How to clean wheel speed sensor – How to clean a wheel speed sensor? It might sound like a task for a mechanic, but with a little know-how, you can tackle this yourself. These sensors, vital for your vehicle’s braking and traction control systems, can get clogged with dirt and debris, affecting their performance. A clean sensor ensures your car’s safety and stability on the road.

This guide will walk you through the process of cleaning a wheel speed sensor, from identifying the signs of a faulty sensor to reconnecting it and testing its functionality. We’ll cover everything you need to know, from the necessary tools to the safety precautions to take.

Understanding Wheel Speed Sensors

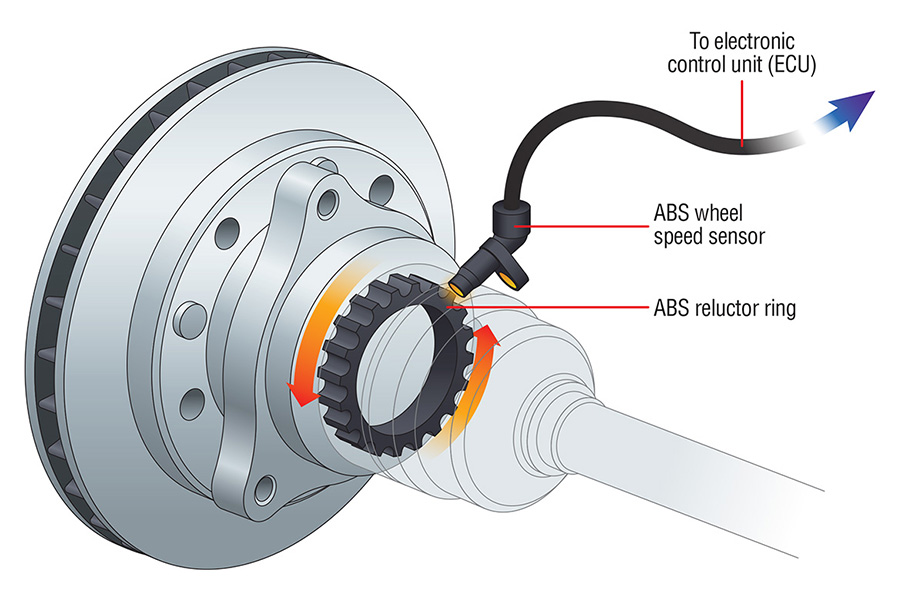

Wheel speed sensors are crucial components in modern vehicles, playing a vital role in ensuring safe and efficient driving. These sensors constantly monitor the speed of each wheel, providing valuable data to various vehicle systems, including the Anti-lock Braking System (ABS), Traction Control System (TCS), and Electronic Stability Control (ESC). By accurately measuring wheel speed, these systems can intervene and prevent wheel lock-up during braking, maintain traction on slippery surfaces, and enhance vehicle stability during maneuvers.

Types of Wheel Speed Sensors

Wheel speed sensors come in various types, each with its unique design and operating principle. The most common types are:

- Passive Magnetic Sensors: These sensors consist of a magnet and a coil. As the wheel rotates, the magnetic field generated by the magnet interacts with the coil, inducing a voltage that is proportional to the wheel speed. This type of sensor is simple, reliable, and widely used in various vehicles.

- Hall Effect Sensors: These sensors use a Hall Effect device, which produces a voltage when a magnetic field is applied. The wheel’s rotation induces a magnetic field that interacts with the Hall Effect device, generating a signal proportional to the wheel speed. Hall Effect sensors are known for their accuracy and resistance to interference.

- Optical Sensors: Optical sensors utilize a light source and a photodetector. As the wheel rotates, a pattern on the wheel interrupts the light beam, creating pulses that are detected by the photodetector. The frequency of these pulses is directly proportional to the wheel speed. Optical sensors offer high accuracy and are often used in high-performance vehicles.

Location of Wheel Speed Sensors

Wheel speed sensors are typically mounted near the wheel hub, in a location that allows them to sense the wheel’s rotation. The exact location may vary depending on the vehicle model, but common locations include:

- Within the wheel hub: Some sensors are integrated into the wheel hub itself, providing a more robust and protected installation.

- On the suspension arm: Sensors may be mounted on the suspension arm, close to the wheel hub, using a bracket or a threaded hole.

- On the brake caliper: Some sensors are mounted on the brake caliper, utilizing the caliper’s mounting points for secure attachment.

Recognizing Signs of a Faulty Wheel Speed Sensor

A faulty wheel speed sensor can significantly impact your vehicle’s performance and safety. It’s crucial to be aware of the signs that indicate a malfunctioning sensor. By understanding these symptoms, you can address the issue promptly and prevent potential hazards.

