Why does my wheel bearing keep going bad? It’s a question that every car owner dreads hearing, especially when it feels like you’re constantly replacing them. Wheel bearings are like the silent heroes of your car, quietly keeping your wheels spinning and your ride smooth. But when they start to fail, it can be a real pain – literally.

From annoying noises to a wobbly ride, a failing wheel bearing can quickly turn into a safety hazard. So what’s the deal? Why are your wheel bearings giving up the ghost so quickly? Let’s dive into the world of wheel bearings and find out what’s causing them to wear out prematurely.

The answer to why your wheel bearings keep going bad can be a combination of factors. From driving habits to road conditions, there are a lot of things that can affect the lifespan of these critical components. But understanding these factors can help you prevent future problems and keep your car running smoothly. So, buckle up and let’s get to the bottom of this wheel bearing mystery!

Understanding Wheel Bearing Failure

Wheel bearings are crucial components in a vehicle’s suspension system, responsible for supporting the weight of the vehicle and allowing the wheels to rotate smoothly. Their proper function is vital for maintaining vehicle stability, handling, and safety. When a wheel bearing fails, it can lead to a range of issues, from a noticeable noise to a complete loss of control.

Types of Wheel Bearings and Failure Modes

Wheel bearings come in different types, each with its own specific failure mechanisms. Understanding these types and their failure modes can help diagnose the root cause of a bearing failure.

