tapered roller bearings offer higher load capacity and are more commonly used in modern vehicles, particularly in heavy-duty applications.

Signs of a Worn or Damaged Wheel Bearing

Worn or damaged wheel bearings can manifest in various symptoms, including:

- Grinding or rumbling noise: A distinct grinding or rumbling sound, especially when turning or driving at higher speeds, often indicates a worn or damaged wheel bearing.

- Vibrations or shaking: If the wheel bearing is damaged, the wheel may vibrate or shake, especially at certain speeds.

- Uneven tire wear: A worn or damaged wheel bearing can cause uneven tire wear, as the wheel may not be rotating smoothly.

- Play or looseness in the wheel: If you can move the wheel up and down or side to side, it indicates a problem with the wheel bearing.

Wheel Bearing Assembly

A wheel bearing assembly typically comprises the following components:

- Bearing race: The inner and outer races form the tracks that the rolling elements (balls or rollers) travel on.

- Rolling elements: These are the steel balls or rollers that rotate between the races.

- Cage: The cage holds the rolling elements in place and prevents them from coming into contact with each other.

- Seal: The seal prevents dirt, debris, and water from entering the bearing, which could cause premature wear and damage.

- Hub: The hub is the central part of the wheel assembly that connects the wheel to the axle.

- Axle: The axle is the shaft that connects the wheels to the vehicle’s drivetrain.

Rear Wheel Bearing Design

Rear wheel bearings are crucial components that support the weight of the vehicle and allow the wheels to rotate smoothly. While they share some similarities with front wheel bearings, their location and function present unique design considerations.

Rear Wheel Bearing Design Differences

Rear wheel bearings experience different stresses and loads compared to their front counterparts due to their position and the vehicle’s weight distribution. Here’s a comparison:

- Load Distribution: Rear wheel bearings primarily support the vehicle’s weight, whereas front wheel bearings handle both weight and steering forces. This difference in load distribution impacts bearing design and material selection.

- Lateral Forces: Rear wheel bearings are generally subjected to lower lateral forces than front wheel bearings, which experience significant forces during cornering. This difference in lateral forces influences the bearing’s internal structure and lubrication requirements.

- Torque: Rear wheel bearings can experience higher torque loads, especially in vehicles with rear-wheel drive or all-wheel drive systems. These torque loads necessitate robust bearing designs capable of handling the increased stress.

Challenges Faced by Rear Wheel Bearings

Rear wheel bearings face specific challenges due to their location and operating environment:

- Environmental Factors: Rear wheel bearings are exposed to harsh environmental conditions, including road debris, moisture, and temperature fluctuations. These factors can lead to premature wear and failure if not properly addressed.

- Limited Accessibility: Rear wheel bearings are often located in tight spaces, making maintenance and replacement difficult. This limited accessibility can lead to longer repair times and increased labor costs.

- Vibration and Shock: Rear wheel bearings are subjected to significant vibration and shock loads, particularly on rough roads. These forces can impact bearing life and performance.

Rear Wheel Bearing Assembly Components

A typical rear wheel bearing assembly consists of the following components:

- Inner Race: The inner race is a ring that fits onto the axle shaft, providing a smooth surface for the bearing rollers to rotate.

- Outer Race: The outer race is a ring that fits into the hub assembly, providing a stationary surface for the bearing rollers to rotate against.

- Bearing Rollers: These are small, cylindrical elements that roll between the inner and outer races, reducing friction and facilitating smooth rotation.

- Cage: The cage acts as a separator for the bearing rollers, ensuring proper spacing and preventing them from coming into contact with each other.

- Seals: Seals are designed to prevent contaminants, such as dirt, water, and debris, from entering the bearing assembly, protecting the bearings and extending their life.

Advantages and Disadvantages of Rear Wheel Bearing Designs

Different rear wheel bearing designs offer distinct advantages and disadvantages:

- Tapered Roller Bearings: These bearings are highly durable and capable of handling heavy radial and axial loads. They are commonly used in rear wheel applications due to their robustness and ability to withstand high torque loads. However, they can be more expensive than other designs.

- Ball Bearings: Ball bearings are known for their low friction and high rotational speed. They are often used in applications where smooth operation is paramount. However, they may not be as robust as tapered roller bearings and are less suited for handling heavy loads.

- Needle Roller Bearings: Needle roller bearings offer a high load-carrying capacity in a compact design. They are commonly used in applications where space is limited. However, they may have a shorter lifespan than other designs.

Identifying Rear Wheel Bearings

Identifying the rear wheel bearings on your vehicle is crucial for proper maintenance and repair. Understanding the location of these bearings is essential for both DIY enthusiasts and professional mechanics alike.

Locations of Rear Wheel Bearings, Are there wheel bearings in the rear

The location of rear wheel bearings can vary depending on the vehicle’s make, model, and year. However, there are some common locations to look for.

