How much to true a bike wheel sets the stage for this enthralling narrative, offering readers a glimpse into a story that is rich in detail and brimming with originality from the outset. A well-trued wheel is the foundation of a smooth and enjoyable ride, ensuring optimal performance and a comfortable experience. But how much does it cost to achieve this perfect balance?

This comprehensive guide delves into the intricacies of wheel truing, exploring the essential techniques, tools, and costs involved in bringing your wheels back to their pristine state.

From understanding the basics of wheel trueness to mastering the art of adjusting spoke tension, we’ll unravel the secrets of wheel truing and empower you with the knowledge to make informed decisions about maintaining your bike’s wheels. Whether you’re a seasoned cyclist or a novice rider, this guide will equip you with the tools and insights needed to navigate the world of wheel truing with confidence.

Understanding Wheel Truing Basics

A well-trued wheel is crucial for a smooth and efficient ride. It ensures that the wheel rotates smoothly and evenly, minimizing friction and improving overall bike performance. A true wheel is a wheel that is perfectly round and balanced, with all spokes evenly tensioned.

Wheel Imperfections and Their Impact

Wheel imperfections can lead to a variety of issues, affecting both the ride quality and the longevity of your wheel. Common imperfections include:

- Wobble: This occurs when the wheel wobbles or oscillates as it rotates, often caused by uneven spoke tension or a bent rim. Wobble can cause a bumpy ride and put stress on the wheel, leading to premature wear.

- Hop: A hop is a sudden jump or bump in the wheel’s rotation, typically caused by a spoke that is too loose or a dent in the rim. Hops can cause a jarring sensation and potentially damage the wheel.

- Lateral Runout: This refers to the side-to-side deviation of the wheel from its center axis. Lateral runout can be caused by uneven spoke tension or a bent rim. It can lead to uneven tire wear and affect braking performance.

Essential Tools for Wheel Truing

To true a wheel effectively, you’ll need the following tools:

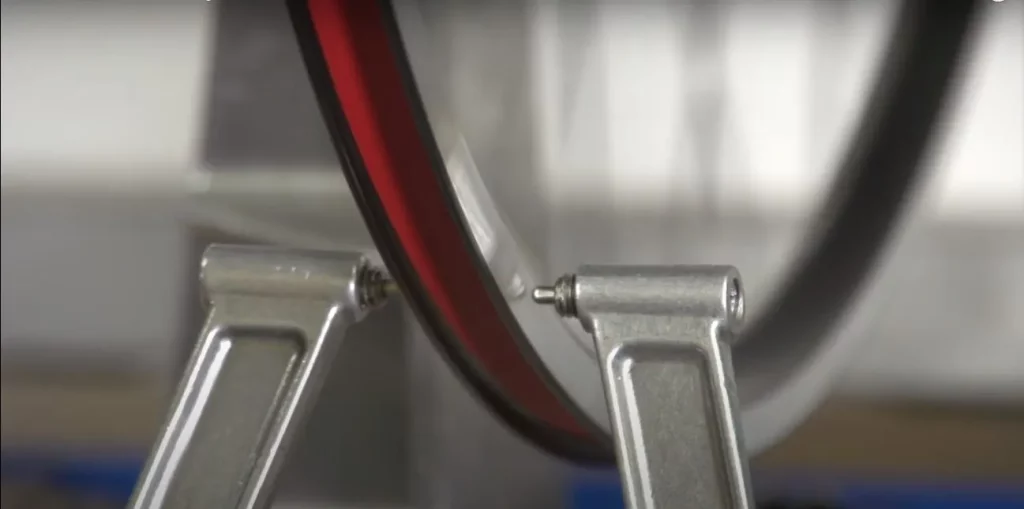

- Truing Stand: A truing stand is a specialized tool that holds the wheel securely in place while you adjust the spokes. It allows you to rotate the wheel and observe any imperfections.

