Does alloy wheels rust? This question often arises as car owners seek to understand the durability and longevity of their vehicles. Alloy wheels, prized for their strength, style, and weight advantages, are susceptible to rust, just like any other metal component. This vulnerability stems from the interaction between the alloy’s composition, environmental factors, and the presence of oxygen and moisture.

Understanding the process of rust formation on alloy wheels is crucial for taking preventative measures. Factors like climate, road conditions, and the type of alloy used all play a role in determining how susceptible a wheel is to corrosion. Regular maintenance, including proper cleaning and the application of protective coatings, can significantly minimize the risk of rust.

What are Alloy Wheels?

Alloy wheels are a popular choice for car owners, offering benefits over traditional steel wheels. They are made from a combination of metals, primarily aluminum and magnesium, to achieve specific properties.

Alloy Wheel Composition

Alloy wheels are made from a mixture of metals, primarily aluminum and magnesium, to achieve specific properties. The exact composition of an alloy wheel varies depending on the desired characteristics.

- Aluminum: The most common metal used in alloy wheels, it is lightweight, strong, and corrosion-resistant. It also has good thermal conductivity, which helps to dissipate heat generated during braking.

- Magnesium: This metal is even lighter than aluminum and offers excellent strength-to-weight ratio. However, it is more expensive and less corrosion-resistant.

- Other metals: Other metals, such as silicon, copper, and zinc, are sometimes added to the alloy to enhance specific properties like strength, durability, and machinability.

Benefits of Alloy Wheels

Alloy wheels offer several advantages over steel wheels, making them a desirable choice for many car owners.

- Lightweight: Alloy wheels are significantly lighter than steel wheels, which can improve vehicle performance by reducing unsprung weight. This results in better acceleration, braking, and handling.

- Stronger: Alloy wheels are generally stronger than steel wheels, offering better resistance to impact and bending. This enhances safety and durability.

- Corrosion-resistant: Alloy wheels are more resistant to corrosion than steel wheels, especially in harsh environments like coastal areas.

This helps to maintain their appearance and structural integrity over time.

- Aesthetics: Alloy wheels are available in a wide variety of designs and finishes, allowing car owners to personalize their vehicles and enhance their aesthetic appeal.

Alloy Wheel Designs

Alloy wheel designs are diverse and cater to different vehicle types and driving styles.

- Spoke designs: These designs feature multiple spokes radiating from the center hub to the outer rim. They offer good ventilation and weight distribution.

- Multi-spoke designs: These designs feature a large number of thin spokes, often creating a more intricate and sporty look. They are popular on performance vehicles.

- Mesh designs: These designs feature a network of interconnected lines that resemble a mesh.

They offer a unique look and can enhance cooling.

- Split-spoke designs: These designs feature spokes that are split into two or more sections, creating a more complex and visually appealing design. They are often found on high-end vehicles.

Rust and its Impact on Alloy Wheels

Rust, a common problem for metal parts, can also affect alloy wheels, potentially leading to damage and safety issues. Understanding the process of rust formation and its impact on alloy wheels is crucial for maintaining their integrity and ensuring safe driving.

Rust Formation on Alloy Wheels

Rust, scientifically known as iron oxide, forms when iron or steel comes into contact with oxygen and moisture. This chemical reaction, called oxidation, leads to the formation of a reddish-brown coating on the metal surface. The presence of salt, particularly from road de-icing agents, can accelerate the rusting process. Alloy wheels, despite being made from a mixture of metals, are still susceptible to rust because they often contain iron or steel as a primary component.

While alloys are designed to be more resistant to corrosion than pure iron, they can still be vulnerable under certain conditions.

Vulnerability of Alloy Wheels to Rust

The vulnerability of alloy wheels to rust depends on various factors:

- Type of Alloy: Alloys with higher iron content are more prone to rusting. For example, aluminum alloys with a high percentage of iron are less resistant to corrosion than those with a lower iron content.

- Wheel Coating: The protective coating on alloy wheels plays a crucial role in preventing rust. A high-quality, durable coating can significantly enhance the wheel’s resistance to corrosion. However, scratches or damage to the coating can expose the underlying metal to oxygen and moisture, increasing the risk of rust formation.

- Environmental Conditions: Exposure to harsh weather conditions, including rain, snow, and salt, can accelerate the rusting process. Areas with high humidity and salt content, such as coastal regions, are particularly susceptible to wheel corrosion.

Consequences of Rust on Alloy Wheels

Rust can have several negative consequences for alloy wheels:

- Aesthetic Damage: Rust formation can significantly affect the appearance of alloy wheels, creating unsightly blemishes and reducing their aesthetic appeal.

- Structural Weakening: Rust can weaken the metal structure of the wheel, compromising its strength and integrity. In severe cases, rust can lead to cracks or holes in the wheel, potentially causing a catastrophic failure.