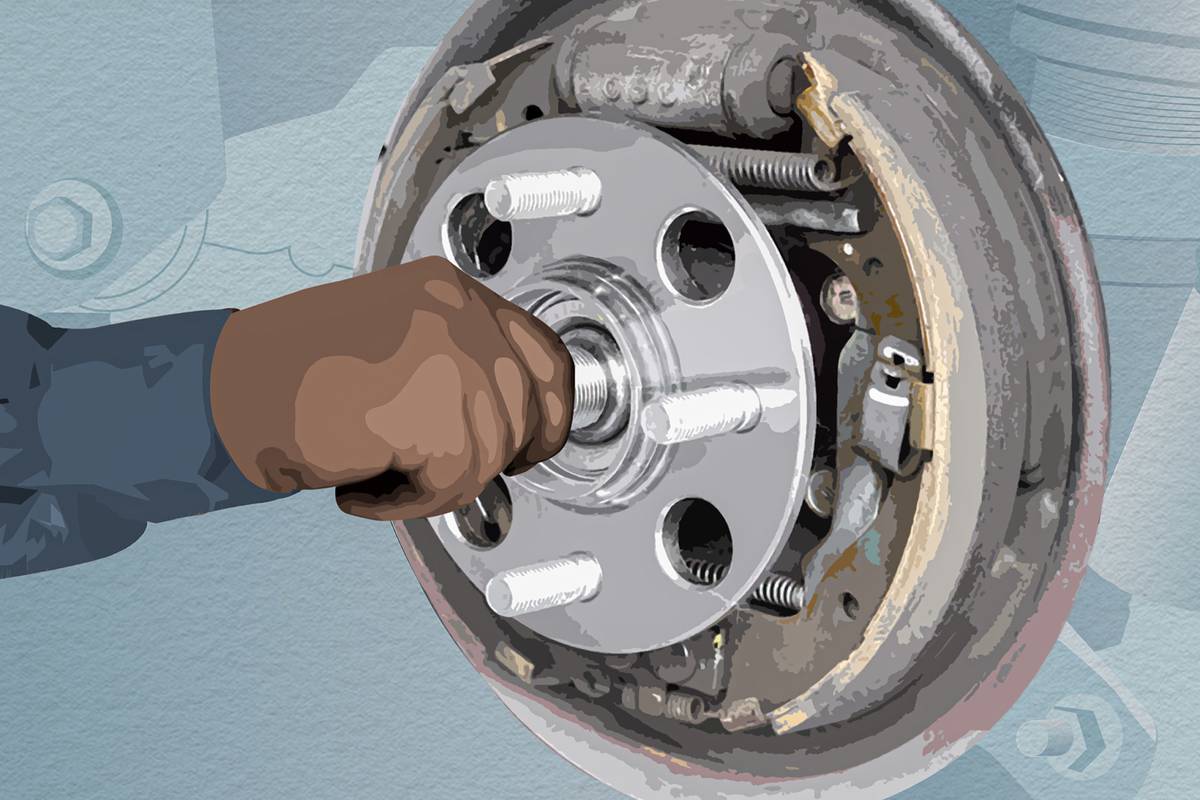

- Inside the hub assembly: This is the most common location for rear wheel bearings. The bearing is integrated into the hub assembly, which is attached to the axle. To access the bearing, the hub assembly must be removed from the vehicle.

- Inside the wheel assembly: Some vehicles have bearings located inside the wheel assembly, which is the part of the wheel that mounts to the hub. To access the bearing, the wheel must be removed from the vehicle.

- On the axle: In some older vehicles, the bearing may be mounted directly on the axle shaft. This type of bearing is usually a sealed unit and is often replaced as a complete assembly.

Identifying Rear Wheel Bearings

Once you have identified the general location of the rear wheel bearings, you can use the following steps to identify them specifically:

- Locate the axle shaft: The axle shaft is the long, cylindrical piece of metal that connects the rear wheels to the differential. The rear wheel bearings are typically located near the ends of the axle shafts, where they connect to the wheels.

- Look for the hub assembly: If the bearings are located inside the hub assembly, you will see a large, circular component that is attached to the axle shaft. The hub assembly is often made of steel or aluminum and has a smooth, cylindrical surface.

- Inspect the wheel assembly: If the bearings are located inside the wheel assembly, you will see a large, circular component that is attached to the hub. The wheel assembly is often made of aluminum and has a series of holes for mounting the lug nuts.

- Check for the bearing seal: The bearing seal is a small, rubber component that helps to keep dirt and water out of the bearing. The seal is usually located on the outside of the bearing, near the hub assembly or wheel assembly.

Common Locations of Rear Wheel Bearings

Here is a table that Artikels the common locations of rear wheel bearings on different vehicle models:

| Vehicle Make & Model | Rear Wheel Bearing Location |

|---|---|

| Ford F-150 (2015-2020) | Inside the hub assembly |

| Toyota Camry (2018-2022) | Inside the hub assembly |

| Honda Civic (2016-2021) | Inside the hub assembly |

| Chevrolet Silverado (2014-2019) | Inside the hub assembly |

| Nissan Altima (2019-2023) | Inside the hub assembly |

Importance of Accurate Identification

Accurately identifying the rear wheel bearings is essential for several reasons:

- Correct replacement: Using the wrong bearing can lead to improper fitment, premature wear, and even damage to the vehicle.

- Safety: Faulty bearings can cause wheel wobble, noise, and even loss of control. Using the correct bearing ensures that the wheels are properly supported and safe to drive.

- Cost savings: Replacing the correct bearing the first time saves time and money in the long run.

In conclusion, rear wheel bearings are essential components that play a critical role in the smooth and safe operation of your vehicle. Understanding their function, design, and maintenance practices is crucial for ensuring a comfortable and reliable driving experience. By paying attention to the signs of wear and tear and performing regular inspections, you can identify and address any potential issues before they escalate, preventing costly repairs and ensuring your vehicle’s longevity.

Expert Answers

How often should I inspect my rear wheel bearings?

It is recommended to inspect your rear wheel bearings at least once a year or every 10,000 miles, whichever comes first. However, more frequent inspections may be necessary depending on your driving conditions and the age of your vehicle.

What are the common symptoms of a worn rear wheel bearing?

Common symptoms include a grinding or rumbling noise when driving, especially at higher speeds, a clicking or popping sound when turning, and a feeling of looseness or instability in the steering wheel.

Can I replace rear wheel bearings myself?

While replacing rear wheel bearings is possible for some individuals with mechanical experience, it is a complex and potentially dangerous procedure. It is generally recommended to have this work performed by a qualified mechanic to ensure proper installation and prevent further damage.