Does a bad wheel bearing cause vibration? Absolutely! The smooth, silent operation of your vehicle relies on a network of components working in harmony, and wheel bearings play a crucial role in this symphony. These bearings, nestled within the wheel hub, allow the wheel to rotate freely while supporting the weight of the vehicle. When a wheel bearing malfunctions, it can disrupt this balance, leading to a range of unsettling symptoms, including vibrations that can range from a subtle tremor to a violent shake.

Understanding the intricacies of wheel bearing function and failure is essential for any car owner. This knowledge empowers you to identify potential issues early, prevent costly repairs, and ensure your safety on the road. In this exploration, we’ll delve into the world of wheel bearings, examining their purpose, common causes of failure, the telltale signs of a failing bearing, and the steps you can take to diagnose and address the problem.

Wheel Bearing Basics

Wheel bearings are essential components in a vehicle’s suspension system, playing a crucial role in smooth and safe driving. They support the weight of the vehicle and allow the wheels to rotate freely, reducing friction and wear.

Types of Wheel Bearings, Does a bad wheel bearing cause vibration

Wheel bearings are classified based on their design and construction. Understanding these types helps in identifying potential issues and selecting the right replacement bearing.

- Ball Bearings: These bearings consist of steel balls rolling between an inner and outer raceway, providing low friction and smooth rotation. They are commonly used in older vehicles and are relatively inexpensive.

- Tapered Roller Bearings: These bearings feature conical rollers that provide higher load capacity and are better suited for heavy-duty applications. They are often found in larger vehicles and trucks.

- Cylindrical Roller Bearings: These bearings utilize cylindrical rollers that offer high load capacity and are suitable for high-speed applications. They are typically used in newer vehicles with high-performance engines.

Signs of a Healthy Wheel Bearing

A healthy wheel bearing should operate silently and smoothly, with no noticeable vibrations or noises.

- Smooth and Quiet Operation: A healthy wheel bearing should rotate without any noticeable grinding, humming, or roaring sounds.

- No Vibration or Shaking: A healthy wheel bearing should not cause any vibration or shaking in the steering wheel or the vehicle itself.

- No Play or Loose Movement: A healthy wheel bearing should have no noticeable play or loose movement when the wheel is shaken or moved side to side.

Vibration Symptoms: Does A Bad Wheel Bearing Cause Vibration

A bad wheel bearing can cause a variety of vibration symptoms that can be felt in the steering wheel, the floorboard, or even the entire vehicle. These vibrations can be subtle at first, but they will likely worsen over time if the problem is not addressed.The type and severity of the vibration will depend on the severity of the wheel bearing damage, the speed of the vehicle, and the type of road surface being driven on.

Vibration Characteristics

The vibration caused by a bad wheel bearing is often described as a “rumble” or “growling” sound that can be felt in the steering wheel or the floorboard. The vibration may be more pronounced at certain speeds, such as when the vehicle is accelerating or decelerating. The vibration may also be more noticeable when turning or driving over rough roads.

The vibration caused by a bad wheel bearing is often described as a “rumble” or “growling” sound.

Vibration Changes with Speed

The vibration caused by a bad wheel bearing will often increase in intensity as the vehicle’s speed increases. This is because the wheel bearing is rotating faster at higher speeds, which can cause the bearing to vibrate more. The vibration may also change pitch or frequency as the vehicle’s speed increases.

The vibration caused by a bad wheel bearing will often increase in intensity as the vehicle’s speed increases.

Vibration Changes with Steering Input

The vibration caused by a bad wheel bearing may also change when the steering wheel is turned. For example, the vibration may be more pronounced when turning to the left or right. This is because the wheel bearing is being subjected to different forces when the steering wheel is turned.

The vibration caused by a bad wheel bearing may also change when the steering wheel is turned.

Comparing Vibration Symptoms

It is important to note that other problems can also cause vibrations in a vehicle. For example, a problem with the tires, brakes, or suspension can also cause vibration. It is important to have a mechanic inspect the vehicle to determine the cause of the vibration.

It is important to have a mechanic inspect the vehicle to determine the cause of the vibration.

Diagnosing a Bad Wheel Bearing

Diagnosing a bad wheel bearing involves a series of steps to identify the issue. It’s essential to conduct a thorough inspection, which includes visually examining the bearing, listening for unusual noises, and testing for play in the wheel. This process helps determine if the wheel bearing is faulty and requires replacement.

Visual Inspection

A visual inspection is the first step in diagnosing a bad wheel bearing. It involves examining the bearing for any signs of damage or wear.

- Look for cracks, chips, or other damage on the bearing race or the bearing itself.

- Check for any signs of rust or corrosion, which can indicate water ingress and bearing damage.

- Examine the bearing seals for any tears or damage, which could allow contaminants to enter the bearing.

These visual cues can provide initial insights into the condition of the wheel bearing. However, a more comprehensive assessment is necessary for a definitive diagnosis.

