How to degree a cam without a degree wheel? It’s a question that often pops up for DIY mechanics and engine enthusiasts looking to optimize their engine performance. While a degree wheel is the traditional tool for precise camshaft timing, alternative methods exist that can achieve similar results. This guide explores those methods, providing a step-by-step approach to degreeing your camshaft without relying on the conventional degree wheel.

Understanding cam timing is crucial for optimal engine performance. The camshaft, a vital component within the engine, controls the opening and closing of the valves, which govern the intake and exhaust of the air-fuel mixture. Incorrect cam timing can lead to reduced power, poor fuel economy, and even engine damage. While factory markings on the camshaft and crankshaft provide a starting point, they are not always accurate and may need adjustments for modifications or repairs.

Understanding Cam Timing: How To Degree A Cam Without A Degree Wheel

Cam timing is a critical aspect of internal combustion engines, playing a crucial role in the engine’s performance and efficiency. It dictates the precise timing of valve opening and closing, directly influencing the intake and exhaust cycles of the engine.

The Role of the Camshaft

The camshaft is a rotating shaft within the engine that controls the opening and closing of the valves. It features lobes that rise and fall, interacting with valve lifters to actuate the valves. The camshaft’s rotation is synchronized with the engine’s crankshaft, ensuring that the valves open and close at specific points in the engine cycle.

Consequences of Incorrect Cam Timing

Incorrect cam timing can have significant negative consequences for engine operation:

- Reduced Power Output: Incorrect timing can disrupt the optimal flow of air and fuel into the cylinders, leading to a decrease in power output.

- Increased Fuel Consumption: Improper timing can lead to incomplete combustion, resulting in higher fuel consumption.

- Engine Misfire: Incorrect timing can cause the valves to open or close at inappropriate times, disrupting the combustion process and leading to misfires.

- Engine Damage: In severe cases, incorrect timing can cause valve damage, piston-to-valve contact, or even catastrophic engine failure.

The Need for Degreeing

Degreeing a camshaft is a crucial process in engine tuning that ensures optimal performance. This involves precisely setting the timing of the camshaft relative to the crankshaft, which dictates when the valves open and close. Proper camshaft timing directly impacts engine performance characteristics like power, torque, and fuel efficiency.

The Relationship Between Camshaft Timing and Engine Performance

The relationship between camshaft timing and engine performance is intricate. Precise camshaft timing optimizes the intake and exhaust cycles, influencing how effectively the engine breathes and burns fuel.

- Valve Timing and Intake/Exhaust Cycles: The camshaft determines when the intake and exhaust valves open and close. Proper valve timing ensures that the engine receives an optimal amount of air and fuel during the intake stroke and effectively expels exhaust gases during the exhaust stroke.

- Engine Power and Torque: Camshaft timing significantly impacts engine power and torque. A camshaft with aggressive timing, where the valves open earlier and close later, can increase power at higher RPMs. Conversely, a camshaft with less aggressive timing can increase torque at lower RPMs, improving drivability.

- Fuel Efficiency: Camshaft timing also influences fuel efficiency. A camshaft that optimizes the intake and exhaust cycles can improve fuel economy by ensuring complete combustion and reducing fuel consumption.

Limitations of Factory Markings

While factory markings on the camshaft and timing gears provide a starting point, they may not always be accurate or suitable for all applications. Factory markings are often intended for stock engines and may not account for modifications or wear and tear.

- Modifications: Modifications like engine rebuilds, head porting, or aftermarket camshafts can alter the ideal camshaft timing.

- Wear and Tear: Over time, wear and tear on the timing components can affect camshaft timing accuracy.

- Engine Tuning: Factory markings do not account for fine-tuning engine performance. For optimal performance, precise camshaft timing adjustments are often required.

