Can a bad wheel bearing cause Stabilitrak problems? The answer, unfortunately, is a resounding yes. Imagine cruising down the highway, feeling the reassuring grip of your car’s stability control system, only to find yourself in a terrifying skid. This unsettling scenario, while potentially alarming, can be traced back to a seemingly innocuous component: the wheel bearing. These often overlooked parts play a crucial role in vehicle stability, and their failure can have far-reaching consequences.

A bad wheel bearing can send the Stabilitrak system into a frenzy, causing it to misinterpret the vehicle’s motion and potentially react in unexpected ways. This is because a failing wheel bearing can disrupt the smooth rotation of the wheel, affecting the wheel speed sensors that feed critical data to the Stabilitrak system. The result can be a jarring, unsettling, and potentially dangerous driving experience.

Understanding Wheel Bearings and Their Function

Wheel bearings are crucial components in any vehicle, playing a vital role in supporting the weight of the vehicle and ensuring smooth, safe, and efficient operation. They allow the wheels to rotate freely while maintaining stability and handling.

Types of Wheel Bearings

Wheel bearings are classified into two main types:

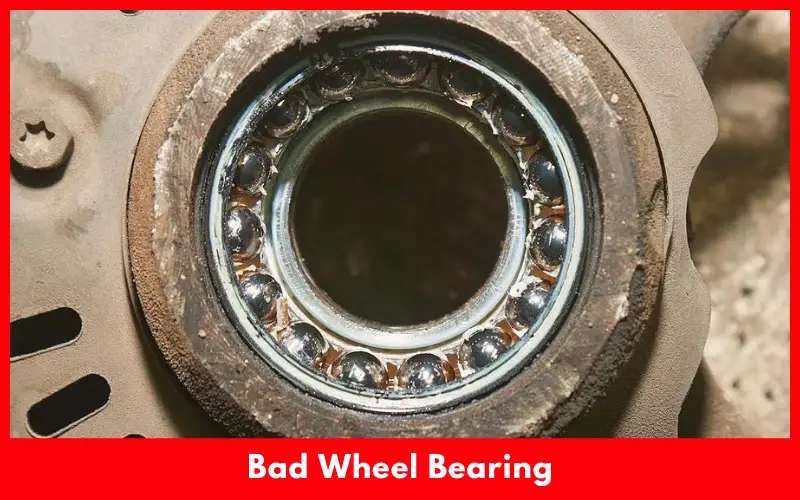

- Ball Bearings: These bearings consist of a series of steel balls that rotate between an inner and outer raceway. They are commonly found in older vehicles and offer relatively low friction and high load capacity.