- Spoke Wrench: A spoke wrench is used to tighten and loosen the spokes. It comes in various sizes to fit different spoke nipples.

- Tension Meter: A tension meter measures the tension of individual spokes. This helps you ensure that all spokes are evenly tensioned, contributing to a true wheel.

Assessing Wheel Trueness: How Much To True A Bike Wheel

Before you begin adjusting your wheel, it’s crucial to understand its current state. This involves a thorough visual inspection and using specialized tools to identify any imperfections. This assessment will guide your truing process and help you achieve the best possible results.

Visual Inspection

A visual inspection is the first step in assessing your wheel’s trueness. This involves examining the wheel from different angles to identify any obvious deviations.

- Spin the wheel: Rotate the wheel slowly and observe its movement. Look for any wobbles, hops, or lateral movement.

- Check for spoke tension: Visually inspect the spokes for any signs of looseness or excessive tension. Loose spokes will appear slack, while overly tight spokes may be bowed or have a pronounced curve.

- Observe the rim: Check for any dents, cracks, or other damage to the rim. These imperfections can affect the wheel’s trueness and overall performance.

- Examine the hub: Ensure the hub is properly seated and that the bearings are smooth and free of any play.

These visual checks provide a basic understanding of your wheel’s condition and can help you pinpoint areas that require further investigation.

Truing Stand

A truing stand is an essential tool for accurately assessing and adjusting wheel trueness. It allows you to precisely measure and correct any deviations in the wheel’s rim and spokes.

- Mount the wheel: Securely mount the wheel onto the truing stand, ensuring it’s properly centered.

- Rotate the wheel: Spin the wheel and observe its movement in relation to the stand’s reference points.

- Identify deviations: Use the stand’s indicators to pinpoint any lateral (side-to-side) or radial (in-and-out) deviations in the rim.

- Mark the spokes: If you identify any deviations, mark the corresponding spokes to help you remember their location for later adjustment.

By using a truing stand, you can accurately identify and quantify the imperfections in your wheel, enabling you to make precise adjustments during the truing process.

Tension Meter

A tension meter is a specialized tool that measures the tension of individual spokes. This information can be invaluable in identifying potential issues and guiding your truing efforts.

- Spoke tension consistency: Ideally, all spokes on a wheel should have similar tension. A tension meter can help you identify any significant variations in spoke tension, which can indicate problems with the wheel’s overall balance and strength.

- Spoke tension and trueness: Tightening or loosening spokes can affect the wheel’s trueness. A tension meter can help you determine how much to adjust each spoke to achieve the desired trueness without over-tightening or loosening them.

- Spoke tension and wheel building: When building a new wheel, a tension meter is essential for ensuring that each spoke is tensioned correctly. This helps to create a balanced and durable wheel.

Using a tension meter alongside your truing stand can significantly improve the accuracy and effectiveness of your wheel truing efforts.

Wheel Truing Techniques

Wheel truing is the process of adjusting spoke tension to ensure the wheel runs smoothly and true. This involves addressing three common wheel imperfections: lateral runout, wobble, and hop.

Adjusting Spoke Tension for Lateral Runout

Lateral runout refers to the side-to-side deviation of the rim from its center axis. To correct lateral runout, you need to adjust the tension of the spokes on one side of the wheel to bring the rim closer to the center.

- Identify the affected area: Rotate the wheel and observe where the rim deviates the most. This is the area that needs adjustment.

- Locate the spokes: Identify the spokes on the side of the wheel where the rim is deviating. These are the spokes that need to be adjusted.

- Adjust spoke tension: If the rim is deviating outwards, tighten the spokes on that side. If the rim is deviating inwards, loosen the spokes on that side. Use a spoke wrench to adjust the tension.

- Check for improvement: After each adjustment, rotate the wheel again and observe the change. Repeat the process until the lateral runout is minimized.