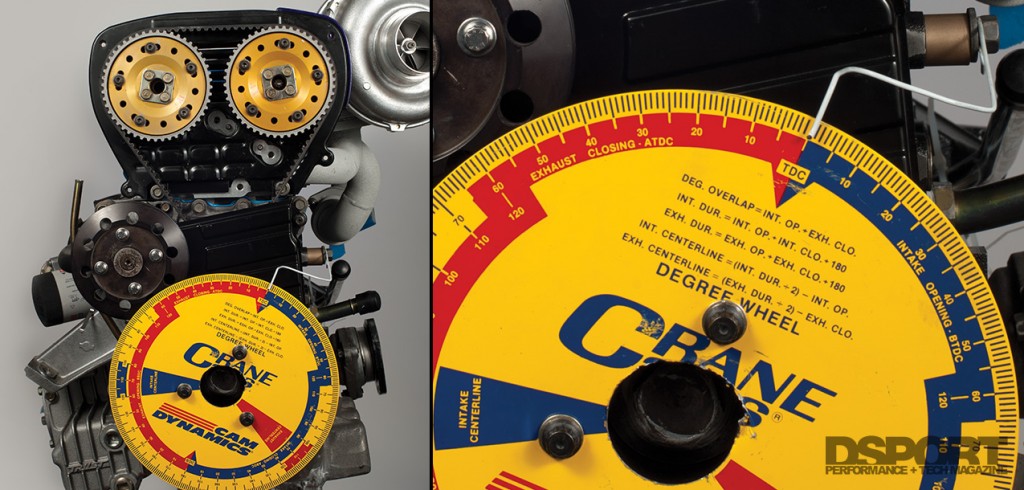

Alternative Methods to Degreeing Without a Degree Wheel

While a degree wheel provides the most accurate and direct method for determining camshaft timing, there are alternative methods that can be employed in situations where a degree wheel is unavailable or impractical. These methods utilize readily available tools and techniques, allowing for reasonable accuracy in setting camshaft timing.

Using a Dial Indicator

The dial indicator method relies on measuring the movement of a specific point on the engine’s valvetrain as the camshaft rotates. This method is particularly effective for engines with adjustable rocker arms or lifters.

- Attaching the Dial Indicator: Secure the dial indicator base to a rigid surface near the engine. The dial indicator’s contact point should be positioned on the valve stem or rocker arm, depending on the engine design. Ensure that the contact point is perpendicular to the valve stem or rocker arm movement.

- Establishing a Reference Point: Rotate the camshaft to the desired timing mark, such as the intake valve fully closed or the exhaust valve fully open. Zero the dial indicator at this reference point. This reference point corresponds to a specific degree of camshaft rotation.

- Measuring Movement: As the camshaft rotates, observe the dial indicator reading. The dial indicator reading will change as the valve opens and closes, reflecting the camshaft’s lobe profile.

- Determining Timing: Compare the dial indicator readings with the camshaft specifications. This information can be found in the engine’s service manual or camshaft manufacturer’s specifications. The dial indicator readings will indicate the valve lift and timing at different camshaft rotations, allowing for precise timing adjustments.

The dial indicator method offers reasonable accuracy, but it requires careful setup and precise measurements. It is crucial to ensure the dial indicator is properly mounted and that the contact point is perpendicular to the valve stem or rocker arm movement.

Essential Tools and Equipment

Degreeing a camshaft without a degree wheel requires specific tools and equipment to ensure accurate measurements and proper timing. This section will discuss the essential tools and their functions.

Essential Tools and Equipment

This table provides a list of essential tools and equipment required for degreeing a camshaft without a degree wheel.

| Tool Name | Description | Function |

|---|---|---|

| Dial Indicator | A precision measuring instrument consisting of a dial with a graduated scale, a plunger, and a base. | Measures the movement of the camshaft lobe, providing accurate measurements of valve lift and timing. |

| Magnetic Base | A base with a strong magnet, used to securely mount the dial indicator to the engine block or other metal surfaces. | Provides a stable platform for the dial indicator, ensuring accurate measurements. |

| Timing Light | A tool that emits a bright light that flashes in sync with the engine’s ignition timing. | Used to verify the accuracy of the ignition timing after adjusting the camshaft. |

| Torque Wrench | A wrench with a calibrated mechanism that provides precise torque control. | Ensures proper tightening of camshaft bolts and other engine components to prevent damage. |

| Socket Set | A set of sockets of various sizes, used to tighten and loosen nuts and bolts. | Provides the necessary sockets for working on the camshaft and other engine components. |

| Wrench Set | A set of wrenches of various sizes, used to tighten and loosen nuts and bolts. | Provides the necessary wrenches for working on the camshaft and other engine components. |

| Pliers | A hand tool with two arms that grip and manipulate objects. | Used to hold and manipulate small parts during the degreeing process. |

| Screwdriver Set | A set of screwdrivers of various sizes and types, used to drive screws. | Provides the necessary screwdrivers for working on the camshaft and other engine components. |

| Valve Spring Compressor | A tool designed to compress valve springs, allowing for the removal and installation of valve components. | Ensures safe removal and installation of valves during the camshaft degreeing process. |

| Feeler Gauges | A set of thin metal blades of various thicknesses, used to measure gaps or clearances. | Used to measure valve lash and ensure proper valve clearance. |

Step-by-Step Procedure

This section Artikels a detailed procedure for degreeing a camshaft without using a degree wheel. While this method is less precise than using a degree wheel, it can be helpful in situations where a degree wheel is unavailable or impractical.

