Can tantalum rings be cut off? This question, while seemingly simple, delves into the fascinating world of tantalum, a metal renowned for its unique properties and diverse applications. From its use in high-end jewelry to its role in medical implants, tantalum’s durability and biocompatibility have made it a prized material. But what happens when you need to remove a tantalum ring?

Can it be cut, or does its strength pose an insurmountable obstacle?

This article explores the challenges and techniques involved in cutting tantalum rings, highlighting the importance of safety precautions and exploring alternative materials for ring construction. We’ll also delve into the ethical and environmental considerations surrounding tantalum mining and processing, shedding light on the complexities of this valuable metal.

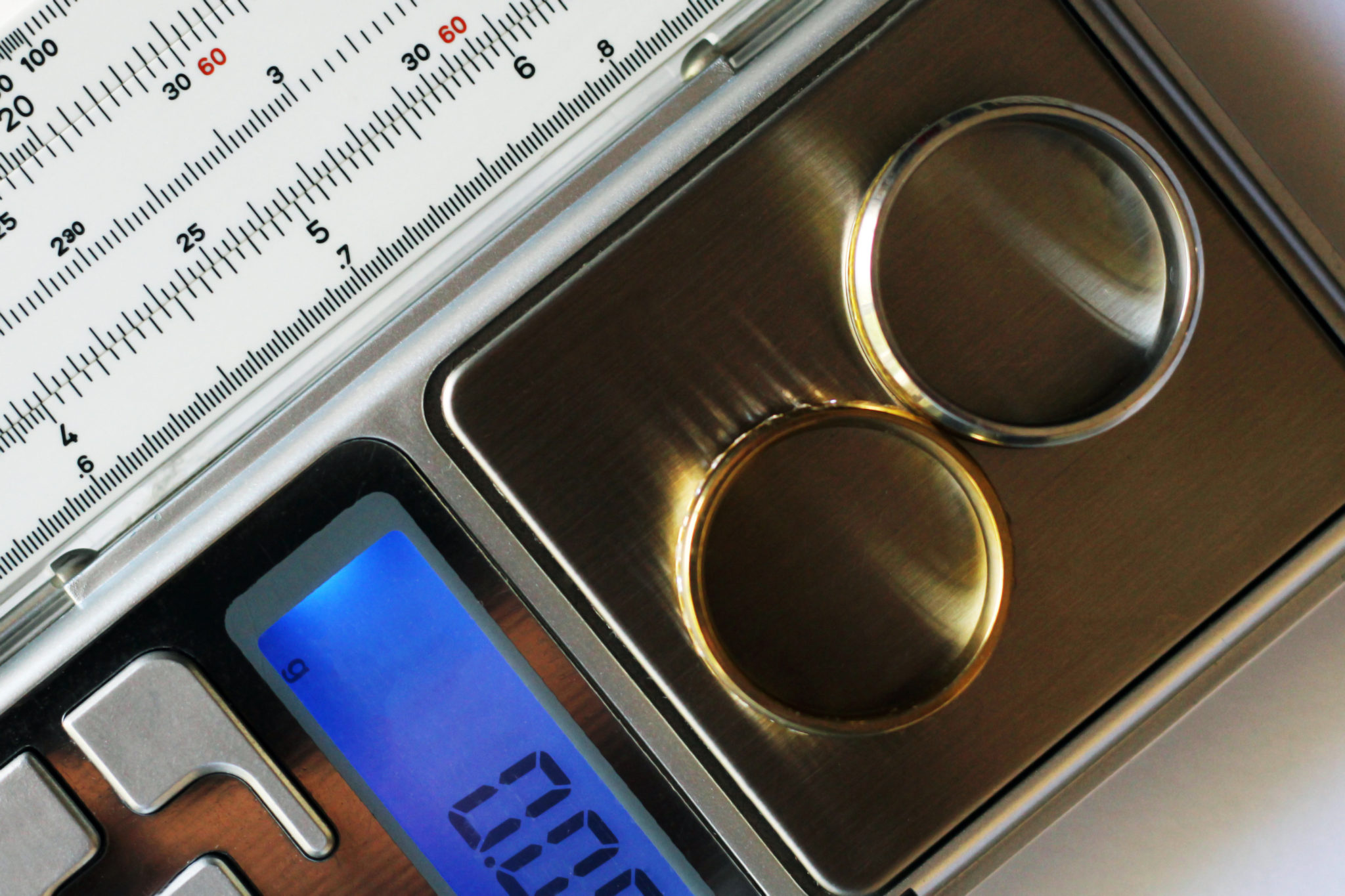

Tantalum Rings

Tantalum rings are a relatively new addition to the jewelry market, gaining popularity due to their unique properties and aesthetic appeal. Tantalum is a rare, hard, and corrosion-resistant transition metal, making it an ideal material for jewelry, particularly rings.

Tantalum Properties and Applications

Tantalum possesses several properties that make it suitable for ring construction. Its high melting point, hardness, and resistance to corrosion ensure its durability and longevity. Additionally, tantalum is hypoallergenic, making it an excellent choice for individuals with sensitive skin.

- High Melting Point: Tantalum has one of the highest melting points among all elements, reaching 3017 °C (5463 °F). This exceptional heat resistance makes tantalum rings highly durable and resistant to deformation under extreme temperatures.

- Hardness: Tantalum’s hardness is comparable to that of steel, making it resistant to scratching and wear. This property ensures that tantalum rings retain their pristine appearance over time.

- Corrosion Resistance: Tantalum exhibits remarkable resistance to corrosion, even in aggressive environments. It is inert to most acids, including aqua regia, a mixture of nitric and hydrochloric acids that can dissolve gold and platinum. This exceptional corrosion resistance makes tantalum ideal for applications where chemical stability is paramount.

- Biocompatibility: Tantalum is biocompatible, meaning it does not trigger allergic reactions or cause tissue rejection. This property makes it suitable for medical implants, including bone plates, screws, and stents. Tantalum’s biocompatibility and corrosion resistance are particularly advantageous for long-term implants, ensuring minimal tissue irritation and implant longevity.

Applications of Tantalum Rings

Tantalum rings are increasingly popular in jewelry and medical applications.

