Can am wheel bearing – Can-Am wheel bearings, the unsung heroes of your off-road adventures, play a crucial role in ensuring smooth and safe rides. These bearings, responsible for supporting the weight of your vehicle and allowing the wheels to rotate freely, are subjected to constant stress and wear. Understanding their function, common issues, and proper maintenance is essential for maximizing your Can-Am’s performance and longevity.

This guide will delve into the intricacies of Can-Am wheel bearings, from their basic principles to the practical steps involved in diagnosing and replacing them. We’ll explore common problems, preventative measures, and the potential consequences of neglecting these vital components. By equipping yourself with this knowledge, you can ensure your Can-Am remains a reliable companion on all your off-road escapades.

Can-Am Wheel Bearing Basics

Can-Am vehicles, renowned for their off-road prowess, rely on robust wheel bearings to support the weight of the vehicle and facilitate smooth wheel rotation. These bearings are crucial components that ensure optimal performance and longevity of your Can-Am.

Types of Wheel Bearings Used in Can-Am Models

Wheel bearings in Can-Am vehicles are typically of two main types: tapered roller bearings and ball bearings.

- Tapered Roller Bearings: These bearings consist of tapered rollers that fit between a conical inner race and a cup-shaped outer race. The tapered design allows for efficient load distribution, making them ideal for handling heavy loads and high-speed applications. Tapered roller bearings are commonly found in Can-Am’s larger models, like the Maverick X3 and Outlander.

- Ball Bearings: Ball bearings utilize small, hard spheres that rotate between the inner and outer races. These bearings are known for their low friction and smooth operation, making them suitable for lighter loads and applications where high precision is required. Ball bearings are often found in smaller Can-Am models, such as the Spyder and Renegade.

Components of a Can-Am Wheel Bearing Assembly

A Can-Am wheel bearing assembly typically consists of the following components:

- Inner Race: The inner race is a metal ring that is pressed onto the axle shaft. It houses the rolling elements (rollers or balls) and provides a smooth surface for them to rotate on.

- Outer Race: The outer race is a metal ring that is pressed into the wheel hub. It also houses the rolling elements and provides a smooth surface for them to rotate against.

- Rolling Elements: These are the tapered rollers or balls that are responsible for supporting the load and allowing the wheel to rotate smoothly.

- Cage: The cage is a metal or plastic component that separates and spaces the rolling elements, preventing them from coming into contact with each other.

- Seal: The seal is a rubber or metal component that prevents dirt, water, and other contaminants from entering the bearing assembly.

Common Wheel Bearing Problems: Can Am Wheel Bearing

Recognizing the signs of a failing wheel bearing in your Can-Am is crucial for ensuring safe and enjoyable riding. Early detection and timely repair can prevent further damage and potential accidents. This section delves into the most common signs of wheel bearing failure, explores potential causes, and provides real-world examples to illustrate the importance of proper maintenance.

Signs of a Failing Wheel Bearing

Identifying the early signs of a failing wheel bearing is essential for timely repair and avoiding further damage. Here are some of the most common indicators:

- Noise: A grinding, roaring, or humming sound that increases with speed is a telltale sign of a failing wheel bearing. This sound often gets louder when turning or braking, and it might be accompanied by a vibration in the steering wheel.

- Vibration: If you feel a vibration in the steering wheel or the vehicle itself, particularly at higher speeds, it could indicate a worn-out wheel bearing. This vibration might be more noticeable when driving on rough terrain.

- Play in the Wheel: If you can feel a noticeable amount of play or looseness in the wheel when you try to move it back and forth, it could indicate a worn or damaged wheel bearing. This play can be felt in the steering wheel as well.

- Uneven Tire Wear: While not always a direct indication, uneven tire wear can sometimes be a symptom of a failing wheel bearing. If the bearing is worn, it can affect the alignment of the wheel, leading to uneven tire wear.

- Heating Up: If the wheel or hub area feels excessively hot to the touch, especially after driving, it could indicate a failing wheel bearing. The friction caused by a damaged bearing can generate heat.

Causes of Wheel Bearing Failure

Wheel bearing failure can be attributed to various factors, including:

- Wear and Tear: Over time, the components of a wheel bearing, such as the balls, races, and seals, wear down due to friction and load. This wear can lead to increased play and eventually failure.

- Improper Maintenance: Neglecting regular maintenance, such as lubricating the bearings, can accelerate wear and tear, leading to premature failure.

