How many wheel speed sensors are on a car? This question might seem simple, but the answer reveals a fascinating world of automotive technology. These unassuming sensors play a crucial role in ensuring your safety and driving experience. From preventing wheel lock-up during braking to providing accurate speed readings, wheel speed sensors are essential components of modern vehicles.

The number of wheel speed sensors in a car typically depends on the vehicle’s type, make, and model. Sedans often have four sensors, one for each wheel, while SUVs and trucks may have additional sensors for their all-wheel drive systems. Understanding the function and location of these sensors can help you better appreciate the complex workings of your vehicle.

The Importance of Wheel Speed Sensors: How Many Wheel Speed Sensors Are On A Car

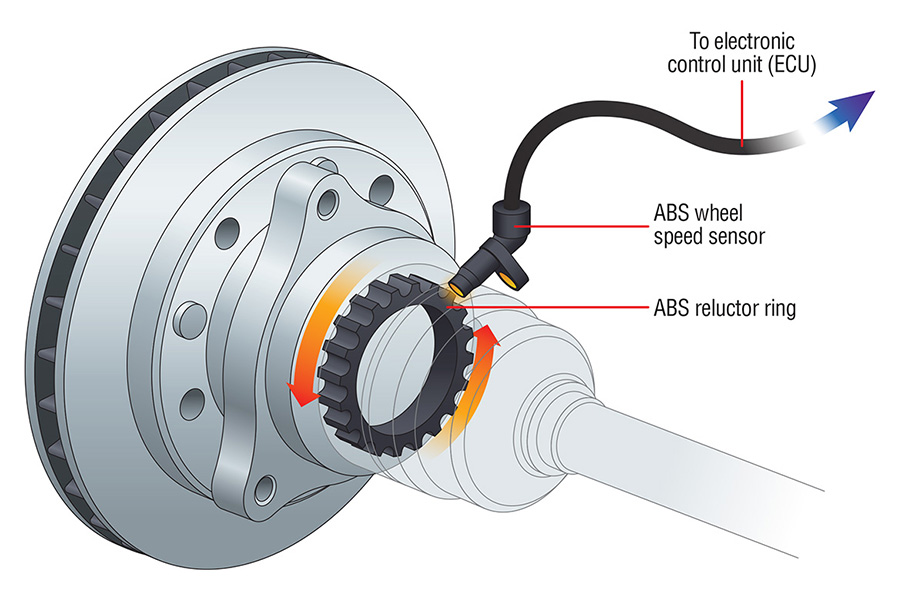

Wheel speed sensors are vital components in modern vehicles, playing a crucial role in enhancing safety, performance, and overall driving experience. These sensors monitor the rotation of each wheel, providing essential information to the vehicle’s electronic control units (ECUs). This data is then used to activate various safety features and ensure accurate vehicle speed readings.

Contribution to Safety Features

Wheel speed sensors are instrumental in the operation of critical safety systems such as Anti-lock Braking System (ABS) and Electronic Stability Control (ESC).

- Anti-lock Braking System (ABS): ABS prevents the wheels from locking up during braking, allowing the driver to maintain steering control and shorten stopping distances. The wheel speed sensors monitor the rotation of each wheel. If a wheel starts to lock up, the ABS system uses the sensor data to modulate brake pressure individually to each wheel, preventing wheel lock-up and maintaining traction.

- Electronic Stability Control (ESC): ESC enhances vehicle stability by detecting and correcting potential skids or rollovers. The system uses data from the wheel speed sensors, steering angle sensor, and yaw rate sensor to determine if the vehicle is losing traction. When a loss of traction is detected, ESC intervenes by applying individual brakes and reducing engine power to help regain control.

Accurate Vehicle Speed Readings

Wheel speed sensors are essential for providing accurate vehicle speed readings to the speedometer and other systems that rely on this information.

- Speedometer Accuracy: By monitoring the rotation of each wheel, the wheel speed sensors calculate the vehicle’s speed and transmit it to the speedometer for display. This ensures that the speedometer accurately reflects the vehicle’s actual speed.

- Cruise Control: Cruise control systems rely on accurate speed readings from the wheel speed sensors to maintain a set speed. The sensors provide feedback to the cruise control system, allowing it to adjust engine power and throttle to maintain the desired speed.

- Other Systems: Wheel speed sensor data is used by other systems, such as the traction control system, navigation system, and driver assistance systems, to function correctly.

Number of Wheel Speed Sensors in a Car

Most cars have four wheel speed sensors, one for each wheel. These sensors play a crucial role in various vehicle systems, including anti-lock brakes (ABS), traction control, and electronic stability control (ESC). They provide the vehicle’s control unit with real-time information about the speed of each wheel, enabling these systems to function effectively.

Number of Wheel Speed Sensors Based on Vehicle Type

The number of wheel speed sensors can vary depending on the vehicle type, with some exceptions.

| Vehicle Type | Number of Wheel Speed Sensors |

|---|---|

| Sedan | 4 |

| SUV | 4 |

| Truck | 4 |

Factors Affecting the Number of Wheel Speed Sensors

The number of wheel speed sensors in a car can vary depending on the vehicle’s make, model, and year.

