What is a wheel knuckle? It’s not a knuckle sandwich, but it’s definitely a crucial part of your car’s suspension system. Imagine your car as a giant, metal skeleton, and the wheel knuckles are like the joints that connect the limbs (wheels) to the body (chassis). They allow your car to turn, absorb bumps, and keep your wheels in line.

Think of them as the silent heroes of your car’s ride, working tirelessly behind the scenes to keep you comfortable and safe.

But there’s more to these little marvels than meets the eye. They come in different shapes and sizes, with various materials and designs. Each type has its own strengths and weaknesses, depending on the car’s intended use. From the humble family sedan to the roaring race car, the wheel knuckle plays a vital role in how your car handles and performs.

What is a Wheel Knuckle?

A wheel knuckle, also known as a steering knuckle, is a crucial component in a vehicle’s suspension system. Its primary function is to connect the wheel hub to the suspension, enabling the wheel to turn and absorb shock loads during driving.

Function of a Wheel Knuckle

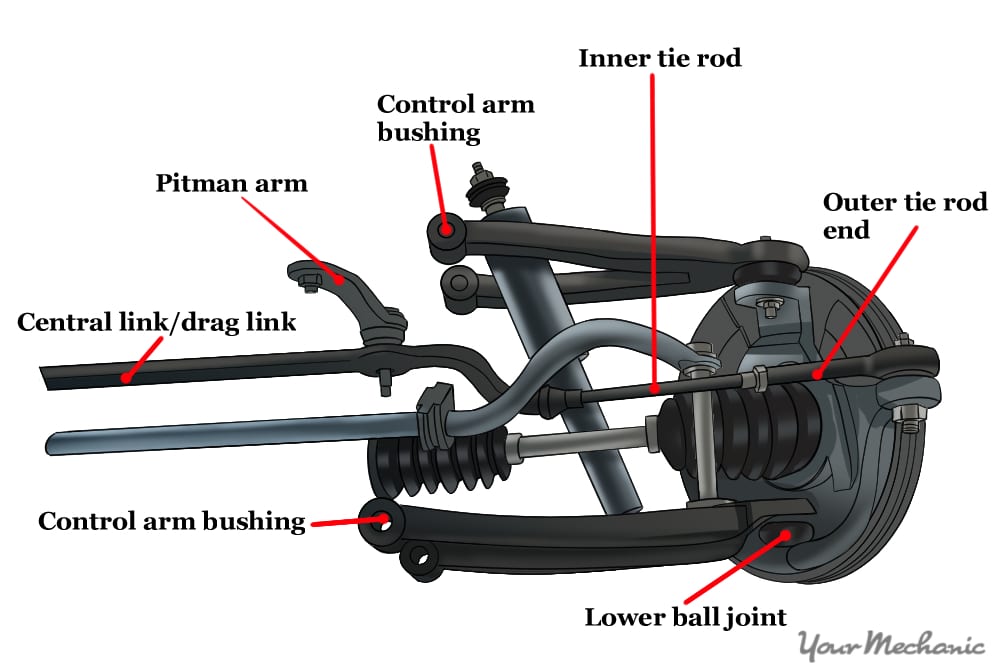

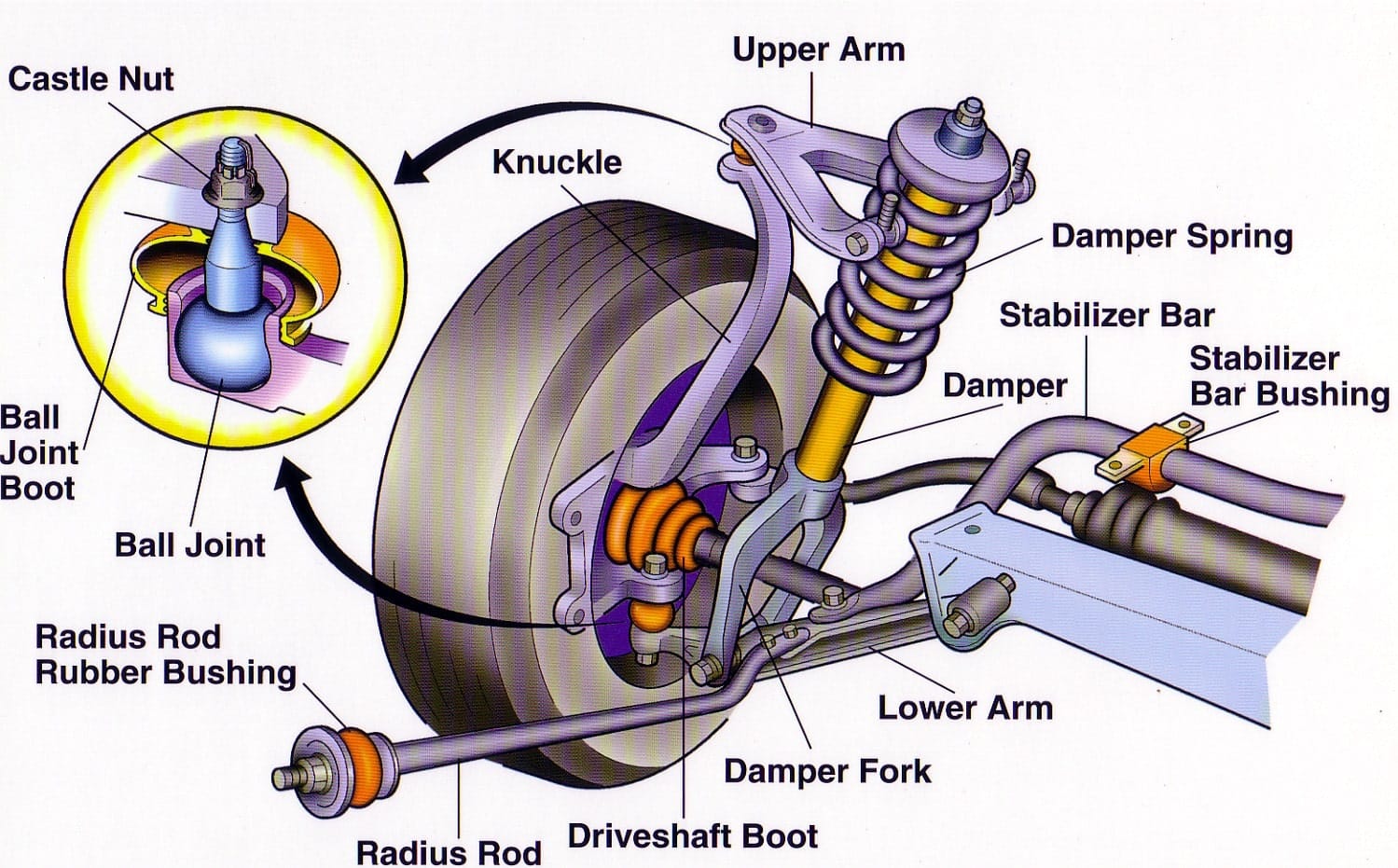

The wheel knuckle acts as a pivot point for the wheel, allowing it to rotate freely while maintaining a secure connection to the suspension. It facilitates steering by transferring steering forces from the steering linkage to the wheel. The knuckle also provides a mounting point for the brake caliper, ensuring proper braking performance.

Connecting the Wheel Hub to the Suspension

The wheel knuckle is typically attached to the suspension via a ball joint, which allows for both vertical and lateral movement. The wheel hub is then secured to the knuckle using bearings, enabling the wheel to rotate smoothly. This connection ensures the wheel’s proper alignment and stability during driving.

Materials Used in Wheel Knuckle Construction

Wheel knuckles are usually constructed from high-strength steel, which provides the necessary durability and resistance to stress and fatigue. For some vehicles, aluminum knuckles may be used, offering weight reduction benefits. However, steel knuckles are more common due to their superior strength and resistance to wear.