- Off-Road Use: Can-Ams designed for off-road adventures often encounter harsh conditions, such as rocks, mud, and water, which can put significant stress on wheel bearings. This stress can lead to premature wear and damage.

- Impact Damage: Hitting a large object or obstacle can damage the wheel bearing, causing it to fail prematurely. This can happen even if the impact doesn’t cause any visible damage to the wheel or tire.

- Corrosion: Exposure to water and other elements can lead to corrosion on the bearing components, which can reduce their effectiveness and cause premature failure.

Real-World Scenarios

Here are some examples of real-world scenarios where Can-Am wheel bearing issues have occurred:

- Off-Road Enthusiast: A Can-Am owner who frequently rides on rocky trails experienced a loud grinding noise from the front wheel after a particularly challenging ride. The noise worsened when turning, and the wheel had noticeable play. Inspection revealed a worn-out front wheel bearing, likely due to the harsh off-road conditions.

- Weekend Rider: A Can-Am owner who primarily uses their vehicle for weekend rides noticed a vibration in the steering wheel at highway speeds. The vibration became more pronounced when turning, and the wheel felt loose. A mechanic diagnosed a worn-out rear wheel bearing, likely due to a combination of wear and tear and lack of regular maintenance.

- Water Crossing: A Can-Am owner who crossed a deep puddle experienced a loud grinding noise from the front wheel shortly after. The noise persisted even on dry pavement, and the wheel had a significant amount of play. Inspection revealed a damaged front wheel bearing, likely due to water ingress and corrosion.

Diagnosing Wheel Bearing Problems

Diagnosing a faulty wheel bearing in a Can-Am ATV or side-by-side requires a systematic approach. The process involves careful observation, listening for specific sounds, and conducting a visual inspection. By understanding the symptoms and using the right tools, you can effectively identify a wheel bearing problem and prevent further damage.

Visual Inspection

A visual inspection can help you identify any obvious signs of damage or wear. Look for:

- Grease leaks: Excess grease or signs of leakage around the bearing seal indicate a potential problem.

- Loose or damaged components: Check for any loose or damaged components, such as the axle shaft, wheel hub, or bearing races.

- Visible rust or corrosion: Rust or corrosion on the bearing components can indicate water intrusion and potential bearing damage.

- Damaged seals: Examine the wheel bearing seals for any signs of damage or wear.

Sound Testing

Wheel bearing problems often manifest as distinct sounds.

- Grinding or roaring noise: A grinding or roaring noise, especially when turning or driving over bumps, is a common symptom of a worn or damaged bearing.

- Clicking or popping noise: Clicking or popping sounds, particularly when turning, may indicate a damaged or loose bearing race.

- Whistling or humming noise: A whistling or humming sound, often accompanied by vibration, can point to a worn or damaged bearing seal.

Other Considerations

While these symptoms are often associated with wheel bearing problems, it is important to consider other potential issues that might cause similar noises or vibrations:

- Tire issues: Uneven tire wear, a flat tire, or a damaged tire can produce noises similar to a bad wheel bearing.

- Suspension problems: Worn or damaged suspension components, such as ball joints, tie rod ends, or control arm bushings, can also cause noise and vibration.

- Brake problems: Worn or damaged brake pads or rotors can generate noises that resemble a bad wheel bearing.

Tools and Equipment

For an effective diagnosis, you will need the following tools:

- Jack and jack stands: To safely lift the Can-Am and access the wheel bearing.

- Lug wrench: To remove the wheel.

- Torque wrench: To ensure proper tightening of the wheel nuts.

- Pry bar: To help separate the wheel hub from the axle shaft if needed.

- Inspection mirror: To provide a better view of the bearing and surrounding components.

- Stethoscope: To amplify sounds and pinpoint the source of the noise.

Differentiating Wheel Bearing Issues from Other Problems

Distinguishing between wheel bearing issues and other potential problems requires careful observation and listening.

- Wheel bearing noise is typically localized to a specific wheel. It intensifies when turning or driving over bumps, and the sound often changes depending on the direction of travel.

- Tire issues usually produce a consistent noise regardless of steering input or driving conditions.

- Suspension problems often cause noises that are more pronounced when driving over bumps or rough terrain.

- Brake problems typically produce a grinding or squealing noise that intensifies when applying the brakes.