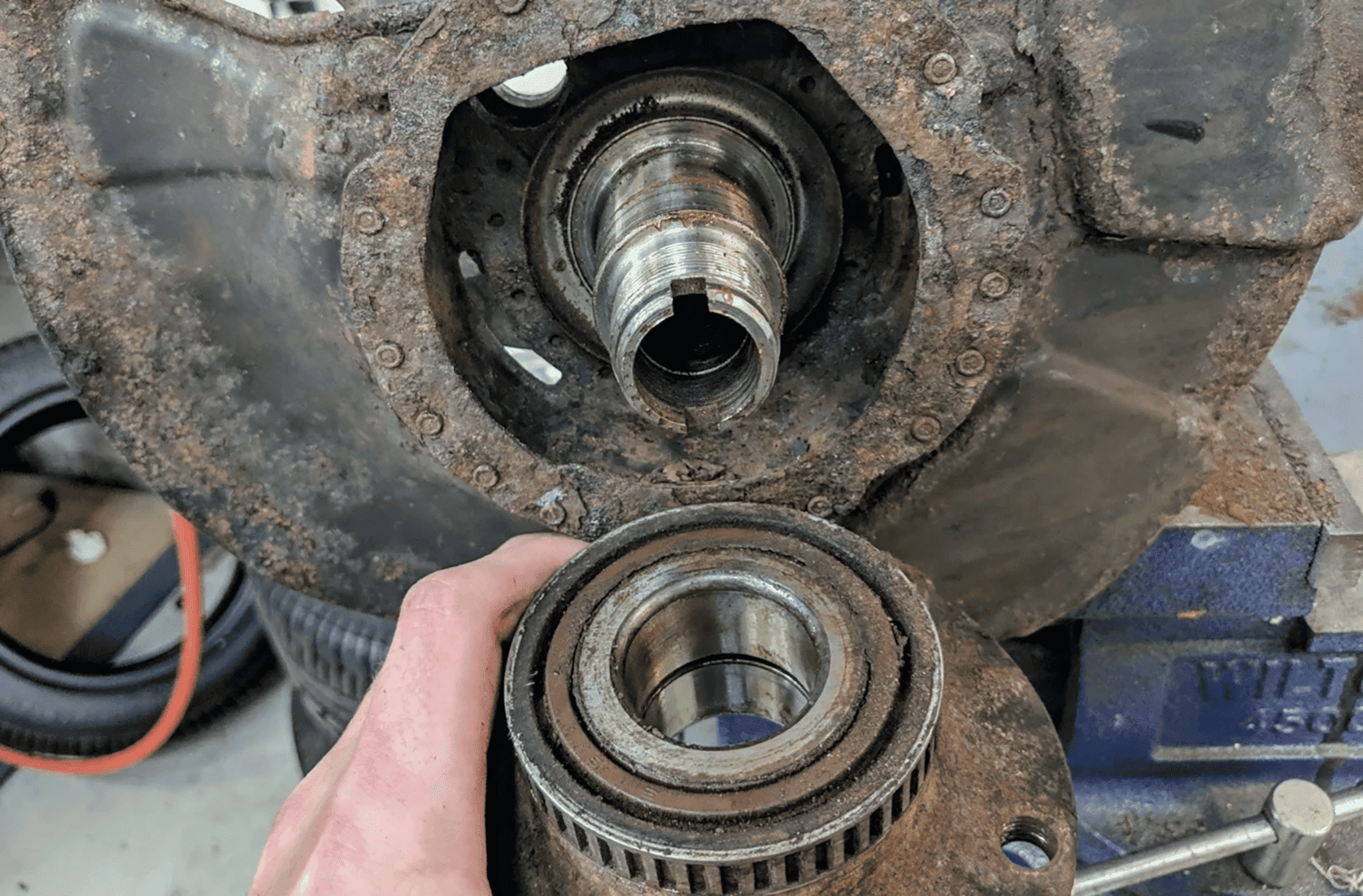

- Tapered Roller Bearings: These bearings consist of tapered rollers that fit between two races. They are commonly used in heavy-duty vehicles and offer high load-carrying capacity. Common failure modes include wear and tear on the rollers and races, as well as damage caused by debris or improper lubrication.

- Ball Bearings: These bearings utilize balls that rotate between two races. They are often used in lighter vehicles and offer smooth rotation. Common failure modes include wear and tear on the balls and races, as well as damage caused by improper installation or contamination.

- Spherical Roller Bearings: These bearings feature spherical rollers that allow for angular misalignment. They are commonly used in heavy-duty applications where misalignment is expected. Common failure modes include wear and tear on the rollers and races, as well as damage caused by overloading or improper lubrication.

Signs and Symptoms of a Failing Wheel Bearing

Recognizing the signs of a failing wheel bearing is crucial for addressing the issue before it becomes a safety hazard.

- Noise: A common symptom is a rumbling, grinding, or roaring noise that increases with speed. This noise is often accompanied by a vibration that can be felt in the steering wheel.

- Steering Wheel Wobble: A failing wheel bearing can cause a wobble in the steering wheel, especially at higher speeds. This wobble can be accompanied by a feeling of instability or a loss of control.

- Uneven Tire Wear: A failing wheel bearing can cause uneven tire wear, particularly on one side of the vehicle. This is due to the uneven load distribution caused by the failing bearing.

- Vehicle Pulling: In some cases, a failing wheel bearing can cause the vehicle to pull to one side. This is due to the uneven load distribution caused by the failing bearing.

- Increased Steering Effort: A failing wheel bearing can increase the effort required to steer the vehicle. This is due to the increased friction caused by the failing bearing.

Causes of Frequent Wheel Bearing Failure

Wheel bearing failure is a common automotive issue, and while it’s normal for them to wear out eventually, frequent failures can indicate underlying problems that need to be addressed. This can be frustrating and costly, as it often leads to unexpected repairs and downtime. Understanding the root causes of premature wheel bearing failure is crucial for preventing future issues and ensuring a smoother driving experience.

Impact of Driving Conditions

Driving conditions significantly impact the lifespan of wheel bearings. Harsh environments and aggressive driving habits can accelerate wear and tear, leading to premature failure.

- Rough Roads: Driving on uneven or pothole-ridden roads subjects wheel bearings to constant shock and vibration, increasing stress and wear.

- Heavy Loads: Vehicles carrying heavy loads, such as towing trailers or hauling cargo, place additional stress on wheel bearings, increasing the risk of premature failure.

- Aggressive Driving: Frequent hard braking, accelerating, and cornering at high speeds can cause excessive strain on wheel bearings, leading to rapid wear and tear.

- Off-Road Driving: Driving on unpaved roads, trails, or in off-road conditions exposes wheel bearings to dust, dirt, and debris, which can accelerate wear and tear.

Maintenance Practices

Regular maintenance plays a crucial role in extending the life of wheel bearings. Neglecting routine inspections and lubrication can lead to premature failure.

- Lubrication: Wheel bearings are designed to operate with a thin layer of grease. Insufficient or contaminated grease can lead to friction and premature wear.

- Inspection: Regularly inspecting wheel bearings for signs of wear, damage, or excessive play can help identify problems early on, allowing for timely repairs.

- Wheel Alignment: Proper wheel alignment ensures even tire wear and reduces stress on wheel bearings, prolonging their lifespan.

Other Contributing Factors

Besides driving conditions and maintenance, other factors can contribute to frequent wheel bearing failure.

- Manufacturing Defects: Defective wheel bearings can fail prematurely due to faulty materials or manufacturing processes.

- Improper Installation: Incorrect installation of wheel bearings can lead to misalignment, excessive play, and premature wear.

- Corrosion: Exposure to salt, water, and other corrosive elements can damage wheel bearings, leading to premature failure.

Factors Affecting Wheel Bearing Life

Wheel bearings, crucial components for smooth and safe vehicle operation, are subject to wear and tear over time. Various factors contribute to their lifespan, and understanding these factors can help prevent premature failure and ensure a long-lasting, reliable driving experience.

Vehicle Weight and Load Capacity

The weight of a vehicle and its load capacity play a significant role in determining the lifespan of wheel bearings. Heavier vehicles, especially those carrying heavy loads, exert greater stress on bearings, leading to accelerated wear and tear.