- Safety Concerns: A weakened or damaged wheel can compromise the safety of the vehicle. If a wheel fails during driving, it can lead to loss of control, accidents, and serious injuries.

Factors Influencing Rust on Alloy Wheels

Rust formation on alloy wheels is a common issue, influenced by various factors. Understanding these factors is crucial for taking preventive measures and extending the lifespan of your alloy wheels.

Environmental Factors

Environmental factors play a significant role in the development of rust on alloy wheels.

- Climate: High humidity and frequent rainfall create a conducive environment for rust. Moisture promotes the oxidation process, leading to the formation of rust. Areas with coastal climates, where salt spray is prevalent, are particularly susceptible to rust.

- Road Conditions: Roads treated with salt during winter months can accelerate rust formation. Saltwater, often used for de-icing, reacts with the metal surface, leading to corrosion. Similarly, exposure to road grime, dirt, and other pollutants can contribute to rust development.

- Exposure to Salt: Saltwater, whether from sea spray or road de-icing, is highly corrosive and a major contributor to rust formation. The salt reacts with the metal, breaking down the protective oxide layer and allowing rust to develop.

Maintenance Practices

Regular maintenance practices are essential for preventing rust on alloy wheels.

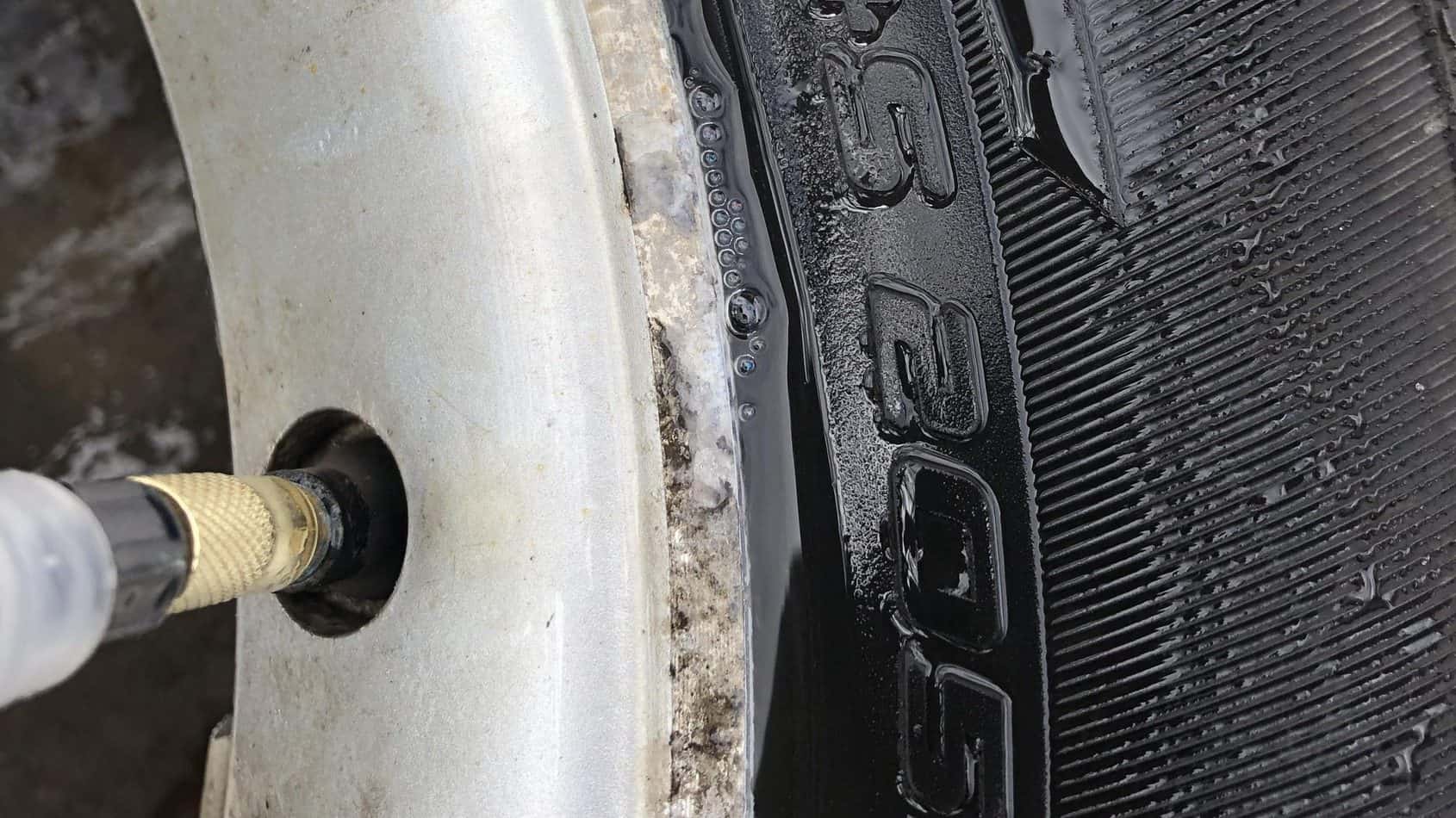

- Cleaning: Regular cleaning removes dirt, grime, and salt deposits that can trap moisture and accelerate rust formation. Washing your wheels with a dedicated wheel cleaner and a soft brush is recommended. It is essential to rinse thoroughly to remove any residue.