Replacing Wheel Bearings

Replacing a Can-Am wheel bearing is a task that requires a degree of mechanical aptitude and the right tools. It’s essential to follow the correct steps to ensure a successful and safe replacement.

Tools and Equipment

Before you begin, gather the necessary tools and equipment. This will ensure a smooth and efficient process.

- Jack and jack stands

- Torque wrench

- Socket set

- Breaker bar

- Hammer

- Pry bar

- Grease gun

- New wheel bearing

- Wheel bearing race and seal

- Clean rags

- Safety glasses

- Gloves

Step-by-Step Guide

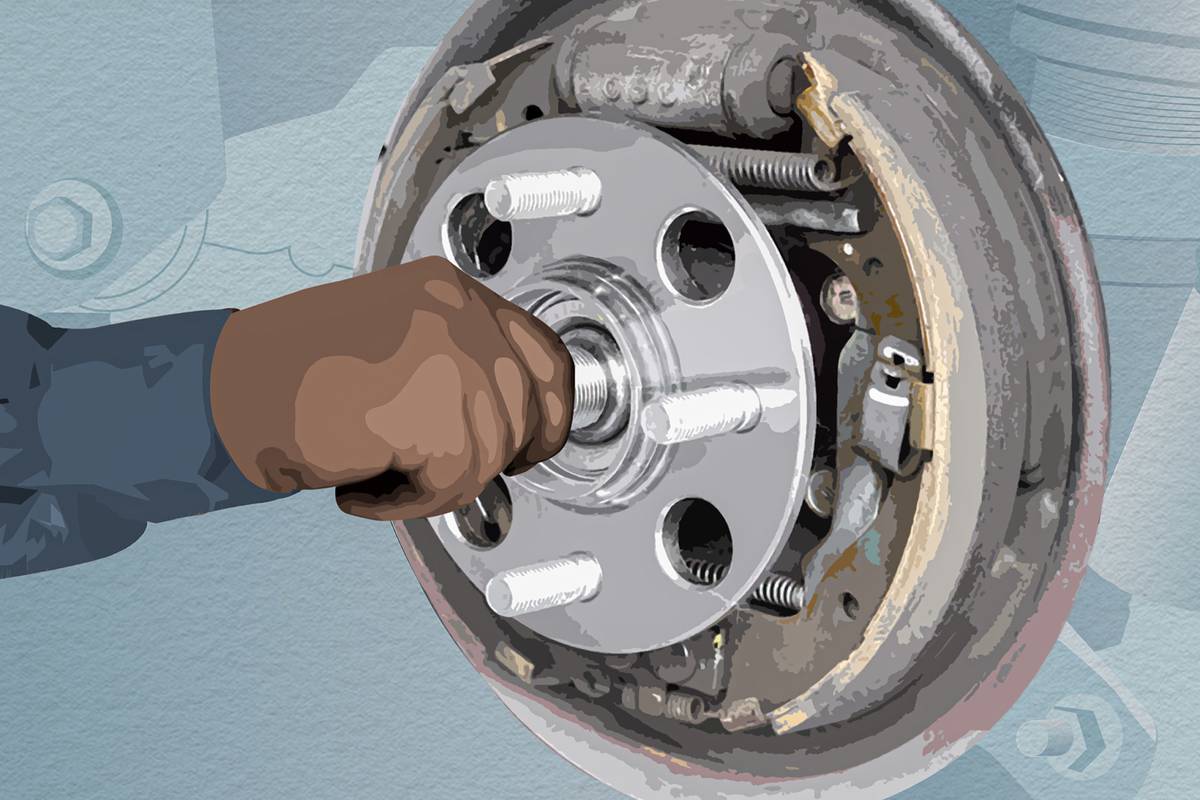

Replacing a Can-Am wheel bearing involves a series of steps that need to be followed carefully.

- Park the vehicle on a level surface and engage the parking brake. Ensure the vehicle is stable and secure before proceeding.

- Loosen the lug nuts on the wheel you’ll be working on. This is easier to do before jacking up the vehicle.

- Jack up the vehicle and support it with jack stands. Ensure the jack stands are securely positioned under the vehicle’s frame, not just the suspension.

- Remove the wheel. Once the vehicle is securely supported, remove the lug nuts and take off the wheel.

- Remove the brake caliper. Using a wrench, loosen the caliper mounting bolts and remove the caliper. Be careful not to damage the brake lines.