Consequences of a Faulty Wheel Speed Sensor

A malfunctioning wheel speed sensor can lead to various problems, affecting your vehicle’s safety and performance.

- Anti-lock Braking System (ABS) Malfunction: The ABS relies on wheel speed sensor data to determine wheel slip and adjust braking pressure accordingly. A faulty sensor can cause the ABS to malfunction, resulting in reduced braking effectiveness and an increased risk of skidding.

- Traction Control System (TCS) Malfunction: Similar to ABS, TCS uses wheel speed sensor data to detect wheel slip and apply corrective measures. A faulty sensor can lead to TCS malfunction, making it difficult to maintain control on slippery surfaces.

- Electronic Stability Control (ESC) Malfunction: ESC relies on wheel speed sensor data to detect vehicle instability and apply corrective measures. A faulty sensor can cause ESC malfunction, increasing the risk of accidents.

- Incorrect Speedometer Readings: The speedometer relies on wheel speed sensor data to display the vehicle’s speed. A faulty sensor can lead to inaccurate speedometer readings, making it difficult to gauge your vehicle’s speed and comply with traffic regulations.

- Check Engine Light (CEL): A faulty wheel speed sensor can trigger the CEL, indicating a problem with the vehicle’s electronic systems.

Dangerous Situations with a Faulty Wheel Speed Sensor, How to clean wheel speed sensor

A faulty wheel speed sensor can pose significant risks in certain situations.

- Emergency Braking: If the ABS malfunctions due to a faulty sensor, the vehicle may not be able to brake effectively in an emergency situation, increasing the risk of an accident.

- Slippery Surfaces: A faulty TCS, caused by a malfunctioning wheel speed sensor, can make it difficult to maintain control on slippery surfaces, such as icy roads or wet pavement, increasing the risk of skidding and losing control.

- High-Speed Driving: A faulty ESC, caused by a malfunctioning wheel speed sensor, can make it difficult to maintain stability at high speeds, increasing the risk of accidents.

Preparing for Cleaning the Wheel Speed Sensor

Before diving into the cleaning process, it’s essential to gather the necessary tools and materials and understand the safety precautions involved. Cleaning a wheel speed sensor requires a systematic approach to ensure both your safety and the proper functioning of the sensor.

Tools and Materials

Having the right tools and materials at hand makes the cleaning process more efficient and less stressful. Here’s a list of what you’ll need:

- A cleaning solution: A sensor-safe cleaning solution, such as isopropyl alcohol or brake cleaner, is essential for removing dirt and debris. Avoid using harsh chemicals that could damage the sensor’s delicate components.

- Clean rags or paper towels: Use clean, lint-free rags or paper towels to wipe the sensor and surrounding areas. Avoid using materials that could leave behind fibers or particles that might obstruct the sensor.

- A small brush or toothbrush: A soft-bristled brush or toothbrush is helpful for gently cleaning the sensor’s crevices and removing stubborn dirt.

- A socket wrench: This tool is necessary for loosening and tightening the sensor’s mounting bolts. Choose a socket size that matches the sensor’s mounting bolts.

- A multimeter: While not always necessary for cleaning, a multimeter is helpful for testing the sensor’s functionality after cleaning. This allows you to confirm that the sensor is working properly.

Safety Precautions

Safety should always be a top priority when working with automotive components. Here are some essential safety precautions to keep in mind:

- Disconnect the battery: Always disconnect the vehicle’s battery before working on any electrical components, including the wheel speed sensor. This prevents accidental electrical shocks.

- Wear safety glasses: Protect your eyes from potential debris or splashes of cleaning solution by wearing safety glasses.

- Work in a well-ventilated area: When using cleaning solutions, ensure adequate ventilation to avoid inhaling harmful fumes.

- Avoid touching the sensor’s electrical contacts: Handle the sensor carefully and avoid touching the electrical contacts, as this could damage the sensor or cause a short circuit.

Disconnecting the Wheel Speed Sensor

Before cleaning the sensor, you need to safely disconnect it from the vehicle’s electrical system. Here’s a step-by-step guide:

- Locate the sensor: The wheel speed sensor is typically located on the suspension hub, near the wheel. It’s a small, cylindrical sensor with a wire harness connected to it.

- Locate the connector: Find the connector where the sensor’s wire harness plugs into the vehicle’s electrical system. This connector is usually located near the sensor.

- Release the connector: Carefully release the connector by pressing the release tab or lever, if present. If there’s no release tab, gently pull the connector apart.