Components of a Wheel Knuckle

The wheel knuckle is a crucial component in a vehicle’s suspension system, acting as the primary connection point between the wheel and the suspension. It houses several critical parts that work together to enable steering, suspension, and braking functions.

Components of a Wheel Knuckle

The wheel knuckle is comprised of several key components that work together to support the wheel and facilitate its movement.

- Steering Arm: The steering arm is attached to the knuckle and connects to the tie rod end. When the steering wheel is turned, the steering arm rotates, causing the wheel to turn in the desired direction. This arm is usually made of forged steel and is a critical component in steering control.

- Ball Joint: The ball joint is a spherical joint that connects the steering arm to the suspension control arm. It allows for a range of motion, enabling the wheel to move up and down, in and out, and even rotate. This joint is crucial for providing the necessary flexibility and movement required for smooth driving and maneuvering.

- Spindle: The spindle is a cylindrical shaft that protrudes from the knuckle and acts as the hub for the wheel. It supports the wheel bearings and is the primary connection point for the wheel to the knuckle. The spindle is designed to withstand significant loads and stresses, ensuring the wheel remains securely attached to the vehicle.

Function of Components in Relation to Wheel Knuckle Operation

The components of a wheel knuckle work together to ensure smooth and efficient operation of the suspension system.

- The steering arm transmits steering input from the steering wheel to the wheel, allowing for precise control of the vehicle’s direction.

- The ball joint allows for a wide range of motion, facilitating the suspension’s ability to absorb bumps and dips in the road surface, providing a comfortable ride and maintaining tire contact with the road.

- The spindle provides a stable and secure connection between the wheel and the knuckle, ensuring the wheel remains securely attached and can handle the forces generated during braking, acceleration, and cornering.

Components of a Wheel Knuckle and their Roles

The table below summarizes the components of a wheel knuckle and their respective roles:

| Component | Role |

|---|---|

| Steering Arm | Connects to the tie rod end and transmits steering input to the wheel |

| Ball Joint | Connects the steering arm to the suspension control arm, allowing for a wide range of motion |

| Spindle | Provides a stable and secure connection between the wheel and the knuckle, supporting the wheel bearings |

Types of Wheel Knuckles

Wheel knuckles are crucial components in a vehicle’s suspension system, connecting the steering and suspension components to the wheel hub. They are designed to withstand significant forces, including braking, acceleration, and cornering. The type of wheel knuckle used in a vehicle can significantly impact its performance, durability, and cost.

Wheel Knuckle Manufacturing Methods

Wheel knuckles are typically manufactured using three primary methods: forging, casting, and machining. Each method has its advantages and disadvantages, impacting the strength, durability, and cost of the final product.

- Forged Wheel Knuckles: Forging involves heating metal to a high temperature and then shaping it using a hammer or press. This process creates a strong and durable component, as the grain structure of the metal is aligned with the shape of the knuckle. Forged wheel knuckles are known for their exceptional strength and resistance to fatigue, making them suitable for high-performance vehicles and demanding applications.

However, forging is a more expensive process than casting or machining. Examples of vehicles using forged wheel knuckles include high-performance sports cars like the Porsche 911 and the Chevrolet Corvette.

- Cast Wheel Knuckles: Casting involves pouring molten metal into a mold, allowing it to solidify into the desired shape. This process is generally less expensive than forging but results in a component with lower strength and durability. Cast wheel knuckles are typically used in mass-produced vehicles, where cost is a primary concern. However, advancements in casting techniques have led to the development of stronger and more durable cast wheel knuckles, often used in modern vehicles.

Examples of vehicles using cast wheel knuckles include the Honda Civic and Toyota Camry.

- Machined Wheel Knuckles: Machining involves removing material from a solid block of metal using tools like lathes, mills, and grinders. This process is highly precise and allows for complex shapes, but it is also relatively expensive. Machined wheel knuckles are often used in applications where high precision and specific dimensions are required. They can also be used to create custom wheel knuckles for specialized vehicles or modifications.

Examples of vehicles using machined wheel knuckles include race cars and custom-built vehicles.