Eliminating Wobble

Wobble is a more pronounced deviation of the rim, causing the wheel to shake or vibrate as it rotates. This is usually caused by a combination of uneven spoke tension and dish. Dish refers to the offset of the rim from the center of the hub.

- Address uneven spoke tension: First, identify the areas where the rim is deviating the most. Then, adjust the spoke tension on both sides of the wheel to even out the tension. Tighten the spokes on the side where the rim is deviating outwards and loosen the spokes on the side where the rim is deviating inwards.

- Adjust dish: If the wobble persists, you may need to adjust the dish. This involves loosening or tightening spokes on one side of the wheel to move the rim closer to the center of the hub. The goal is to achieve a balanced tension on both sides of the wheel.

- Re-check and repeat: After each adjustment, rotate the wheel and observe the change. Repeat the process until the wobble is eliminated.

Addressing Hop

Hop is a sudden jump or bump in the wheel’s rotation, usually caused by a single spoke that is too tight or too loose.

- Identify the affected spoke: Rotate the wheel slowly and observe where the hop occurs. This will help you identify the affected spoke.

- Adjust the spoke tension: If the spoke is too tight, loosen it slightly. If the spoke is too loose, tighten it slightly. You may need to experiment with different adjustments to find the optimal tension.

- Re-check and repeat: After each adjustment, rotate the wheel and observe the change. Repeat the process until the hop is eliminated.

Truing a Wheel

Truing a wheel is a fundamental skill for any cyclist who wants to ensure their bike rides smoothly and efficiently. A true wheel will roll straight and without wobble, improving handling, comfort, and overall performance. While a professional mechanic can handle this task, learning to true a wheel yourself allows for quick adjustments and can save you money in the long run.

This guide will walk you through the process of truing a wheel using a truing stand.

Truing a Wheel: Step-by-Step Guide

A truing stand is a specialized tool that holds the wheel securely and allows you to assess and adjust the spoke tension. It features a rotating arm that holds the wheel and a gauge to measure the runout. The stand helps visualize the wheel’s imperfections and enables you to make precise adjustments.

- Secure the Wheel on the Truing Stand: Start by placing the wheel securely on the truing stand. Ensure the axle is properly secured and the wheel rotates freely without any obstruction.

- Initial Assessment: With the wheel rotating, observe the runout using the gauge. This will help you identify the areas where the wheel is out of true. Pay attention to the lateral runout (side-to-side wobble) and radial runout (deviation from the center).

- Adjusting Spoke Tension:

- Lateral Runout: To correct lateral runout, adjust the tension of the spokes on the side of the wheel that is furthest from the gauge. If the wheel is wobbling to the right, tighten the spokes on the right side and loosen the spokes on the left side. Conversely, if the wheel is wobbling to the left, tighten the spokes on the left side and loosen the spokes on the right side.

- Radial Runout: To correct radial runout, adjust the tension of the spokes at the top and bottom of the wheel. If the rim is higher than the center at a particular point, tighten the spokes at the top and loosen the spokes at the bottom. Conversely, if the rim is lower than the center, tighten the spokes at the bottom and loosen the spokes at the top.

Remember to make small adjustments to the spoke tension and observe the effect on the runout. It’s crucial to be patient and make gradual adjustments until the runout is minimized.

- Checking for Dish: After adjusting for lateral and radial runout, check the dish of the wheel. The dish refers to the difference in distance between the rim on either side of the hub. A properly dished wheel will have equal distances on both sides. To adjust the dish, tighten the spokes on the side with the larger distance and loosen the spokes on the side with the smaller distance.

- Final Check: Once the runout and dish are within acceptable limits, spin the wheel again and visually inspect it for any remaining imperfections. You can also test ride the bike to confirm that the wheel is running smoothly.