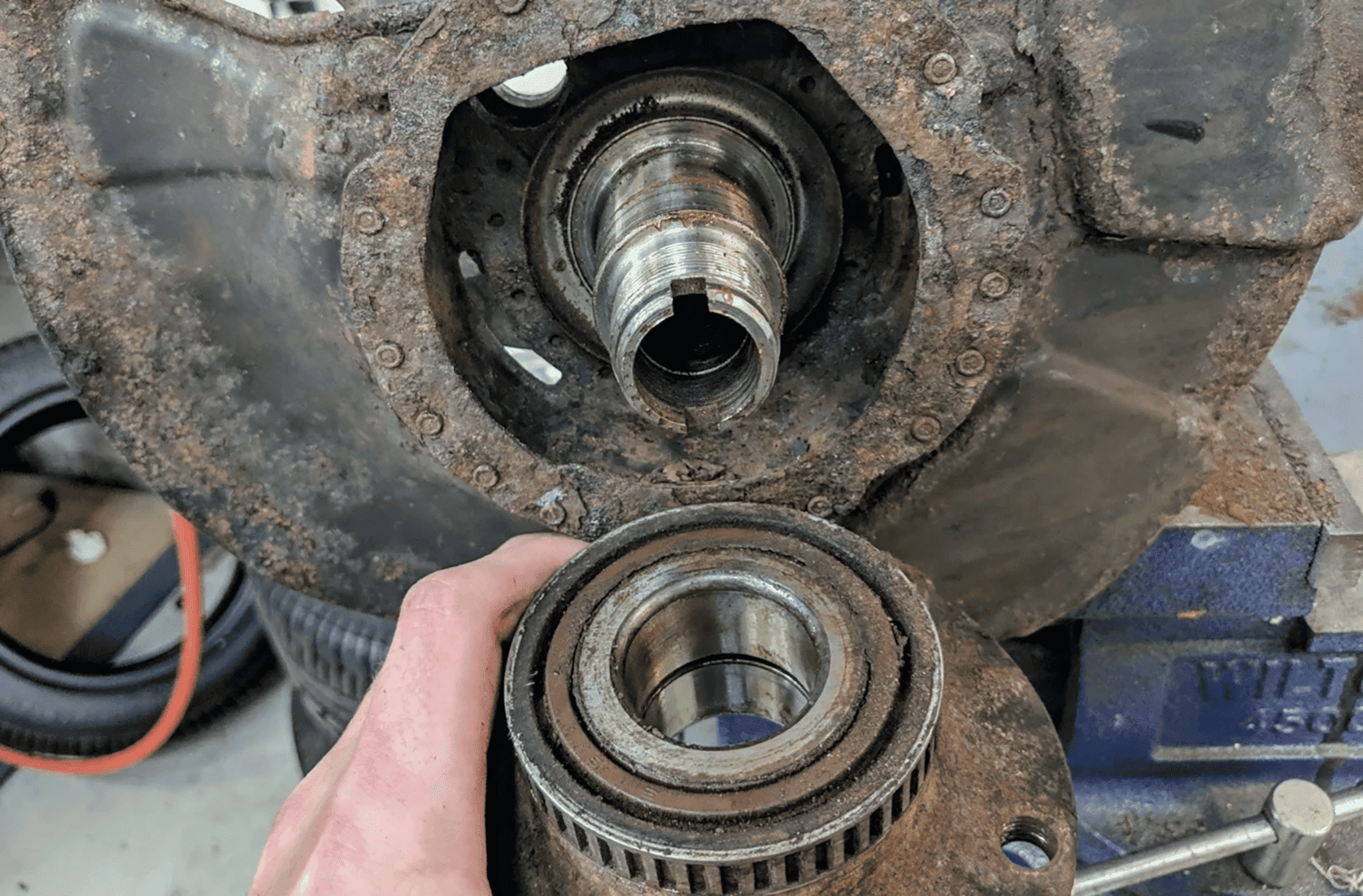

- Tapered Roller Bearings: These bearings use tapered rollers that rotate between a conical inner raceway and a cylindrical outer raceway. They provide higher load capacity and better resistance to axial loads compared to ball bearings, making them suitable for heavy-duty vehicles.

How a Wheel Bearing Works, Can a bad wheel bearing cause stabilitrak problems

A wheel bearing acts as a critical interface between the wheel hub and the suspension system. The bearing allows the wheel to rotate freely while supporting the vehicle’s weight.

- The wheel hub, which is attached to the wheel, is held in place by the bearing.

- The bearing is typically housed within a sealed unit, preventing contamination from dirt, water, and debris.

- When the vehicle is in motion, the wheel hub rotates, and the bearing allows this rotation to occur smoothly with minimal friction.

- The bearing also absorbs radial and axial loads, ensuring that the wheel remains properly aligned and stable during driving.

How a Bad Wheel Bearing Can Trigger Stabilitrak Problems

A bad wheel bearing can affect the Stabilitrak system, a safety feature designed to maintain vehicle stability, by interfering with the wheel speed sensors. These sensors play a crucial role in the Stabilitrak system’s operation, and a faulty wheel bearing can disrupt their accurate readings, leading to potential problems.

How a Bad Wheel Bearing Affects Wheel Speed Sensors

A bad wheel bearing can affect the wheel speed sensors by causing a variety of issues. These sensors are located near the wheel hub and use magnetic fields to detect the rotation of the wheel. When a wheel bearing fails, it can cause the wheel to wobble or vibrate, disrupting the magnetic field and leading to inaccurate readings from the sensor.

This disruption in the sensor’s readings can cause the Stabilitrak system to misinterpret the wheel’s speed and direction, potentially triggering unwanted interventions.

How the Stabilitrak System Interprets Wheel Speed Sensor Data

The Stabilitrak system relies on data from the wheel speed sensors to monitor the vehicle’s speed and direction. The system compares the speeds of each wheel to detect any inconsistencies or sudden changes. If the system detects a significant difference in wheel speed, it interprets this as a loss of traction or a potential skid. In such situations, the Stabilitrak system may intervene by applying brakes to individual wheels or reducing engine power to regain control and prevent a skid.

Scenarios Where a Bad Wheel Bearing Can Cause Stabilitrak Activation

A bad wheel bearing can cause the Stabilitrak system to activate in various scenarios. For example, if a wheel bearing fails and causes a wheel to spin at a different speed than the other wheels, the Stabilitrak system may detect this inconsistency and interpret it as a potential skid. This could lead to the system applying brakes to the affected wheel or reducing engine power, resulting in a noticeable intervention while driving.

Additionally, if the wheel bearing failure causes a significant vibration or wobble, the Stabilitrak system might interpret this as a loss of control and activate accordingly.

Diagnosing and Troubleshooting Stabilitrak Problems

Diagnosing Stabilitrak problems can be a bit tricky, as the system is designed to intervene discreetly and sometimes its errors can be subtle. However, with a methodical approach and the right tools, you can effectively pinpoint the source of the issue.

Diagnosing Stabilitrak Problems

When Stabilitrak malfunctions, it’s essential to understand that a bad wheel bearing isn’t the only culprit. Other issues like faulty sensors, wiring problems, or even software glitches can also trigger the system. Here’s a step-by-step approach to help you diagnose Stabilitrak problems:

- Check for warning lights: The Stabilitrak system usually has a dedicated warning light on the dashboard. If the light is illuminated, it’s a clear indication of a problem. This light may be accompanied by a message on the instrument cluster, providing further clues about the issue.