Using a Piston Stop, How to degree a cam without a degree wheel

The piston stop method is a common technique for degreeing a camshaft without a degree wheel. This method relies on accurately positioning the piston at Top Dead Center (TDC) and then using the camshaft lobes to determine the cam timing.

- Prepare the Engine: Remove the valve cover and spark plugs to gain access to the camshaft and piston. Ensure the engine is at TDC on the compression stroke of the cylinder you are working on. This can be confirmed by inserting a long screwdriver or rod through the spark plug hole and checking that it meets the piston at its highest point.

- Install the Piston Stop: Insert the piston stop into the spark plug hole. The piston stop is a tool designed to prevent the piston from moving further down the cylinder. Make sure the piston stop is securely in place and that the piston is resting against it.

- Rotate the Crankshaft: With the piston stop in place, rotate the crankshaft in the direction of engine rotation (clockwise in most engines) until the piston is at TDC. You should feel resistance as the piston hits the stop.

- Mark the Camshaft: Once the piston is at TDC, use a permanent marker or a scribe to mark the camshaft lobe at its highest point. This mark represents the camshaft’s position at TDC.

- Rotate the Camshaft: Rotate the camshaft in the direction of engine rotation until the intake valve is fully open. This is typically when the camshaft lobe is at its lowest point. Mark the camshaft lobe at this position.

- Measure the Cam Timing: The distance between the two marks on the camshaft represents the intake cam timing. You can measure this distance with a ruler or a tape measure.

- Repeat for Exhaust Cam: Repeat steps 5-6 for the exhaust cam to determine its timing.

Troubleshooting and Common Mistakes

Degreeing a camshaft without a degree wheel requires precision and attention to detail. Even minor errors can lead to significant performance issues or engine damage. This section will identify potential problems that may arise during the degreeing process, discuss common mistakes, and provide troubleshooting tips to help you resolve these issues.

Identifying Potential Issues

Potential issues that might arise during the degreeing process can be categorized as follows:

- Incorrect Valve Timing: This is the most common issue. If the camshaft is not properly degreed, the valves will open and close at the wrong times, affecting engine performance and potentially causing damage.

- Engine Misfire: Misfiring is often a symptom of incorrect valve timing. The engine may run rough, lack power, or even stall.

- Premature Valve Wear: Incorrect valve timing can cause the valves to open or close too early or too late, leading to increased wear and tear on the valve train components.

- Reduced Engine Efficiency: The engine may not operate at its optimal efficiency if the camshaft is not properly degreed, leading to decreased fuel economy and power output.

- Engine Damage: In severe cases, incorrect valve timing can lead to engine damage, such as bent valves, broken pistons, or even a blown head gasket.

Common Mistakes When Degreeing a Camshaft Without a Degree Wheel

Here are some common mistakes made when degreeing a camshaft without a degree wheel:

- Incorrectly Measuring the Cam Timing Marks: The timing marks on the camshaft and crankshaft may not be perfectly aligned. Carefully verify their alignment and make any necessary adjustments.

- Incorrectly Measuring the Valve Lift: If you’re using a dial indicator to measure valve lift, ensure it is properly calibrated and positioned. The dial indicator should be firmly mounted and secured to prevent movement during the measurement process.

- Incorrectly Measuring the Piston Position: The piston position must be accurate for proper valve timing. Ensure that the piston is at the correct position before making any measurements.

- Not Using the Correct Tools: Using the right tools is crucial for accurate measurements. Make sure all tools are properly calibrated and in good working condition.

- Improperly Setting the Valve Lash: The valve lash is the gap between the valve and the rocker arm. It must be set correctly to ensure proper valve operation. Refer to your engine’s specifications for the correct valve lash setting.

- Not Checking for Interferences: If you’re using a high-lift camshaft, you need to check for valve-to-piston clearance. This is important to prevent the valves from hitting the pistons when the engine is running.