Common Truing Mistakes and Solutions

Even the most experienced wheel builders can make mistakes when truing a wheel. These mistakes can lead to a wheel that is not properly balanced, which can cause a variety of problems, including uneven tire wear, a bumpy ride, and even damage to the wheel itself. This section will identify common mistakes made during wheel truing, their consequences, and how to troubleshoot issues.

It will also provide tips for avoiding common mistakes and achieving optimal wheel trueness.

Over-Tightening Spokes

Over-tightening spokes is a common mistake that can lead to a variety of problems. When a spoke is over-tightened, it can become stressed and break. It can also cause the rim to deform, which can lead to a wobbly wheel.

- Consequences: Over-tightening spokes can lead to spoke breakage, rim deformation, and uneven spoke tension.

- Troubleshooting: If a spoke is over-tightened, it can be loosened by turning the spoke nipple counter-clockwise. However, it is important to note that loosening a spoke can also affect the tension of other spokes in the wheel. It is best to loosen a spoke by a small amount at a time and then re-check the wheel trueness.

- Tips for Avoiding: Use a spoke tension meter to ensure that all spokes are tightened to the correct tension. Do not over-tighten spokes, and always tighten them in a criss-cross pattern to ensure even tension.

Uneven Spoke Tension, How much to true a bike wheel

Uneven spoke tension is another common mistake that can lead to a variety of problems. When spokes are not evenly tensioned, the wheel will not be balanced and can wobble. This can lead to uneven tire wear and a bumpy ride.

- Consequences: Uneven spoke tension can lead to a wobbly wheel, uneven tire wear, and a bumpy ride.

- Troubleshooting: If a spoke is too loose, it can be tightened by turning the spoke nipple clockwise. However, it is important to note that tightening a spoke can also affect the tension of other spokes in the wheel. It is best to tighten a spoke by a small amount at a time and then re-check the wheel trueness.

- Tips for Avoiding: Use a spoke tension meter to ensure that all spokes are tightened to the correct tension. When truing a wheel, make small adjustments to the spoke tension and re-check the wheel trueness after each adjustment.

Improper Dish

Improper dish is a common mistake that can lead to a wheel that is not balanced. Dish refers to the amount of offset between the hub and the rim. A wheel with improper dish will have a wobbly rim and will not roll smoothly.

- Consequences: Improper dish can lead to a wobbly wheel, uneven tire wear, and a bumpy ride.

- Troubleshooting: If a wheel has improper dish, it can be corrected by adjusting the spoke tension. However, it is important to note that adjusting the spoke tension can also affect the wheel trueness. It is best to make small adjustments to the spoke tension and then re-check the wheel trueness after each adjustment.

- Tips for Avoiding: Use a dishing tool to ensure that the wheel is properly dished. When truing a wheel, make sure to adjust the spoke tension evenly on both sides of the wheel.

Truing a bike wheel is an essential skill for any cyclist who wants to ensure a smooth and enjoyable ride. By understanding the basics of wheel trueness, the tools involved, and the techniques for adjusting spoke tension, you can achieve optimal performance and extend the life of your wheels. While the cost of professional truing can vary, learning the basics yourself can save you money and provide a sense of accomplishment.

So, grab your tools, put on your cycling gloves, and embark on a journey to master the art of wheel truing. Your bike, and your rides, will thank you for it.

Questions and Answers

What are the signs that my bike wheel needs truing?

Common signs include a wobbly wheel, a noticeable hop when riding, or a feeling of unevenness or instability.

How often should I true my bike wheels?

The frequency depends on riding conditions and the type of wheel. However, it’s generally recommended to true your wheels at least once a year or whenever you notice any imperfections.

Can I true my bike wheels myself?

Yes, with the right tools and a little patience, you can true your bike wheels yourself. There are many online resources and videos that can guide you through the process.

Is it cheaper to true my wheels myself or take them to a bike shop?

Truing your wheels yourself can save you money in the long run, especially if you’re a frequent rider. However, if you’re unsure or lack the necessary tools, it’s best to take your wheels to a professional.