- Jewelry: Tantalum rings are valued for their durability, hypoallergenic properties, and unique aesthetic appeal. They are available in various colors, including silver, black, and blue, achieved through surface treatments like anodization. Tantalum rings offer a distinctive alternative to traditional precious metals, appealing to individuals seeking unique and durable jewelry.

- Medical Implants: Tantalum’s biocompatibility and corrosion resistance make it a valuable material for medical implants. Tantalum rings are used as medical implants, particularly in bone reconstruction and dental applications. They are highly resistant to corrosion and tissue rejection, ensuring long-term implant stability and minimizing the risk of complications.

Durability and Biocompatibility of Tantalum Rings

Tantalum rings are highly durable due to their inherent properties. Their high melting point and hardness make them resistant to scratching, wear, and deformation. The corrosion resistance of tantalum ensures that the rings retain their pristine appearance over time, even in harsh environments.

- Durability: Tantalum rings are known for their durability and longevity. They are resistant to scratching, wear, and deformation, making them ideal for everyday wear. Tantalum’s hardness ensures that the rings retain their original shape and luster over time, even with regular use.

- Biocompatibility: Tantalum’s biocompatibility makes it an excellent choice for medical implants. It does not trigger allergic reactions or cause tissue rejection, ensuring long-term implant stability and minimizing the risk of complications. Tantalum’s inertness and biocompatibility make it ideal for individuals with sensitive skin or allergies to other metals.

Cutting Tantalum Rings

Tantalum is a highly refractory metal, renowned for its exceptional strength, high melting point, and resistance to corrosion. These properties, while advantageous in many applications, pose significant challenges when it comes to cutting tantalum rings. The inherent hardness and high melting point of tantalum necessitate specialized cutting techniques that can effectively overcome these obstacles.

Cutting Techniques for Tantalum Rings, Can tantalum rings be cut off

The cutting of tantalum rings requires specialized techniques due to its unique properties. Several methods have been developed to address the challenges posed by its high melting point and hardness.

- Laser Cutting: This method utilizes a focused laser beam to melt and vaporize the material, creating a precise cut. Laser cutting offers high precision and minimal heat-affected zones, making it suitable for intricate designs. The laser beam’s focused energy allows for accurate cuts, minimizing material waste and ensuring a clean surface finish.