- Vehicle Model and Configuration: Some vehicles, particularly those with advanced drivetrain systems like all-wheel drive (AWD) or four-wheel drive (4WD), might have additional sensors to monitor the speed of the wheels on both axles. For example, an AWD system might have a sensor on each wheel, totaling four sensors, while a 4WD system might have additional sensors on the front or rear axles, leading to a total of six sensors.

- Year of Manufacture: Older vehicles might have fewer sensors compared to newer models. This is because modern cars often utilize more sophisticated safety and performance systems that require additional sensor data. For example, early ABS systems might have only two sensors, while newer systems might have four sensors for better braking control.

- Vehicle Manufacturer: Different manufacturers might have different design philosophies and utilize different sensor configurations based on their vehicle’s specific requirements. For example, some manufacturers might incorporate sensors into the wheel hub, while others might use separate sensors mounted near the wheel.

Location of Wheel Speed Sensors

Wheel speed sensors are strategically placed on a vehicle to monitor the rotation of each wheel. Their location varies depending on the vehicle’s design and type of wheel drive. Understanding where these sensors are located is crucial for diagnosing issues related to ABS, traction control, and vehicle stability.

Common Locations of Wheel Speed Sensors

The most common locations for wheel speed sensors are:

- Inside the wheel hub: This is the most frequent placement, where the sensor is integrated within the hub assembly. It directly senses the wheel’s rotation by detecting the passing of teeth on the wheel’s tone ring.

- On the suspension arm: In some vehicles, the sensor is mounted on the suspension arm, close to the wheel hub. This placement allows the sensor to detect the wheel’s rotation through a magnetic field generated by a tone ring attached to the wheel hub.

- On the brake caliper: In certain models, the sensor is positioned on the brake caliper, where it detects the wheel’s rotation through a magnetic field generated by a tone ring attached to the brake rotor.

Locations of Wheel Speed Sensors on Different Wheel Types

The placement of wheel speed sensors can differ depending on the type of wheel drive system:

| Wheel Type | Image Description |

|---|---|

| Front Wheel Drive | [Image: Depiction of a front wheel drive vehicle with wheel speed sensors positioned on the front wheels, typically inside the wheel hub or on the suspension arm.] |

| Rear Wheel Drive | [Image: Illustration of a rear wheel drive vehicle with wheel speed sensors placed on the rear wheels, usually inside the wheel hub or on the suspension arm.] |

| All Wheel Drive | [Image: Visualization of an all wheel drive vehicle showcasing wheel speed sensors located on all four wheels, commonly inside the wheel hub or on the suspension arm.] |

Identifying the Location of Wheel Speed Sensors on a Specific Vehicle

To pinpoint the location of wheel speed sensors on a particular vehicle, you can refer to the vehicle’s service manual or use a diagnostic tool. The service manual will provide detailed diagrams and specifications for your specific model, indicating the sensor’s placement and connection points. A diagnostic tool can be used to scan the vehicle’s computer system and retrieve information about the sensor’s location and any related codes.

Types of Wheel Speed Sensors

Wheel speed sensors are crucial components in modern vehicles, providing vital information about the rotational speed of each wheel. This information is used for various functions, including anti-lock braking systems (ABS), traction control, electronic stability control (ESC), and cruise control. There are several different types of wheel speed sensors commonly used in vehicles, each with its unique features, advantages, and disadvantages.

Types of Wheel Speed Sensors

The types of wheel speed sensors used in vehicles are broadly classified into two categories:

- Passive Wheel Speed Sensors

- Active Wheel Speed Sensors

Passive Wheel Speed Sensors

Passive wheel speed sensors are the most common type of sensor used in vehicles. They rely on the magnetic field generated by a rotating component on the wheel, such as a toothed ring or a reluctor wheel.

-

Toothed Ring Sensors

Toothed ring sensors are typically used in older vehicles. These sensors consist of a stationary sensor unit mounted near the wheel hub and a toothed ring attached to the wheel’s axle. The toothed ring has a series of evenly spaced teeth that interrupt the magnetic field generated by the sensor as the wheel rotates. Each interruption generates a pulse, and the frequency of these pulses is proportional to the wheel’s rotational speed.

- Advantages: Toothed ring sensors are relatively inexpensive and durable. They are also simple to install and maintain.

- Disadvantages: Toothed ring sensors are prone to wear and tear, especially in harsh environments. They can also be susceptible to damage from debris or road hazards.

-

Reluctor Wheel Sensors

Reluctor wheel sensors are a more advanced type of passive sensor that utilizes a reluctor wheel, which is a metal disc with a series of teeth or notches. As the wheel rotates, the reluctor wheel’s teeth pass by the sensor, generating a series of magnetic pulses. The frequency of these pulses is directly proportional to the wheel’s rotational speed.