- Protective Coatings: Applying a protective coating, such as wax or sealant, creates a barrier against moisture and contaminants, minimizing the risk of rust. These coatings help to repel water and prevent salt from adhering to the wheel surface.

Susceptibility of Different Alloy Wheels

Different types of alloy wheels exhibit varying levels of susceptibility to rust.

- Coatings and Finishes: Wheels with protective coatings, such as powder coating or chrome plating, are more resistant to rust than uncoated wheels. These coatings act as a barrier against moisture and corrosion. However, scratches or chips in the coating can expose the underlying metal, making it vulnerable to rust.

- Material Composition: Alloy wheels are typically made from aluminum or magnesium alloys. While both are resistant to corrosion, aluminum alloys are generally more susceptible to rust than magnesium alloys. This is because aluminum reacts more readily with oxygen, forming a less protective oxide layer compared to magnesium.

Preventing and Treating Rust on Alloy Wheels

Preventing and treating rust on alloy wheels is crucial for maintaining their aesthetic appeal and structural integrity. Rust not only detracts from the vehicle’s appearance but can also weaken the wheel, potentially leading to cracks or even failure.

Preventing Rust Formation

Preventing rust formation is far more effective than dealing with it after it appears. Here are some effective methods:

- Regular Cleaning: Frequent cleaning of alloy wheels is essential. Use a dedicated wheel cleaner, which is specifically formulated to remove brake dust, road grime, and other contaminants that can accelerate rust formation. Avoid using harsh chemicals or abrasive cleaners that can damage the wheel’s protective coating.

- Waxing: Applying a good quality wax to the alloy wheels creates a protective barrier against moisture and contaminants. This helps prevent rust from forming and also adds a layer of shine to the wheels.

- Protective Coatings: Specialized coatings, such as ceramic coatings or sealant, provide an extra layer of protection against rust. These coatings create a hard, durable surface that repels water and contaminants, effectively preventing rust formation.

Removing Existing Rust

If rust has already formed on alloy wheels, prompt action is necessary to prevent further damage. Here are some techniques for removing existing rust:

- Mild Cleaning Agents: For minor rust spots, a mild cleaning agent like a rust remover or a solution of baking soda and water can be effective. Apply the cleaning agent to the affected area and gently scrub with a soft-bristled brush.

- Steel Wool: Fine-grade steel wool can be used to remove rust from alloy wheels. However, exercise caution as excessive scrubbing can damage the wheel’s surface. It is recommended to use steel wool sparingly and with a gentle touch.

- Sandpaper: For more stubborn rust, sandpaper can be used to remove the affected area. Start with a coarse grit sandpaper and gradually work your way down to a finer grit. This will help remove the rust without damaging the wheel’s surface.

Professional Intervention for Severe Rust Damage, Does alloy wheels rust

For severe rust damage that cannot be effectively removed with home remedies, it is advisable to seek professional assistance. A qualified automotive technician can assess the damage and recommend appropriate repair options. This may involve:

- Sandblasting: Sandblasting is a common technique used to remove rust and prepare the surface for repainting. It involves blasting the wheel with a high-pressure stream of abrasive material, which effectively removes rust and other contaminants.

- Wheel Repair: If the rust damage is extensive, the wheel may require repair or replacement. A professional can assess the severity of the damage and determine the best course of action.

In conclusion, while alloy wheels offer many advantages, their susceptibility to rust is a concern. By understanding the factors that contribute to corrosion and implementing preventative measures, car owners can extend the lifespan of their alloy wheels and maintain their aesthetic appeal. Regular cleaning, protective coatings, and prompt attention to any signs of rust are essential for preserving the integrity and beauty of these valuable components.

Detailed FAQs: Does Alloy Wheels Rust

What are the signs of rust on alloy wheels?

Rust appears as reddish-brown spots or patches on the surface of the wheel. It can also manifest as pitting or flaking of the metal.

Can I remove rust from alloy wheels myself?

For light rust, you can use a mild abrasive cleaner and a soft brush. For more severe rust, professional intervention may be necessary.

What is the best way to prevent rust on alloy wheels?

Regular cleaning, waxing, and the application of protective coatings like sealant or ceramic coating are effective methods for preventing rust.