- Diamond Sawing: This technique involves using a diamond-impregnated saw blade to cut through the tantalum. The diamond’s exceptional hardness allows it to effectively cut through the metal. Diamond sawing is particularly effective for cutting thick tantalum rings, and it offers a relatively smooth surface finish. However, it is a slower process compared to laser cutting.

- Electrochemical Machining (ECM): ECM utilizes an electrochemical process to remove material. A tool electrode is used to create a precise cut by dissolving the tantalum through an electrochemical reaction. ECM is a highly precise method that can achieve intricate shapes, but it requires specialized equipment and expertise.

Safety and Precautions for Cutting Tantalum Rings

Cutting tantalum rings presents unique safety challenges due to the material’s properties. Tantalum is a hard, dense metal that can generate significant heat during cutting, creating potential hazards from dust, fumes, and sparks. Therefore, implementing proper safety precautions is crucial to protect workers and the environment.

Safety Hazards Associated with Cutting Tantalum

Cutting tantalum rings can generate various safety hazards, requiring appropriate safety measures and protective equipment.

- Tantalum Dust: Cutting tantalum produces fine dust particles that can be inhaled, posing a respiratory hazard. Tantalum dust is not considered carcinogenic, but prolonged exposure can irritate the lungs and lead to respiratory problems.

- Tantalum Fumes: Cutting tantalum, especially at high temperatures, can release fumes containing tantalum oxides. These fumes can irritate the eyes, skin, and respiratory system.

- Sparks: Cutting tantalum produces sparks that can ignite flammable materials. This risk is particularly high when cutting tantalum in an environment with combustible materials.

- Noise: Cutting tantalum rings can generate significant noise, potentially causing hearing damage if appropriate ear protection is not used.

Safety Precautions for Cutting Tantalum Rings

To minimize the risks associated with cutting tantalum rings, it is essential to implement the following safety precautions:

- Personal Protective Equipment (PPE): Workers handling tantalum during cutting should wear appropriate PPE, including:

- Respiratory Protection: A respirator with a high-efficiency particulate air (HEPA) filter is essential to prevent inhalation of tantalum dust.

- Eye Protection: Safety glasses or goggles are required to protect the eyes from sparks and dust.

- Skin Protection: Gloves made of a material resistant to tantalum dust and sparks should be worn. Long-sleeved clothing and closed-toe shoes are also recommended.

- Hearing Protection: Earmuffs or earplugs are necessary to protect against the noise generated during cutting.

- Ventilation: Adequate ventilation is crucial to remove tantalum dust and fumes from the work area. Use a local exhaust ventilation system (LEV) to capture the dust and fumes at the source.

- Fire Safety: Keep a fire extinguisher readily available in the work area. Remove any flammable materials from the vicinity of the cutting operation.

- Waste Disposal: Dispose of tantalum dust and scrap in a safe and environmentally responsible manner. Follow local regulations for hazardous waste disposal.

- Training: Workers handling tantalum should receive proper training on the risks associated with the material and the necessary safety precautions.

Importance of Proper Ventilation and Waste Disposal

- Ventilation: Proper ventilation is essential for protecting workers from the hazards of tantalum dust and fumes. An LEV system is highly recommended, as it captures the dust and fumes at the source, preventing them from spreading throughout the work area.

- Waste Disposal: Tantalum dust and scrap should be disposed of properly to prevent environmental contamination. Local regulations for hazardous waste disposal should be strictly followed.

Alternative Materials for Rings: Can Tantalum Rings Be Cut Off

Rings are enduring symbols of love, commitment, and personal style. While tantalum offers unique properties for ring construction, other materials have also been widely used, each with its own advantages and disadvantages. This section explores common ring materials, comparing their properties and applications to better understand tantalum’s place in the world of jewelry.

