How to remove a stuck wheel hub can seem daunting, but with the right approach and tools, it’s a task that can be accomplished safely and efficiently. A stuck wheel hub can be caused by several factors, including corrosion, seized bearings, or even a damaged hub itself. This guide will walk you through the process of removing a stuck wheel hub, from identifying the problem to reinstalling the hub with proper torque settings.

Understanding the potential risks associated with a stuck wheel hub is crucial. A malfunctioning hub can lead to loss of control, wheel separation, or even an accident. Therefore, it’s essential to address this issue promptly and take all necessary safety precautions before attempting any repairs.

Identifying the Problem

A stuck wheel hub can be a frustrating and potentially dangerous issue. It occurs when the hub, which is the central part of the wheel that attaches to the axle, becomes seized or jammed, preventing the wheel from rotating freely. This can happen for various reasons, and it’s crucial to understand the underlying causes to address the problem effectively.

Common Causes of a Stuck Wheel Hub

The most common reasons for a stuck wheel hub include:

- Corrosion: Rust and corrosion can build up between the hub and the axle, creating a tight bond that prevents the hub from rotating smoothly.

- Worn Bearings: Wheel bearings are responsible for allowing the hub to rotate smoothly. When they wear out, they can cause friction and eventually lead to a stuck hub.

- Damaged Hub: A damaged or cracked hub can create a rough surface that makes it difficult for the hub to rotate.

- Overtightened Lug Nuts: If the lug nuts are overtightened, they can put excessive pressure on the hub and cause it to seize.

- Improper Lubrication: Lack of proper lubrication in the hub assembly can lead to friction and ultimately a stuck hub.

Potential Risks Associated with a Stuck Wheel Hub

A stuck wheel hub poses several risks, including:

- Loss of Control: A stuck wheel will not be able to rotate, making it impossible to steer or brake properly, leading to a loss of vehicle control.

- Damage to Other Components: The force of a stuck wheel can damage the axle, suspension components, or even the tire itself.

- Increased Wear and Tear: A stuck wheel can cause excessive wear on other components, leading to premature failure.

- Accidents: Loss of control due to a stuck wheel can lead to serious accidents.

Symptoms of a Stuck Wheel Hub

Several symptoms can indicate a stuck wheel hub. If you notice any of these, it’s essential to investigate further and address the issue promptly:

- Unusual Noise: A grinding, squeaking, or clunking sound when turning or driving could be a sign of a stuck hub.

- Vibration: A stuck wheel hub can cause vibration in the steering wheel or the entire vehicle.

- Difficulty Steering: If you experience difficulty turning the steering wheel, it could be a sign of a stuck hub.

- Uneven Tire Wear: A stuck wheel can cause uneven tire wear due to the lack of rotation.

- Wheel Feels Hot: Excessive heat in the wheel area could be a sign of friction caused by a stuck hub.

Safety Precautions

Removing a stuck wheel hub can be a challenging task, and it’s crucial to prioritize safety throughout the process. Failure to adhere to proper safety measures can lead to serious injuries, so it’s essential to understand and follow these guidelines.

Before attempting to remove a stuck wheel hub, ensure you have the necessary tools and equipment. Using the wrong tools or equipment can not only hinder the process but also increase the risk of accidents. Additionally, working on a vehicle with a stuck wheel hub can be dangerous, as the vehicle may become unstable or move unexpectedly.

Essential Safety Measures

Before attempting to remove a stuck wheel hub, it’s crucial to take the following safety measures:

- Park the vehicle on a level surface and engage the parking brake. This prevents the vehicle from rolling while you’re working on it.

- Chock the wheels. Place wheel chocks behind the wheels that are not being worked on to further prevent the vehicle from rolling.

- Wear appropriate safety gear. This includes safety glasses, gloves, and sturdy footwear. It’s also advisable to wear a face mask to protect against dust and debris.

- Use a jack stand to support the vehicle. Never rely solely on the jack to support the vehicle’s weight. Always use a jack stand to ensure stability and prevent the vehicle from falling.

- Disconnect the battery. This prevents electrical hazards while working on the vehicle’s suspension system.

Using Appropriate Tools and Equipment

The tools and equipment you use for removing a stuck wheel hub are crucial for a successful and safe operation. Here’s a list of essential tools and equipment:

- Hydraulic press. A hydraulic press is often necessary to apply significant force to remove a stuck wheel hub. It’s essential to use a press with a capacity that exceeds the force required to remove the hub.

- Impact wrench. An impact wrench is used to loosen and tighten the lug nuts. It’s essential to use an impact wrench with a torque setting that matches the lug nuts’ specifications.

- Socket set. A socket set with various sizes is necessary to fit the lug nuts and other fasteners involved in the removal process.