Wheel Knuckle Design Considerations

Wheel knuckles are critical components in the suspension system of a vehicle, responsible for connecting the wheel to the steering and suspension mechanisms. Their design directly impacts the vehicle’s handling, stability, and overall performance. Therefore, meticulous consideration of various factors is crucial during the design process.

Load Capacity

The load capacity of a wheel knuckle is paramount, as it needs to withstand the weight of the vehicle, the forces generated during braking and acceleration, and the lateral forces experienced during cornering. The design must ensure sufficient strength and rigidity to prevent deformation or failure under these loads.

- Material Selection: High-strength materials like steel alloys, aluminum alloys, or composites are often chosen for their superior strength-to-weight ratio. For example, forged steel is widely used due to its high tensile strength and durability.

- Cross-sectional Shape: The shape of the wheel knuckle, particularly its cross-section, plays a crucial role in its load-bearing capacity. A larger cross-section provides greater surface area for distributing load, enhancing strength and rigidity.

- Finite Element Analysis (FEA): FEA is a powerful tool used to simulate the behavior of the wheel knuckle under various load conditions. This allows engineers to optimize the design and ensure it can withstand the expected loads.

Steering Geometry

The wheel knuckle plays a vital role in determining the steering geometry of a vehicle, which influences its handling characteristics. Precise design considerations are necessary to ensure accurate steering response and predictable vehicle behavior.

- Kingpin Inclination: This angle affects the vehicle’s self-centering ability and steering feel. A higher kingpin inclination leads to a more stable and self-centering steering response.

- Caster Angle: This angle influences the vehicle’s directional stability and resistance to wandering. A positive caster angle improves stability, while a negative caster angle can enhance maneuverability.

- Camber Angle: This angle affects the tire contact patch and handling characteristics. A negative camber angle improves cornering grip, while a positive camber angle can increase tire wear.

Material Properties

The choice of material for the wheel knuckle significantly impacts its performance and longevity. Factors such as strength, ductility, fatigue resistance, and corrosion resistance are critical considerations.

- Yield Strength: The yield strength of the material determines its ability to withstand deformation under load. A higher yield strength indicates greater resistance to permanent deformation.

- Tensile Strength: The tensile strength represents the maximum stress the material can withstand before fracturing. This property is crucial for ensuring the knuckle’s structural integrity.

- Fatigue Resistance: The wheel knuckle experiences repeated loading and unloading cycles during normal driving, which can lead to fatigue failure. Materials with high fatigue resistance are essential to prevent premature failure.

- Corrosion Resistance: Wheel knuckles are exposed to various environmental factors, such as moisture, salt, and road debris. Materials with excellent corrosion resistance are required to prevent rusting and deterioration.

Maintenance and Repair of Wheel Knuckles

Wheel knuckles, as critical components in a vehicle’s suspension system, require regular maintenance and occasional repair to ensure safe and reliable operation. Proper care can extend the lifespan of the wheel knuckle and prevent potential safety hazards.

Common Maintenance Procedures

Regular inspections and maintenance of wheel knuckles are essential to prevent premature wear and tear and ensure safe operation.

- Visual Inspection: Regularly inspect the wheel knuckle for signs of damage, cracks, or excessive wear. Look for any visible deformation, corrosion, or loose fasteners.

- Lubrication: Apply grease to the bearing surfaces and pivot points of the wheel knuckle to reduce friction and wear. Follow the manufacturer’s recommendations for the type and quantity of grease to use.

- Tightening Fasteners: Regularly check the tightness of all fasteners on the wheel knuckle, including the lug nuts, ball joint bolts, and tie rod ends. Tighten any loose fasteners to the manufacturer’s specifications.

Causes of Wheel Knuckle Failure

Wheel knuckle failure can occur due to various factors, including:

- Impacts: A strong impact, such as hitting a pothole or curb, can damage the wheel knuckle, leading to cracks or deformation.

- Excessive Wear: Over time, the bearings and other components of the wheel knuckle can wear out, leading to increased friction and eventual failure. This is often due to lack of proper lubrication or extreme driving conditions.