Jacking and Inspection

To inspect the wheel bearing, you need to jack up the vehicle and remove the wheel. This allows for a closer look at the bearing and surrounding components.

- Engage the parking brake and chock the rear wheels to prevent the vehicle from rolling.

- Use a jack to lift the vehicle until the affected wheel is off the ground.

- Remove the lug nuts and take off the wheel.

- Carefully inspect the bearing for any signs of damage or wear.

- Look for signs of grease leakage, which can indicate a damaged seal or bearing.

- Check for any play in the wheel by attempting to move it back and forth. Excessive movement indicates a worn or damaged bearing.

This process provides a more detailed assessment of the bearing’s condition and helps identify any potential issues.

Using a Stethoscope

A stethoscope can be a valuable tool for diagnosing a bad wheel bearing. It amplifies the sounds from the bearing, allowing you to listen for any unusual noises that may indicate a problem.

- Place the stethoscope on the bearing while the vehicle is idling.

- Listen for any grinding, roaring, or clicking noises, which are common signs of a bad wheel bearing.

- Compare the sound from the suspected bearing to the sound from a good bearing on the opposite side of the vehicle.

The stethoscope can help identify subtle noises that might not be easily detected by ear alone.

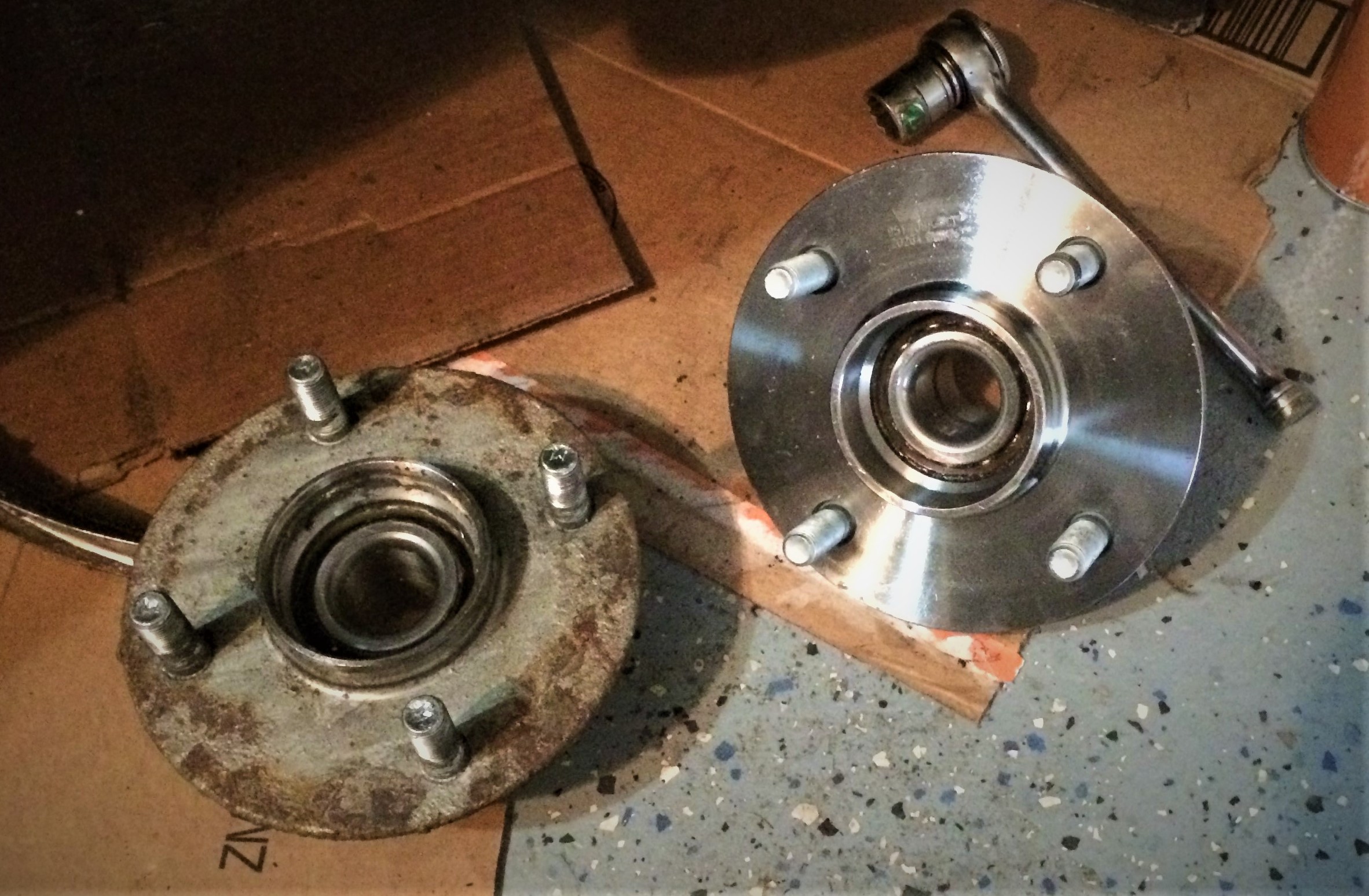

Repair and Replacement

Replacing a bad wheel bearing is a common repair job, and it can be done by experienced DIYers with the right tools and knowledge. The process involves removing the old bearing and installing a new one, ensuring proper lubrication and alignment.