- Remove the rotor. The rotor is typically secured by a few bolts. Once these are removed, the rotor can be pulled off the hub.

- Remove the old wheel bearing. Use a hammer and pry bar to gently tap the old bearing out of the hub. Be careful not to damage the hub.

- Install the new wheel bearing. Carefully install the new bearing into the hub. Ensure it’s seated properly and not damaged.

- Install the new race and seal. The race and seal are essential components of the wheel bearing assembly. Install them according to the manufacturer’s instructions.

- Reinstall the rotor and brake caliper. Secure the rotor with the bolts and reattach the caliper, ensuring the brake lines are not kinked or damaged.

- Install the wheel and tighten the lug nuts. Ensure the lug nuts are tightened to the manufacturer’s specifications using a torque wrench.

- Lower the vehicle and remove the jack stands. Once the vehicle is safely on the ground, remove the jack stands.

- Test drive the vehicle. Take a short test drive to ensure the wheel bearing is functioning properly and there are no unusual noises or vibrations.

Tips and Advice

Here are some tips to ensure a successful and safe replacement:

- Use a torque wrench to tighten the lug nuts to the correct specifications. Over-tightening can damage the wheel studs, while under-tightening can cause the wheel to loosen and potentially come off.

- Apply grease to the new bearing and race. This will help to reduce friction and wear. Use a grease gun to apply a generous amount of grease.

- Be careful not to damage the hub when removing the old bearing. A damaged hub will require replacement, adding to the cost of the repair.

- Inspect the brake pads and rotors for wear and tear. If they’re worn, they should be replaced at the same time as the wheel bearing.

- If you’re not comfortable replacing the wheel bearing yourself, take it to a qualified mechanic. They have the experience and tools to do the job safely and correctly.

Maintenance and Prevention

Prolonging the life of your Can-Am wheel bearings goes beyond just replacing them when they fail. Implementing a proactive maintenance strategy is crucial to ensure optimal performance and prevent premature wear. Regular inspections and lubrication are essential components of this strategy, along with adopting preventive measures to minimize the risk of bearing failure.

Regular Inspections

Regular inspections are the cornerstone of proactive wheel bearing maintenance. Visual inspections allow you to identify early signs of wear and tear, preventing minor issues from escalating into major problems.

- Visual Inspection: Look for signs of damage, such as cracks, dents, or excessive wear on the bearing races and seals. Also, check for any signs of leakage, indicating a potential seal failure.

- Rotation Test: Rotate the wheel by hand and listen for any unusual noises, such as grinding, clicking, or humming. These sounds are often indicative of worn or damaged bearings.

- Play Check: Check for excessive play in the wheel by attempting to move it in and out or up and down. This can indicate loose bearings or worn bearing races.

Lubrication

Proper lubrication is vital for reducing friction and heat generation within the wheel bearings.

- Type of Grease: Use a high-quality, lithium-based grease specifically designed for wheel bearings. Consult your Can-Am owner’s manual for recommended grease specifications.

- Frequency: Lubricate the wheel bearings every 500-1000 miles or according to the manufacturer’s recommendations.

- Procedure: Remove the wheel, clean the bearing races and seals thoroughly, and pack the bearings with fresh grease. Ensure that the grease is evenly distributed and that the seals are properly seated.

Preventative Measures

Taking preventative measures can significantly reduce the risk of wheel bearing failure.

- Avoid Overloading: Exceeding the vehicle’s weight capacity puts extra stress on the wheel bearings, increasing the risk of premature wear.

- Maintain Tire Pressure: Incorrect tire pressure can cause uneven wear and tear on the bearings. Regularly check and adjust tire pressure to the manufacturer’s recommendations.

- Avoid Aggressive Driving: Aggressive driving habits, such as sudden acceleration and braking, can generate excessive heat and stress on the bearings.

- Inspect and Replace Damaged Components: If you notice any damage to the wheel hub, axles, or suspension components, replace them promptly to prevent further damage to the bearings.

Impact of Wheel Bearing Failure

Ignoring a faulty wheel bearing can have serious consequences, affecting both your safety and the longevity of your Can-Am. Understanding the potential risks associated with driving with a damaged wheel bearing is crucial for ensuring a safe and enjoyable riding experience.