Troubleshooting Tips

- Double-Check Your Measurements: Repeat all measurements to ensure accuracy. If you find any discrepancies, go back and verify your work.

- Verify the Timing Marks: Ensure that the timing marks on the camshaft and crankshaft are correctly aligned. If they are not, you may need to adjust the camshaft or crankshaft position.

- Check the Valve Lash: Make sure the valve lash is set correctly according to your engine’s specifications. Adjust the lash if necessary.

- Inspect the Valve Train: Examine the valve train components for any signs of wear or damage. Replace any worn or damaged parts.

- Check for Interferences: If you’re using a high-lift camshaft, check for valve-to-piston clearance. If there is an interference, you may need to adjust the camshaft timing or use a different camshaft.

- Use a Degree Wheel: If you are experiencing difficulty degreeing the camshaft without a degree wheel, consider investing in one. A degree wheel can provide much more accurate measurements and make the process easier.

Safety Considerations

Working on an engine, especially with components like the camshaft, requires a high level of caution and awareness of potential hazards. Improper handling can lead to serious injuries. Here’s a comprehensive look at the necessary safety precautions to ensure a safe and successful camshaft degreeing process.

Potential Hazards

Camshaft degreeing involves working with moving parts, sharp tools, and potentially hazardous substances like engine fluids. Understanding these potential hazards is crucial to avoid accidents and injuries.

- Moving Parts: The engine’s crankshaft and camshaft are rotating components. Improperly securing or engaging these parts during the degreeing process can result in severe injuries from contact with moving parts.

- Sharp Tools: Tools like wrenches, screwdrivers, and socket sets can cause cuts and puncture wounds if handled carelessly. It is important to use these tools with care and wear appropriate protective gear.

- Engine Fluids: Engine oil, coolant, and fuel are flammable and can cause skin irritation or even burns. Wear protective clothing and gloves when working with these fluids, and ensure adequate ventilation to prevent inhalation of fumes.

Safety Equipment

Using the right safety equipment is essential for minimizing risks during camshaft degreeing.

- Eye Protection: Safety glasses or goggles should be worn at all times to protect the eyes from flying debris, splashes, and harmful fumes.

- Hand Protection: Heavy-duty gloves, preferably with a good grip, are essential to protect hands from cuts, burns, and chemical exposure. Choose gloves that are appropriate for the specific tasks involved.

- Protective Clothing: Wear long-sleeved shirts and long pants to minimize the risk of skin contact with hot engine parts or fluids. Consider wearing a shop apron to protect clothing from spills and grime.

- Respiratory Protection: In environments with poor ventilation or when working with engine fluids, a respirator mask can help protect the lungs from harmful fumes and dust.

- Hearing Protection: If the engine is running during the degreeing process, earplugs or earmuffs are necessary to protect hearing from loud noises.

Additional Safety Measures

Beyond basic safety equipment, additional measures contribute to a safe working environment.

- Clear Work Area: Keep the work area clean and free of clutter to prevent tripping hazards and ensure clear access to tools and components.

- Proper Lighting: Adequate lighting is essential for visibility and to prevent eye strain. Use a work light if necessary to illuminate the work area properly.

- Fire Extinguisher: Have a fire extinguisher readily available in case of a fire. Ensure you are familiar with its operation.

- First Aid Kit: Keep a well-stocked first aid kit within easy reach in case of minor injuries.

- Emergency Contact Information: Have emergency contact information readily available in case of a serious accident.

Degreeing a camshaft without a degree wheel requires meticulous attention to detail, a solid understanding of engine mechanics, and the right tools. By following the steps Artikeld in this guide, you can confidently achieve accurate cam timing, unlocking the full potential of your engine. Remember, safety should always be a priority when working on engine components, so always wear appropriate safety gear and follow recommended procedures.

Popular Questions

What are the potential risks of incorrect cam timing?

Incorrect cam timing can lead to a variety of issues, including reduced power, poor fuel economy, engine misfires, and even engine damage.

Can I use a dial indicator for degreeing a camshaft?

Yes, a dial indicator is a common alternative to a degree wheel for degreeing a camshaft. It measures the movement of the valve as the crankshaft rotates, allowing you to determine the camshaft timing.

What are some common mistakes made when degreeing a camshaft?

Some common mistakes include misreading the dial indicator, not using the correct reference points, and failing to properly secure the camshaft.