- Advantages: Reluctor wheel sensors are more accurate and reliable than toothed ring sensors. They are also less susceptible to wear and tear.

- Disadvantages: Reluctor wheel sensors are more expensive than toothed ring sensors. They can also be more complex to install and maintain.

Active Wheel Speed Sensors, How many wheel speed sensors are on a car

Active wheel speed sensors are less common than passive sensors. They typically use a Hall-effect sensor to detect the magnetic field generated by a rotating magnet attached to the wheel.

-

Hall-Effect Sensors

Hall-effect sensors work on the principle of the Hall effect, which states that a voltage is generated across a conductor when it is placed in a magnetic field. In a wheel speed sensor, the sensor’s output voltage changes as the magnet rotates, providing a signal that is proportional to the wheel’s rotational speed.

- Advantages: Hall-effect sensors are highly accurate and reliable. They are also less susceptible to wear and tear than passive sensors.

- Disadvantages: Hall-effect sensors are more expensive than passive sensors. They are also more complex to install and maintain.

Troubleshooting Wheel Speed Sensors

Wheel speed sensors are crucial for the proper functioning of your car’s safety and performance systems. Understanding how to troubleshoot these sensors can help you identify and resolve issues quickly and efficiently.

Common Symptoms of a Faulty Wheel Speed Sensor

A faulty wheel speed sensor can manifest in a variety of ways, including:

- ABS Light On: The most common symptom of a faulty wheel speed sensor is the ABS light illuminating on the dashboard. This indicates that the ABS system is not receiving accurate speed readings from one or more wheels.

- Traction Control Malfunction: The traction control system relies on wheel speed sensor data to regulate wheel slip. If a sensor is faulty, the traction control system may not function properly, leading to loss of traction.

- Erratic Speedometer Readings: A faulty wheel speed sensor can cause the speedometer to display incorrect or fluctuating speed readings.

- ABS System Inoperative: In some cases, a faulty wheel speed sensor can completely disable the ABS system, leaving your vehicle vulnerable to skidding in emergency braking situations.

Diagnosing Wheel Speed Sensor Issues

Diagnosing a faulty wheel speed sensor typically involves a combination of visual inspection, diagnostic tool analysis, and testing.

- Visual Inspection: Begin by inspecting the wheel speed sensor itself. Look for any visible damage, such as broken wires, corrosion, or debris buildup.

- Diagnostic Tool Analysis: Use an OBD-II scanner to retrieve diagnostic trouble codes (DTCs) related to the wheel speed sensors. These codes can pinpoint the specific sensor or sensors that are malfunctioning.

- Resistance Testing: Using a multimeter, measure the resistance of the wheel speed sensor. This will help you determine if the sensor is open or shorted.

The resistance reading should fall within the manufacturer’s specifications for that particular sensor.

- Signal Testing: Test the sensor’s output signal using an oscilloscope. This will help you determine if the sensor is producing a consistent and accurate signal.

A faulty sensor may produce a weak, intermittent, or erratic signal.

Replacing a Wheel Speed Sensor

If you determine that a wheel speed sensor is faulty, it will need to be replaced.

- Locate the Sensor: The wheel speed sensor is typically located near the wheel hub, either on the axle or the suspension arm. Refer to your vehicle’s service manual for the exact location.

- Disconnect the Electrical Connector: Carefully disconnect the electrical connector from the sensor.

- Remove the Sensor: Use a wrench or socket to remove the sensor from its mounting bracket.

If the sensor is held in place by a clip, carefully pry it loose.

- Install the New Sensor: Install the new sensor in the same location as the old one, ensuring that it is properly secured.

- Reconnect the Electrical Connector: Reconnect the electrical connector to the new sensor.

- Clear DTCs: After installing the new sensor, clear the diagnostic trouble codes using your OBD-II scanner.

- Test Drive: Take the vehicle for a test drive to ensure that the new sensor is functioning properly.

Wheel speed sensors are essential for modern vehicles, playing a vital role in safety features like ABS and traction control, as well as providing accurate speed readings. While the number of sensors can vary, their importance remains constant. By understanding the function and location of these sensors, you can gain a deeper appreciation for the intricate workings of your vehicle and potentially troubleshoot any issues that may arise.

General Inquiries

What happens if a wheel speed sensor fails?

A faulty wheel speed sensor can lead to issues with ABS, traction control, and accurate speedometer readings. In some cases, it may even trigger a warning light on your dashboard.

How can I check if my wheel speed sensor is working?

You can use an OBD-II scanner to check for any error codes related to wheel speed sensors. You can also visually inspect the sensors for any signs of damage or corrosion.

Can I replace a wheel speed sensor myself?

While replacing a wheel speed sensor is a relatively simple task, it’s best to consult a mechanic if you’re unsure. Incorrect installation can lead to further issues.

How often should I check my wheel speed sensors?

It’s a good idea to have your wheel speed sensors inspected as part of your regular car maintenance routine. However, if you notice any issues with ABS, traction control, or your speedometer, it’s best to get them checked immediately.