- Pry bar. A pry bar can be used to gently pry the hub from the axle. It’s essential to use a pry bar with a sturdy construction to avoid bending or breaking.

- Penetrating fluid. Penetrating fluid helps loosen rusted or seized components. It’s essential to apply penetrating fluid liberally to the hub and axle before attempting to remove them.

Risks of Working on a Vehicle with a Stuck Wheel Hub

Working on a vehicle with a stuck wheel hub presents several risks, including:

- Injury from falling vehicle. If the jack or jack stand fails, the vehicle can fall, causing serious injury.

- Injury from flying debris. When using tools to remove the stuck hub, flying debris can cause eye injuries or cuts.

- Injury from the hydraulic press. Improper use of a hydraulic press can result in pinched fingers or other injuries.

- Damage to the vehicle. Using the wrong tools or excessive force can damage the vehicle’s suspension system.

Tools and Equipment

Having the right tools and equipment is crucial for a successful wheel hub removal. This section Artikels the necessary tools and their usage, ensuring a safe and efficient process.

Tool Requirements, How to remove a stuck wheel hub

The tools required for removing a stuck wheel hub vary depending on the specific vehicle and the severity of the issue. However, a basic set of tools will cover most situations.

- Breaker Bar: This tool is essential for loosening the lug nuts. It provides extra leverage, allowing you to apply significant force to break the nuts free.

- Socket Set: A socket set with various sizes is needed to fit the lug nuts on your vehicle. Ensure you have the correct size for your vehicle’s lug nuts.

- Torque Wrench: After removing the lug nuts, a torque wrench is crucial for tightening them back to the manufacturer’s specifications. This ensures the nuts are properly secured without overtightening them, which can damage the wheel studs.

- Hammer: A hammer can be used to tap on the hub to help loosen it. However, be cautious not to damage the hub or surrounding components.

- Pry Bar: A pry bar can be used to gently pry the hub away from the axle if it’s stuck. Use caution to avoid damaging the hub or axle.

- Penetrating Fluid: Penetrating fluid, such as WD-40, can be used to loosen rusted or seized nuts and bolts. Apply it liberally to the lug nuts and allow it to penetrate for a few minutes before attempting to loosen them.

- Jack and Jack Stands: These are essential for safely lifting the vehicle to access the wheel hub. Ensure the jack is rated for the weight of your vehicle and use jack stands to support the vehicle securely while working on the hub.

Alternative Tools

If the primary tools are unavailable, alternative tools can be used.

- Pipe Wrench: If a breaker bar is unavailable, a pipe wrench can be used to loosen the lug nuts. However, use caution as this can damage the lug nuts if not used properly.

- Adjustable Wrench: An adjustable wrench can be used as a substitute for a socket wrench if necessary. However, it may not provide the same grip and leverage as a socket wrench.

- Impact Wrench: An impact wrench can be used to loosen stubborn lug nuts. However, this tool requires caution as it can easily strip the lug nuts if used incorrectly.

Tool Usage Table

The following table provides a detailed breakdown of the purpose and usage of each tool:

| Tool | Purpose | Usage |

|---|---|---|

| Breaker Bar | To loosen lug nuts | Place the breaker bar over the lug nut and apply force in a counterclockwise direction to loosen the nut. |

| Socket Set | To fit the lug nuts | Select the correct size socket for your vehicle’s lug nuts and attach it to the breaker bar or ratchet. |

| Torque Wrench | To tighten lug nuts to the manufacturer’s specifications | Set the torque wrench to the specified torque value for your vehicle and tighten the lug nuts until the wrench clicks. |

| Hammer | To tap on the hub to help loosen it | Gently tap on the hub with a hammer to loosen it. Use caution not to damage the hub or surrounding components. |

| Pry Bar | To gently pry the hub away from the axle | Place the pry bar between the hub and the axle and gently pry it away. Use caution to avoid damaging the hub or axle. |

| Penetrating Fluid | To loosen rusted or seized nuts and bolts | Apply penetrating fluid to the lug nuts and allow it to penetrate for a few minutes before attempting to loosen them. |

| Jack and Jack Stands | To safely lift the vehicle to access the wheel hub | Use the jack to lift the vehicle and place jack stands under the vehicle for support before working on the hub. |

Removal Process

The removal process of a stuck wheel hub involves a series of steps that require careful attention to detail and adherence to safety precautions. It is essential to have the right tools and equipment, and to understand the potential risks involved. This section provides a step-by-step guide to remove a stuck wheel hub safely and effectively.

Step-by-Step Guide

-

Step 1: Preparation

-Ensure the vehicle is parked on a level surface and the parking brake is engaged.

-Use wheel chocks to prevent the vehicle from rolling.

-Disconnect the negative terminal of the battery to prevent electrical shocks.