The greater the load, the higher the force acting on the bearings, which can significantly reduce their lifespan.

For instance, a pickup truck hauling a heavy trailer will experience much higher loads on its wheel bearings compared to a compact car. This increased stress can cause the bearing components to wear down more quickly, resulting in premature failure.

Troubleshooting and Diagnosis

Diagnosing wheel bearing issues requires a systematic approach to pinpoint the root cause of failure. This involves a combination of visual inspection, listening for telltale signs, and potentially using diagnostic tools.

Visual Inspection

Visual inspection is the first step in diagnosing wheel bearing problems. It involves a thorough examination of the wheel bearing and surrounding components for signs of damage or wear.

- Look for signs of damage, such as cracks, pitting, or excessive wear on the bearing races, rollers, or seals.

- Inspect the bearing housing for any signs of damage, such as cracks or dents.

- Examine the wheel hub for signs of excessive play or looseness, which could indicate a worn bearing.

- Check the brake pads and rotors for signs of damage or wear, which can be a symptom of a failing wheel bearing.

Listening for Sounds

A failing wheel bearing often produces distinct sounds that can help diagnose the problem.

- Listen for a rumbling or grinding noise, especially when turning or braking.

- Pay attention to any whistling or screeching sounds, which could indicate a damaged bearing seal.

- Check for a clicking or popping noise when turning the wheel, which can be a sign of a loose bearing.

Using Diagnostic Tools

While visual inspection and listening for sounds can provide valuable information, using diagnostic tools can help confirm the diagnosis and identify the root cause of the failure.

- Bearing Tester: A bearing tester is a specialized tool that can measure the amount of play or looseness in a bearing. It can be used to assess the condition of the bearing and determine if it needs to be replaced.

- Digital Multimeter: A digital multimeter can be used to check the electrical resistance of the wheel bearing sensor, which can help identify a faulty sensor.

Professional Inspection and Repair

While some basic inspection and diagnosis can be done at home, it is highly recommended to seek professional assistance for a thorough inspection and repair of wheel bearings.

- A qualified mechanic has the experience and tools to accurately diagnose the problem and determine the best course of action for repair.

- Professional repair ensures that the wheel bearings are properly installed and adjusted, minimizing the risk of future problems.

Repair and Replacement: Why Does My Wheel Bearing Keep Going Bad

Replacing a faulty wheel bearing is a necessary procedure to restore the safe and smooth operation of your vehicle. This process involves removing the old bearing and installing a new one, requiring a combination of mechanical skills and specialized tools.

Tools and Equipment

The necessary tools and equipment for replacing a wheel bearing vary depending on the vehicle model and the specific bearing design. However, some common tools include:

- Jack and jack stands

- Lug wrench

- Torque wrench

- Wheel bearing puller

- Socket set

- Wrench set

- Hammer

- Pry bar

- Grease gun

- Clean rags

- Safety glasses

- Work gloves

It is crucial to have the appropriate tools and equipment in good condition to ensure a safe and efficient repair.

Importance of High-Quality Replacement Parts, Why does my wheel bearing keep going bad

Using high-quality replacement parts is paramount for ensuring the longevity and performance of your vehicle’s wheel bearings.

- Durability: High-quality bearings are manufactured with superior materials and precise tolerances, leading to increased durability and resistance to wear and tear.

- Performance: Properly designed and manufactured bearings contribute to smooth and quiet operation, reducing noise and vibration while driving.

- Safety: Defective bearings can lead to premature failure, potentially resulting in dangerous situations like wheel lock-up or complete axle failure. Using high-quality parts minimizes these risks.

Investing in high-quality replacement parts not only ensures a safer and more reliable driving experience but also helps avoid costly repairs down the line.

Keeping your wheel bearings in tip-top shape is crucial for a safe and enjoyable driving experience. By understanding the common causes of wheel bearing failure, you can take steps to prevent premature wear and tear. Regular maintenance, proper driving habits, and a keen eye for early warning signs can all help extend the life of your wheel bearings and keep your car running smoothly.

So, remember to listen to your car, take care of its vital components, and you’ll be rolling down the road with confidence for many miles to come.

FAQ Guide

What are the most common signs of a failing wheel bearing?

The most common signs include a grinding or roaring noise that gets louder as you speed up, a feeling of vibration or shaking in the steering wheel, and a noticeable wobble or uneven tire wear.

How often should I have my wheel bearings inspected?

It’s a good idea to have your wheel bearings inspected at least once a year or every 10,000 miles, whichever comes first. If you notice any of the warning signs, get them checked out immediately.

Can I replace a wheel bearing myself?

While it’s possible to replace a wheel bearing yourself, it’s a complex and potentially dangerous job. It’s best to have it done by a qualified mechanic who has the right tools and experience.