Safety Risks Associated with Driving with a Damaged Wheel Bearing

A damaged wheel bearing can lead to a range of safety hazards, putting you and others at risk. Here are some of the key concerns:

- Loss of Vehicle Control: A damaged wheel bearing can cause the wheel to wobble or even detach from the vehicle. This loss of control can lead to accidents, especially at high speeds.

- Tire Failure: The excessive heat generated by a failing bearing can damage the tire, causing it to blow out. This sudden tire failure can result in a loss of control and a serious accident.

- Suspension Damage: The stress on the suspension components from a failing bearing can cause damage to other parts of the suspension system, further compromising the vehicle’s stability and control.

Impact on Vehicle Performance and Handling

A damaged wheel bearing can significantly impact the performance and handling of your Can-Am. Here are some common symptoms:

- Unusual Noise: A damaged wheel bearing will often make a grinding, humming, or roaring noise, especially when turning or driving over bumps. This noise will typically increase in intensity as the bearing deteriorates.

- Vibration: A damaged wheel bearing can cause vibrations in the steering wheel or throughout the vehicle, especially at higher speeds.

- Uneven Tire Wear: A damaged wheel bearing can cause uneven tire wear, leading to premature tire replacement.

- Difficulty Steering: A damaged wheel bearing can make it difficult to steer, especially at low speeds or when turning.

Choosing the Right Wheel Bearings

Selecting the right wheel bearings for your Can-Am is crucial for ensuring smooth operation, optimal performance, and longevity. The wrong bearings can lead to premature wear, noise, and even catastrophic failure. This section provides guidance on selecting the appropriate wheel bearings for your specific Can-Am model, comparing different brands and types available in the market, and discussing key factors to consider for replacement bearings.

Wheel Bearing Types and Brands

Choosing the right wheel bearing involves understanding the different types available and the brands that offer reliable quality.

- Tapered Roller Bearings: These bearings are commonly used in Can-Am vehicles due to their high load capacity and durability. They consist of tapered rollers that fit between an inner and outer raceway, providing excellent support for radial and axial loads. Popular brands include Timken, SKF, and Koyo.

- Ball Bearings: While less common in Can-Am applications, ball bearings offer smoother operation and lower friction compared to tapered roller bearings. They are typically used in applications with lighter loads and higher speeds. Brands like FAG and INA are well-known for their ball bearings.

Factors to Consider When Choosing Replacement Bearings, Can am wheel bearing

When selecting replacement wheel bearings, several factors influence the decision:

- Quality and Durability: Opting for high-quality bearings from reputable brands ensures long-term performance and reduces the risk of premature failure. Look for bearings made from high-quality materials and with precise tolerances.

- Load Capacity: Ensure the bearings have sufficient load capacity to handle the weight and stress your Can-Am experiences. This is particularly important for off-road vehicles that encounter extreme conditions and heavy loads.

- Price: While price is a factor, it should not be the primary consideration. Choosing cheaper bearings may lead to early failure and costly repairs in the long run. Striking a balance between quality and affordability is essential.

Choosing the Right Wheel Bearing for Your Can-Am

The best way to ensure you choose the right wheel bearing for your Can-Am is to consult your owner’s manual or a reputable parts dealer. They can provide specific recommendations based on your model year, trim level, and intended use.

Maintaining your Can-Am wheel bearings is a crucial aspect of responsible off-roading. By understanding their function, recognizing signs of failure, and implementing proper maintenance practices, you can significantly extend their lifespan and ensure your vehicle remains safe and reliable. Remember, proactive care is the key to a smooth and enjoyable off-road experience.

Q&A

What are the most common signs of a failing wheel bearing in a Can-Am?

Common signs include unusual noises like grinding, humming, or clicking sounds, especially when turning or driving at high speeds. You may also experience vibrations in the steering wheel or feel a looseness in the wheel.

How often should I inspect my Can-Am wheel bearings?

It’s recommended to inspect your wheel bearings every 5,000 miles or after any significant off-road use. Check for signs of wear, damage, or excessive play in the bearings.

Can I use generic wheel bearings instead of OEM parts?

While generic bearings may be cheaper, it’s generally recommended to use OEM (Original Equipment Manufacturer) parts for optimal performance and compatibility with your Can-Am model.

What is the best way to lubricate my Can-Am wheel bearings?

Use a high-quality grease specifically designed for wheel bearings. Consult your Can-Am owner’s manual for the recommended grease type and application method.