-Wear safety glasses and gloves to protect your eyes and hands. -

Step 2: Loosen the Lug Nuts

-Using a breaker bar and socket, loosen the lug nuts while the vehicle is still on the ground. This helps to break the nuts free before lifting the vehicle.

-Do not remove the lug nuts completely at this stage. -

Step 3: Raise the Vehicle

-Use a jack to raise the vehicle, ensuring the jack is positioned on a solid and stable surface.

-Raise the vehicle until the tire is about 6 inches off the ground. -

Step 4: Remove the Lug Nuts

-Remove the lug nuts completely using a socket wrench.

-Store the lug nuts in a safe place. -

Step 5: Remove the Wheel

-Carefully remove the wheel from the hub. -

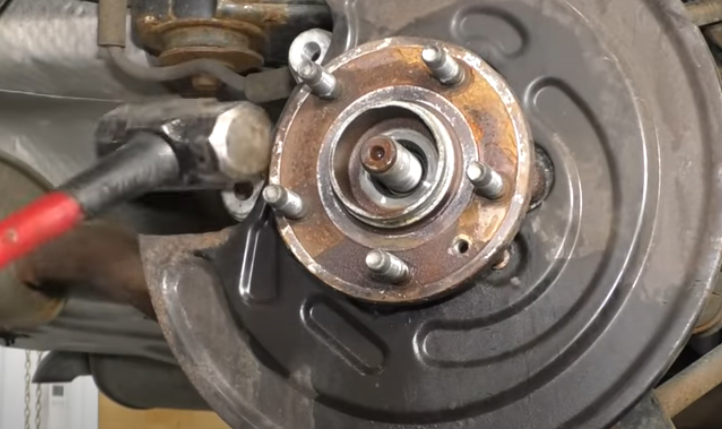

Step 6: Access the Wheel Hub

-Once the wheel is removed, you will have access to the wheel hub.

-Inspect the hub for any damage or signs of wear. -

Step 7: Apply Penetrating Fluid

-If the hub is stuck, apply a penetrating fluid like WD-40 to the hub.

-Allow the fluid to penetrate for a few minutes. -

Step 8: Use a Hub Puller

-Use a hub puller to remove the hub from the axle.

-The hub puller is a specialized tool designed for this purpose.

-It consists of a central screw that pulls the hub off the axle.

-Follow the manufacturer’s instructions for using the hub puller. -

Step 9: Remove the Hub

-Once the hub is loosened, carefully remove it from the axle. -

Step 10: Inspect the Hub and Axle

-After removing the hub, inspect both the hub and axle for any damage.

-If there is any damage, replace the damaged parts. -

Step 11: Reassembly

-Once the hub is removed, the reassembly process involves reversing the removal steps.

-Ensure that all parts are properly aligned and secured.

-Tighten the lug nuts to the specified torque.

-Lower the vehicle and remove the jack.

-Reconnect the negative terminal of the battery.

Troubleshooting and Solutions

Even with the right tools and techniques, removing a stuck wheel hub can present challenges. This section will discuss common problems and provide troubleshooting techniques and alternative solutions for a successful removal.

Common Challenges During Wheel Hub Removal

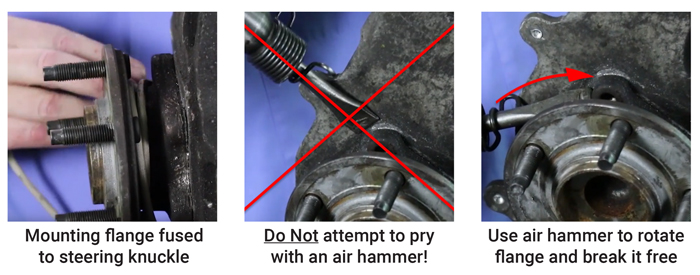

A stuck wheel hub can be caused by several factors, including corrosion, wear and tear, or improper installation. Here are some common challenges encountered during the removal process:

- Corrosion: Over time, rust and corrosion can build up between the wheel hub and the spindle, making it difficult to separate the two components.

- Seized Bearings: The wheel bearings, which support the wheel hub, can become seized due to lack of lubrication or damage. This can prevent the hub from rotating freely, making removal difficult.

- Damaged Threads: The threads on the wheel studs or lug nuts can be damaged, making it challenging to loosen them. This can happen due to over-tightening or improper use of tools.

- Stuck Spindle Nut: The spindle nut, which secures the wheel hub to the spindle, can become stuck due to corrosion or over-tightening.

Troubleshooting Techniques

When faced with a stuck wheel hub, it’s essential to identify the specific issue causing the problem. Here are some troubleshooting techniques to help address different challenges:

- Penetrating Fluid: Applying a penetrating fluid like WD-40 or PB Blaster to the area where the wheel hub meets the spindle can help loosen rust and corrosion. Allow the fluid to soak for several minutes before attempting to remove the hub.