Tools and Equipment Needed

The necessary tools and equipment for replacing a wheel bearing vary depending on the vehicle make and model. However, some common tools include:

- Jack and jack stands

- Lug wrench

- Wheel chocks

- Torque wrench

- Socket set

- Hammer

- Pry bar

- Bearing race and seal remover/installer

- Grease gun

- Clean rags

- Safety glasses and gloves

Selecting High-Quality Replacement Bearings

Choosing the right replacement bearing is crucial for ensuring the longevity and performance of your vehicle.

- OEM (Original Equipment Manufacturer) bearings: These are manufactured by the same company that made the original bearing for your vehicle and are typically the highest quality option. They are designed to meet the specific requirements of your vehicle and offer the best fit and performance.

- Aftermarket bearings: These are made by other manufacturers and can be a more affordable option. However, it’s important to research and choose a reputable brand that offers high-quality bearings.

- Consider the bearing’s size, type, and specifications: The bearing’s size and type must match the original bearing, and the specifications, such as the bearing’s load capacity and operating temperature, should be suitable for your vehicle’s usage.

- Look for bearings with a warranty: This can provide peace of mind and ensure that you can get a replacement if the bearing fails prematurely.

Preventive Maintenance

Regular wheel bearing inspection is crucial for ensuring the safety and longevity of your vehicle. Neglecting this vital component can lead to costly repairs and potentially dangerous driving situations. By proactively inspecting your wheel bearings, you can identify potential issues early on and address them before they escalate into major problems.

Signs of Wear and Tear

Identifying the signs of wear and tear on your wheel bearings is essential for preventing premature failure. These signs can manifest in various ways, and recognizing them early can save you from significant inconvenience and expense.

- Unusual Noises: A grinding, humming, or roaring sound, especially when turning or driving at higher speeds, could indicate a failing wheel bearing.

- Vibration: If you experience vibrations in the steering wheel or through the vehicle, particularly at higher speeds, it could be a sign of a worn-out wheel bearing.

- Uneven Tire Wear: Premature or uneven tire wear can also be a symptom of a damaged wheel bearing, as it can cause the wheel to misalign.

- Loose Steering: A loose or wobbly steering wheel can be another indicator of a faulty wheel bearing, as it can affect the vehicle’s handling.

Lubrication and Maintenance

Proper lubrication is essential for the smooth operation and longevity of your wheel bearings. Neglecting lubrication can lead to excessive friction, wear, and ultimately, failure.

- Type of Lubricant: Wheel bearings typically require grease, specifically designed for high-speed applications and extreme temperatures. The type of grease recommended will vary depending on the specific bearing type and operating conditions.

- Frequency of Lubrication: The frequency of lubrication will depend on factors such as driving conditions, vehicle age, and the type of grease used. However, a general guideline is to lubricate wheel bearings every 12,000 to 15,000 miles or annually.

- Lubrication Process: The process of lubricating wheel bearings can vary depending on the type of bearing. Some bearings require repacking with grease, while others may have sealed units that do not require regular lubrication.

Navigating the world of car maintenance can feel overwhelming, but understanding the role of wheel bearings is a vital step towards ensuring your vehicle’s safety and longevity. Recognizing the symptoms of a bad wheel bearing, from subtle vibrations to alarming noises, empowers you to take proactive measures. By addressing issues early, you can prevent costly repairs and ensure a smooth, comfortable driving experience.

Remember, a little knowledge goes a long way in maintaining your vehicle’s health and ensuring your safety on the road.

Questions Often Asked

Can a bad wheel bearing cause a clicking noise?

Yes, a bad wheel bearing can often produce a clicking or grinding noise, especially when turning or driving over bumps.

How long can I drive with a bad wheel bearing?

It’s not advisable to drive with a bad wheel bearing for an extended period. The problem can worsen quickly, leading to a loss of control and potentially a catastrophic failure.

Is it expensive to replace a wheel bearing?

The cost of replacing a wheel bearing varies depending on the vehicle and the complexity of the repair. It’s best to consult a mechanic for an accurate estimate.

Can I replace a wheel bearing myself?

While some DIY enthusiasts may attempt to replace a wheel bearing, it’s a complex procedure that requires specialized tools and knowledge. It’s generally recommended to have a qualified mechanic perform the repair.