- Disconnect the sensor: Once the connector is released, carefully pull the sensor’s wire harness out of the connector.

Cleaning the Wheel Speed Sensor: How To Clean Wheel Speed Sensor

Now that you have gathered the necessary tools and materials, it’s time to tackle the cleaning process itself. Cleaning the wheel speed sensor involves carefully removing dirt and debris from both the magnetic ring and the sensor tip, ensuring optimal functionality.

Cleaning Techniques

The cleaning techniques for the wheel speed sensor depend on the type of dirt or debris present. For instance, if the sensor is covered in brake dust or road grime, a gentle approach using a soft-bristled brush and compressed air is sufficient. However, if the sensor is heavily contaminated with grease or oil, a more thorough cleaning process is required.

- Using a Soft-Bristled Brush and Compressed Air: For light dirt and debris, gently brush away the contaminants using a soft-bristled brush. This method is effective for removing loose dirt and debris, ensuring minimal damage to the sensor. After brushing, use compressed air to blow away any remaining particles. Remember to use a low pressure setting to avoid damaging the sensor.

- Using a Cleaning Solution: For stubborn dirt or debris, a mild cleaning solution is necessary. A solution of isopropyl alcohol or a specialized electronic cleaner is effective for removing grease and oil. Dip a cotton swab or a soft cloth into the solution and gently clean the magnetic ring and sensor tip. Avoid using harsh chemicals or abrasive cleaners, as they can damage the sensor.

Drying the Wheel Speed Sensor

After cleaning the sensor, it is crucial to ensure it is completely dry before reconnecting it. Moisture can lead to corrosion and damage the sensor.

- Air Drying: Allow the sensor to air dry naturally. This is the safest and most effective method. Place the sensor in a clean, dry area and allow it to dry completely. Avoid using a hairdryer or any other heat source, as this could damage the sensor.

- Using Compressed Air: If you are in a hurry, you can use compressed air to dry the sensor. However, be sure to use a low pressure setting and avoid blowing directly onto the sensor tip.

Reinstalling and Testing the Wheel Speed Sensor

Now that your wheel speed sensor is clean, it’s time to put it back where it belongs and check if it’s working properly.

Reconnecting the Wheel Speed Sensor

Reconnect the sensor to the vehicle’s electrical system by plugging the connector back into the sensor. Make sure the connection is secure and the connector is fully seated. If the connector is loose, it can cause intermittent problems.

Testing the Wheel Speed Sensor

After reconnecting the sensor, you need to test it to confirm that it’s functioning correctly. Here’s how:

- Use a digital multimeter: A multimeter can be used to measure the resistance of the sensor. The resistance should be within the manufacturer’s specifications. If the resistance is outside of the specified range, it indicates a problem with the sensor.

- Check for continuity: Using a multimeter, test for continuity between the sensor’s terminals. If there is no continuity, the sensor is faulty and needs to be replaced.

- Use an OBD-II scanner: A scanner can read the sensor’s output and provide information about its performance. If the sensor is not working properly, the scanner will display error codes.

Troubleshooting Remaining Issues

Even after cleaning and testing the sensor, you might still experience issues with your vehicle’s speed sensor. Here are some troubleshooting steps:

- Inspect the wiring: Check for any damage, corrosion, or loose connections in the wiring leading to the sensor. Repair or replace any damaged wiring.

- Inspect the ABS ring: The ABS ring is a toothed ring that the sensor reads to determine wheel speed. If the ring is damaged or missing teeth, it can cause sensor issues. Replace the ring if necessary.

- Check the ABS module: The ABS module is responsible for processing the signals from the wheel speed sensors. If the module is faulty, it can cause problems with the sensors. You may need to have the module diagnosed and repaired or replaced.

Cleaning your wheel speed sensor is a simple yet crucial task that can save you money and ensure your car’s safety. By following the steps Artikeld in this guide, you can confidently maintain your vehicle’s braking and traction control systems. Remember to always prioritize safety and consult a mechanic if you’re unsure about any aspect of the process. Happy driving!

Key Questions Answered

What are the common signs of a faulty wheel speed sensor?

Common signs include ABS light on, traction control malfunction, speedometer not working, and erratic braking.

What happens if I don’t clean my wheel speed sensor?

A dirty sensor can lead to inaccurate speed readings, affecting your car’s braking and traction control systems, potentially causing dangerous situations.

Can I use any cleaning solution on my wheel speed sensor?

It’s best to use a specialized electronic contact cleaner or isopropyl alcohol. Avoid harsh chemicals or solvents that could damage the sensor.