- Heat: Using a heat gun or torch to warm up the area around the wheel hub can help loosen rust and expand metal, making it easier to separate the components. Exercise caution to avoid damaging surrounding parts.

- Impact Wrench: An impact wrench can provide significant torque, making it easier to loosen stuck nuts or bolts. Ensure the impact wrench is set to the appropriate torque setting to avoid damaging the threads.

- Breaker Bar: If a standard wrench or socket isn’t enough to loosen the spindle nut, a breaker bar can provide additional leverage. Be sure to use a breaker bar that is long enough to provide adequate force without risking injury.

- Hydraulic Press: In some cases, a hydraulic press can be used to apply pressure to the wheel hub, forcing it off the spindle. This method requires specialized equipment and expertise.

Alternative Solutions for Removing a Stuck Wheel Hub

If conventional methods fail, consider these alternative solutions:

- Cutting the Hub: As a last resort, a cutting torch or saw can be used to cut the wheel hub off the spindle. This method should only be used if other options have been exhausted, as it can damage the spindle and require replacement.

- Professional Assistance: If you’re unable to remove the stuck wheel hub yourself, seeking professional help from a qualified mechanic or automotive repair shop is recommended. They have the experience and tools to safely and effectively remove the hub.

Reinstallation and Final Checks: How To Remove A Stuck Wheel Hub

Once you’ve successfully removed the stuck wheel hub, it’s time to reinstall it and ensure everything is working properly. This involves carefully putting the hub back in place, securing it with the correct torque, and conducting thorough final checks to guarantee a safe and smooth ride.

Reinstalling the Wheel Hub

Reinstalling the wheel hub requires careful attention to ensure it’s properly seated and secured.

- Clean the Hub and Spindle: Before reinstallation, thoroughly clean both the wheel hub and the spindle. This removes any debris or rust that could hinder proper seating. Use a wire brush, cleaning solvent, and a clean cloth to ensure both surfaces are free of contaminants.

- Lubricate the Spindle: Apply a thin layer of grease to the spindle. This helps prevent friction and wear during operation. Ensure the grease is compatible with the materials of the spindle and hub.

- Align the Hub: Align the wheel hub with the spindle, ensuring the mounting holes on the hub match those on the spindle. Carefully slide the hub onto the spindle, avoiding any forced movements that could damage the components.

- Install the Nuts and Washers: Install the appropriate nuts and washers onto the studs, ensuring they are properly seated and tightened.

Torque Settings

Securing the wheel hub with the correct torque is crucial for safety and performance.

- Refer to the Owner’s Manual: Consult your vehicle’s owner’s manual for the specific torque specifications for your wheel hub. This manual provides the recommended torque values for your make and model, ensuring proper tightening.

- Use a Torque Wrench: Use a torque wrench to tighten the nuts to the specified torque. A torque wrench measures the amount of force applied, ensuring consistent and accurate tightening.

- Tighten in a Star Pattern: Tighten the nuts in a star pattern, gradually increasing the torque on each nut until they reach the specified value. This pattern helps distribute the force evenly and prevents warping of the hub or spindle.

Final Checks

After reinstallation, it’s essential to conduct thorough final checks to ensure the wheel hub is secure and functioning correctly.

- Visual Inspection: Visually inspect the installed hub for any signs of damage or misalignment. Ensure the hub is properly seated on the spindle and the nuts are securely tightened.

- Test Drive: Take your vehicle for a short test drive. Pay attention to any unusual noises, vibrations, or handling issues that may indicate a problem with the wheel hub.

- Re-torque Nuts: After the test drive, re-torque the wheel hub nuts to ensure they haven’t loosened. This is a crucial step to prevent loosening and potential safety hazards.

Removing a stuck wheel hub requires patience, precision, and the right tools. By following the steps Artikeld in this guide, you can safely and effectively address this common automotive issue. Remember to always prioritize safety, use appropriate tools, and consult a professional if you encounter any significant challenges. With a little effort and the right information, you can confidently tackle this task and keep your vehicle running smoothly.

Quick FAQs

What are the signs of a stuck wheel hub?

A stuck wheel hub can manifest in various ways, including a grinding noise when braking or turning, a loose or wobbly wheel, or a noticeable vibration in the steering wheel.

What tools do I need to remove a stuck wheel hub?

You’ll need a jack, lug wrench, breaker bar, socket set, penetrating oil, and possibly a hammer and chisel.

What if I can’t remove the hub with a breaker bar?

If the hub is severely stuck, you may need to use a specialized hub puller tool. A professional mechanic may also be able to assist.

What are the risks of driving with a stuck wheel hub?

Driving with a stuck wheel hub can lead to wheel separation, loss of control, and even an accident. It’s essential to address the issue promptly and safely.