- Inspect the vehicle’s behavior: Pay attention to how the vehicle handles, especially during cornering or braking. If you notice any unusual pulling, drifting, or instability, it could be a sign of a Stabilitrak malfunction.

- Review the vehicle’s maintenance history: Check if any recent repairs or modifications have been performed, as these could be related to the Stabilitrak problem.

- Use a diagnostic scanner: A scan tool specifically designed for your vehicle’s make and model can retrieve diagnostic trouble codes (DTCs) stored in the Stabilitrak system’s control module. These codes provide valuable information about the specific component or circuit causing the issue.

- Check for loose connections: Inspect the wiring harness and connectors related to the Stabilitrak system. Loose connections can cause intermittent problems.

- Test the sensors: Use a multimeter to check the voltage output of the Stabilitrak sensors, such as the wheel speed sensors, steering angle sensor, and yaw rate sensor.

- Inspect the wheel bearings: If you suspect a wheel bearing is the culprit, check for signs of wear, damage, or excessive play.

Tools and Equipment

- Diagnostic scanner: A scan tool compatible with your vehicle’s make and model is essential for retrieving diagnostic trouble codes (DTCs) and accessing the Stabilitrak system’s data.

- Multimeter: A multimeter is useful for testing the voltage output of the Stabilitrak sensors and checking for electrical continuity in the wiring harness.

- Torque wrench: If you need to tighten or loosen any bolts or fasteners related to the Stabilitrak system, a torque wrench is essential for ensuring proper torque specifications.

- Technical manuals: Consult your vehicle’s service manual or a reputable online resource for detailed information on the Stabilitrak system, its components, and troubleshooting procedures.

Differentiating Stabilitrak Problems

While a bad wheel bearing can trigger Stabilitrak issues, other problems can also cause similar symptoms. To differentiate, consider the following:

- Wheel bearing noise: A bad wheel bearing often produces a distinctive grinding, roaring, or humming sound, especially when turning or driving at higher speeds. This sound is usually more pronounced when the vehicle is turning in a specific direction.

- Stabilitrak warning light: A Stabilitrak warning light may illuminate if the system detects a fault, even if the problem isn’t directly related to a wheel bearing.

- Vehicle behavior: If the vehicle pulls or drifts excessively during cornering or braking, it could indicate a problem with the steering system, suspension components, or even tire pressure.

- Diagnostic trouble codes: The DTCs retrieved using a scan tool can help pinpoint the specific component or circuit causing the Stabilitrak problem.

Preventive Measures and Maintenance: Can A Bad Wheel Bearing Cause Stabilitrak Problems

Preventing wheel bearing problems is a proactive approach to maintaining your vehicle’s stability and safety. Regular maintenance and inspections are crucial, along with using high-quality components.

Regular Vehicle Maintenance and Inspections

Regular maintenance and inspections play a vital role in preventing wheel bearing problems.

- Regular Inspections: Visual inspections for signs of wear and tear, such as grease leaks, cracks, or excessive play in the wheel, should be performed during routine oil changes or tire rotations. This helps identify potential issues early on.

- Lubrication: Wheel bearings require regular lubrication to reduce friction and wear. During routine maintenance, ensure that the bearings are adequately greased. Refer to your vehicle’s owner’s manual for recommended lubrication intervals.

- Wheel Alignment: Proper wheel alignment helps distribute weight evenly across the tires and reduces stress on the wheel bearings. Schedule regular wheel alignments, especially after hitting potholes or rough roads.

Using High-Quality Wheel Bearings and Components

Investing in high-quality wheel bearings and components is essential for long-term performance and reliability.

- OEM or Reputable Aftermarket Brands: Opt for original equipment manufacturer (OEM) parts or reputable aftermarket brands that meet or exceed OEM standards. These components are designed to withstand demanding conditions and offer extended service life.

- Proper Installation: Ensure that the wheel bearings are installed correctly by a qualified mechanic. Improper installation can lead to premature failure and potential safety hazards.

- Regular Monitoring: Keep an eye out for any unusual noises or vibrations that may indicate a potential wheel bearing problem. Address these issues promptly to prevent further damage.

Understanding the intricate relationship between wheel bearings and Stabilitrak systems is crucial for ensuring a safe and enjoyable driving experience. By recognizing the warning signs of a failing wheel bearing, taking preventative measures, and performing regular vehicle maintenance, you can minimize the risk of encountering Stabilitrak problems. Remember, a smooth ride starts with healthy wheels, and a vigilant driver is a safe driver.

Top FAQs

How do I know if my wheel bearing is bad?

Common signs include a grinding or humming noise when driving, a feeling of looseness or wobble in the steering wheel, and a noticeable vibration in the car, especially at higher speeds.

What are the risks of ignoring a bad wheel bearing?

Ignoring a bad wheel bearing can lead to premature tire wear, loss of control, and even a complete wheel failure, posing a serious safety hazard.

How often should I have my wheel bearings inspected?

It’s recommended to have your wheel bearings inspected as part of your regular vehicle maintenance, typically every 50,000 miles or as per your car’s manufacturer’s recommendations.