Comparison of Ring Materials

The choice of material for a ring depends on factors like durability, aesthetics, affordability, and personal preference. Here’s a table comparing the properties and applications of popular ring materials:

| Material | Properties | Applications | Advantages/Disadvantages |

|---|---|---|---|

| Gold |

|

|

Advantages:

Disadvantages:

|

| Platinum |

|

|

Advantages:

Disadvantages:

|

| Titanium |

|

|

Advantages:

Disadvantages:

|

| Stainless Steel |

|

|

Advantages:

Disadvantages:

|

Tantalum, with its exceptional hardness, biocompatibility, and resistance to corrosion, presents unique advantages for ring construction. While its high melting point poses challenges for traditional jewelry-making techniques, its durability and hypoallergenic nature make it a promising alternative for individuals seeking a long-lasting and comfortable ring.

Ethical and Environmental Considerations for Tantalum Mining and Processing

Tantalum, a highly sought-after metal used in various technologies, faces ethical and environmental challenges due to its extraction and processing methods. Understanding these concerns is crucial for promoting responsible sourcing and sustainable practices within the tantalum industry.

Ethical Implications of Tantalum Mining

The ethical implications of tantalum mining stem from its association with conflict zones and potential human rights abuses. The sourcing of tantalum from conflict-affected areas, particularly in the Democratic Republic of Congo (DRC), has raised serious concerns.

- Conflict Minerals: Tantalum has been labeled a “conflict mineral” due to its role in funding armed groups and fueling conflicts in the DRC. These groups often exploit local populations, engage in violence, and violate human rights.

- Human Rights Abuses: Reports of forced labor, child labor, and unsafe working conditions in tantalum mines have been documented. The lack of regulation and enforcement in conflict zones can lead to the exploitation of vulnerable populations.

- Transparency and Traceability: The opaque nature of the tantalum supply chain makes it difficult to track the origin of the metal and ensure ethical sourcing. This lack of transparency hinders efforts to address human rights violations and conflict financing.

Environmental Impacts of Tantalum Extraction and Processing

The extraction and processing of tantalum can have significant environmental impacts, particularly in areas with limited environmental regulations.

- Habitat Destruction: Tantalum mining often involves the clearing of forests and other natural habitats, leading to biodiversity loss and ecosystem disruption.

- Water Pollution: Mining operations can contaminate water sources with heavy metals, chemicals, and sediment. This pollution can harm aquatic life, affect human health, and degrade water quality.

- Air Pollution: Processing tantalum ores can release harmful pollutants into the air, including dust, particulate matter, and greenhouse gases. This can contribute to respiratory problems and climate change.

Responsible Sourcing and Sustainable Practices

Addressing the ethical and environmental concerns associated with tantalum mining requires a commitment to responsible sourcing and sustainable practices.

- Due Diligence: Companies involved in the tantalum supply chain must conduct due diligence to ensure that the metal they source is conflict-free and produced ethically.

- Transparency and Traceability: Establishing transparent and traceable supply chains is crucial for identifying and addressing human rights violations and environmental impacts.

- Sustainable Mining Practices: Implementing sustainable mining practices, such as minimizing habitat destruction, reducing water pollution, and promoting worker safety, is essential for environmental protection.

- Recycling and Reuse: Recycling and reusing tantalum can help reduce the demand for newly mined metal, mitigating environmental impacts and ethical concerns.

Cutting tantalum rings presents a unique set of challenges due to the metal’s exceptional hardness and high melting point. However, with the right techniques and safety precautions, it is possible to remove a tantalum ring safely and effectively. Understanding the properties of tantalum, the available cutting methods, and the ethical implications of its extraction is crucial for making informed decisions about this versatile material.

Whether you’re a jeweler, a medical professional, or simply curious about the world of metals, the knowledge gained from this exploration will provide valuable insights into the fascinating realm of tantalum.

FAQ Overview

What are the main applications of tantalum rings?

Tantalum rings are used in various applications, including high-end jewelry, medical implants, and industrial components. Their biocompatibility and resistance to corrosion make them ideal for implants, while their durability and lustrous finish make them popular in jewelry.

Is it safe to cut a tantalum ring yourself?

Cutting tantalum rings can be hazardous due to the potential for dust, fumes, and sparks. It is highly recommended to seek professional assistance from a qualified jeweler or metalworker.

What are some alternative materials for rings besides tantalum?

Common alternatives to tantalum for rings include gold, platinum, titanium, and stainless steel. Each material offers unique properties and applications, and the best choice depends on individual preferences and needs.