- Manufacturing Defects: Occasionally, wheel knuckles may have manufacturing defects that can lead to premature failure. This is less common but can be a contributing factor.

Replacing a Damaged Wheel Knuckle

If a wheel knuckle is damaged beyond repair, it must be replaced. Here is a step-by-step guide for replacing a damaged wheel knuckle:

- Jack Up the Vehicle: Safely jack up the vehicle and support it with jack stands. Ensure the vehicle is securely supported before proceeding.

- Remove the Wheel: Remove the lug nuts and take off the wheel.

- Disconnect Components: Disconnect the brake lines, tie rod end, and ball joint from the wheel knuckle. This may require using specialized tools.

- Remove the Wheel Knuckle: Remove the wheel knuckle from the vehicle by loosening and removing the mounting bolts.

- Install the New Wheel Knuckle: Install the new wheel knuckle, ensuring that it is properly aligned and secured with the mounting bolts.

- Reconnect Components: Reconnect the brake lines, tie rod end, and ball joint to the new wheel knuckle. Tighten all fasteners to the manufacturer’s specifications.

- Lower the Vehicle: Lower the vehicle and remove the jack stands.

- Test Drive: Test drive the vehicle to ensure that the new wheel knuckle is functioning correctly. Listen for any unusual noises or vibrations.

Wheel Knuckle in Different Vehicle Applications

The design and functionality of wheel knuckles vary significantly across different vehicle types, reflecting the unique demands placed on each application. These variations stem from the specific requirements of each vehicle, including weight, speed, terrain, and intended use.

Wheel Knuckles in Passenger Cars

Passenger car wheel knuckles are typically designed for light-duty applications, prioritizing comfort, handling, and fuel efficiency. They are generally made from lightweight materials like aluminum or steel alloys, with a focus on reducing unsprung weight. The design often incorporates features like integrated steering knuckles, which combine the steering and suspension functions for improved packaging and reduced weight.

Wheel Knuckles in Trucks

Truck wheel knuckles, on the other hand, are designed for heavy-duty applications, emphasizing strength and durability. They are typically made from high-strength steel and are often reinforced with additional components like gussets or brackets to handle the increased loads and stresses. Truck wheel knuckles are also designed to accommodate larger wheels and tires, as well as heavier suspension components.

Wheel Knuckles in Off-Road Vehicles, What is a wheel knuckle

Off-road vehicles require wheel knuckles that are both robust and flexible. These knuckles are often made from high-strength steel with a focus on durability and impact resistance. They typically feature a more rugged design with increased ground clearance and articulation, allowing for greater maneuverability over challenging terrain.

Specialized Wheel Knuckle Designs in Racing and Performance Vehicles

Racing and performance vehicles demand highly specialized wheel knuckle designs that prioritize performance and handling. These knuckles are often made from lightweight materials like forged aluminum or titanium, and they may incorporate features like integrated steering knuckles, adjustable camber plates, or lightweight bearings to reduce unsprung weight and improve handling.

So next time you’re cruising down the road, take a moment to appreciate the unsung heroes under your car. Those wheel knuckles might not be glamorous, but they’re the backbone of your ride, keeping you going wherever the road takes you. And just like any good hero, they deserve a little respect and occasional maintenance to keep them in top shape.

After all, a well-maintained wheel knuckle is a happy wheel knuckle, and a happy wheel knuckle means a happy driver!

FAQ Summary

What happens if a wheel knuckle breaks?

It’s not a good thing! Your wheel will likely detach from the car, which is a recipe for disaster. Best case scenario: a very rough ride. Worst case scenario: a very expensive tow truck bill.

How often should I check my wheel knuckles?

During routine maintenance, especially if you hear any unusual noises coming from your suspension. Think of it as a checkup for your car’s “bones.”

Can I replace a wheel knuckle myself?

Unless you’re a skilled mechanic, it’s best to leave this job to the professionals. Replacing a wheel knuckle requires specialized tools and knowledge. Think of it as a job for a superhero, not a novice.